Laser Cutting Template: A Comprehensive Guide

Introduction

Laser cutting is a precise and versatile manufacturing process that utilizes a laser beam to cut materials into complex shapes. A laser cutting template is a crucial element in this process, providing the instructions for the laser cutter to follow. This article delves into the intricacies of laser cutting templates, exploring their types, materials, design considerations, and optimization techniques.

Table of Content

- 1 Laser Cutting Template: A Comprehensive Guide

- 1.1 Introduction

- 1.2 H1: Types of Laser Cutting Templates

- 1.3 H2: Materials for Laser Cutting Templates

- 1.4 H1: Types of Laser Cutting Templates

- 1.5 H3: Design Considerations for Laser Cutting Templates

- 1.6 H4: Optimizing Laser Cutting Templates

- 1.7 H5: Conclusion

- 1.8 H6: Frequently Asked Questions (FAQs)

H1: Types of Laser Cutting Templates

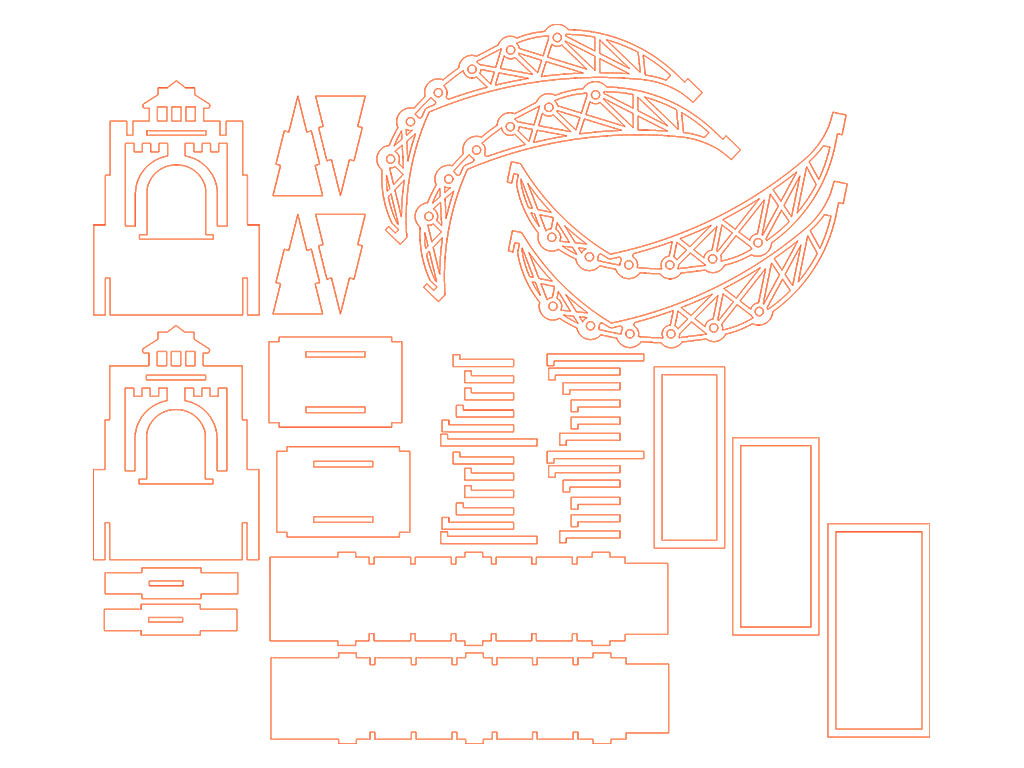

Computer-aided design (CAD) files are digital blueprints that define the geometry of the part to be cut. These files are typically created using software such as AutoCAD or SolidWorks and contain detailed information about the shape, dimensions, and tolerances of the part.

2. DXF Files

Drawing exchange format (DXF) files are a type of CAD file that is commonly used for laser cutting. DXF files are ASCII-based and can be opened by a wide range of software programs, making them a versatile option for sharing designs.

3. G-Code Files

G-code files are machine instructions that guide the laser cutter through the cutting process. These files contain specific commands for the laser, such as the speed, power, and path to follow.

H2: Materials for Laser Cutting Templates

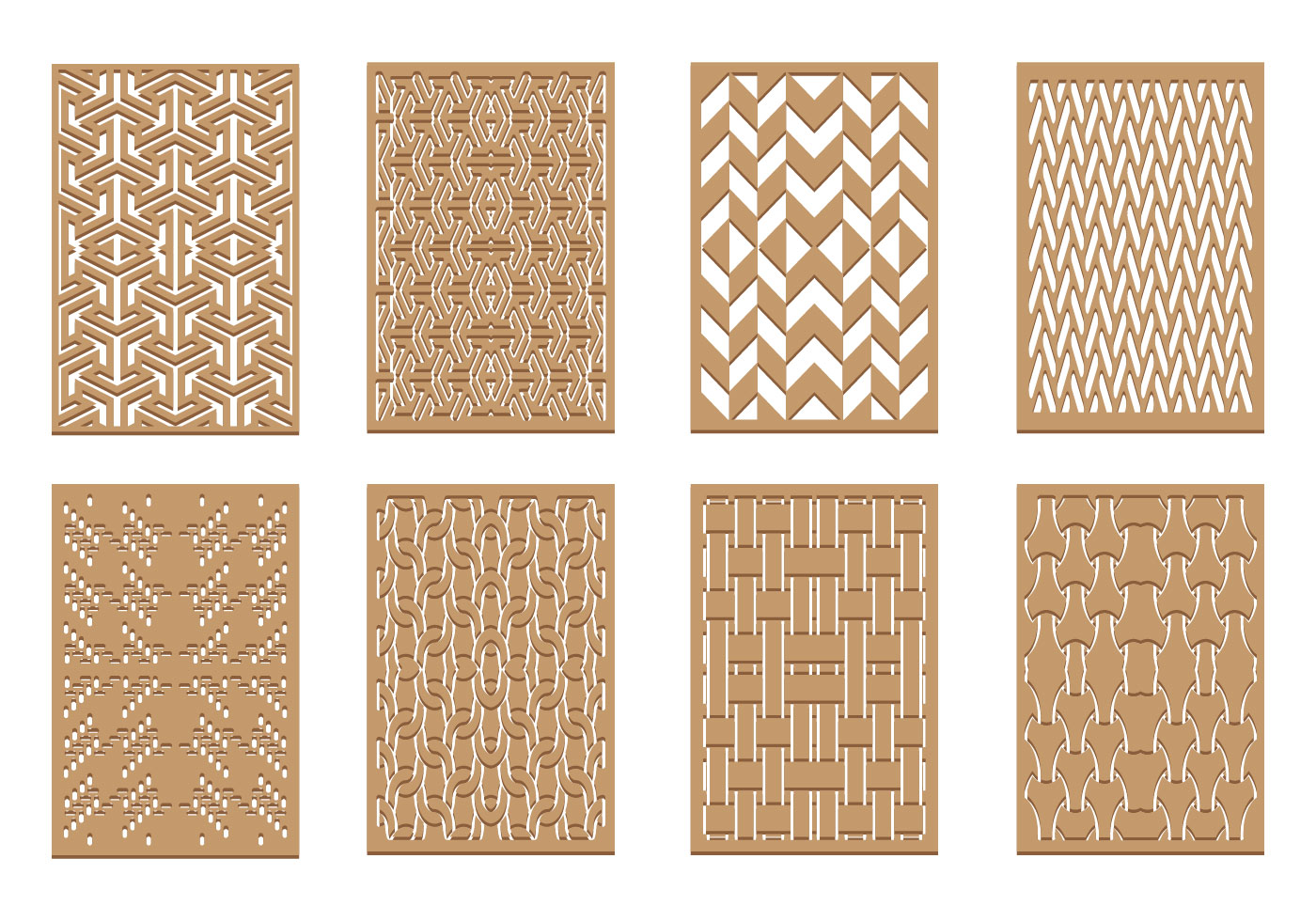

The choice of material for a laser cutting template depends on the specific application and material being cut. Common materials include:

1. Acrylic

Acrylic is a lightweight and durable plastic that is easy to laser cut. It is often used for templates for cutting thin materials, such as paper, cardboard, or fabric.

2. Plywood

Laser cutting is a precise and versatile manufacturing process that utilizes a laser beam to cut materials into complex shapes. A laser cutting template is a crucial element in this process, providing the instructions for the laser cutter to follow. This article delves into the intricacies of laser cutting templates, exploring their types, materials, design considerations, and optimization techniques.

- 3d Scanner For Laser Cutting 3D Scanners For Laser Cutting: A Comprehensive Guide

- 3d Tube Cutting 3D Tube Cutting: A Comprehensive Guide To Advanced Manufacturing

- 3d Laser Cut Designs 3D Laser Cut Designs: Unleashing Creativity And Precision

- Laser Cut 3d Names Laser Cut 3D Names: A Personalized And Unique Gift

- 3d Laser Cutting Uk 3D Laser Cutting UK: A Comprehensive Guide To Advanced Manufacturing

H1: Types of Laser Cutting Templates

1. CAD Files

Computer-aided design (CAD) files are digital blueprints that define the geometry of the part to be cut. These files are typically created using software such as AutoCAD or SolidWorks and contain detailed information about the shape, dimensions, and tolerances of the part.

2. DXF Files

Drawing exchange format (DXF) files are a type of CAD file that is commonly used for laser cutting. DXF files are ASCII-based and can be opened by a wide range of software programs, making them a versatile option for sharing designs.

Plywood is a versatile and affordable material that is suitable for a wide range of laser cutting applications. It is strong and durable, making it ideal for templates that will be used repeatedly.

3. MDF (Medium-Density Fiberboard)

MDF is a dense and stable material that is often used for laser cutting templates. It has a smooth surface that is easy to cut and produces clean edges.

H3: Design Considerations for Laser Cutting Templates

1. Kerf Width

The kerf width is the width of the material removed by the laser beam. It is important to consider the kerf width when designing a laser cutting template to ensure that the parts fit together properly.

2. Tabs and Slots

Tabs and slots are features that help to hold parts together after they have been cut. Tabs are small projections that fit into slots on the mating part.

3. Material Thickness

The thickness of the material being cut will affect the design of the laser cutting template. Thicker materials require a stronger laser and may need additional support during cutting.

H4: Optimizing Laser Cutting Templates

1. Nesting

Nesting is a technique used to arrange multiple parts on a single laser cutting template to minimize material waste. This can significantly reduce production costs.

2. Lead-In and Lead-Out

Lead-in and lead-out are sections of the laser path that are used to start and stop the laser beam. These sections should be designed to minimize stress on the material and prevent burn marks.

3. Laser Power and Speed

The power and speed of the laser should be optimized to achieve the desired cutting quality and efficiency. Higher power and speed will result in faster cutting, but may also produce rougher edges.

H5: Conclusion

Laser cutting templates are an essential component of the laser cutting process. By understanding the different types, materials, design considerations, and optimization techniques, manufacturers can create templates that produce high-quality parts efficiently.

H6: Frequently Asked Questions (FAQs)

1. What is the best software for creating laser cutting templates?

The best software for creating laser cutting templates depends on the specific application. Popular options include AutoCAD, SolidWorks, and Inkscape.

2. What is the difference between a DXF and a G-code file?

DXF files are digital blueprints that define the geometry of the part, while G-code files are machine instructions that guide the laser cutter through the cutting process.

3. How do I optimize a laser cutting template for nesting?

To optimize a laser cutting template for nesting, use a software program that supports nesting algorithms. These algorithms automatically arrange parts on the template to minimize material waste.