Laser Cut 3D Model Plans: A Comprehensive Guide

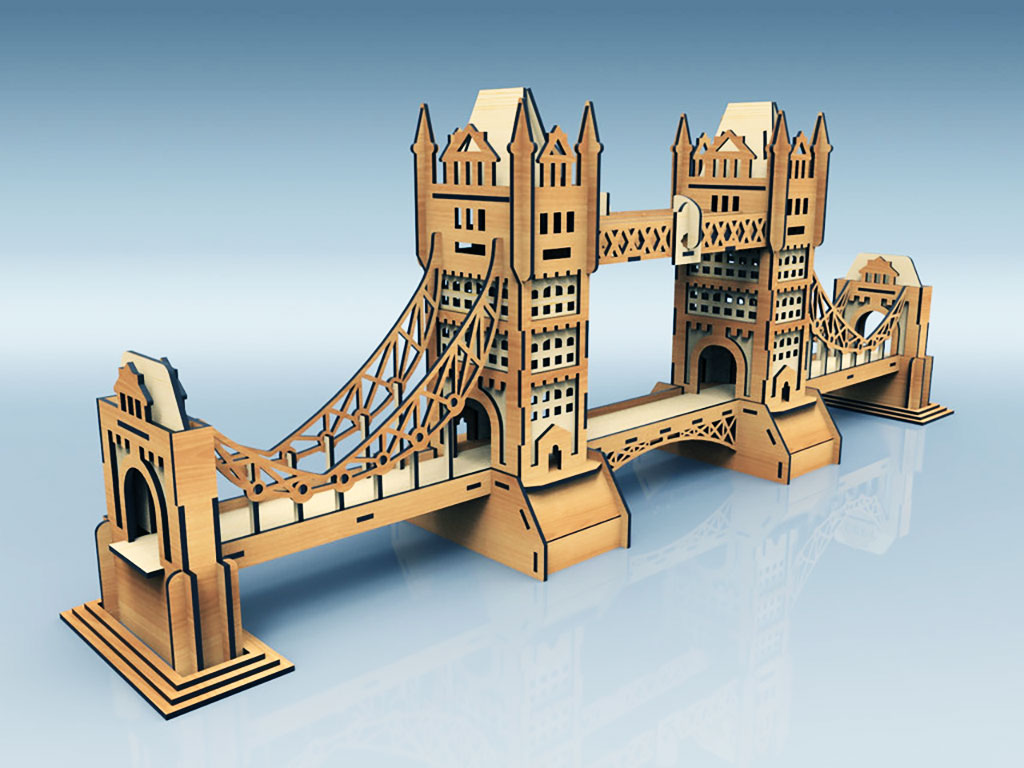

Laser cutting is a precise and versatile fabrication technique that has revolutionized the creation of 3D models. By utilizing high-powered lasers to cut and shape materials such as wood, acrylic, and metal, laser cutting enables the production of intricate and detailed models with unmatched accuracy and speed.

Benefits of Using Laser Cut 3D Model Plans

Table of Content

- 1 Laser Cut 3D Model Plans: A Comprehensive Guide

- 1.1 Benefits of Using Laser Cut 3D Model Plans

- 1.2 How to Create Laser Cut 3D Model Plans

- 1.3 Choosing the Right Material for Laser Cutting

- 1.4 Benefits of Using Laser Cut 3D Model Plans

- 1.5 How to Create Laser Cut 3D Model Plans

- 1.6 Applications of Laser Cut 3D Model Plans

- 1.7 Conclusion

- 1.8 FAQs

1. Precision and Accuracy: Laser cutting machines operate with extreme precision, ensuring the exact replication of complex designs. This eliminates the need for manual labor and reduces the risk of errors.

3. Versatility: Laser cutting can be used with a wide range of materials, including wood, acrylic, metal, and even fabric. This allows for the creation of diverse models for various applications.

4. Cost-Effectiveness: While laser cutting machines may require a significant initial investment, they offer substantial cost savings in the long run due to increased efficiency and reduced labor costs.

How to Create Laser Cut 3D Model Plans

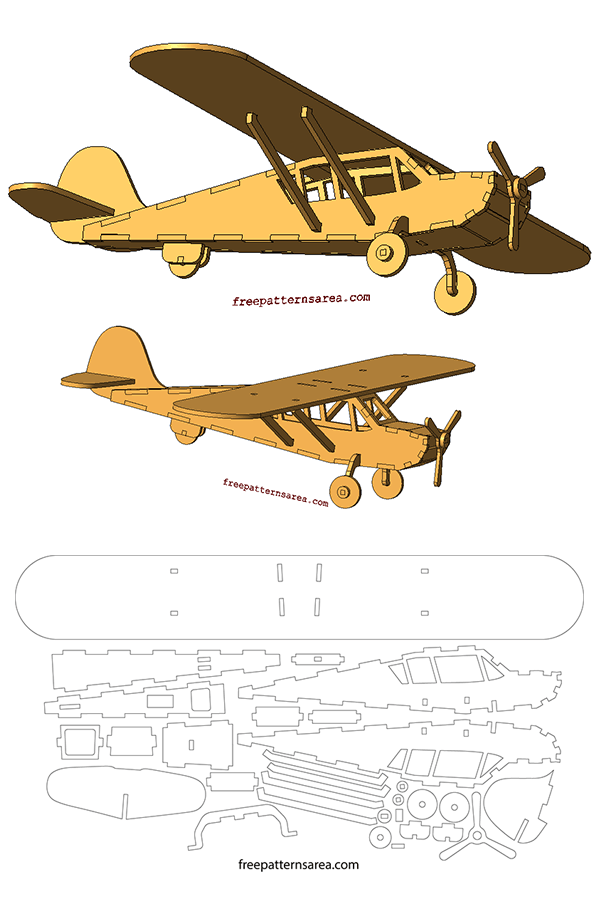

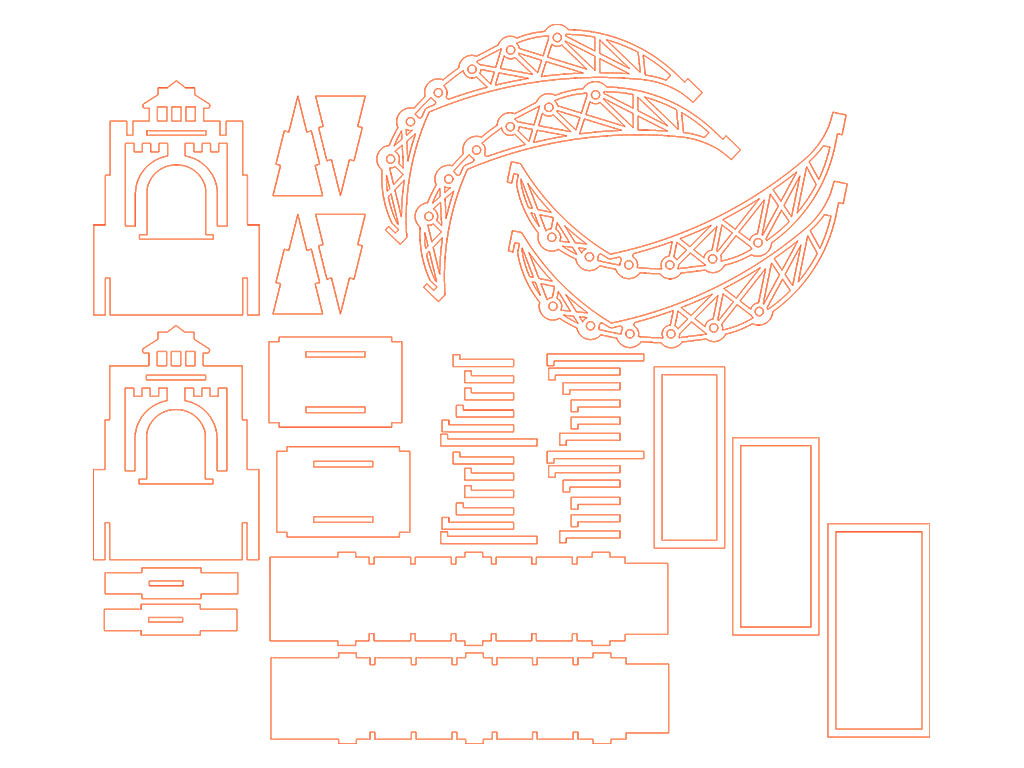

1. Design: Begin by creating a 3D model using CAD software. Ensure that the model is compatible with laser cutting by considering factors such as material thickness and design complexity.

2. Generate Cut Paths: Import the 3D model into laser cutting software and generate the cut paths. These paths define the laser’s movement to cut the material.

3. Optimize Cut Settings: Adjust the laser settings, such as power, speed, and focus, based on the material being used. This ensures optimal cutting quality and minimizes material waste.

Choosing the Right Material for Laser Cutting

1. Wood: Plywood, MDF, and hardwood are common choices for laser cutting due to their affordability and ease of cutting. However, wood can produce smoke and require additional finishing.

2. Acrylic: Acrylic is a versatile material that offers excellent clarity and durability. It is suitable for a wide range of applications, including displays, signage, and jewelry.

3. Metal: Laser cutting can be used to cut thin sheets of metal, such as aluminum, stainless steel, and brass. Metal models offer superior strength and durability but may require additional post-processing.

Benefits of Using Laser Cut 3D Model Plans

- Laser Cut 3d Animal Puzzle Laser Cut 3D Animal Puzzle: A Journey Into Intricate Wooden Masterpieces

- 3d Printing And Laser Cutting Book 3D Printing And Laser Cutting: A Comprehensive Guide For Makers And Designers

- 3d Fabric Laser Cut 3D Fabric Laser Cutting: A Revolutionary Textile Innovation

- 3d Laser Cut Ornaments 3D Laser Cut Ornaments: A Guide To Crafting Exquisite Festive Decor

- Laser Cut 3d Names Laser Cut 3D Names: A Personalized And Unique Gift

1. Precision and Accuracy: Laser cutting machines operate with extreme precision, ensuring the exact replication of complex designs. This eliminates the need for manual labor and reduces the risk of errors.

2. Efficiency and Speed: Laser cutting is a highly efficient process that can produce large quantities of models in a short amount of time. This makes it ideal for prototyping, production, and mass customization.

3. Versatility: Laser cutting can be used with a wide range of materials, including wood, acrylic, metal, and even fabric. This allows for the creation of diverse models for various applications.

4. Cost-Effectiveness: While laser cutting machines may require a significant initial investment, they offer substantial cost savings in the long run due to increased efficiency and reduced labor costs.

How to Create Laser Cut 3D Model Plans

Applications of Laser Cut 3D Model Plans

1. Prototyping: Laser cutting is ideal for creating prototypes of new products or designs. It allows for rapid iteration and testing of different design concepts.

2. Production: Laser cutting can be used for mass production of 3D models for various industries, including automotive, aerospace, and consumer electronics.

3. Customization: Laser cutting enables the creation of personalized and customized models based on individual specifications. This is particularly valuable for products such as jewelry, trophies, and promotional items.

Conclusion

Laser cut 3D model plans provide a powerful tool for creating intricate and detailed models with precision, efficiency, and versatility. By following the steps outlined in this article, you can design and produce high-quality 3D models for a wide range of applications.

FAQs

1. What is the difference between laser cutting and 3D printing?

Laser cutting involves cutting and shaping materials using a laser, while 3D printing involves building models layer by layer using deposited material. Laser cutting offers greater precision and speed, while 3D printing allows for the creation of more complex geometries.

2. What file formats are compatible with laser cutting software?

Common file formats for laser cutting include DXF, SVG, and AI. These formats allow for the precise definition of cut paths and material properties.

3. How can I minimize material waste during laser cutting?

To minimize material waste, optimize the nesting of cut paths within the material sheet. Consider using software that automatically optimizes the placement of parts to maximize material utilization.