3D Slicing Software for Laser Cutting: A Comprehensive Guide

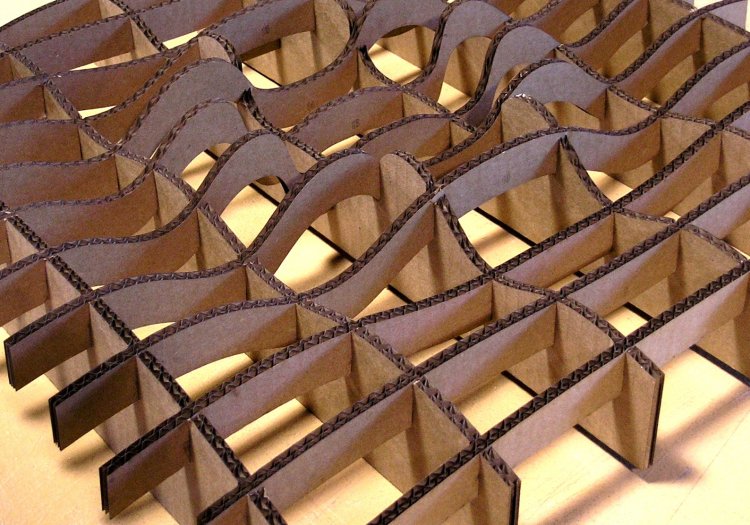

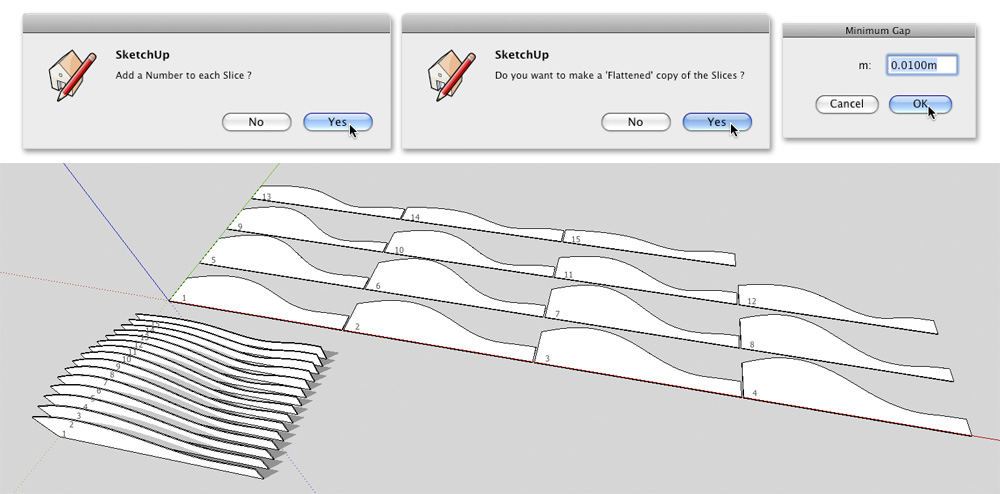

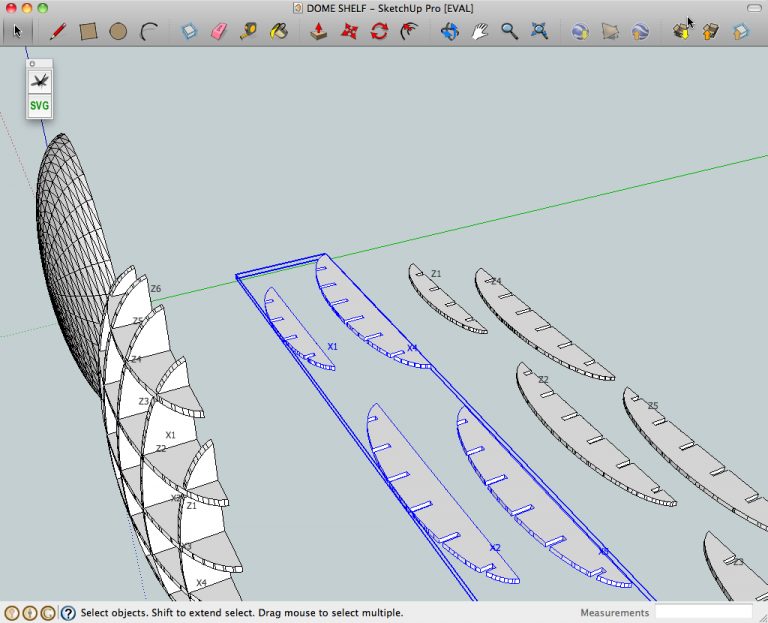

Laser cutting has become increasingly popular in various industries, including manufacturing, prototyping, and art. To effectively use a laser cutter, it is essential to utilize 3D slicing software. This software converts 3D models into a series of 2D slices, guiding the laser cutter to cut the material precisely.

What is 3D Slicing Software?

Table of Content

- 1 3D Slicing Software for Laser Cutting: A Comprehensive Guide

- 1.1 What is 3D Slicing Software?

- 1.2 Types of 3D Slicing Software

- 1.3 What is 3D Slicing Software?

- 1.4 Key Features of 3D Slicing Software

- 1.5 Benefits of Using 3D Slicing Software

- 1.6 Choosing the Right 3D Slicing Software

- 1.7 Popular 3D Slicing Software Options

- 1.8 Conclusion

- 1.9 FAQs

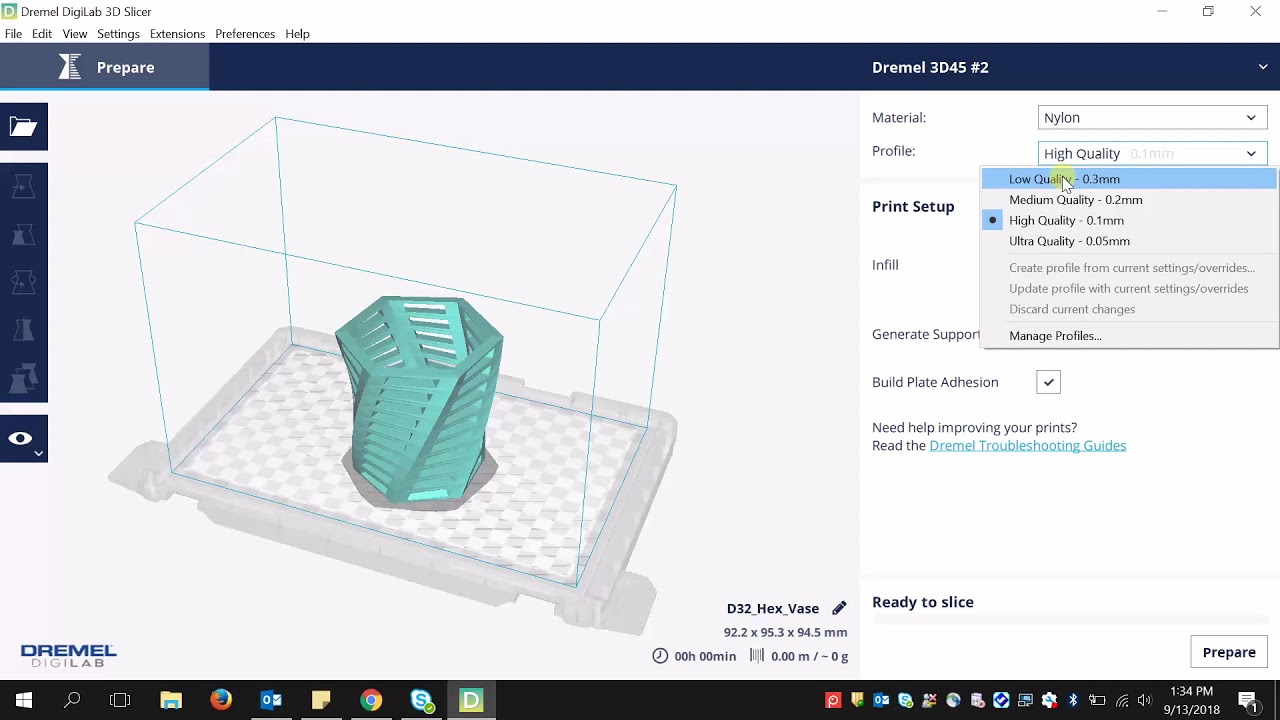

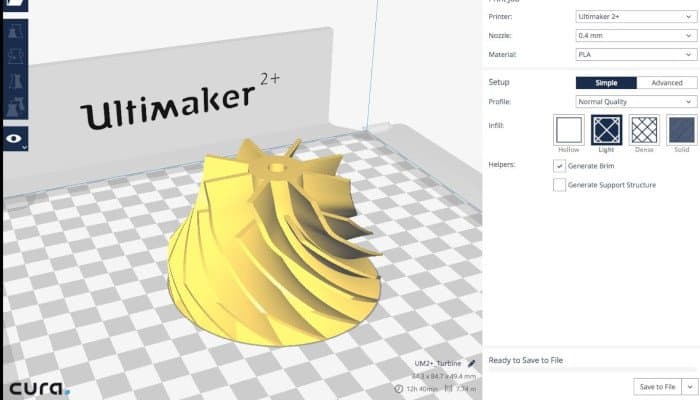

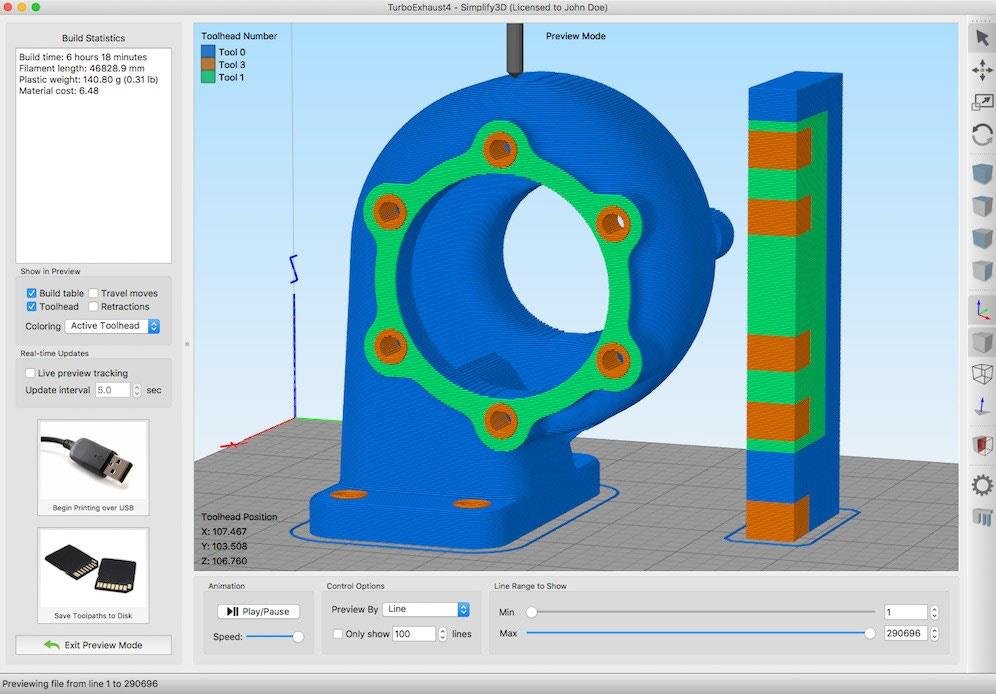

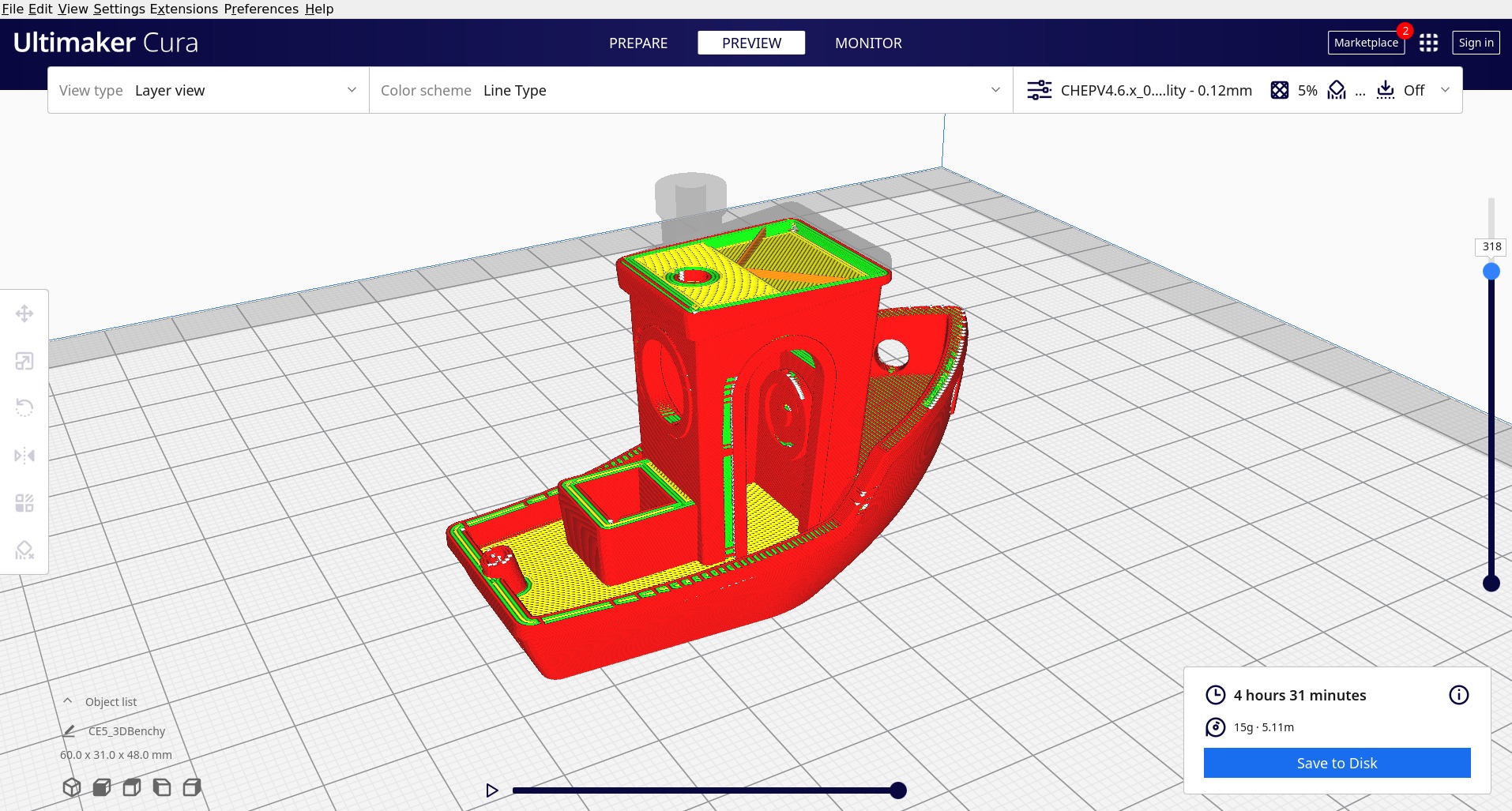

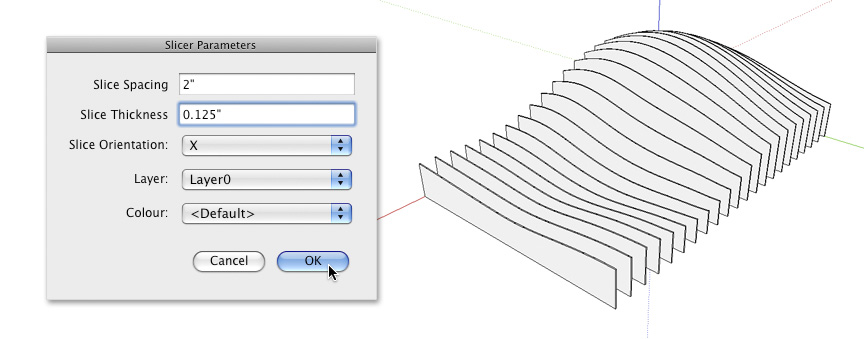

3D slicing software is a computer program that takes a 3D model as input and generates a set of instructions for a laser cutter. These instructions include the path the laser should follow, the cutting speed, and the laser power. By slicing the model into thin layers, the software ensures that the laser cutter can cut the material accurately and efficiently.

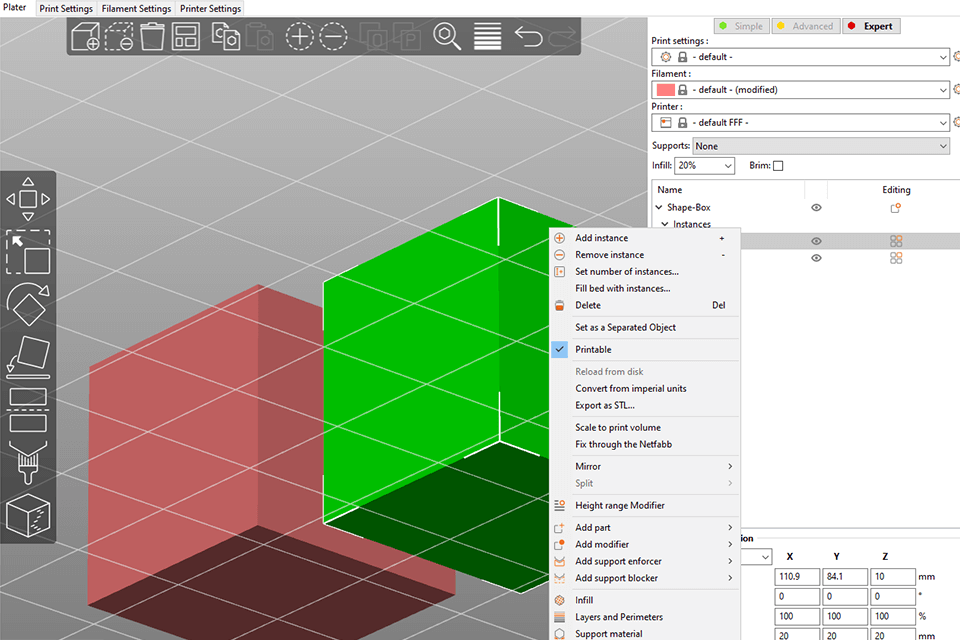

- Model Import and Editing: Allows users to import 3D models from various file formats and make necessary adjustments, such as scaling, rotation, and repairs.

- Slice Generation: Generates 2D slices from the 3D model, defining the cutting paths and parameters for each layer.

- Material Settings: Provides options to specify the material being cut, including its thickness, density, and laser cutting properties.

- Toolpath Optimization: Optimizes the cutting path to minimize laser travel time and reduce material waste.

- Simulation: Allows users to simulate the cutting process before executing it, ensuring accuracy and avoiding errors.

- Job Management: Enables users to organize and manage multiple cutting jobs, including scheduling, queuing, and monitoring.

Types of 3D Slicing Software

There are two main types of 3D slicing software:

What is 3D Slicing Software?

- 3d Laser Cutting Chess 3D Laser Cutting Chess: A Revolution In The Game Of Kings

- 3d Printed Christmas Tree Laser Cut 3D Printed Christmas Tree Laser Cut: A Festive And Sustainable Holiday Decoration

- 3d Crystal Laser Cutting Machine 3D Crystal Laser Cutting Machine: A Comprehensive Guide

- 3d Printing And Laser Cutting 3D Printing And Laser Cutting: A Comprehensive Guide

- 3d Laser Cutting Photos 3D Laser Cutting: Revolutionizing The Manufacturing Industry

3D slicing software is a computer program that takes a 3D model as input and generates a set of instructions for a laser cutter. These instructions include the path the laser should follow, the cutting speed, and the laser power. By slicing the model into thin layers, the software ensures that the laser cutter can cut the material accurately and efficiently.

Key Features of 3D Slicing Software

- Model Import and Editing: Allows users to import 3D models from various file formats and make necessary adjustments, such as scaling, rotation, and repairs.

- Slice Generation: Generates 2D slices from the 3D model, defining the cutting paths and parameters for each layer.

- Divides the 3D model into a grid of pixels.

- Generates a cutting path that traces the contours of the model.

- Suitable for cutting thin and complex materials.

- Converts the 3D model into a series of vectors.

- Generates a cutting path that follows the vectors precisely.

- Suitable for cutting thicker and more rigid materials.

- Increased Precision: Generates accurate cutting paths, ensuring precise cuts.

- Improved Efficiency: Optimizes toolpaths to minimize cutting time and material waste.

- Enhanced Safety: Allows users to simulate the cutting process before execution, reducing the risk of errors.

- Material Versatility: Supports a wide range of materials, from thin plastics to thick metals.

- Time Savings: Automates the slicing process, freeing up users for other tasks.

- Compatibility with Laser Cutter: Ensure the software is compatible with your specific laser cutter model.

- Material Support: Choose software that supports the materials you intend to cut.

- Features and Functionality: Evaluate the software’s features to meet your specific requirements.

- Ease of Use: Consider the software’s user interface and learning curve.

- Price: Determine the software’s cost and compare it to your budget.

- LightBurn: User-friendly software with a wide range of features and material support.

- LaserGRBL: Open-source software known for its flexibility and customization options.

- RDWorks: Proprietary software designed specifically for Ruida laser controllers.

- Fusion 360: Comprehensive CAD/CAM software that includes slicing capabilities.

- SolidWorks: Advanced CAD/CAM software with integrated slicing functionality.

1. Raster Slicing Software:

2. Vector Slicing Software:

Benefits of Using 3D Slicing Software

Choosing the Right 3D Slicing Software

When selecting 3D slicing software, consider the following factors:

Popular 3D Slicing Software Options

Conclusion

3D slicing software is an indispensable tool for laser cutting. It enables users to accurately convert 3D models into cutting instructions, optimizing the laser cutting process. By choosing the right software and utilizing its features effectively, businesses and individuals can unlock the full potential of laser cutting technology.

FAQs

Q1: What file formats do 3D slicing software typically support?

A1: Common file formats include STL, OBJ, DXF, and G-Code.

Q2: Can I edit 3D models within 3D slicing software?

A2: Most slicing software allows for basic editing, such as scaling, rotation, and repairs.

Q3: How can I optimize the cutting path to minimize material waste?

A3: Use slicing software that offers toolpath optimization features, such as nesting and offsetting.

Q4: Is it necessary to simulate the cutting process before execution?

A4: Simulation is highly recommended to detect errors and ensure accurate results.

Q5: What are the key differences between raster and vector slicing software?

A5: Raster slicing is suitable for thin and complex materials, while vector slicing is more precise for thicker and more rigid materials.