3D Printer and Laser Cutter in One: A Revolutionary Tool for Creation and Innovation

Introduction

In the realm of modern technology, the convergence of different capabilities has led to the creation of versatile and groundbreaking devices. One such innovation is the 3D printer and laser cutter in one, a revolutionary tool that combines the precision and flexibility of 3D printing with the versatility and power of laser cutting. This article will delve into the world of these remarkable machines, exploring their features, applications, and the transformative impact they have on various industries.

Table of Content

- 1 3D Printer and Laser Cutter in One: A Revolutionary Tool for Creation and Innovation

- 1.1 Introduction

- 1.2 H1: Unveiling the Capabilities of 3D Printer and Laser Cutter in One

- 1.3 H2: Applications Across Industries

- 1.4 H1: Unveiling the Capabilities of 3D Printer and Laser Cutter in One

- 1.5 H2: Benefits and Advantages

- 1.6 H2: Considerations and Limitations

- 1.7 H2: Future Outlook and Advancements

- 1.8 H2: Conclusion

- 1.9 FAQs

H1: Unveiling the Capabilities of 3D Printer and Laser Cutter in One

3D printing, also known as additive manufacturing, empowers users to create three-dimensional objects directly from digital designs. These machines work by depositing layers of material, such as plastic, metal, or ceramic, upon each other, gradually building up the desired shape. 3D printing offers immense flexibility in design, allowing for the production of complex geometries and intricate details that would be challenging or impossible to achieve through traditional manufacturing methods.

H2: Laser Cutting: Precision and Versatility in Material Processing

Laser cutting utilizes a focused beam of light to cut, engrave, or etch various materials with exceptional accuracy. This technology offers a wide range of capabilities, including precise cutting of intricate shapes, intricate engraving designs, and the ability to work with diverse materials such as wood, acrylic, leather, and metal. Laser cutting is renowned for its precision, speed, and non-contact nature, resulting in clean cuts and minimal material distortion.

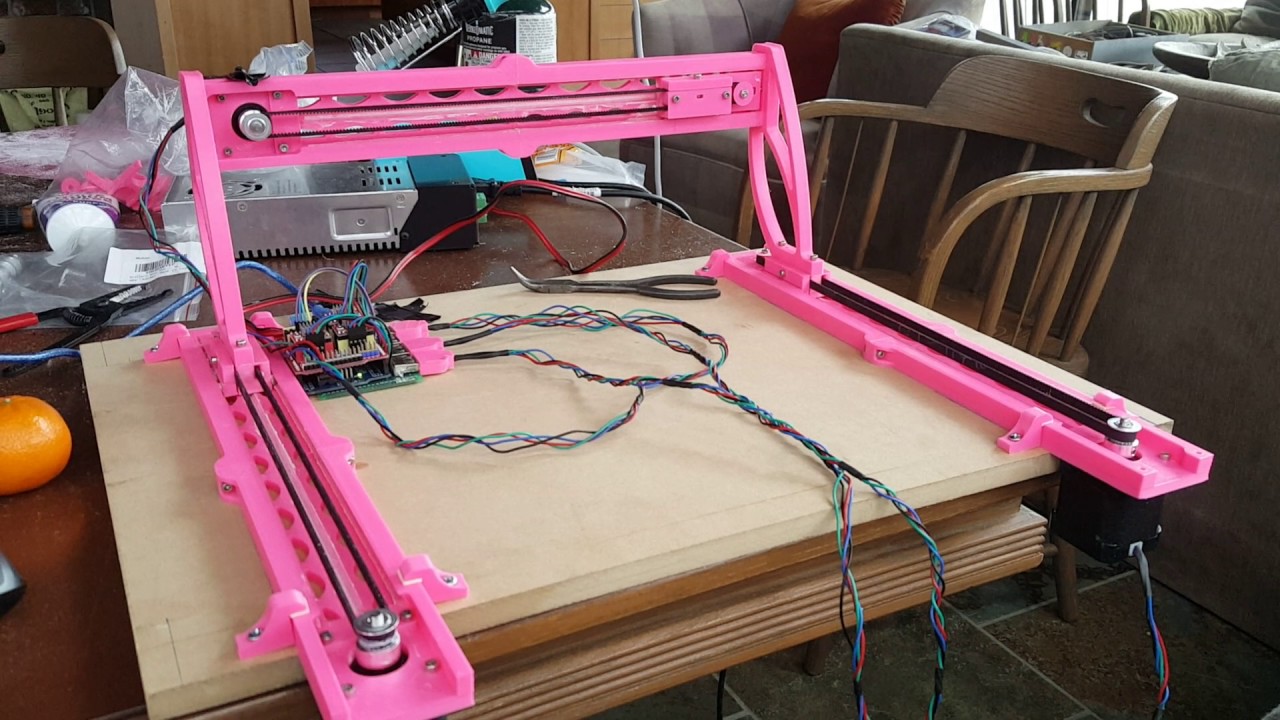

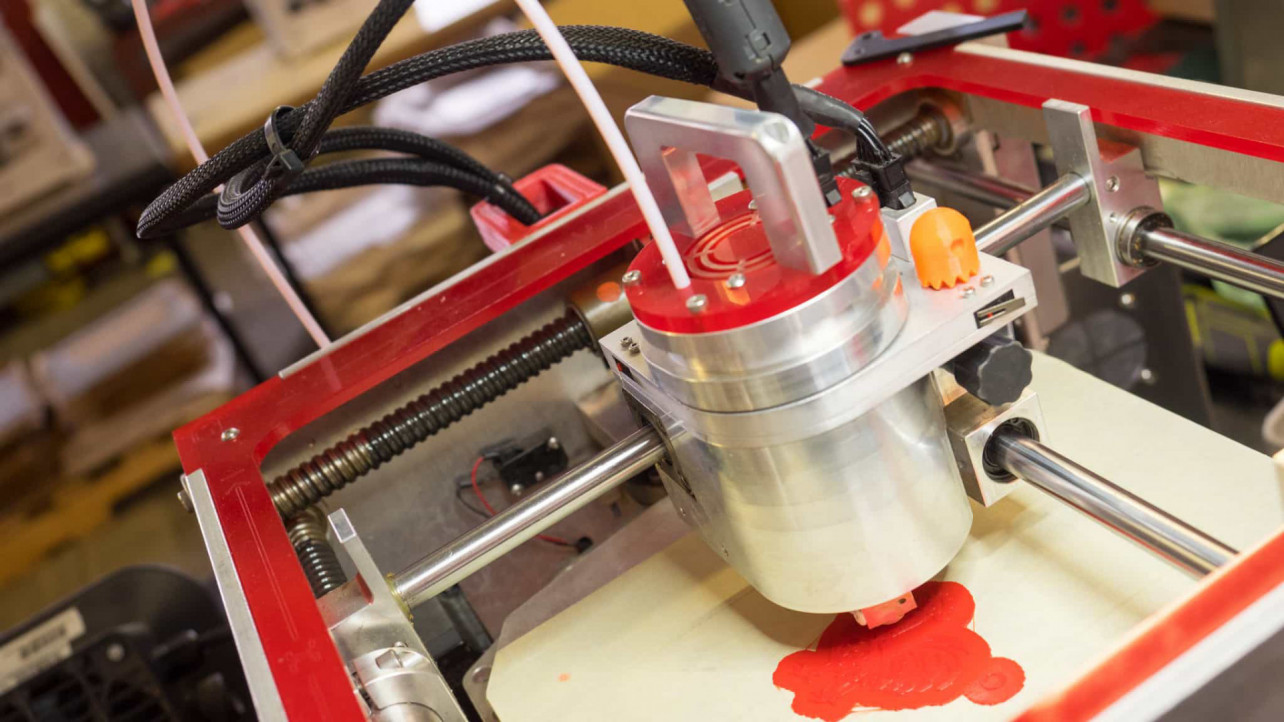

H3: The Synergy of 3D Printing and Laser Cutting

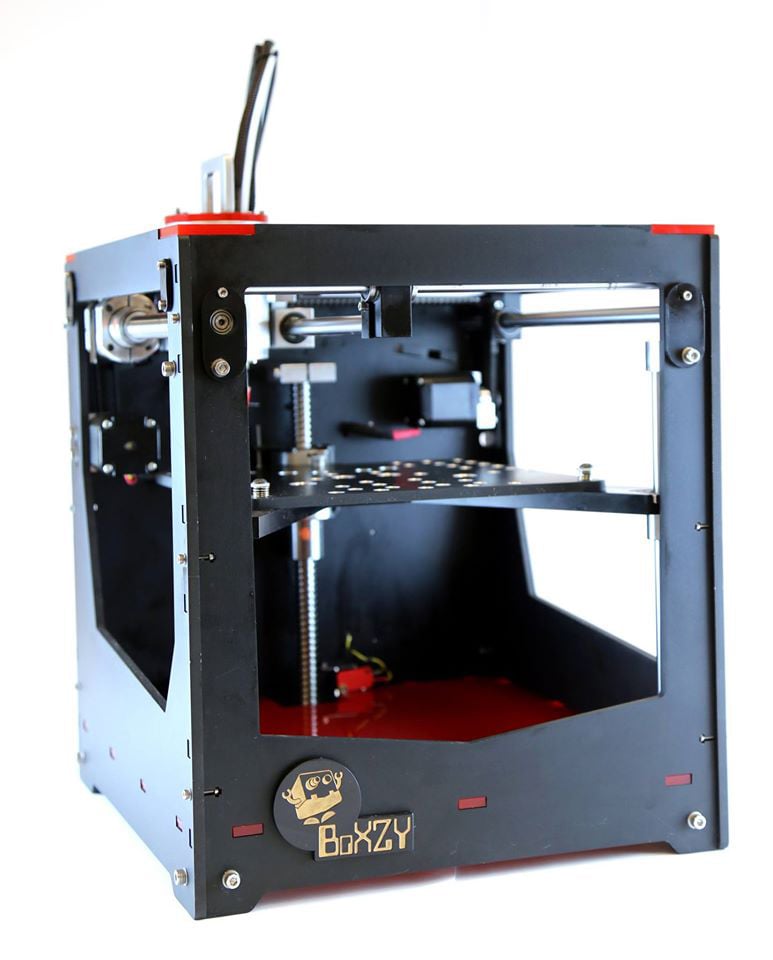

The combination of 3D printing and laser cutting in a single machine unlocks a world of possibilities. This synergy empowers users to not only create three-dimensional objects but also customize, modify, and embellish them with intricate laser-cut details. The seamless integration of these two technologies enables the production of highly customized and intricate products, prototypes, and models.

H2: Applications Across Industries

The 3D printer and laser cutter in one has found widespread adoption across numerous industries, including:

H3: Product Design and Prototyping:

The rapid prototyping capabilities of these machines allow designers and engineers to quickly and cost-effectively create physical models of their designs for testing, evaluation, and refinement.

H3: Manufacturing and Production:

In the realm of modern technology, the convergence of different capabilities has led to the creation of versatile and groundbreaking devices. One such innovation is the 3D printer and laser cutter in one, a revolutionary tool that combines the precision and flexibility of 3D printing with the versatility and power of laser cutting. This article will delve into the world of these remarkable machines, exploring their features, applications, and the transformative impact they have on various industries.

- Free Laser Cut Files Free Laser Cut Files: A Comprehensive Guide For Unleashing Your Creativity

- 3d And Laser Cut 3D And Laser Cutting: A Comprehensive Guide To Advanced Manufacturing Techniques

- How To Laser Cut A 3d Model How To Laser Cut A 3D Model: A Comprehensive Guide

- 3d Puzzle Template 3D Puzzle Template: An Immersive Crafting Experience

- Laser Cut Project Laser Cut Project: A Comprehensive Guide To Unleashing Your Creativity

H1: Unveiling the Capabilities of 3D Printer and Laser Cutter in One

H2: 3D Printing: Shaping Ideas into Tangible Creations

3D printing, also known as additive manufacturing, empowers users to create three-dimensional objects directly from digital designs. These machines work by depositing layers of material, such as plastic, metal, or ceramic, upon each other, gradually building up the desired shape. 3D printing offers immense flexibility in design, allowing for the production of complex geometries and intricate details that would be challenging or impossible to achieve through traditional manufacturing methods.

H2: Laser Cutting: Precision and Versatility in Material Processing

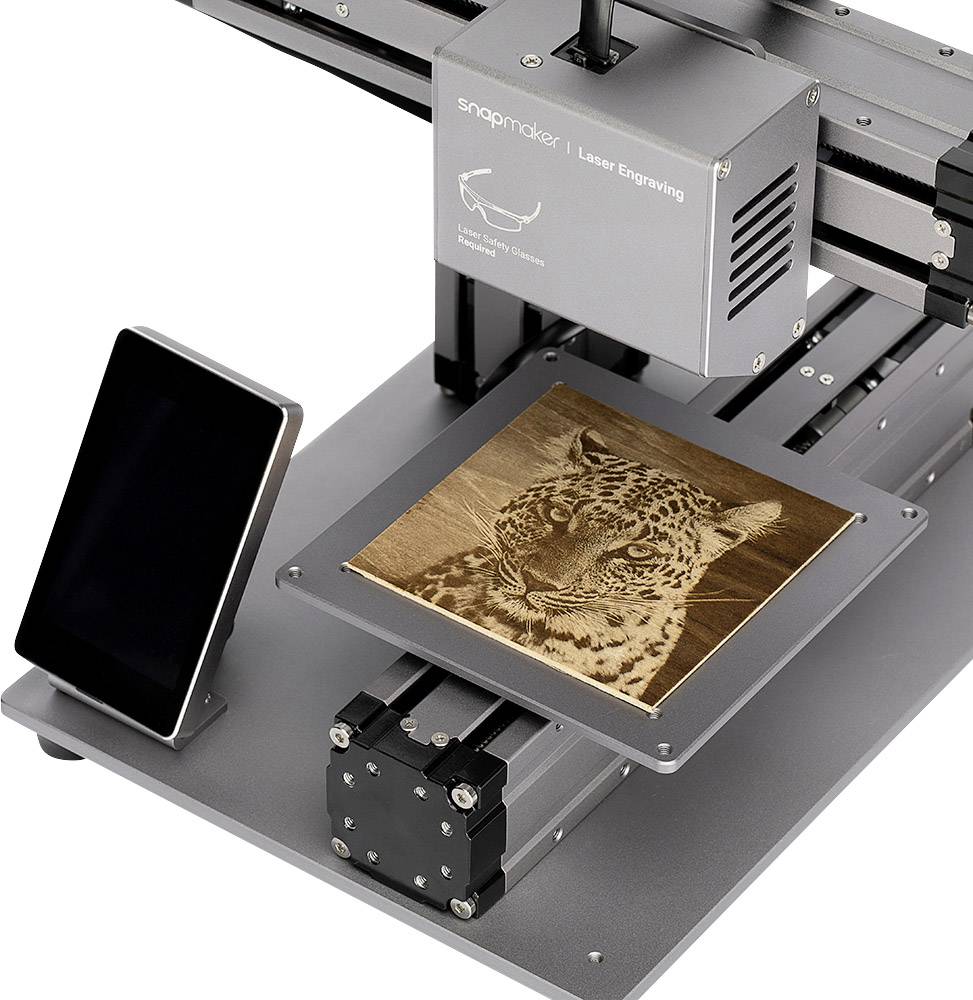

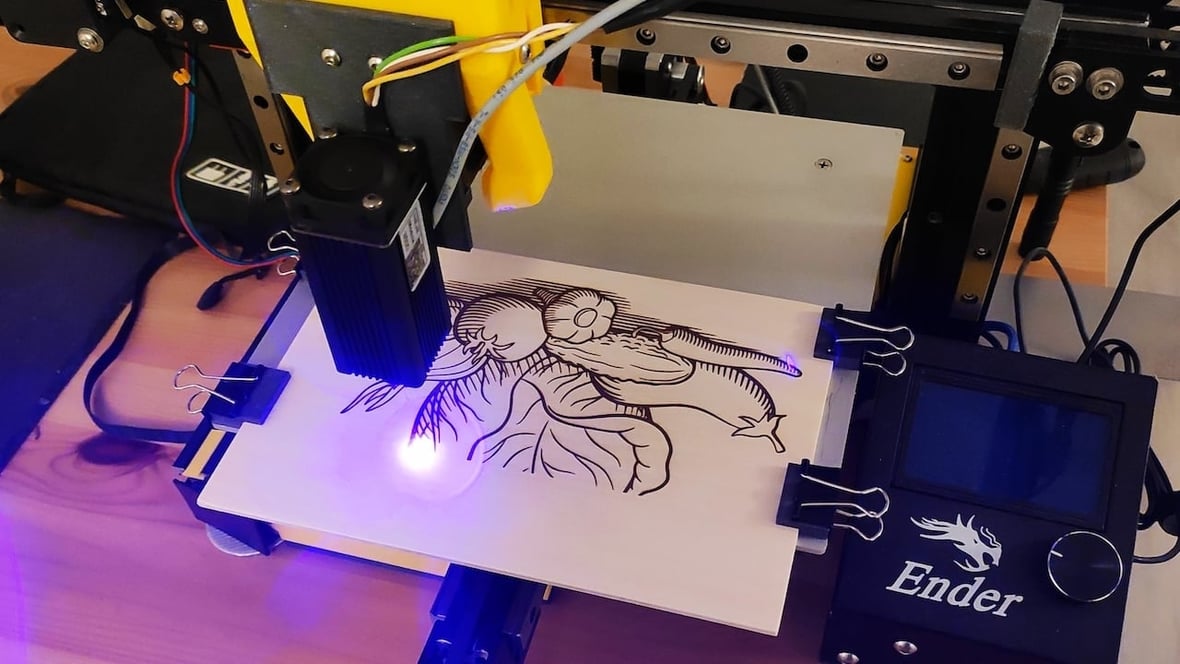

Laser cutting utilizes a focused beam of light to cut, engrave, or etch various materials with exceptional accuracy. This technology offers a wide range of capabilities, including precise cutting of intricate shapes, intricate engraving designs, and the ability to work with diverse materials such as wood, acrylic, leather, and metal. Laser cutting is renowned for its precision, speed, and non-contact nature, resulting in clean cuts and minimal material distortion.

3D printing and laser cutting streamline production processes by enabling the fabrication of custom parts, tools, and fixtures on-demand, reducing lead times and enhancing flexibility.

H3: Arts and Crafts:

These machines empower artists and hobbyists to create unique and personalized works of art, jewelry, home décor, and other crafts with intricate details and precise cuts.

H3: Education and Research:

In educational and research settings, 3D printer and laser cutter in one provides students and researchers with hands-on experience in design, prototyping, and fabrication, fostering creativity and innovation.

H2: Benefits and Advantages

H3: Enhanced Design Flexibility:

The combination of 3D printing and laser cutting allows for the creation of complex and intricate designs that would be difficult or impossible to achieve with traditional methods.

H3: Reduced Time and Cost:

These machines streamline production processes, eliminating the need for external suppliers and reducing lead times. The ability to create prototypes and custom parts in-house saves time and money.

H3: Increased Accuracy and Precision:

Laser cutting ensures precise cutting and engraving, while 3D printing enables the production of objects with high dimensional accuracy.

H3: Versatility and Material Compatibility:

These machines can work with a wide range of materials, including plastics, metals, wood, and leather, offering versatility in project creation.

H2: Considerations and Limitations

H3: Material Limitations:

While these machines offer versatility, they may have limitations in working with certain materials, such as very hard or thick materials.

H3: Safety Precautions:

Laser cutting involves the use of a high-power laser, so proper safety precautions, such as wearing protective eyewear and ensuring adequate ventilation, are essential.

H3: Software Requirements:

3D printing and laser cutting require specialized software for design and operation. Users should be familiar with these software programs to effectively utilize the machines.

H2: Future Outlook and Advancements

The future of 3D printer and laser cutter in one holds exciting possibilities, including:

H3: Multi-Material Printing and Cutting:

Advancements in technology may enable these machines to work with multiple materials simultaneously, expanding design and fabrication capabilities.

H3: Automation and Robotics:

Integration with automation and robotics could further streamline production processes, enhancing efficiency and productivity.

H3: Integration with AI and Machine Learning:

Artificial intelligence and machine learning algorithms can optimize design and production processes, reducing errors and improving quality.

H2: Conclusion

The 3D printer and laser cutter in one is a groundbreaking tool that empowers users to create, innovate, and bring their ideas to life. Its versatility, precision, and efficiency make it a valuable asset in various industries, ranging from product design to manufacturing, arts and crafts, and education. As technology continues to advance, we can expect even more exciting developments and applications for this transformative machine.

FAQs

Q: What are the key advantages of a 3D printer and laser cutter in one?

A: Enhanced design flexibility, reduced time and cost, increased accuracy and precision, and versatility in material compatibility.

Q: What materials can these machines work with?

A: A wide range of materials, including plastics, metals, wood, leather, and more.

Q: Is it difficult to use a 3D printer and laser cutter in one?

A: While some technical knowledge is required, user-friendly software and training resources make these machines accessible to both experienced and novice users.

Q: What industries are these machines most commonly used in?

A: Product design and prototyping, manufacturing and production, arts and crafts, and education and research.

Q: What are the future advancements expected in this technology?

A: Multi-material printing and cutting, automation and robotics integration, and the use of AI and machine learning for optimization and quality control.

/cdn0.vox-cdn.com/uploads/chorus_image/image/53633569/Snapmaker_3_in_1.0.jpg)