3D Laser Cut Design: A Comprehensive Guide to Crafting Precision and Creativity

Introduction

3D laser cut design is a cutting-edge technology that empowers designers and makers to create intricate and precise three-dimensional objects from a wide range of materials. By harnessing the power of lasers, this innovative technique offers unparalleled accuracy, versatility, and speed, revolutionizing the way we design, prototype, and manufacture products.

Table of Content

- 1 3D Laser Cut Design: A Comprehensive Guide to Crafting Precision and Creativity

- 1.1 Introduction

- 1.2 H1: Understanding the Process of 3D Laser Cutting

- 1.3 H2: Materials Suitable for 3D Laser Cutting

- 1.4 H1: Understanding the Process of 3D Laser Cutting

- 1.5 H2: How Does 3D Laser Cutting Work?

- 1.6 H2: Materials Suitable for 3D Laser Cutting

- 1.7 H3: Advantages of 3D Laser Cutting

- 1.8 H1: Applications of 3D Laser Cut Design

- 1.9 H2: Design and Prototyping

- 1.10 H2: Manufacturing

- 1.11 H2: Art and Decoration

- 1.12 H3: Examples of 3D Laser Cut Design Applications

- 1.13 H1: Considerations for 3D Laser Cut Design

- 1.14 H2: Choosing the Right Material

- 1.15 H2: Design Optimization

- 1.16 H2: Safety Precautions

- 1.17 H1: Conclusion

- 1.18 FAQs

H1: Understanding the Process of 3D Laser Cutting

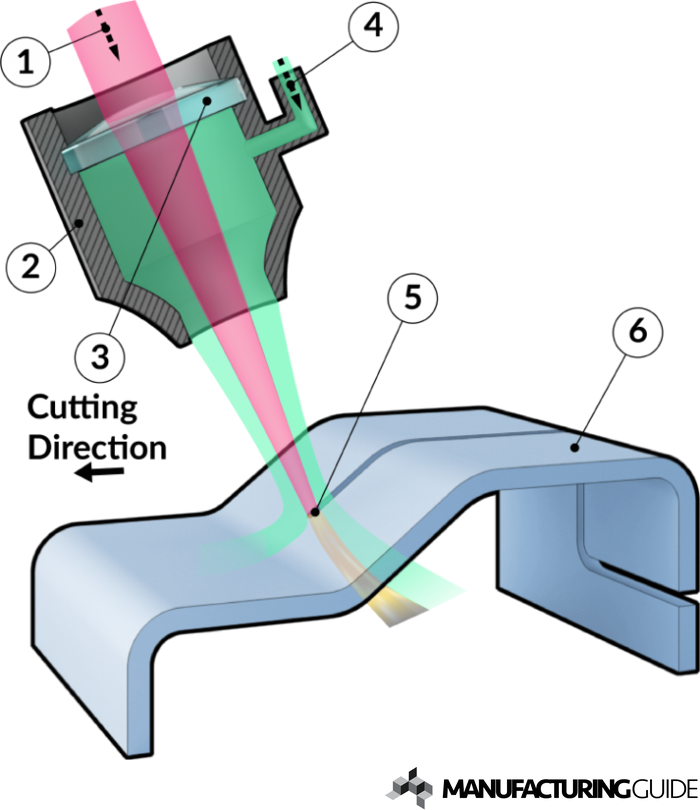

3D laser cutting involves using a computer-controlled laser beam to precisely cut and engrave materials, creating three-dimensional shapes and designs. The laser beam is focused onto the surface of the material, vaporizing or melting it away, resulting in clean and accurate cuts.

H2: Materials Suitable for 3D Laser Cutting

A diverse range of materials can be processed using 3D laser cutting, including:

- Wood: Plywood, MDF, and hardwoods

- Acrylic: Clear, colored, and frosted

- Metal: Steel, aluminum, and stainless steel

- Fabric: Leather, textiles, and felt

- Paper: Cardstock, cardboard, and specialty papers

3D laser cut design is a cutting-edge technology that empowers designers and makers to create intricate and precise three-dimensional objects from a wide range of materials. By harnessing the power of lasers, this innovative technique offers unparalleled accuracy, versatility, and speed, revolutionizing the way we design, prototype, and manufacture products.

- 3d Printing And Laser Cutting 3D Printing And Laser Cutting: A Comprehensive Guide

- Laser Cutting 3d Objects Laser Cutting 3D Objects: A Comprehensive Guide

- Simple 3d Laser Cut Simple 3D Laser Cut: A Comprehensive Guide

- 3d Models For Laser Cutting 3D Models For Laser Cutting: Unleashing Precision And Creativity

- 3d Laser Cutting Projects 3D Laser Cutting Projects: Unleashing Creativity And Precision

H1: Understanding the Process of 3D Laser Cutting

H2: How Does 3D Laser Cutting Work?

3D laser cutting involves using a computer-controlled laser beam to precisely cut and engrave materials, creating three-dimensional shapes and designs. The laser beam is focused onto the surface of the material, vaporizing or melting it away, resulting in clean and accurate cuts.

H2: Materials Suitable for 3D Laser Cutting

A diverse range of materials can be processed using 3D laser cutting, including:

H3: Advantages of 3D Laser Cutting

- Precision: Laser cutting ensures extreme precision, enabling the creation of intricate designs with tolerances of up to 0.001 inches.

- Versatility: The ability to cut and engrave a wide range of materials opens up endless possibilities for design and prototyping.

- Speed: Laser cutting is a highly efficient process, allowing for rapid production of prototypes and finished products.

- Cost-effectiveness: Automated laser cutting eliminates the need for manual labor, reducing production costs and improving efficiency.

- Sustainability: Laser cutting minimizes waste and reduces the environmental impact compared to traditional manufacturing methods.

H1: Applications of 3D Laser Cut Design

H2: Design and Prototyping

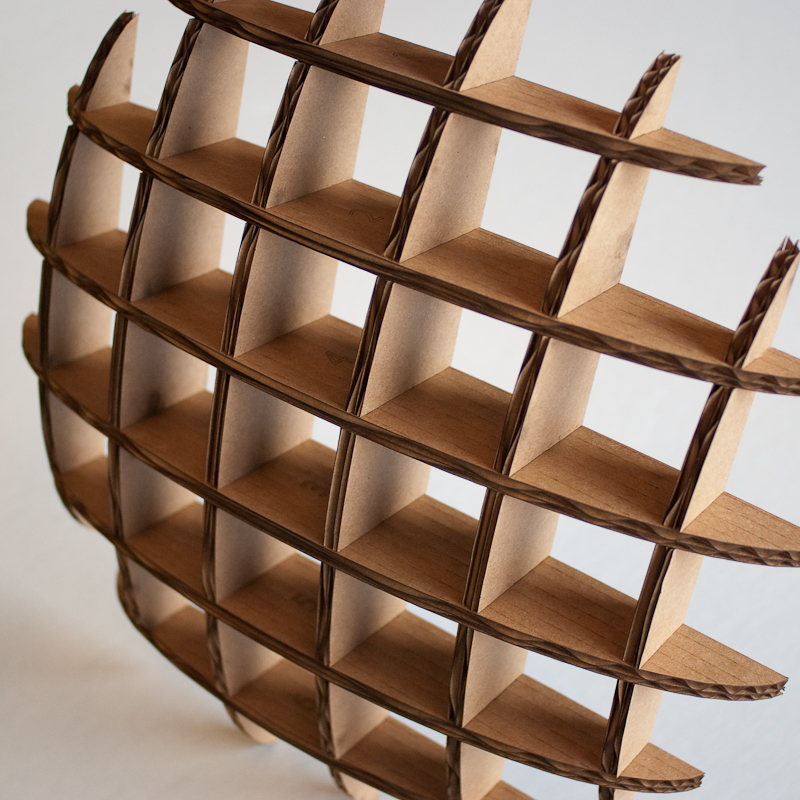

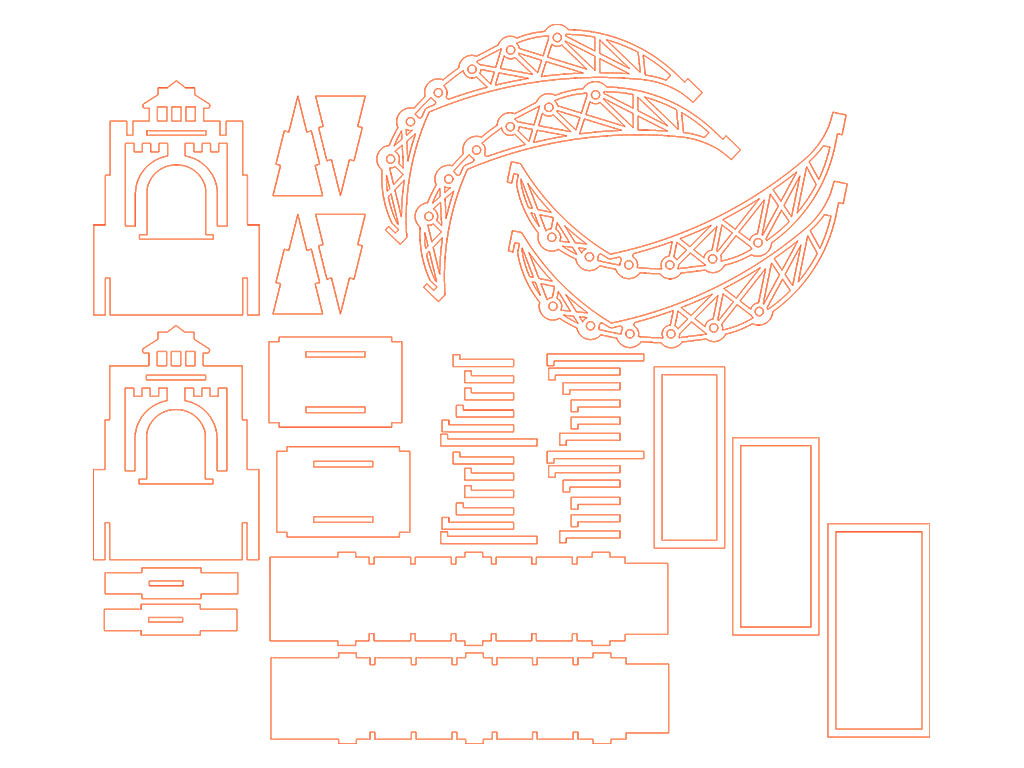

3D laser cutting is a powerful tool for designers and engineers to rapidly create prototypes and test different design iterations. It enables the visualization of complex designs and the identification of potential issues before mass production.

H2: Manufacturing

3D laser cutting is used in various manufacturing industries to produce precision components, custom parts, and intricate products. It offers high-volume production capabilities while maintaining accuracy and quality.

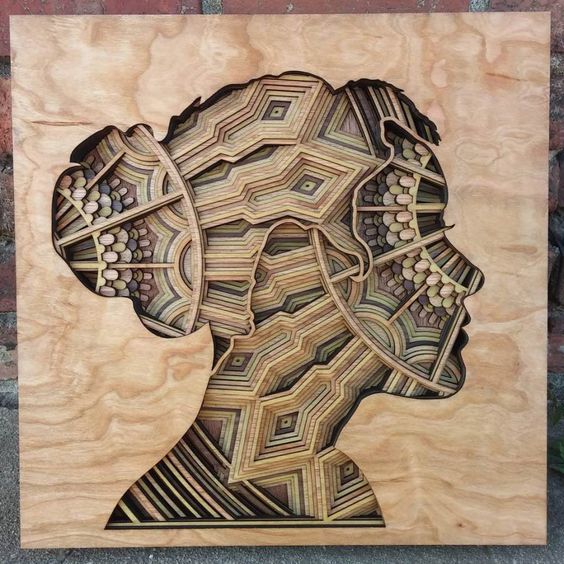

H2: Art and Decoration

Laser cutting has become an integral part of art and design, allowing artists to create unique sculptures, installations, and decorative elements. It offers a versatile medium for expressing creativity and imagination.

H3: Examples of 3D Laser Cut Design Applications

- Automotive components: Intricate interior trim, custom dashboards, and lightweight parts

- Aerospace components: Precision-machined parts, honeycomb structures, and lightweight designs

- Medical devices: Surgical instruments, implants, and prosthetics

- Jewelry and accessories: Delicate pendants, intricate earrings, and custom-made pieces

- Furniture and home décor: Unique tables, chairs, lamps, and decorative wall art

H1: Considerations for 3D Laser Cut Design

H2: Choosing the Right Material

The choice of material depends on the desired application, aesthetic preferences, and budget. Each material has unique properties and limitations, so it’s crucial to select the best fit for the project.

H2: Design Optimization

Optimizing designs for laser cutting can enhance efficiency and reduce material waste. Considerations include:

- Geometry: Avoid sharp corners and thin sections that may weaken the material.

- Kerf: Account for the width of the laser cut, which can vary depending on the material and laser settings.

- Assembly: Design interlocking parts or consider post-processing methods for joining components.

H2: Safety Precautions

Laser cutting involves high-power lasers, so safety is paramount. Precautions include:

- Proper ventilation: Laser cutting generates fumes and debris, so adequate ventilation is essential.

- Eye protection: Wear appropriate laser safety glasses to protect eyes from harmful laser radiation.

- Closed-toe shoes and protective clothing: Protect skin from potential debris and laser reflections.

- Fire extinguisher: Keep a fire extinguisher nearby for emergencies.

H1: Conclusion

3D laser cut design is a transformative technology that empowers designers, engineers, and artists to create with precision, versatility, and speed. Its applications span diverse industries, from manufacturing to art and decoration. By understanding the process, materials, and considerations involved, users can harness the full potential of this cutting-edge technology to bring their creative visions to life.

FAQs

Q: What is the difference between 2D and 3D laser cutting?

A: 2D laser cutting cuts flat materials, while 3D laser cutting creates three-dimensional objects by cutting and engraving materials along multiple axes.

Q: What software is used for 3D laser cut design?

A: Popular software for 3D laser cut design includes AutoCAD, SolidWorks, and Rhino.

Q: How do I prepare my design for laser cutting?

A: Designs should be created in a vector format (e.g., SVG, DXF) and optimized for laser cutting by considering geometry, kerf, and assembly.

Q: How much does 3D laser cutting cost?

A: The cost of 3D laser cutting varies depending on the size, complexity, and material used. Contact service providers for specific quotes.

Q: Is 3D laser cutting safe?

A: Yes, 3D laser cutting is safe when proper safety precautions are followed, including ventilation, eye protection, and protective clothing.