Laser Cutting 3D Printer: A Comprehensive Guide

Introduction

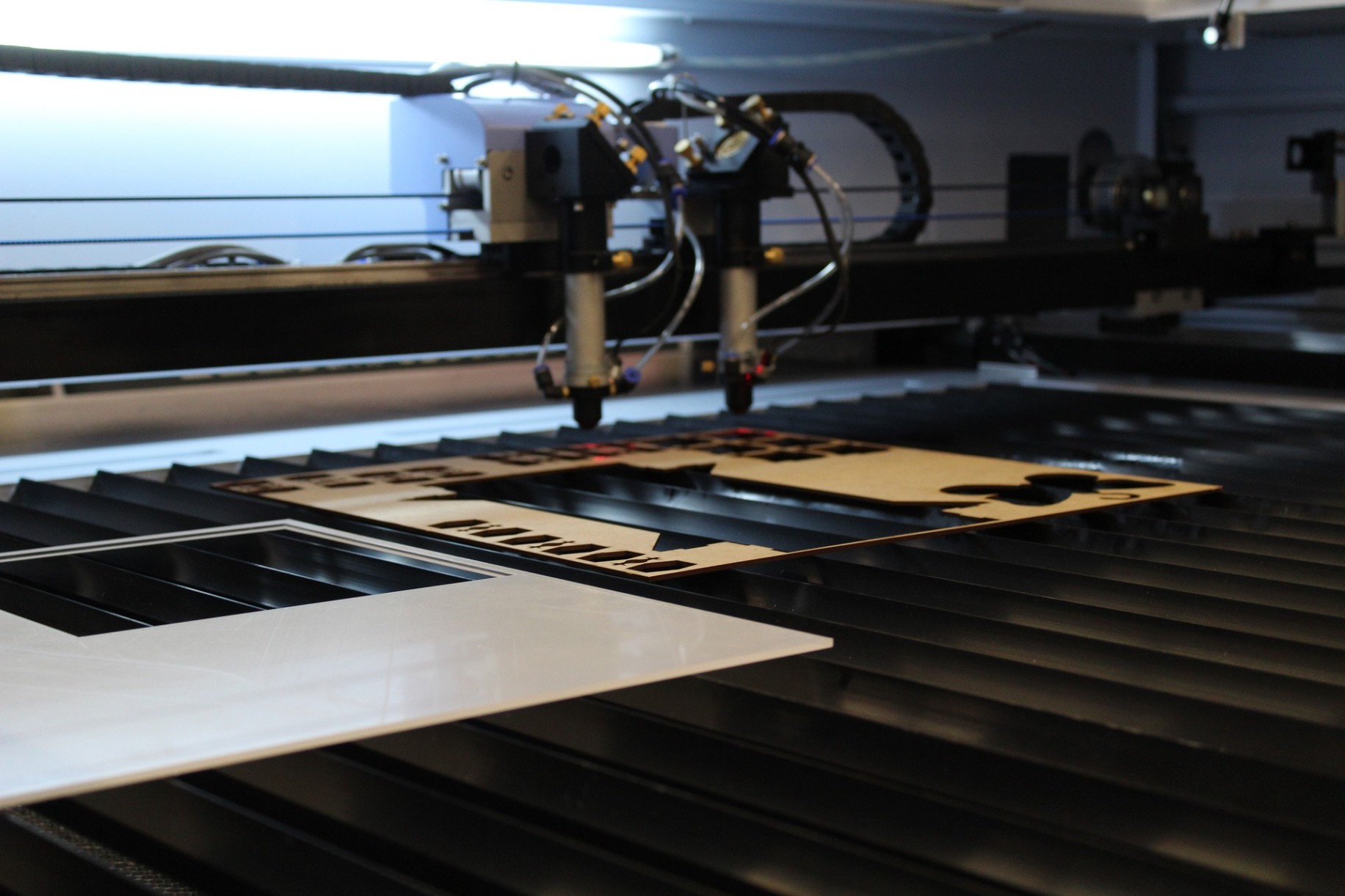

Laser cutting 3D printers are advanced manufacturing tools that combine the precision of laser cutting with the versatility of 3D printing. These machines use a laser beam to cut and engrave materials, enabling the creation of intricate designs and complex geometries. In this article, we will delve into the world of laser cutting 3D printers, exploring their capabilities, applications, and benefits.

Table of Content

- 1 Laser Cutting 3D Printer: A Comprehensive Guide

- 1.1 Introduction

- 1.2 H1: How Laser Cutting 3D Printers Work

- 1.3 H2: Types of Laser Cutting 3D Printers

- 1.4 H1: How Laser Cutting 3D Printers Work

- 1.5 H3: Materials Compatible with Laser Cutting 3D Printers

- 1.6 H4: Applications of Laser Cutting 3D Printers

- 1.7 H2: Benefits of Laser Cutting 3D Printers

- 1.8 H2: Considerations When Choosing a Laser Cutting 3D Printer

- 1.9 H2: Maintenance and Safety Tips

- 1.10 Conclusion

- 1.11 FAQs

H1: How Laser Cutting 3D Printers Work

The process involves the following steps:

- CAD Design: The desired design is created using a computer-aided design (CAD) software.

- Material Preparation: The material to be cut or engraved is placed on the printer’s build platform.

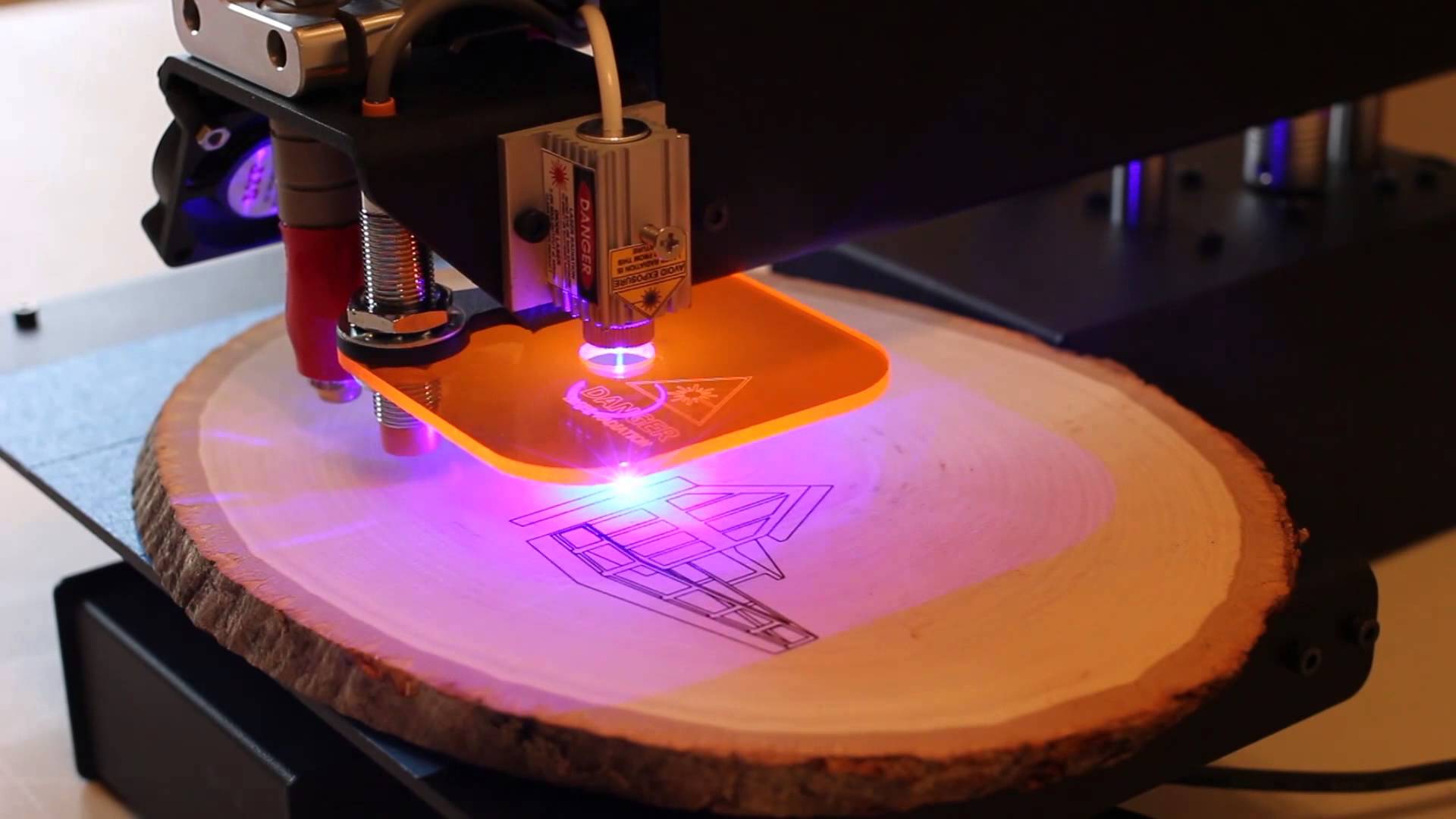

- Laser Cutting: The laser beam is directed onto the material, following the programmed design.

- Material Removal: The vaporized or melted material is removed using an exhaust system.

H2: Types of Laser Cutting 3D Printers

There are two main types of laser cutting 3D printers:

- Afinia Emblaser 2 Afinia Emblaser 2: A Comprehensive Guide To Laser Engraving And Cutting

- Laser Cut Multilayer 3d Mandala Dxf File Laser Cut Multilayer 3D Mandala DXF File: Unleashing Intricate Beauty

- 3d Printing With Laser Cut 3D Printing With Laser Cutting: A Comprehensive Guide

- 3d Laser Cut Plane 3D Laser Cut Plane: A Comprehensive Guide

- Sculpteo Laser Cutting Sculpteo Laser Cutting: A Comprehensive Guide To Precision Manufacturing

- CAD Design: The desired design is created using a computer-aided design (CAD) software.

- CO2 Laser Printers: These printers use a carbon dioxide (CO2) laser, which produces a continuous beam of infrared light. They are known for their high power and cutting speed, making them suitable for cutting thicker materials.

- Fiber Laser Printers: These printers use a fiber optic cable to deliver a laser beam to the cutting head. They offer higher precision and finer detail than CO2 printers, making them ideal for intricate designs and delicate materials.

- Metals: Stainless steel, aluminum, titanium, brass

- Plastics: Acrylic, ABS, polycarbonate, polyethylene

- Wood: Plywood, MDF, balsa wood

- Leather: Genuine leather, faux leather

- Glass: Float glass, tempered glass

- Industrial Manufacturing: Cutting and engraving metal parts, electronic components, and medical devices

- Automotive: Prototyping and production of automotive parts, including interior trim and dashboards

- Jewelry: Creating intricate jewelry designs, cutting gemstones, and engraving personalized pieces

- Architecture: Model making, architectural signage, and decorative elements

- Medical: Surgical instruments, dental implants, and biomedical devices

- Precision and Accuracy: Lasers provide unmatched precision and accuracy, enabling the creation of intricate designs and complex geometries.

- Speed and Efficiency: Laser cutting is a fast and efficient process, reducing production time and increasing productivity.

- Material Versatility: Laser cutting 3D printers can cut and engrave a wide range of materials, offering flexibility in design and material selection.

- Minimal Waste: The focused nature of the laser beam minimizes material waste, resulting in cost savings and environmental benefits.

- Automation: Laser cutting 3D printers can be automated, allowing for continuous operation and reduced labor costs.

- Laser Power and Wavelength: The power and wavelength of the laser determine the cutting speed, precision, and materials that can be processed.

- Build Volume: The build volume refers to the maximum size of the objects that can be cut or engraved.

- Software Compatibility: Ensure that the printer is compatible with your preferred CAD software.

- Safety Features: Laser cutting involves high-powered lasers, so safety features such as enclosure, fume extraction, and interlocks are essential.

- Budget: Laser cutting 3D printers vary in cost depending on their capabilities and features.

- Regular Cleaning: Clean the laser lens, mirrors, and other optical components regularly to prevent contamination.

- Filter Replacement: Replace the exhaust filter periodically to ensure proper ventilation and remove harmful fumes.

- Laser Alignment: Periodically check and adjust the laser alignment to maintain precision.

- Safety Precautions: Always wear appropriate safety gear, including laser safety glasses, gloves, and protective clothing.

- Proper Ventilation: Ensure adequate ventilation to remove fumes and prevent respiratory hazards.

Laser cutting 3D printers are advanced manufacturing tools that combine the precision of laser cutting with the versatility of 3D printing. These machines use a laser beam to cut and engrave materials, enabling the creation of intricate designs and complex geometries. In this article, we will delve into the world of laser cutting 3D printers, exploring their capabilities, applications, and benefits.

H1: How Laser Cutting 3D Printers Work

Laser cutting 3D printers operate on the principle of laser ablation. A high-powered laser beam is focused onto the material, causing it to vaporize or melt. The precision of the laser allows for precise cutting and engraving, creating intricate designs and smooth surfaces.

The process involves the following steps:

H3: Materials Compatible with Laser Cutting 3D Printers

Laser cutting 3D printers can cut and engrave a wide range of materials, including:

H4: Applications of Laser Cutting 3D Printers

Laser cutting 3D printers have numerous applications across various industries, such as:

H2: Benefits of Laser Cutting 3D Printers

Laser cutting 3D printers offer several advantages over traditional manufacturing methods:

H2: Considerations When Choosing a Laser Cutting 3D Printer

When selecting a laser cutting 3D printer, several factors should be considered:

H2: Maintenance and Safety Tips

Proper maintenance and safety practices are crucial for the optimal performance and longevity of laser cutting 3D printers:

Conclusion

Laser cutting 3D printers are versatile and powerful manufacturing tools that enable the creation of intricate designs and complex geometries. Their precision, speed, material versatility, and automation capabilities make them ideal for a wide range of applications in various industries. By carefully considering the factors discussed in this article, you can choose the right laser cutting 3D printer to meet your specific needs and unlock its full potential.

FAQs

Q: What is the difference between laser cutting and 3D printing?

A: Laser cutting involves removing material using a laser beam, while 3D printing involves building objects layer by layer. Laser cutting 3D printers combine these technologies, allowing for both cutting and engraving.

Q: Can laser cutting 3D printers cut through metal?

A: Yes, laser cutting 3D printers can cut through various metals, including stainless steel, aluminum, and titanium. The thickness of the metal that can be cut depends on the power of the laser.

Q: What materials can laser cutting 3D printers engrave?

A: Laser cutting 3D printers can engrave a wide range of materials, including metals, plastics, wood, leather, and glass. The engraving depth and detail depend on the material and laser power.

Q: Are laser cutting 3D printers safe to use?

A: Laser cutting 3D printers involve high-powered lasers, so it is essential to follow proper safety precautions. These include wearing appropriate safety gear, ensuring adequate ventilation, and adhering to the manufacturer’s operating instructions.