3D Cutting Machine: A Comprehensive Guide

Introduction

3D cutting machines are revolutionizing various industries by enabling the precise and efficient fabrication of complex three-dimensional objects. These machines utilize advanced computer-aided design (CAD) software and sophisticated cutting technologies to transform raw materials into intricate shapes. This article provides a comprehensive guide to 3D cutting machines, exploring their types, applications, benefits, and considerations.

Table of Content

- 1 3D Cutting Machine: A Comprehensive Guide

- 1.1 Introduction

- 1.2 Types of 3D Cutting Machines

- 1.3 Types of 3D Cutting Machines

- 1.4 Applications of 3D Cutting Machines

- 1.5 Benefits of 3D Cutting Machines

- 1.6 Considerations for Choosing a 3D Cutting Machine

- 1.7 Conclusions from the Discussion Topics

- 1.8 FAQs

Types of 3D Cutting Machines

- Utilize a focused laser beam to cut materials by melting, vaporizing, or burning them.

- Offer high precision, speed, and intricate cutting capabilities.

- Suitable for cutting a wide range of materials, including metals, plastics, and wood.

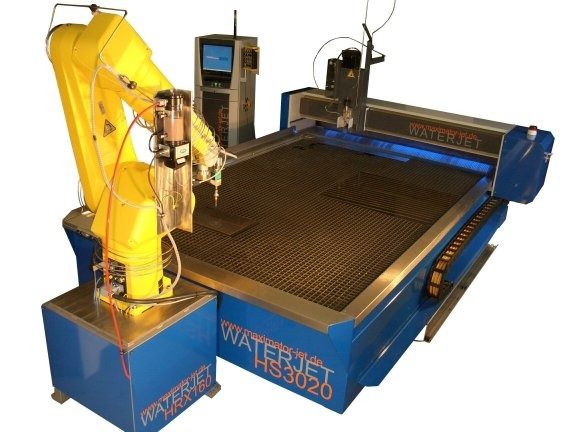

2. Waterjet Cutting Machines

- Use a high-pressure stream of water mixed with abrasives to cut materials.

- Provide excellent edge quality and minimize heat-affected zones.

- Ideal for cutting hard materials, such as stone, ceramics, and titanium.

- 3d Laser Cut Eagle 3D Laser Cut Eagle: Intricate Metalwork For Decor And Symbolism

- 3d Laser Cut Temple 3D Laser Cut Temple: A Marvel Of Architectural Innovation

- 3d Laser Cut Wood Models 3D Laser Cut Wood Models: An Intricate And Enchanting World Of Precision And Creativity

- 3d Laser Cut Flower 3D Laser Cut Flowers: A Guide To Design, Creation, And Applications

- 3d Laser Cut Wooden Models For Sale 3D Laser Cut Wooden Models For Sale: A Comprehensive Guide

- Utilize a focused laser beam to cut materials by melting, vaporizing, or burning them.

- Offer high precision, speed, and intricate cutting capabilities.

- Employ a plasma torch to cut materials by ionizing the air and forming a high-temperature plasma stream.

- Offer high speed and productivity, suitable for large-scale cutting operations.

- Best suited for cutting conductive metals, such as steel and aluminum.

- Use rotating cutting tools to remove material from a workpiece.

- Provide high accuracy and versatility, allowing for complex 3D contours and surface finishes.

- Capable of cutting various materials, including metals, plastics, and composites.

- Aerospace: Fabrication of aircraft components, such as wings, fuselages, and engine parts.

- Automotive: Production of body panels, chassis, and engine blocks.

- Medical: Manufacturing of surgical instruments, prosthetics, and implants.

- Construction: Cutting of architectural elements, such as facades, panels, and roofing systems.

- Jewelry: Creation of intricate designs and patterns in precious metals.

- Precision and Accuracy: Advanced CAD software and precise cutting mechanisms ensure highly accurate and consistent results.

- Efficiency and Speed: Automation and high-speed cutting capabilities significantly reduce production time.

- Versatility: Can cut a wide range of materials and produce complex shapes, eliminating the need for multiple machines.

- Cost-Effectiveness: Automated processes minimize labor costs and reduce material waste.

- Innovation and Customization: Enables the production of unique and customized products with complex designs.

- Material Type: Determine the materials to be cut and select a machine that is compatible with those materials.

- Cutting Speed and Accuracy: Consider the desired speed and precision requirements for the application.

- Machine Size and Capacity: Ensure the machine has sufficient working area and cutting capacity for the intended projects.

- Software Compatibility: Choose a machine that supports the CAD software used for design and programming.

- Maintenance and Support: Consider the availability and cost of maintenance and technical support.

- 3D cutting machines are versatile tools that enable the fabrication of complex three-dimensional objects with high precision and efficiency.

- The choice of cutting technology depends on the material type, cutting speed, accuracy, and application requirements.

- Proper consideration of factors such as material compatibility, machine size, and software support is crucial for selecting the optimal 3D cutting machine.

3D cutting machines are revolutionizing various industries by enabling the precise and efficient fabrication of complex three-dimensional objects. These machines utilize advanced computer-aided design (CAD) software and sophisticated cutting technologies to transform raw materials into intricate shapes. This article provides a comprehensive guide to 3D cutting machines, exploring their types, applications, benefits, and considerations.

Types of 3D Cutting Machines

1. Laser Cutting Machines

3. Plasma Cutting Machines

4. CNC Milling Machines

Applications of 3D Cutting Machines

3D cutting machines find applications in numerous industries, including:

Benefits of 3D Cutting Machines

Considerations for Choosing a 3D Cutting Machine

Conclusions from the Discussion Topics

FAQs

1. What is the difference between a laser cutter and a plasma cutter?

A laser cutter uses a focused laser beam, while a plasma cutter employs a high-temperature plasma stream. Laser cutters offer higher precision and intricate cutting capabilities, while plasma cutters provide higher speed and productivity.

2. Can 3D cutting machines be used for home use?

Yes, there are compact and affordable 3D cutting machines available for home use. These machines are ideal for hobbyists, makers, and small-scale projects.

3. What safety precautions should be taken when using a 3D cutting machine?

Wear appropriate protective gear, including safety glasses, gloves, and earplugs. Ensure proper ventilation to remove fumes and particles. Follow the manufacturer’s instructions for safe operation and maintenance.