3D Laser Wood Cutting Machine: Revolutionizing Woodworking with Precision and Efficiency

Introduction

In the ever-evolving world of woodworking, the advent of 3D laser cutting machines has marked a transformative milestone. These advanced tools empower artisans and manufacturers alike to create intricate, three-dimensional designs with unparalleled precision and efficiency.

Table of Content

- 1 3D Laser Wood Cutting Machine: Revolutionizing Woodworking with Precision and Efficiency

- 1.1 Introduction

- 1.2 H1: Unlocking the Capabilities of 3D Laser Wood Cutting Machines

- 1.3 H2: Key Features and Specifications

- 1.4 H1: Unlocking the Capabilities of 3D Laser Wood Cutting Machines

- 1.5 H3: Choosing the Right 3D Laser Wood Cutting Machine

- 1.6 H4: Applications of 3D Laser Wood Cutting Machines

- 1.7 H5: Safety Considerations

- 1.8 Conclusion

- 1.9 FAQs

H1: Unlocking the Capabilities of 3D Laser Wood Cutting Machines

- Precision and Accuracy: Laser cutters operate with pinpoint accuracy, allowing for the creation of highly detailed designs with minimal deviation.

- Versatility: These machines can process a wide range of wood species, from softwoods to hardwoods, offering versatility in project materials.

- Speed and Efficiency: Laser cutting is significantly faster than manual cutting methods, enabling the production of large quantities of parts with minimal labor.

- Automation: 3D laser cutting machines can be programmed to perform repetitive tasks with consistency and precision, reducing human error and increasing productivity.

H2: Key Features and Specifications

When selecting a 3D laser wood cutting machine, several key features and specifications should be considered:

- Laser Power: The laser power determines the cutting speed and depth. Higher power lasers can cut thicker materials and produce cleaner edges.

- 3d Laser Cut Templates 3D Laser Cut Templates: Unleashing Creativity And Precision

- 3d Printing Vs Laser Cutting 3d Printing Vs Laser Cutting

- Laser Cut 3d Puzzle Free Download Laser Cut 3D Puzzle: Free Download And Assembly Guide

- Laser Cut 3d Warehouse Laser Cut 3D Warehouse: Unleashing The Power Of Precision Fabrication

- 3d Slicing Software For Laser Cutting 3D Slicing Software For Laser Cutting: A Comprehensive Guide

- Precision and Accuracy: Laser cutters operate with pinpoint accuracy, allowing for the creation of highly detailed designs with minimal deviation.

- Versatility: These machines can process a wide range of wood species, from softwoods to hardwoods, offering versatility in project materials.

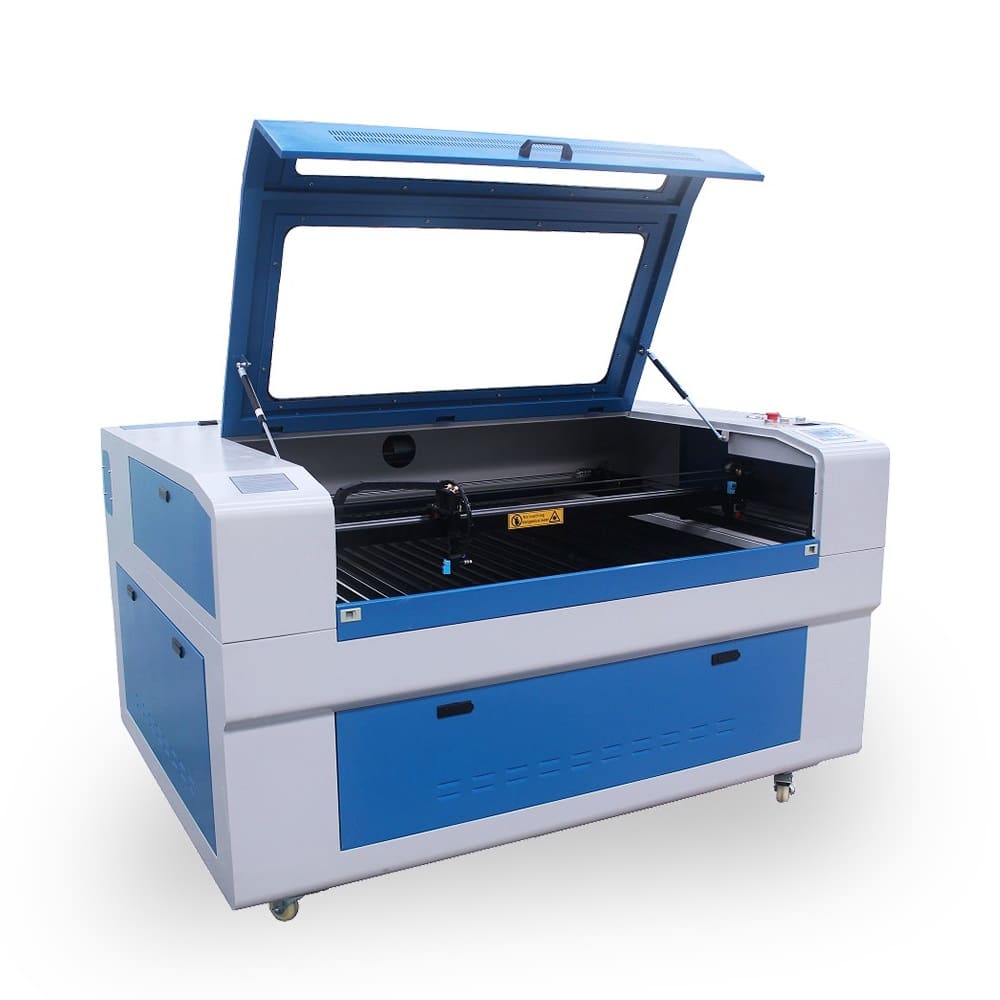

- Working Area: The working area defines the maximum size of the materials that can be processed.

- Software Compatibility: Ensure compatibility between the laser cutter and your design software for seamless file transfer and operation.

- Safety Features: Look for machines with safety features such as laser guards, fume extraction systems, and emergency stop buttons.

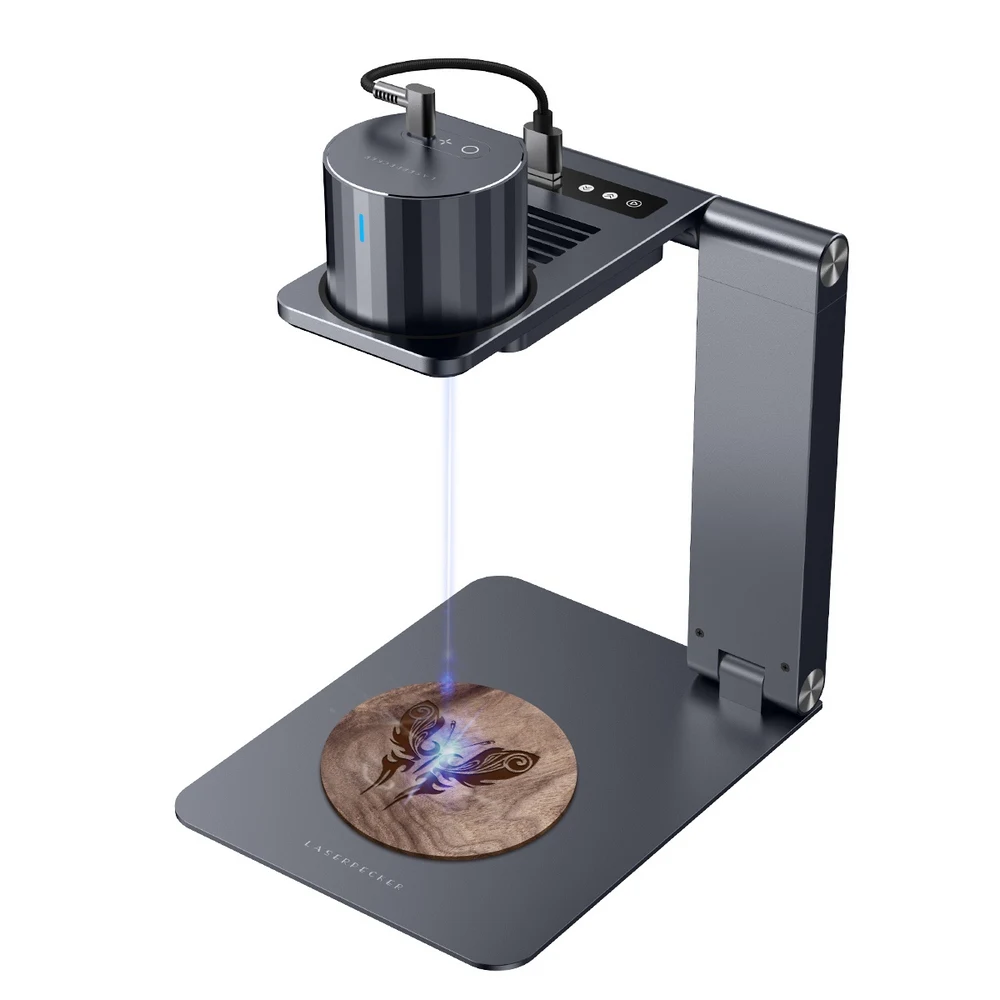

- Project Size and Complexity: Determine the maximum size and complexity of the designs you intend to create.

- Material Thickness: Consider the thickness of the wood materials you will be cutting.

- Budget: Set a realistic budget and explore machines that offer the best value for your needs.

- Furniture and Cabinetry: Precision cutting of complex furniture designs and intricate cabinet components.

- Signage and Displays: Creation of custom signage, display boards, and promotional materials.

- Toys and Games: Production of intricate toy parts and game components with precision and speed.

- Architectural Models: Fabrication of detailed architectural models for design and presentation purposes.

- Prototyping and Product Development: Rapid prototyping of new products and components for testing and evaluation.

- Laser Safety: Wear appropriate eye protection and avoid direct exposure to the laser beam.

- Fume Extraction: Ensure proper ventilation to remove harmful fumes generated during the cutting process.

- Fire Safety: Keep the work area clear of flammable materials and have a fire extinguisher readily available.

- Electrical Safety: Follow all electrical safety guidelines and ensure proper grounding.

In the ever-evolving world of woodworking, the advent of 3D laser cutting machines has marked a transformative milestone. These advanced tools empower artisans and manufacturers alike to create intricate, three-dimensional designs with unparalleled precision and efficiency.

H1: Unlocking the Capabilities of 3D Laser Wood Cutting Machines

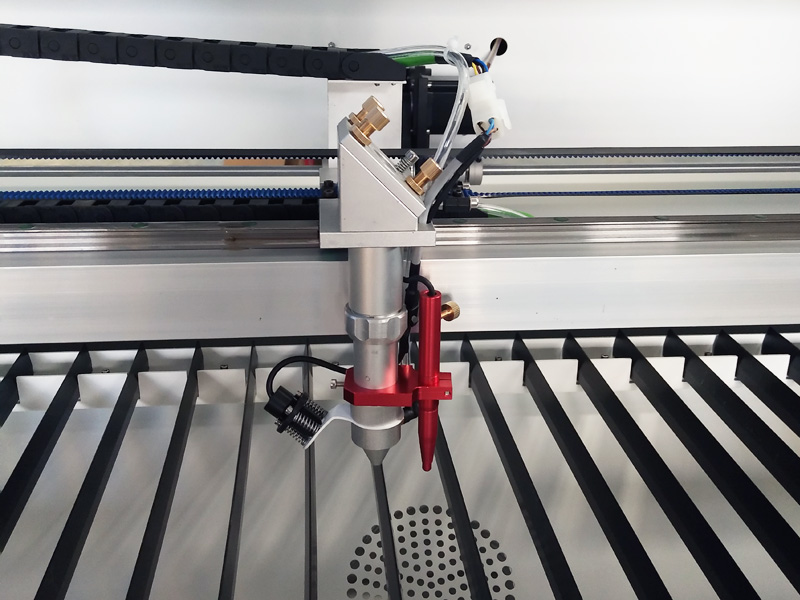

3D laser wood cutting machines utilize a focused beam of laser energy to cut, engrave, and etch wood materials. This cutting-edge technology offers a myriad of advantages over traditional woodworking methods:

H3: Choosing the Right 3D Laser Wood Cutting Machine

Selecting the ideal 3D laser wood cutting machine depends on the specific requirements and budget of the user. Factors to consider include:

H4: Applications of 3D Laser Wood Cutting Machines

3D laser wood cutting machines find application in a wide range of industries, including:

H5: Safety Considerations

When operating a 3D laser wood cutting machine, it is crucial to adhere to safety precautions:

Conclusion

3D laser wood cutting machines have revolutionized the woodworking industry, empowering artisans and manufacturers with unparalleled precision, efficiency, and versatility. By carefully selecting the right machine for their specific needs, users can unlock the full potential of this transformative technology and achieve exceptional results in their woodworking projects.

FAQs

Q: What is the difference between 2D and 3D laser cutting?

A: 2D laser cutting involves cutting flat materials, while 3D laser cutting enables the creation of three-dimensional objects by cutting and stacking layers of material.

Q: Can 3D laser wood cutting machines cut other materials besides wood?

A: Yes, some 3D laser cutting machines can also process materials such as acrylic, leather, and paper.

Q: How much does a 3D laser wood cutting machine cost?

A: The cost of a 3D laser wood cutting machine varies depending on factors such as laser power, working area, and features. Expect to pay anywhere from a few thousand to hundreds of thousands of dollars.