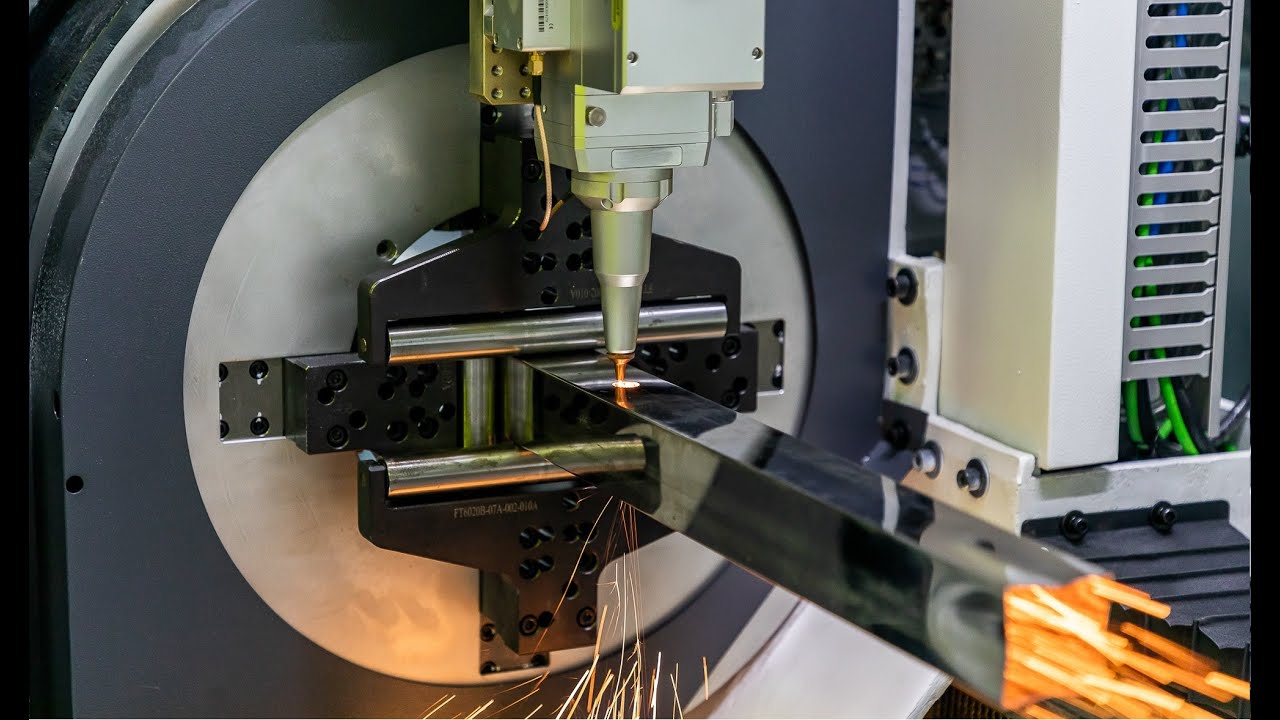

3D Pipe Laser Cutting: Revolutionizing Metal Fabrication

Introduction

3D pipe laser cutting has emerged as a game-changer in the metal fabrication industry, offering unparalleled precision, efficiency, and versatility. This advanced technology empowers manufacturers to create complex and intricate metal structures with remarkable speed and accuracy.

Table of Content

Benefits of 3D Pipe Laser Cutting

3D laser cutters utilize laser beams focused through advanced optics to cut metal pipes with micron-level precision. This allows for the production of highly accurate and consistent components, eliminating the need for costly rework or post-processing.

Speed and Efficiency:

Compared to traditional cutting methods, 3D laser cutting significantly increases production speed. The laser beam’s concentrated energy quickly melts and vaporizes metal, resulting in faster cutting times and increased throughput.

Versatility and Flexibility:

3D pipe laser cutters are highly versatile and can process a wide range of materials, including stainless steel, aluminum, and titanium. The ability to cut pipes in various diameters, shapes, and thicknesses enables manufacturers to produce complex geometries with ease.

Reduced Material Waste:

The precision of 3D laser cutting minimizes material waste, as it eliminates the need for extensive setup and tooling changes. This results in cost savings and improved environmental sustainability.

Applications of 3D Pipe Laser Cutting

Industrial Machinery:

3D pipe laser cutting is widely used in the production of industrial machinery components, such as pumps, valves, and piping systems. The precise cuts and intricate designs enhance the performance and reliability of these machines.

3D pipe laser cutting has emerged as a game-changer in the metal fabrication industry, offering unparalleled precision, efficiency, and versatility. This advanced technology empowers manufacturers to create complex and intricate metal structures with remarkable speed and accuracy.

- 3d Laser Cut Kit 3D Laser Cut Kit: Unleashing Precision And Creativity In Model Making

- Laser Cut 3d Rose Laser Cut 3D Rose: A Guide To Intricate And Stunning Creations

- Snapmaker Laser Cutting Guide Snapmaker Laser Cutting Guide: A Comprehensive Walkthrough

- Laser Cutting 3d Model Free Download Laser Cutting 3D Model Free Download: A Comprehensive Guide

- 3d Laser Cutting Design 3D Laser Cutting Design: Revolutionizing Manufacturing And Creativity

Benefits of 3D Pipe Laser Cutting

Precision and Accuracy:

3D laser cutters utilize laser beams focused through advanced optics to cut metal pipes with micron-level precision. This allows for the production of highly accurate and consistent components, eliminating the need for costly rework or post-processing.

Speed and Efficiency:

Compared to traditional cutting methods, 3D laser cutting significantly increases production speed. The laser beam’s concentrated energy quickly melts and vaporizes metal, resulting in faster cutting times and increased throughput.

Automotive Industry:

The automotive industry utilizes 3D pipe laser cutting for the fabrication of exhaust systems, fuel lines, and other structural components. The ability to cut complex shapes and weld joints simultaneously reduces assembly time and improves vehicle performance.

Aerospace Engineering:

In the aerospace industry, 3D pipe laser cutting is employed to produce lightweight and high-strength components for aircraft and spacecraft. The precise cuts and intricate designs minimize weight and maximize structural integrity.

How 3D Pipe Laser Cutting Works

3D pipe laser cutting involves the following steps:

1. Design and Programming:

The desired cut pattern is designed using computer-aided design (CAD) software and converted into a numerical control (NC) program.

2. Machine Setup:

The pipe is loaded onto the laser cutting machine and aligned with the laser beam. Cutting parameters, such as speed, power, and gas flow, are optimized based on the material and thickness.

3. Laser Cutting:

The laser beam is directed onto the pipe, melting and vaporizing the metal along the desired cut path. The cut edge is clean and free of burrs.

4. Post-Processing:

Depending on the application, additional post-processing steps, such as deburring, welding, or bending, may be required to complete the fabrication process.

Conclusion

3D pipe laser cutting technology has transformed the metal fabrication industry, enabling manufacturers to achieve unprecedented levels of precision, speed, and versatility. Its applications span a wide range of industries, from industrial machinery to aerospace engineering, revolutionizing the way metal components are designed and produced. As technology continues to advance, 3D pipe laser cutting is poised to play an even greater role in shaping the future of metalworking.

Frequently Asked Questions (FAQs)

Q: What materials can be cut using 3D pipe laser cutting?

A: 3D pipe laser cutters can process a wide range of materials, including stainless steel, aluminum, titanium, and other ferrous and non-ferrous metals.

Q: How thick of a pipe can be cut with a 3D laser cutter?

A: The maximum cutting thickness depends on the specific machine and laser power. Generally, 3D pipe laser cutters can cut pipes up to several inches in thickness.

Q: What are the advantages of 3D pipe laser cutting over traditional cutting methods?

A: 3D pipe laser cutting offers superior precision, speed, versatility, and reduced material waste compared to traditional methods like manual cutting or plasma cutting.

Q: Is 3D pipe laser cutting suitable for mass production?

A: Yes, 3D pipe laser cutting is well-suited for mass production due to its high speed, consistency, and automation capabilities.

Q: What are the key considerations for choosing a 3D pipe laser cutting machine?

A: Factors to consider include the desired cutting thickness, material type, precision requirements, production volume, and budget.