H1: Unveiling the Revolutionary World of 3D Laser Marking: A Comprehensive Guide

H2: Introduction: Embracing the Precision of 3D Laser Marking

In the realm of manufacturing, precision and efficiency reign supreme. 3D laser marking has emerged as a game-changer, transforming the way industries etch intricate designs and information onto complex surfaces. This article delves into the captivating world of 3D laser marking, exploring its advantages, applications, and the intricate technicalities that drive its success.

Table of Content

- 1 H1: Unveiling the Revolutionary World of 3D Laser Marking: A Comprehensive Guide

- 1.1 H2: Introduction: Embracing the Precision of 3D Laser Marking

- 1.2 H2: Understanding the Mechanics of 3D Laser Marking

- 1.3 H3: Advantages of 3D Laser Marking: Precision, Versatility, and Durability

- 1.4 H2: Applications of 3D Laser Marking: A Spectrum of Possibilities

- 1.5 H2: Understanding the Mechanics of 3D Laser Marking

- 1.6 H3: Advantages of 3D Laser Marking: Precision, Versatility, and Durability

- 1.7 H2: Technical Considerations: Delving into the Laser Marking Process

- 1.8 H3: Material Considerations: Optimizing Laser Marking Results

- 1.9 H2: Conclusion: Revolutionizing Manufacturing with 3D Laser Marking

- 1.10 H2: FAQs: Addressing Common Inquiries

H2: Understanding the Mechanics of 3D Laser Marking

H3: Advantages of 3D Laser Marking: Precision, Versatility, and Durability

- Unmatched Precision: 3D laser marking offers unparalleled precision, allowing for the creation of intricate designs and fine details with exceptional accuracy.

- Versatile Applications: Its ability to mark on complex surfaces makes 3D laser marking ideal for a vast array of industries, from aerospace and automotive to medical and consumer electronics.

- Durable and Permanent: Laser markings are highly resistant to wear, abrasion, and chemical exposure, ensuring long-lasting identification and traceability.

H2: Applications of 3D Laser Marking: A Spectrum of Possibilities

The versatility of 3D laser marking extends across numerous industries, including:

- Aerospace: Etching serial numbers, logos, and technical specifications onto aircraft components

- 3d Laser Cut Wood Models 3D Laser Cut Wood Models: An Intricate And Enchanting World Of Precision And Creativity

- 3d Laser Cut Wooden Models For Sale 3D Laser Cut Wooden Models For Sale: A Comprehensive Guide

- 3d Laser Cutting Design 3D Laser Cutting Design: Revolutionizing Manufacturing And Creativity

- 3d Laser Cutting Photos 3D Laser Cutting: Revolutionizing The Manufacturing Industry

- 3d Laser Cut Metal Models 3D Laser Cut Metal Models: A Comprehensive Guide To Precision And Creativity

- Unmatched Precision: 3D laser marking offers unparalleled precision, allowing for the creation of intricate designs and fine details with exceptional accuracy.

- Automotive: Marking engine parts, dashboards, and other vehicle components for identification and traceability

- Medical: Creating intricate markings on surgical instruments, implants, and medical devices

- Electronics: Marking circuit boards, connectors, and other electronic components with precise details

- Consumer Goods: Enhancing the aesthetics and functionality of products with customized designs, logos, and information

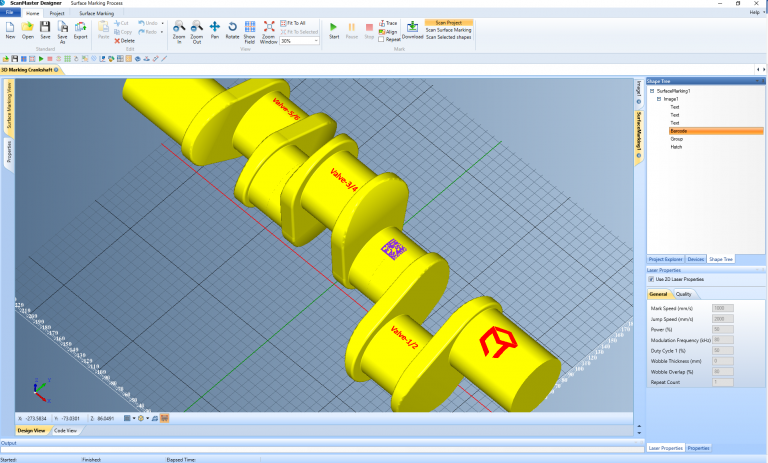

- Laser Source: The type of laser used determines the wavelength and power output, influencing the marking speed and depth.

- Optical System: Lenses and mirrors precisely control the laser beam’s focus, enabling precise marking on complex surfaces.

- Software: Advanced software controls the laser’s movement and marking parameters, ensuring accuracy and repeatability.

In the realm of manufacturing, precision and efficiency reign supreme. 3D laser marking has emerged as a game-changer, transforming the way industries etch intricate designs and information onto complex surfaces. This article delves into the captivating world of 3D laser marking, exploring its advantages, applications, and the intricate technicalities that drive its success.

H2: Understanding the Mechanics of 3D Laser Marking

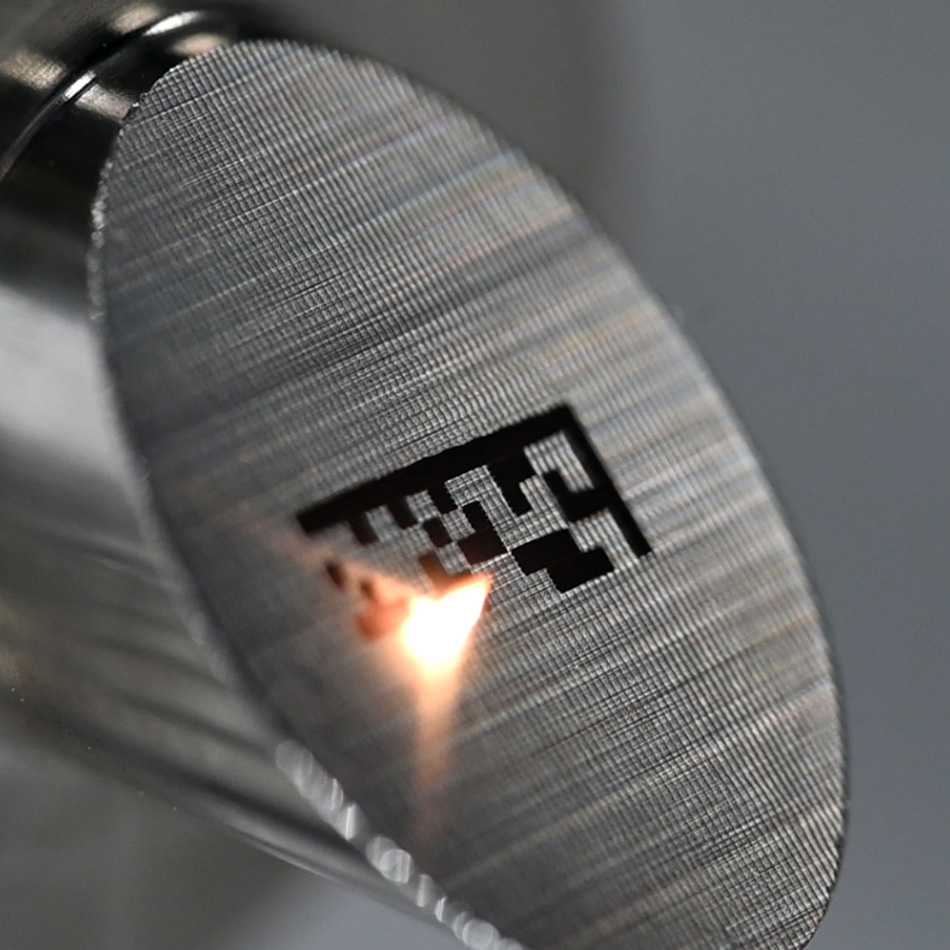

3D laser marking harnesses the power of lasers to create permanent, three-dimensional marks on a wide range of materials, including metals, plastics, ceramics, and even biological tissues. Unlike traditional 2D laser marking, which operates on flat surfaces, 3D laser marking employs advanced optical systems to manipulate the laser beam’s focus and create precise markings on curved or uneven surfaces.

H3: Advantages of 3D Laser Marking: Precision, Versatility, and Durability

H2: Technical Considerations: Delving into the Laser Marking Process

H3: Material Considerations: Optimizing Laser Marking Results

The choice of material significantly impacts the laser marking process. Different materials exhibit varying absorption and reflectivity characteristics, requiring tailored laser parameters for optimal results.

H2: Conclusion: Revolutionizing Manufacturing with 3D Laser Marking

3D laser marking has revolutionized the manufacturing industry, offering unparalleled precision, versatility, and durability. Its ability to mark on complex surfaces has opened up a world of possibilities, enhancing product identification, traceability, and aesthetics. As technology continues to advance, 3D laser marking will undoubtedly play an increasingly vital role in shaping the future of manufacturing.

H2: FAQs: Addressing Common Inquiries

Q: What is the difference between 2D and 3D laser marking?

A: 2D laser marking operates on flat surfaces, while 3D laser marking utilizes advanced optical systems to create precise markings on curved or uneven surfaces.

Q: What materials can be marked using 3D laser marking?

A: 3D laser marking can be used on a wide range of materials, including metals, plastics, ceramics, and even biological tissues.

Q: Is 3D laser marking permanent?

A: Yes, laser markings are highly resistant to wear, abrasion, and chemical exposure, ensuring long-lasting identification and traceability.

Q: What are the advantages of 3D laser marking?

A: 3D laser marking offers unmatched precision, versatility, and durability, making it ideal for a wide range of industries and applications.

Q: What are the key technical considerations for 3D laser marking?

A: Laser source, optical system, and software are critical technical considerations that influence the marking speed, depth, and accuracy.