Laser Cutting Projects: A Comprehensive Guide

Introduction

Laser cutting is a versatile technology that enables precise and intricate cuts on a wide range of materials. From hobbyists to industrial manufacturers, laser cutting offers countless possibilities for creating custom projects. This comprehensive guide will delve into the intricacies of laser cutting, providing you with the knowledge and inspiration to embark on your own laser cutting adventures.

Table of Content

- 1 Laser Cutting Projects: A Comprehensive Guide

- 1.1 Introduction

- 1.2 What is Laser Cutting?

- 1.3 Types of Laser Cutting Machines

- 1.4 Materials Suitable for Laser Cutting

- 1.5 What is Laser Cutting?

- 1.6 Types of Laser Cutting Machines

- 1.7 Design Considerations for Laser Cutting

- 1.8 Laser Cutting Techniques

- 1.9 Laser Cutting Software

- 1.10 Safety Precautions for Laser Cutting

- 1.11 Troubleshooting Laser Cutting Issues

- 1.12 Applications of Laser Cutting

- 1.13 Conclusion

- 1.14 FAQs

What is Laser Cutting?

Types of Laser Cutting Machines

There are various types of laser cutting machines available, each designed for specific applications.

- CO2 Laser Cutters: These machines use carbon dioxide gas to generate the laser beam and are ideal for cutting non-metallic materials such as acrylic, wood, and leather.

- Fiber Laser Cutters: These machines use a fiber-optic cable to deliver the laser beam and are capable of cutting both metallic and non-metallic materials with high precision and speed.

- Diode Laser Cutters: These machines use semiconductor diodes to generate the laser beam and are suitable for engraving and cutting thin materials such as paper, cardboard, and plastic.

Materials Suitable for Laser Cutting

Laser cutters can cut a wide variety of materials, including:

- 3d Laser Wood Cutter 3D Laser Wood Cutter: A Comprehensive Guide

- 3d Laser Cut Maps 3D Laser Cut Maps: Unraveling The World’s Topography

- 3d Cutting Machine 3D Cutting Machine: A Comprehensive Guide

- 3d Software For Laser Cutting 3D Software For Laser Cutting: A Comprehensive Guide

- Laser Cut 3d Model Dragon Laser Cut 3D Model Dragon: A Masterpiece Of Precision And Intricacy

- Acrylic: Clear, colored, or mirrored acrylic is commonly used for signs, displays, and crafts.

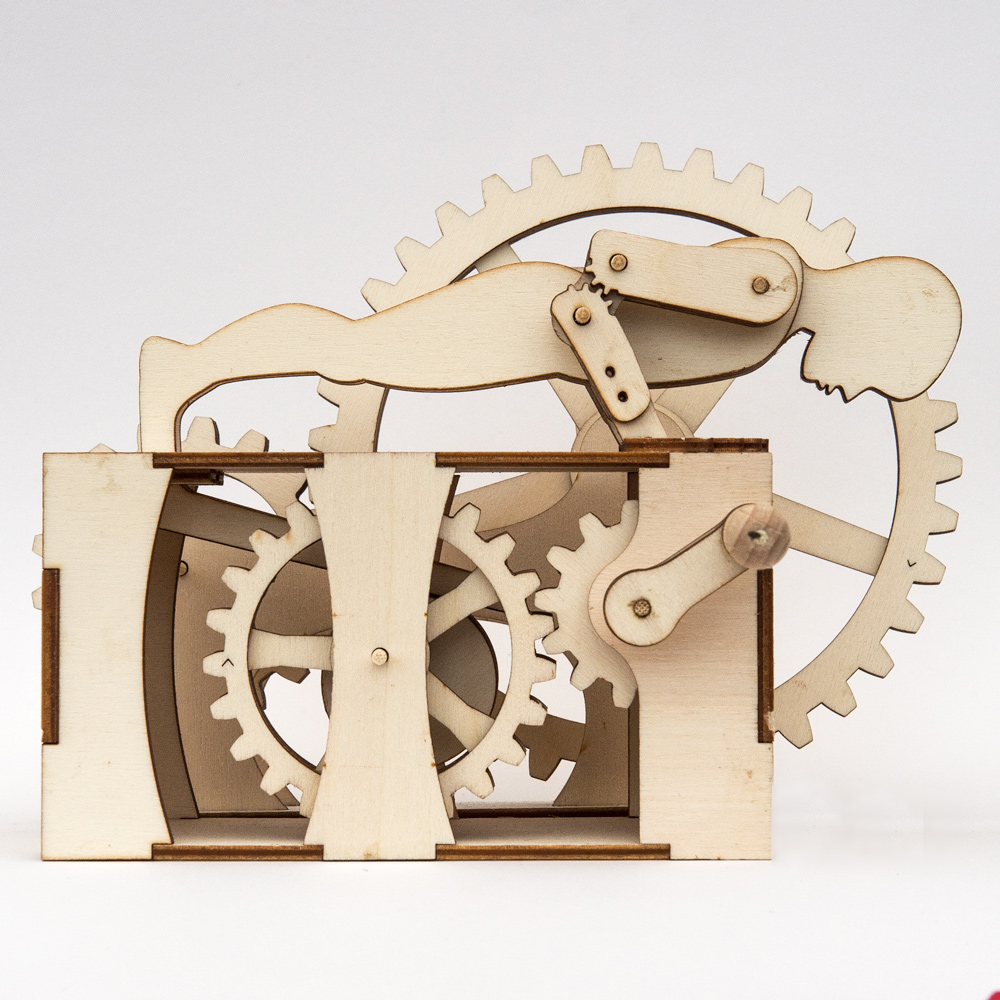

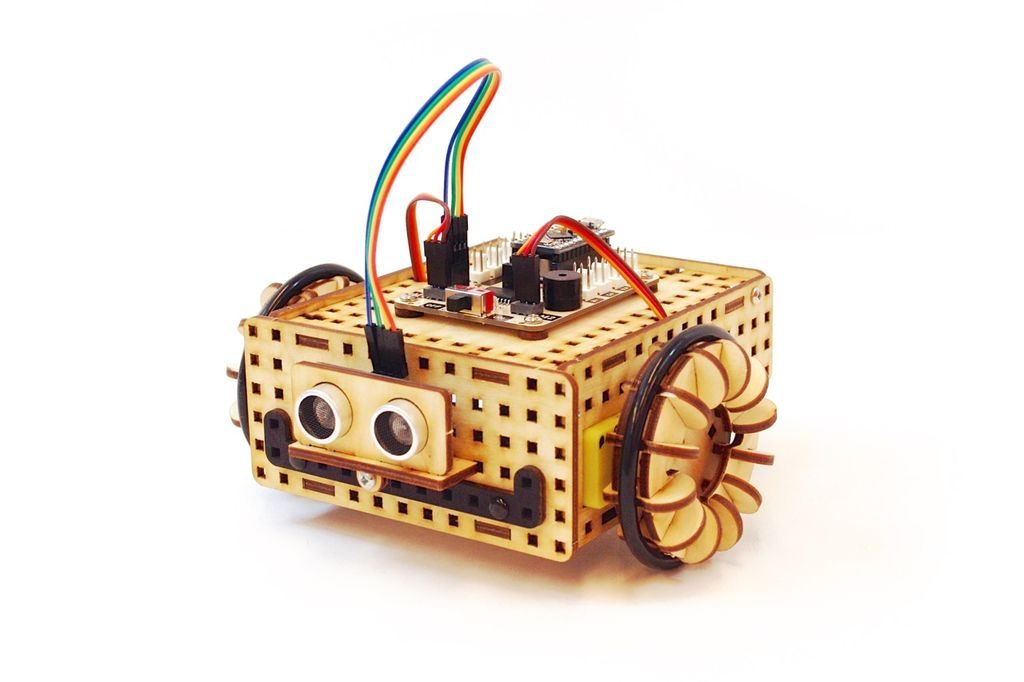

- Wood: Plywood, MDF, and hardwoods are suitable for laser cutting for furniture, toys, and decorative items.

- Metal: Thin sheets of steel, aluminum, and stainless steel can be cut with fiber laser cutters for industrial applications.

- Leather: Laser cutting leather allows for intricate designs and personalization for accessories and garments.

- Fabric: Laser cutters can cut and engrave fabrics for fashion, home décor, and craft projects.

- Cut Width: The laser beam has a specific width, which determines the thickness of the cut.

- Kerf: The kerf is the material that is removed during cutting and affects the overall dimensions of the cut part.

- Material Thickness: The thickness of the material will determine the laser power and cutting speed required.

- Complexity of Design: Intricate designs with sharp corners and small features may require additional laser passes or specialized cutting techniques.

- Vector Cutting: The laser beam follows a predefined path to cut through the material.

- Raster Cutting: The laser beam scans back and forth across the material, creating a raster pattern of cuts.

- Engraving: The laser beam is used to engrave or mark the surface of the material without cutting through it.

- Perforation: The laser beam creates a series of holes or perforations in the material.

- LightBurn: A user-friendly software for beginners and hobbyists.

- LaserCut 5.3: A comprehensive software for industrial and professional applications.

- RDWorks: A software specifically designed for laser cutters using Ruida controllers.

- Wear Protective Gear: Wear safety glasses, gloves, and a respirator to protect yourself from laser radiation and fumes.

- Ventilate the Area: Ensure proper ventilation to remove fumes and particles generated during laser cutting.

- Secure the Material: Secure the material to the cutting bed to prevent movement and potential accidents.

- Follow Laser Cutter Instructions: Read and follow the manufacturer’s instructions for the specific laser cutter being used.

- Poor Cut Quality: Check laser alignment, power settings, and material compatibility.

- Material Melting or Burning: Adjust laser power and speed settings to prevent excessive heat.

- Laser Beam Scattering: Clean or replace laser optics to ensure proper beam focus.

- Software Errors: Verify software settings and ensure compatibility with the laser cutter.

- Industrial Manufacturing: Precision cutting of metal components for automotive, aerospace, and medical industries.

- Fabrication: Creation of custom parts and prototypes for engineering, architecture, and product design.

- Sign Making: Production of signs, displays, and logos from acrylic, metal, and wood.

- Crafting and DIY: Personalization of home décor, jewelry, and other craft items.

- Fashion and Textiles: Intricate cutting and engraving of fabrics for garments, accessories, and home textiles.

Laser cutting is a versatile technology that enables precise and intricate cuts on a wide range of materials. From hobbyists to industrial manufacturers, laser cutting offers countless possibilities for creating custom projects. This comprehensive guide will delve into the intricacies of laser cutting, providing you with the knowledge and inspiration to embark on your own laser cutting adventures.

What is Laser Cutting?

Laser cutting is a subtractive manufacturing process that uses a high-powered laser beam to cut through materials. The laser beam is generated by a laser source and focused onto the material using mirrors and lenses. As the laser beam interacts with the material, it melts, vaporizes, or burns away, leaving a precise cut.

Types of Laser Cutting Machines

There are various types of laser cutting machines available, each designed for specific applications.

Design Considerations for Laser Cutting

When designing for laser cutting, there are several factors to consider:

Laser Cutting Techniques

There are various laser cutting techniques used to achieve different effects:

Laser Cutting Software

Laser cutting software is used to create and send cutting instructions to the laser cutter. Popular software options include:

Safety Precautions for Laser Cutting

Laser cutting involves the use of high-powered lasers, so it is crucial to adhere to safety precautions:

Troubleshooting Laser Cutting Issues

Common laser cutting issues and their solutions include:

Applications of Laser Cutting

Laser cutting finds applications in numerous industries, including:

Conclusion

Laser cutting is a versatile and powerful technology that enables precise cutting and intricate designs on a wide range of materials. By understanding the principles, techniques, and safety precautions involved in laser cutting, you can unlock the potential of this technology and embark on your own creative projects.

FAQs

Q: What is the difference between CO2 and fiber laser cutters?

A: CO2 laser cutters are suitable for non-metallic materials, while fiber laser cutters can cut both metallic and non-metallic materials with higher precision and speed.

Q: Can laser cutters cut thick materials?

A: The thickness of the material that can be cut depends on the laser power and the type of material. Some laser cutters can cut through metal sheets up to several millimeters thick.

Q: Is laser cutting safe?

A: Yes, laser cutting is safe when proper precautions are taken. These include wearing protective gear, ventilating the area, and following laser cutter instructions.

Q: What are some creative applications of laser cutting?

A: Laser cutting can be used to create custom jewelry, personalized gifts, home décor items, and even architectural models.