2D vs. 3D Laser Cutting: A Comprehensive Guide

Introduction

Laser cutting technology has revolutionized manufacturing processes across various industries. Laser cutters utilize a focused beam of light to cut materials with precision and efficiency. Depending on the application, two primary laser cutting methods are employed: 2D laser cutting and 3D laser cutting. This article delves into the distinctions between these two techniques, exploring their capabilities, applications, and advantages to guide readers in selecting the optimal laser cutting method for their specific needs.

Table of Content

- 1 2D vs. 3D Laser Cutting: A Comprehensive Guide

- 1.1 Introduction

- 2 2D Laser Cutting

- 2.2 Applications of 2D Laser Cutting

- 3 2D Laser Cutting

- 3.3 What is 2D Laser Cutting?

- 3.4 Applications of 2D Laser Cutting

- 3.5 Advantages of 2D Laser Cutting

- 4 3D Laser Cutting

- 4.6 What is 3D Laser Cutting?

- 4.7 Applications of 3D Laser Cutting

- 4.8 Advantages of 3D Laser Cutting

- 5 Comparison of 2D and 3D Laser Cutting

- 6 Conclusion

- 7 FAQs

2D Laser Cutting

2D laser cutting involves using a laser beam to cut flat sheet materials, typically in two dimensions (X and Y). The laser beam is directed by a computer-controlled system, following a predetermined cutting path. The process is suitable for cutting a wide range of materials, including metals, plastics, wood, and composites.

Applications of 2D Laser Cutting

2D laser cutting finds extensive applications in industries such as:

- Automotive: Cutting components for vehicles

- Aerospace: Manufacturing aircraft parts

- Electronics: Fabricating circuit boards and electronic components

- Medical: Producing medical devices and implants

- Fabrication: Cutting custom shapes and designs

Laser cutting technology has revolutionized manufacturing processes across various industries. Laser cutters utilize a focused beam of light to cut materials with precision and efficiency. Depending on the application, two primary laser cutting methods are employed: 2D laser cutting and 3D laser cutting. This article delves into the distinctions between these two techniques, exploring their capabilities, applications, and advantages to guide readers in selecting the optimal laser cutting method for their specific needs.

- 3d Laser Cutting Sydney 3D Laser Cutting Sydney: A Comprehensive Guide

- 3d Laser Cut Crystal Cubes 3D Laser Cut Crystal Cubes: The Ultimate Guide To Captivating Decor And Personalized Gifts

- 3d Software For Laser Cutting 3D Software For Laser Cutting: A Comprehensive Guide

- 3d Laser Cut Wood 3D Laser Cut Wood: The Ultimate Guide To Precision And Creativity

- 3d Axis Laser Cut 3D Axis Laser Cutting: A Comprehensive Guide

2D Laser Cutting

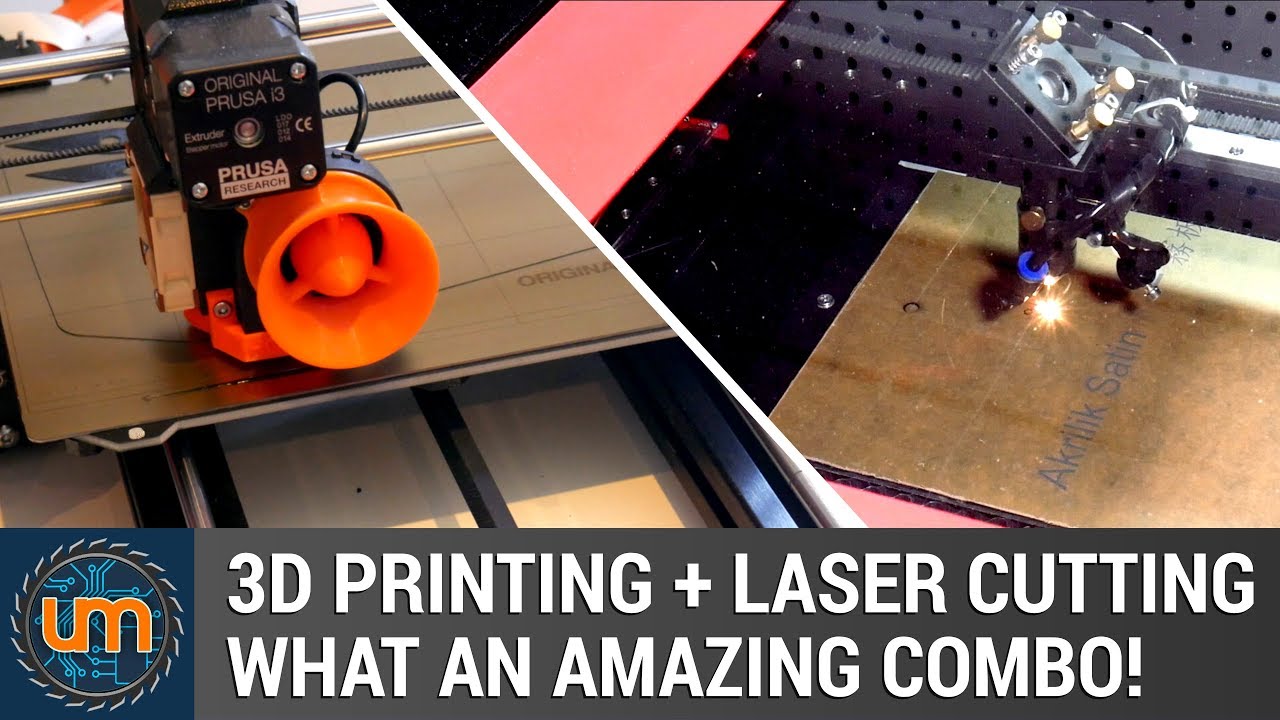

What is 2D Laser Cutting?

2D laser cutting involves using a laser beam to cut flat sheet materials, typically in two dimensions (X and Y). The laser beam is directed by a computer-controlled system, following a predetermined cutting path. The process is suitable for cutting a wide range of materials, including metals, plastics, wood, and composites.

Applications of 2D Laser Cutting

2D laser cutting finds extensive applications in industries such as:

Advantages of 2D Laser Cutting

- Precision: 2D laser cutting provides exceptional precision, producing clean and accurate cuts.

- Speed: The high-speed cutting capabilities of laser cutters enhance productivity.

- Versatility: 2D laser cutters can handle a diverse range of materials, offering flexibility in manufacturing processes.

- Cost-Effective: Compared to traditional cutting methods, 2D laser cutting offers cost savings due to reduced material waste and increased efficiency.

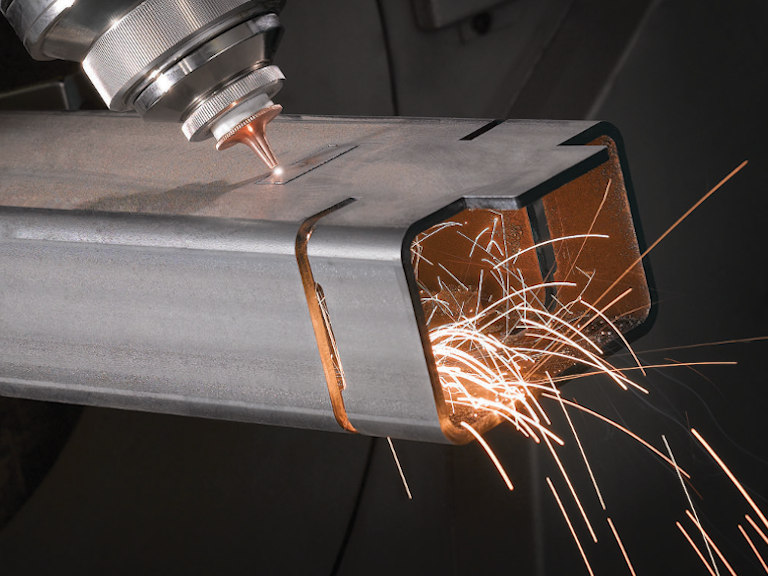

3D Laser Cutting

What is 3D Laser Cutting?

3D laser cutting extends the capabilities of laser cutting into the third dimension (Z-axis). It employs a laser beam to cut complex three-dimensional shapes from solid materials. The laser beam is guided by a computer-aided design (CAD) file, ensuring accurate and intricate cuts.

Applications of 3D Laser Cutting

3D laser cutting finds applications in industries such as:

- Aerospace: Manufacturing complex aircraft components

- Automotive: Producing lightweight and durable car parts

- Medical: Creating custom prosthetics and surgical tools

- Jewelry: Crafting intricate jewelry designs

- Prototyping: Rapidly creating 3D prototypes for design validation

Advantages of 3D Laser Cutting

- Geometric Complexity: 3D laser cutting enables the creation of intricate and complex geometric shapes.

- Design Freedom: It provides designers with greater freedom to explore innovative designs and functional components.

- Accuracy and Precision: 3D laser cutters offer high precision and accuracy, producing parts with tight tolerances.

- Reduced Assembly Time: 3D laser cutting can eliminate the need for multiple assembly steps, saving time and reducing production costs.

Comparison of 2D and 3D Laser Cutting

| Feature | 2D Laser Cutting | 3D Laser Cutting |

|---|---|---|

| Dimensionality | Two-dimensional (X and Y) | Three-dimensional (X, Y, and Z) |

| Material Thickness | Typically thinner materials | Can cut thicker and denser materials |

| Geometric Complexity | Limited to 2D shapes | Can cut intricate 3D shapes |

| Applications | Flat sheet materials | Solid materials |

| Cost | Generally more affordable | Higher cost due to advanced technology |

Conclusion

2D and 3D laser cutting are distinct techniques with unique capabilities. 2D laser cutting offers precision, speed, and versatility for cutting flat sheet materials. 3D laser cutting provides geometric complexity, design freedom, and accuracy for cutting solid materials. The choice between the two methods depends on the specific application and the desired outcomes. By understanding the differences and advantages of each technique, manufacturers can optimize their production processes and create innovative products.

FAQs

Q: Which laser cutting method is more precise?

A: Both 2D and 3D laser cutting offer high precision, but 3D laser cutting may provide slightly higher precision due to its advanced technology.

Q: What materials can be cut with laser cutters?

A: Laser cutters can cut a wide range of materials, including metals, plastics, wood, composites, and ceramics.

Q: How does the cost of 2D and 3D laser cutting compare?

A: 2D laser cutting is typically more affordable than 3D laser cutting due to its simpler technology.

Q: What are the safety considerations for laser cutting?

A: Laser cutting involves high-powered lasers, so proper safety measures are crucial, including wearing appropriate protective gear and ensuring adequate ventilation.