Laser Cut Template: A Comprehensive Guide to Precision Crafting

Introduction

Laser cutting has revolutionized the crafting and manufacturing industries, allowing for intricate and precise cuts in various materials. Laser cut templates serve as essential tools in this process, enabling the creation of complex designs with unmatched accuracy. This article delves into the world of laser cut templates, exploring their advantages, applications, and best practices.

Table of Content

- 1 Laser Cut Template: A Comprehensive Guide to Precision Crafting

- 1.1 Introduction

- 2 Benefits of Laser Cut Templates

- 2.2 Precision and Accuracy

- 2.3 Intricate Designs

- 2.4 Material Versatility

- 2.5 Speed and Efficiency

- 3 Applications of Laser Cut Templates

- 4 Benefits of Laser Cut Templates

- 4.6 Precision and Accuracy

- 4.7 Intricate Designs

- 4.8 Crafting

- 4.9 Industrial Manufacturing

- 4.10 Engineering and Architecture

- 4.11 Education and Research

- 5 Best Practices for Laser Cut Templates

- 5.12 Material Selection

- 5.13 Design Preparation

- 5.14 Laser Cutter Setup

- 5.15 Safety Precautions

- 6 FAQs

- 6.16 What is the difference between a laser cut template and a laser engraved template?

- 6.17 Can laser cut templates be used for multiple cuts?

- 6.18 How do I clean a laser cut template?

- 7 Conclusion

Benefits of Laser Cut Templates

Precision and Accuracy

Lasers produce highly accurate cuts, eliminating human error and ensuring consistency in design. This precision is crucial for applications where exact dimensions are essential, such as in engineering and prototyping.

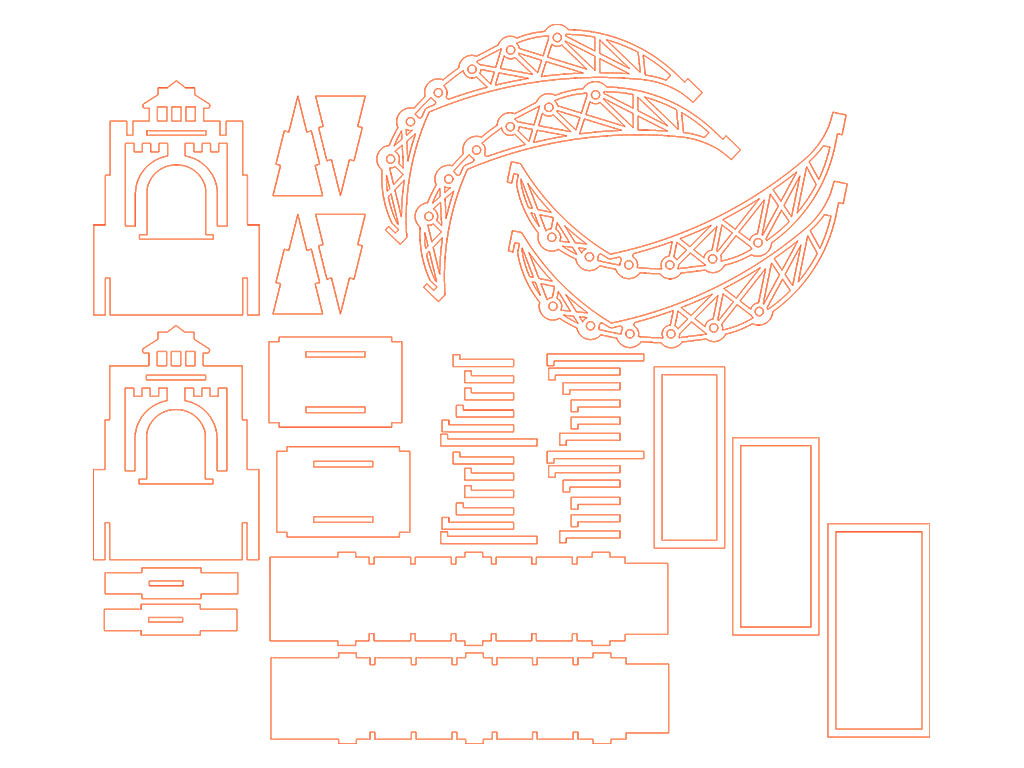

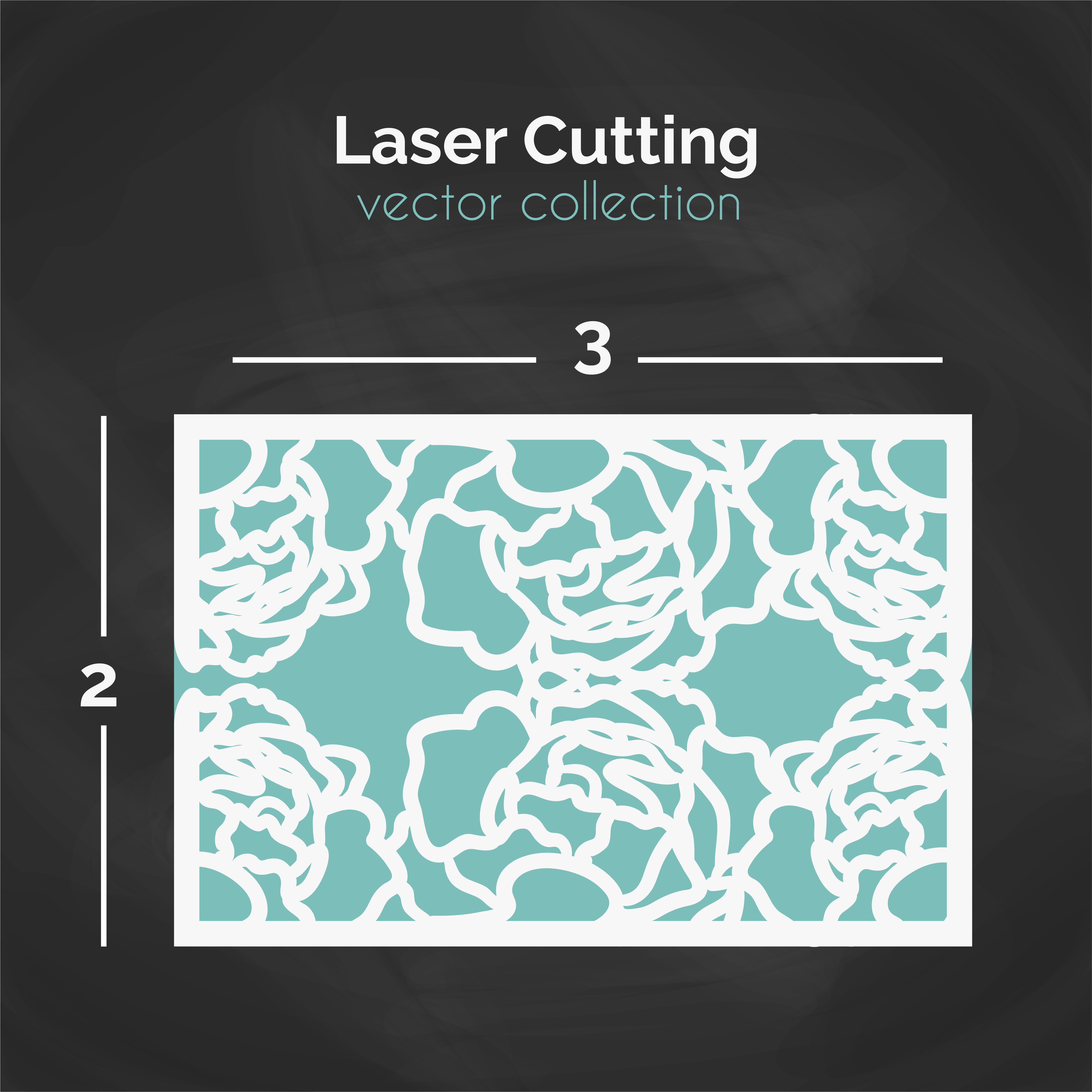

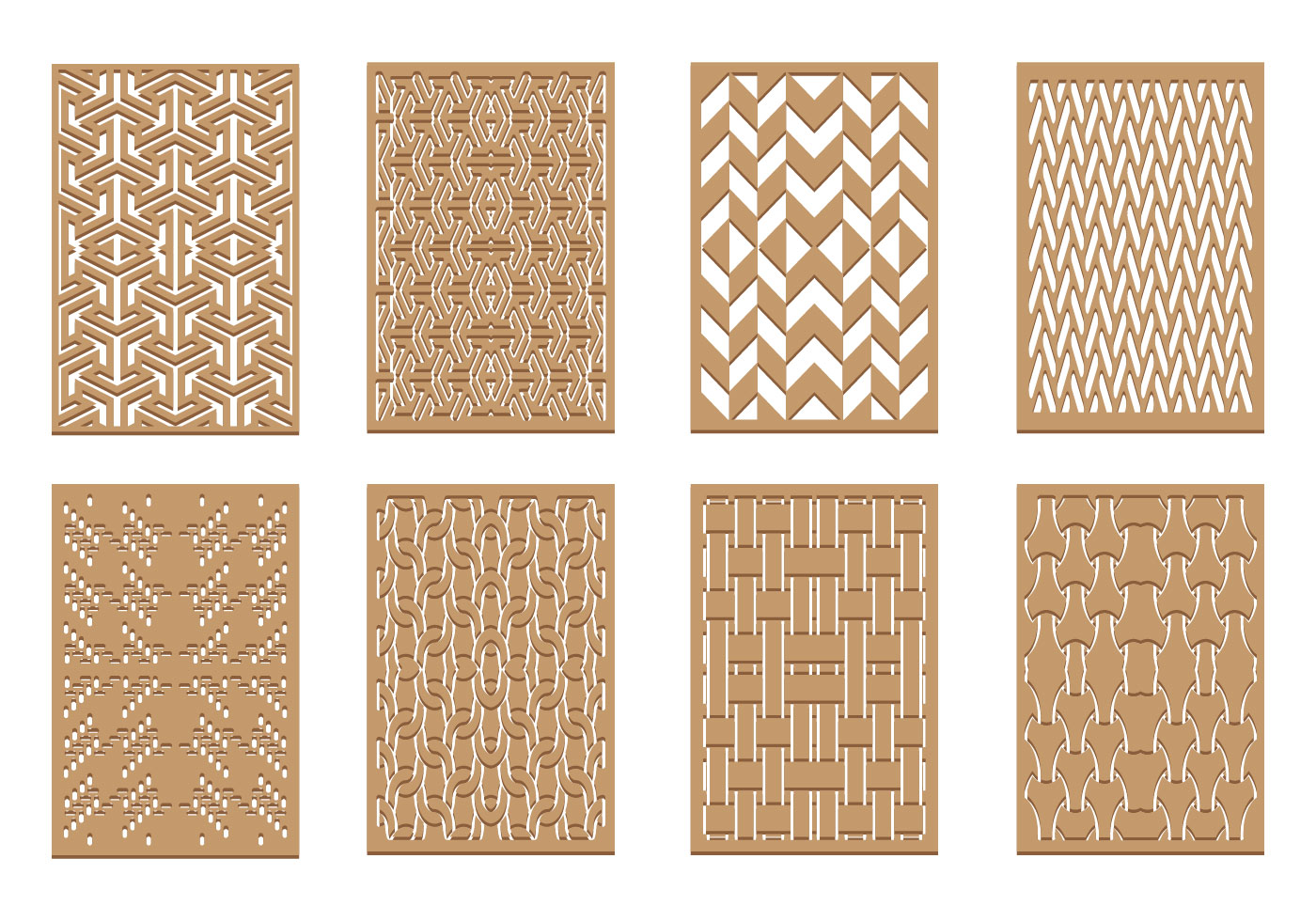

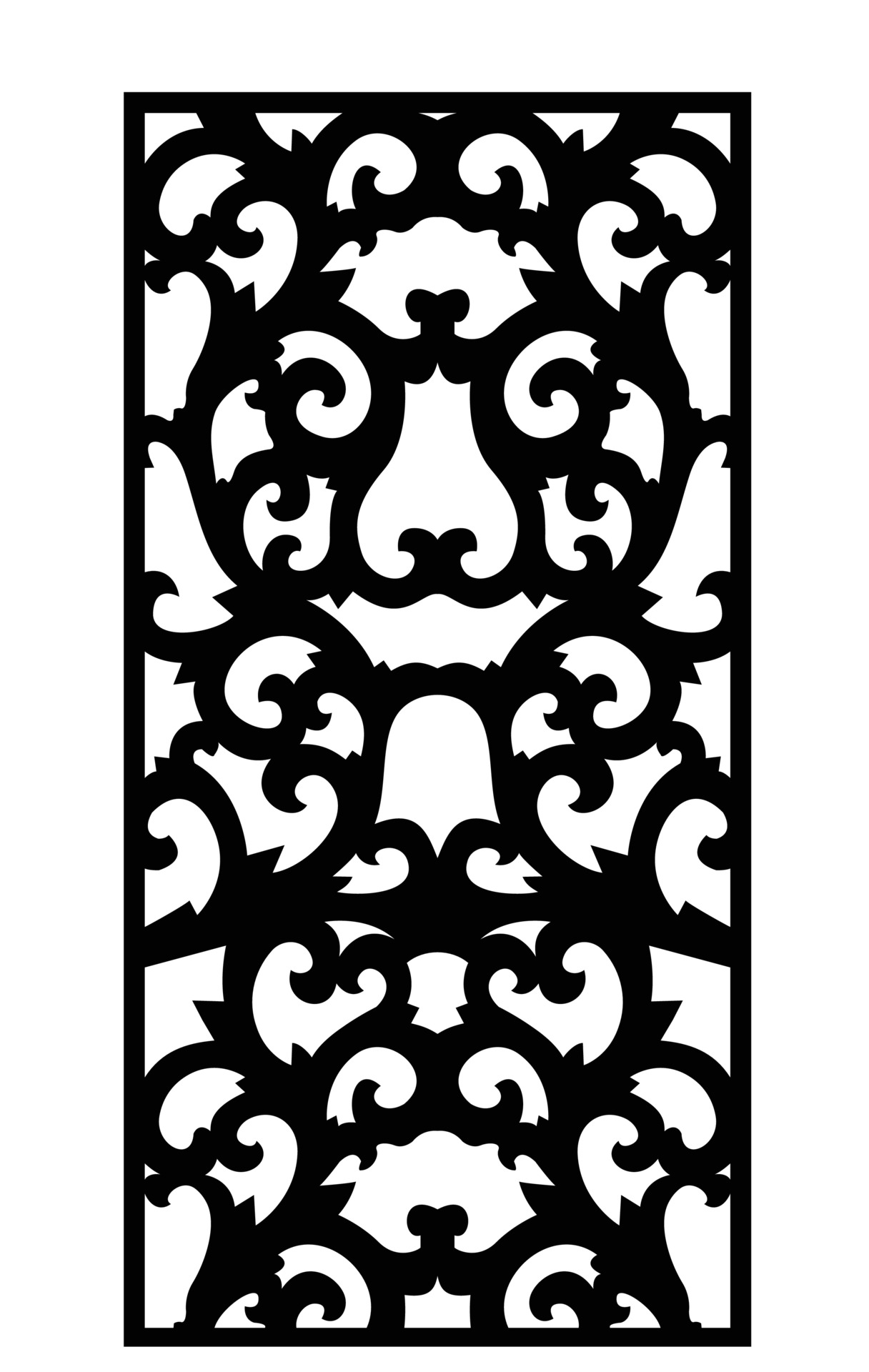

Intricate Designs

Laser cutting allows for the creation of complex and intricate designs that would be impossible to achieve with manual tools. This capability opens up new possibilities for creative expression and functional applications.

Material Versatility

Laser cutters can process a wide range of materials, including wood, metal, plastic, and fabric. This versatility makes laser cut templates suitable for various projects, from crafting to industrial manufacturing.

Speed and Efficiency

Laser cutting is a fast and efficient process, significantly reducing production time compared to traditional methods. This efficiency can save time and costs, making laser cut templates an economical solution.

Applications of Laser Cut Templates

Laser cut templates find applications in a diverse range of industries and projects:

Laser cutting has revolutionized the crafting and manufacturing industries, allowing for intricate and precise cuts in various materials. Laser cut templates serve as essential tools in this process, enabling the creation of complex designs with unmatched accuracy. This article delves into the world of laser cut templates, exploring their advantages, applications, and best practices.

- 3d Laser Cutting Services Near Me 3D Laser Cutting Services Near Me: A Comprehensive Guide

- Laser Cut 3d Illusion Lamp Laser Cut 3D Illusion Lamp: A Captivating And Personalized Lighting Experience

- Laser Cut 3d Warehouse Laser Cut 3D Warehouse: Unleashing The Power Of Precision Fabrication

- 3d Printer To Laser Cutting 3D Printer To Laser Cutting: Unveiling The Seamless Transition

- 3d Laser Metal Cutting Machine 3D Laser Metal Cutting Machine: A Comprehensive Guide

Benefits of Laser Cut Templates

Laser cut templates offer numerous advantages over traditional cutting methods:

Precision and Accuracy

Lasers produce highly accurate cuts, eliminating human error and ensuring consistency in design. This precision is crucial for applications where exact dimensions are essential, such as in engineering and prototyping.

Intricate Designs

Crafting

Laser cut templates are popular in crafting, enabling the creation of intricate designs for jewelry, home décor, and personalized gifts.

Industrial Manufacturing

In industrial settings, laser cut templates are used for prototyping, fabrication, and mass production. They ensure precision and repeatability in manufacturing processes.

Engineering and Architecture

Laser cut templates assist in the design and fabrication of architectural models, scale replicas, and engineering components.

Education and Research

Laser cut templates support educational and research projects, providing a means to create precise and reproducible experimental setups.

Best Practices for Laser Cut Templates

To optimize the use of laser cut templates, consider the following best practices:

Material Selection

Choose the appropriate material for your project, considering its thickness, durability, and compatibility with laser cutting.

Design Preparation

Create a digital design using a CAD software that is compatible with your laser cutter. Ensure the design is precise and includes all necessary cut lines and perforations.

Laser Cutter Setup

Calibrate your laser cutter to the correct power and speed settings for the chosen material. Use a test piece to verify the settings before cutting the actual template.

Safety Precautions

Wear appropriate safety gear, including safety glasses, earplugs, and a dust mask. Ensure the laser cutter is in a well-ventilated area.

FAQs

What is the difference between a laser cut template and a laser engraved template?

Laser cutting removes material to create a through-cut, while laser engraving only marks or etches the surface of the material.

Can laser cut templates be used for multiple cuts?

Yes, laser cut templates can be reused multiple times, provided they are handled carefully and stored properly.

How do I clean a laser cut template?

Use a soft cloth or brush to remove any debris or residue from the template. Avoid using abrasive cleaners or solvents.

Conclusion

Laser cut templates are indispensable tools for precision crafting and manufacturing. Their advantages of accuracy, intricacy, versatility, speed, and efficiency make them suitable for a wide range of applications. By following best practices and adhering to safety precautions, users can harness the power of laser cutting to create intricate and precise designs with ease.