Rhino 3D Laser Cutting: A Comprehensive Guide

Introduction

Rhino 3D is a versatile 3D modeling software that is widely used in various industries, including architecture, design, engineering, and manufacturing. Laser cutting is a precise and efficient technology that allows for the precise cutting of materials such as wood, metal, acrylic, and more. By combining Rhino 3D with laser cutting, users can create complex and intricate designs with ease and precision.

Table of Content

Benefits of Using Rhino 3D for Laser Cutting

Preparing Models for Laser Cutting

1. Create or Import a 3D Model

Start by creating a 3D model using Rhino 3D or import an existing model from another CAD software. Ensure that the model is watertight and has no gaps or holes.

2. Set Cutting Parameters

Rhino 3D is a versatile 3D modeling software that is widely used in various industries, including architecture, design, engineering, and manufacturing. Laser cutting is a precise and efficient technology that allows for the precise cutting of materials such as wood, metal, acrylic, and more. By combining Rhino 3D with laser cutting, users can create complex and intricate designs with ease and precision.

- 3d Laser Cutting Perth 3D Laser Cutting Perth: Precision And Innovation For Your Fabrication Needs

- 3d Laser Engraving 3D Laser Engraving: A Comprehensive Guide

- 3d Laser Cut Puzzles 3D Laser Cut Puzzles: Unlocking The Dimensions Of Brain-Teasing Entertainment

- 3d Laser Cutting Projects 3D Laser Cutting Projects: Unleashing Creativity And Precision

- 3d Printing With Laser Cut 3D Printing With Laser Cutting: A Comprehensive Guide

Benefits of Using Rhino 3D for Laser Cutting

- Accurate and Precise: Rhino 3D allows for the creation of highly detailed and precise 3D models, which translates into accurate and clean laser cuts.

- Versatile Material Compatibility: Rhino 3D can be used to cut a wide range of materials, including wood, metal, acrylic, leather, and more.

- Design Flexibility: Rhino 3D’s advanced modeling capabilities enable the creation of complex and intricate designs, allowing for a wide range of applications.

- Product Prototyping: Create accurate and detailed prototypes for testing and evaluation.

- Custom Fabrication: Manufacture custom parts, components, and products with precision and efficiency.

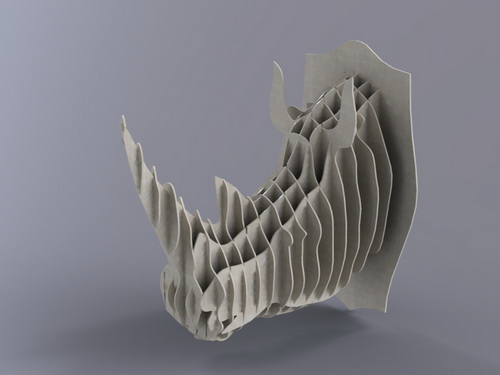

- Art and Design: Produce unique and intricate artworks, sculptures, and decorative pieces.

- Architectural Modeling: Create scale models and prototypes for architectural projects.

- Jewelry Making: Cut intricate jewelry designs from precious metals and other materials.

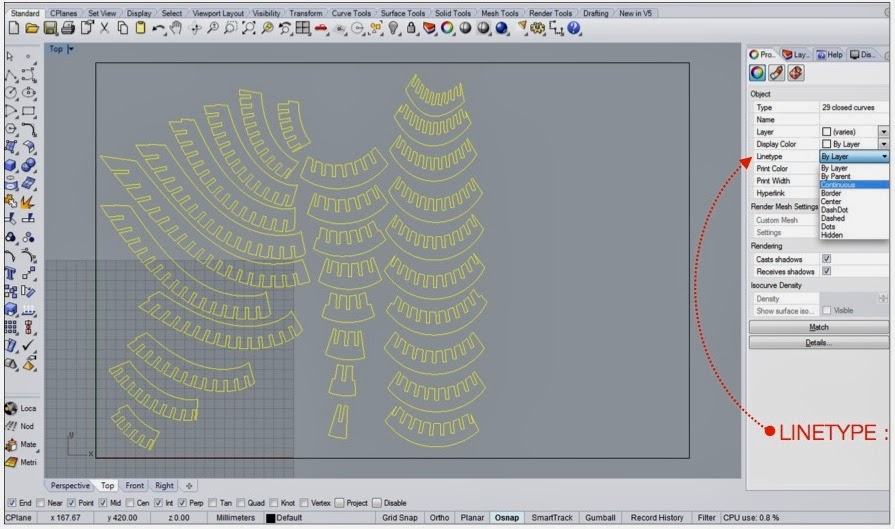

Define the cutting parameters, such as laser power, speed, and kerf width, based on the material and desired cut quality.

3. Generate Toolpaths

Generate toolpaths that specify the laser’s movement during cutting. Use the "LaserCut" command in Rhino 3D to create toolpaths that are optimized for laser cutting.

4. Preview and Export

Preview the toolpaths to ensure accuracy and make any necessary adjustments. Then, export the toolpaths in a format that is compatible with your laser cutting machine.

Laser Cutting Process

1. Material Setup

Secure the material on the laser cutting bed and ensure that it is flat and level.

2. Machine Setup

Load the generated toolpaths into the laser cutting machine and configure the machine settings according to the material and cutting parameters.

3. Cutting

Start the laser cutting process and monitor the progress to ensure that the cut is being executed accurately.

Applications of Rhino 3D Laser Cutting

Conclusion

Rhino 3D Laser Cutting is a powerful combination that empowers users to create complex and precise designs with ease and efficiency. By leveraging Rhino 3D’s advanced modeling capabilities and laser cutting’s precision, users can unlock a wide range of applications and achieve exceptional results.

FAQs

Q: What are the limitations of Rhino 3D Laser Cutting?

A: Rhino 3D Laser Cutting is limited by the capabilities of the laser cutting machine being used, such as the material thickness and cutting speed.

Q: Is Rhino 3D Laser Cutting suitable for beginners?

A: While Rhino 3D is a powerful tool, it requires some learning curve. Laser cutting also involves safety considerations, so it is recommended to have some experience or training before operating a laser cutting machine.

Q: Can I cut 3D objects with Rhino 3D Laser Cutting?

A: Rhino 3D Laser Cutting is primarily used for cutting 2D shapes from flat materials. However, it is possible to create 3D objects by stacking and assembling cut pieces.