Laser Cutting with 3D Printers: A Comprehensive Guide

Introduction

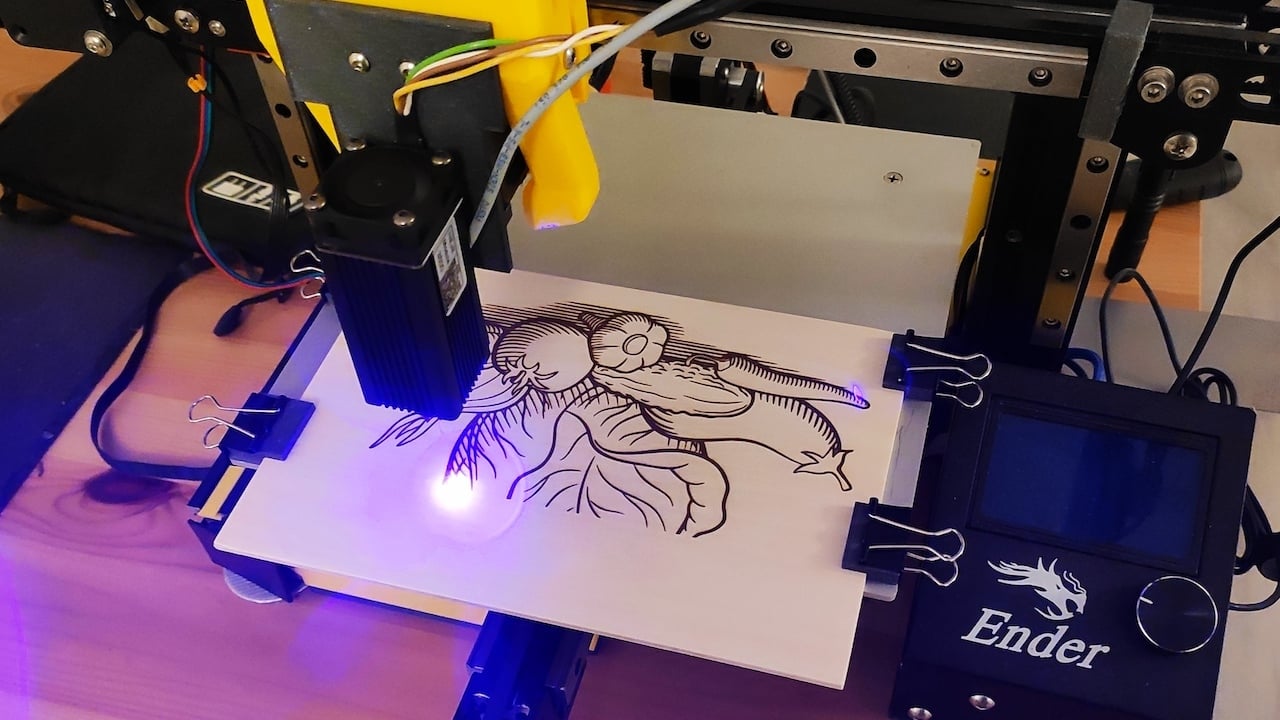

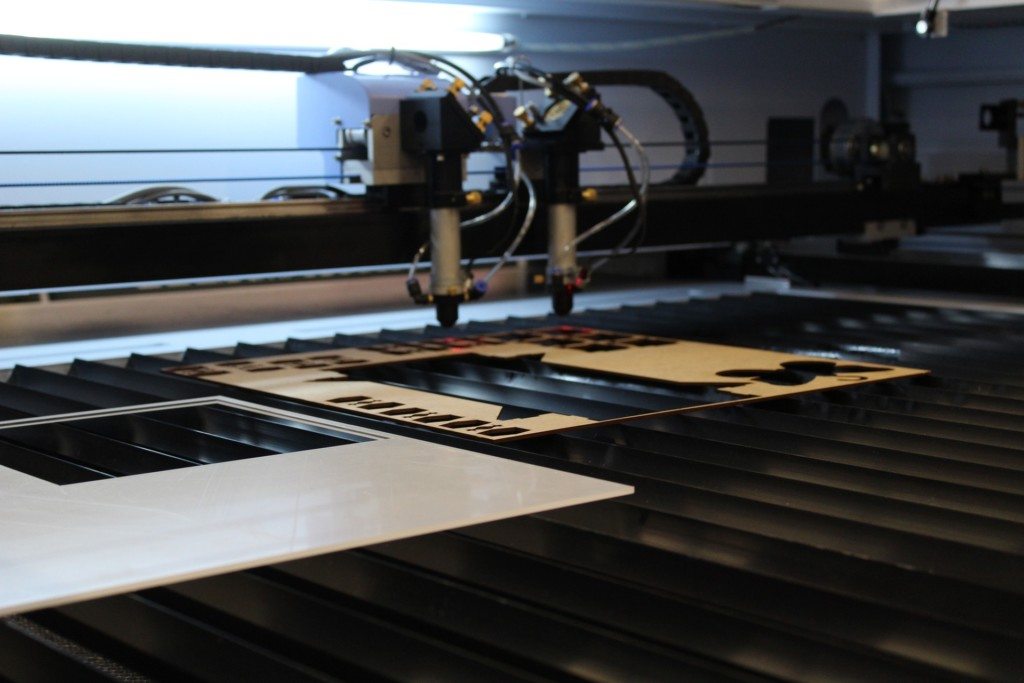

The convergence of laser cutting and 3D printing technologies has revolutionized the manufacturing industry. This innovative combination enables the creation of complex and precise parts with unparalleled efficiency and versatility. In this article, we will delve into the world of laser cutting with 3D printers, exploring its benefits, applications, and best practices.

Table of Content

- 1 Laser Cutting with 3D Printers: A Comprehensive Guide

- 1.1 Introduction

- 1.2 H1: Benefits of Laser Cutting with 3D Printers

- 1.3 H2: Applications of Laser Cutting with 3D Printers

- 1.4 H1: Benefits of Laser Cutting with 3D Printers

- 1.5 H3: Types of Laser Cutting with 3D Printers

- 1.6 H3: Best Practices for Laser Cutting with 3D Printers

- 1.7 H1: Conclusion

- 1.8 FAQs

H1: Benefits of Laser Cutting with 3D Printers

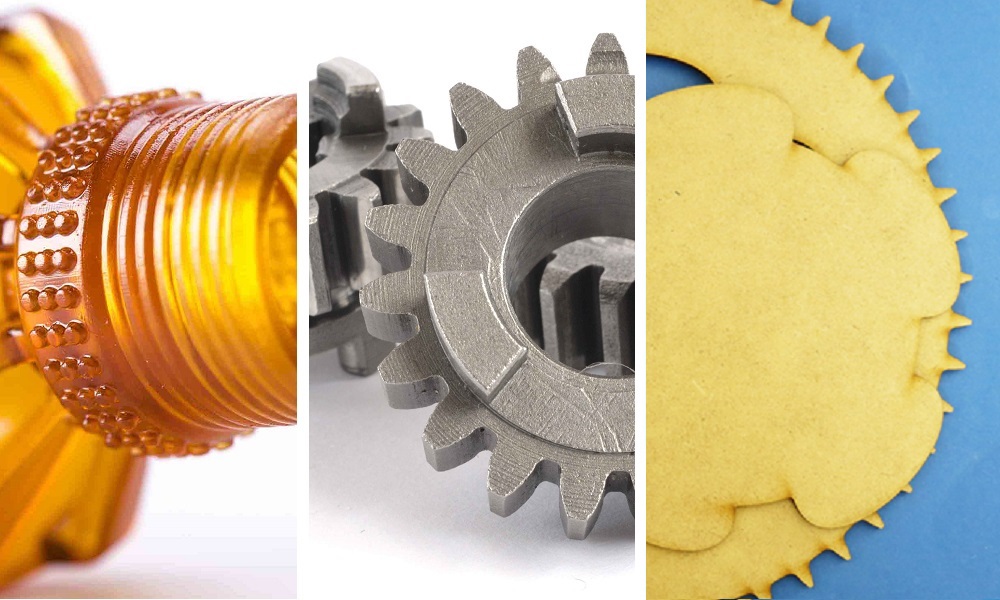

- Precision and Accuracy: Lasers provide unmatched precision, enabling the cutting of intricate designs and geometries with high accuracy.

- Speed and Efficiency: Laser cutting is a rapid process, significantly reducing production time and increasing throughput.

- Flexibility: Laser cutters can handle a wide range of materials, from plastics and metals to ceramics and wood, providing versatility in production.

- Non-Contact Process: Laser cutting eliminates the need for physical contact, minimizing tool wear and ensuring consistent results.

- Reduced Waste: Laser cutting produces minimal waste, maximizing material utilization and reducing environmental impact.

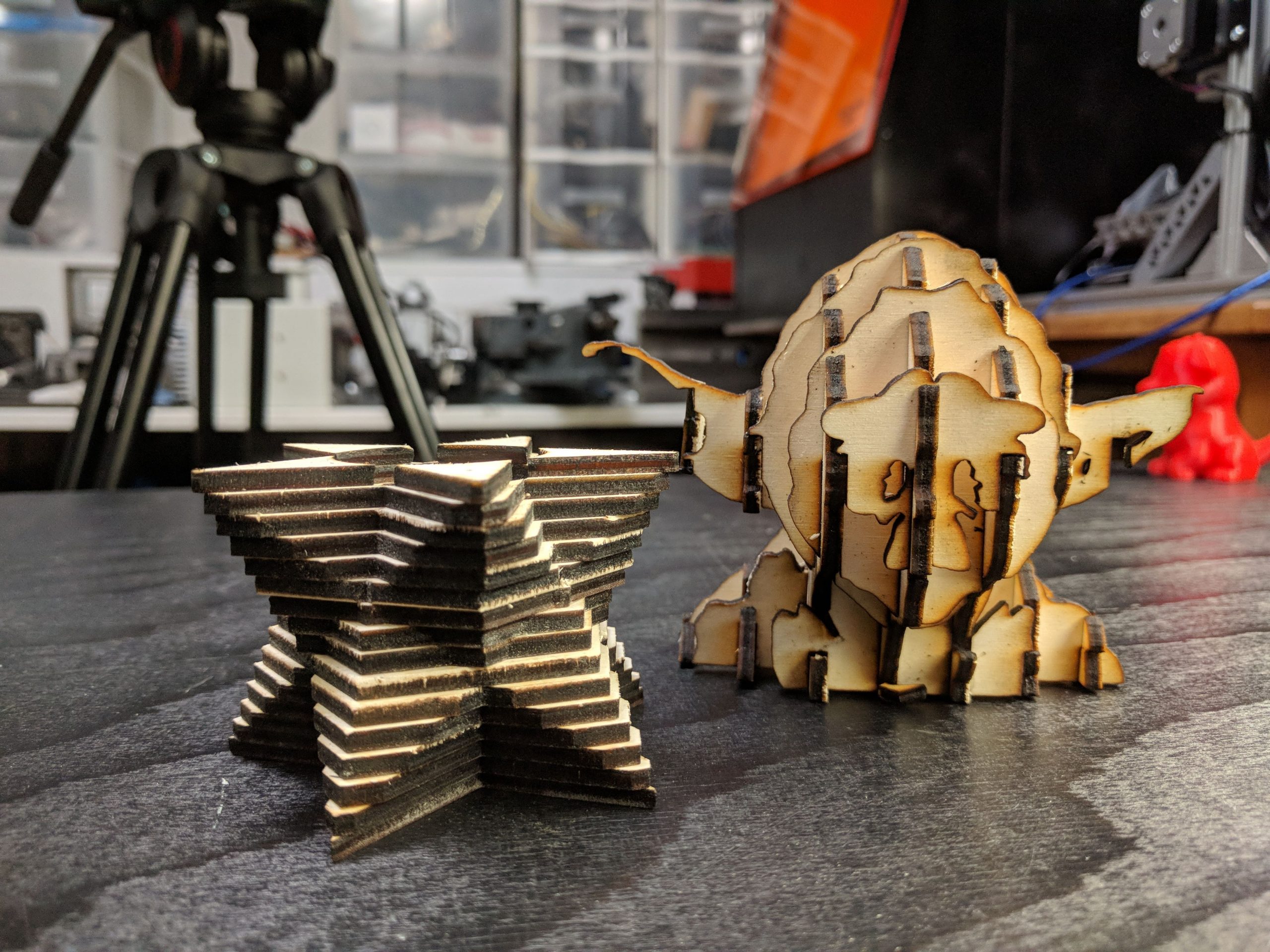

H2: Applications of Laser Cutting with 3D Printers

Laser cutting with 3D printers finds applications in various industries, including:

- 3d Model Decorative Laser Cutting Pattern 3D Model Decorative Laser Cutting Pattern: Transform Your Creations With Precision And Style

- Laser Cut 3d Rose Laser Cut 3D Rose: A Guide To Intricate And Stunning Creations

- Laser Cut 3d Angel Laser Cut 3D Angel: A Celestial Masterpiece For Home Decor And Gift Giving

- 3d Laser Tube Cutting 3D Laser Tube Cutting: A Comprehensive Guide

- 3d Laser Cut Fish 3D Laser Cut Fish: A Comprehensive Guide

- Precision and Accuracy: Lasers provide unmatched precision, enabling the cutting of intricate designs and geometries with high accuracy.

- Speed and Efficiency: Laser cutting is a rapid process, significantly reducing production time and increasing throughput.

- Automotive: Precision cutting of interior and exterior components, such as dashboards, door panels, and body parts.

- Aerospace: Production of lightweight and high-performance components for aircraft and spacecraft.

- Medical: Cutting of surgical instruments, implants, and prosthetics with intricate geometries.

- Electronics: Fabrication of printed circuit boards, connectors, and other electronic components.

- Jewelry: Creation of delicate and intricate jewelry pieces with precise cuts and finishes.

- CO2 Laser Cutting: Uses carbon dioxide lasers to cut non-metallic materials such as plastics, wood, and fabrics.

- Fiber Laser Cutting: Employs fiber lasers to cut a wider range of materials, including metals, ceramics, and certain plastics.

- Material Selection: Choose materials that are compatible with the laser cutter and meet the desired properties.

- Design Optimization: Design parts with appropriate thickness and geometry for laser cutting, considering factors such as kerf width and heat-affected zone.

- Laser Power and Speed Settings: Adjust laser power and speed based on the material and desired cutting quality.

- Ventilation and Safety: Ensure proper ventilation and wear appropriate safety gear, including eye protection and respirators.

- Maintenance and Calibration: Regularly maintain and calibrate the laser cutter to ensure precision and efficiency.

The convergence of laser cutting and 3D printing technologies has revolutionized the manufacturing industry. This innovative combination enables the creation of complex and precise parts with unparalleled efficiency and versatility. In this article, we will delve into the world of laser cutting with 3D printers, exploring its benefits, applications, and best practices.

H1: Benefits of Laser Cutting with 3D Printers

Laser cutting with 3D printers offers numerous advantages over traditional manufacturing methods, including:

H3: Types of Laser Cutting with 3D Printers

There are two main types of laser cutting with 3D printers:

H3: Best Practices for Laser Cutting with 3D Printers

To achieve optimal results with laser cutting using 3D printers, it is essential to follow best practices, including:

H1: Conclusion

Laser cutting with 3D printers has emerged as a transformative technology in the manufacturing industry. Its unique combination of precision, speed, flexibility, and reduced waste makes it an ideal solution for a wide range of applications. By embracing this innovative technology, businesses can enhance their production capabilities, drive innovation, and meet the demands of modern manufacturing.

FAQs

Q: What is the difference between CO2 and fiber laser cutting?

A: CO2 laser cutting is suitable for non-metallic materials, while fiber laser cutting can cut a wider range of materials, including metals.

Q: How does laser cutting affect the surface finish of the material?

A: Laser cutting can create a smooth or rough surface finish depending on the laser power, speed, and material properties.

Q: Can laser cutting be used to cut complex shapes?

A: Yes, laser cutters can cut complex shapes with high precision using computer-aided design (CAD) files.

Q: Is laser cutting safe?

A: Laser cutting requires proper ventilation and safety precautions, such as eye protection and respirators, to mitigate potential hazards.