Laser Cutter and 3D Printer: A Comprehensive Guide to Revolutionizing Your Manufacturing Process

Introduction

In today’s competitive manufacturing landscape, businesses are constantly seeking innovative technologies to enhance their efficiency, precision, and product quality. Laser cutters and 3D printers have emerged as game-changers, offering unparalleled capabilities that can transform manufacturing processes. This comprehensive guide will delve into the world of laser cutters and 3D printers, exploring their applications, benefits, types, and key considerations when making a purchase.

Table of Content

- 1 Laser Cutter and 3D Printer: A Comprehensive Guide to Revolutionizing Your Manufacturing Process

- 1.1 Introduction

- 2 Laser Cutter: The Precision Cutting Solution

- 2.2 Benefits of Laser Cutters

- 2.3 Types of Laser Cutters

- 3 Laser Cutter: The Precision Cutting Solution

- 3.4 What is a Laser Cutter?

- 3.5 Benefits of Laser Cutters

- 4 3D Printer: The Additive Manufacturing Revolution

- 4.6 What is a 3D Printer?

- 4.7 Benefits of 3D Printers

- 4.8 Types of 3D Printers

- 5 Considerations When Purchasing Laser Cutters and 3D Printers

- 5.9 Laser Cutter Considerations

- 5.10 3D Printer Considerations

- 6 Applications of Laser Cutters and 3D Printers

- 6.11 Laser Cutter Applications

- 6.12 3D Printer Applications

- 7 Conclusion

- 8 Frequently Asked Questions (FAQs)

- 8.13 Q: What are the key differences between CO2, fiber, and diode laser cutters?

- 8.14 Q: What is the difference between FDM, SLA, SLS, and MJP 3D printing technologies?

- 8.15 Q: How do I choose the right laser cutter or 3D printer for my business?

- 8.16 Q: What are the advantages of using a laser cutter over traditional cutting methods?

- 8.17 Q: How can 3D printing benefit my product development process?

Laser Cutter: The Precision Cutting Solution

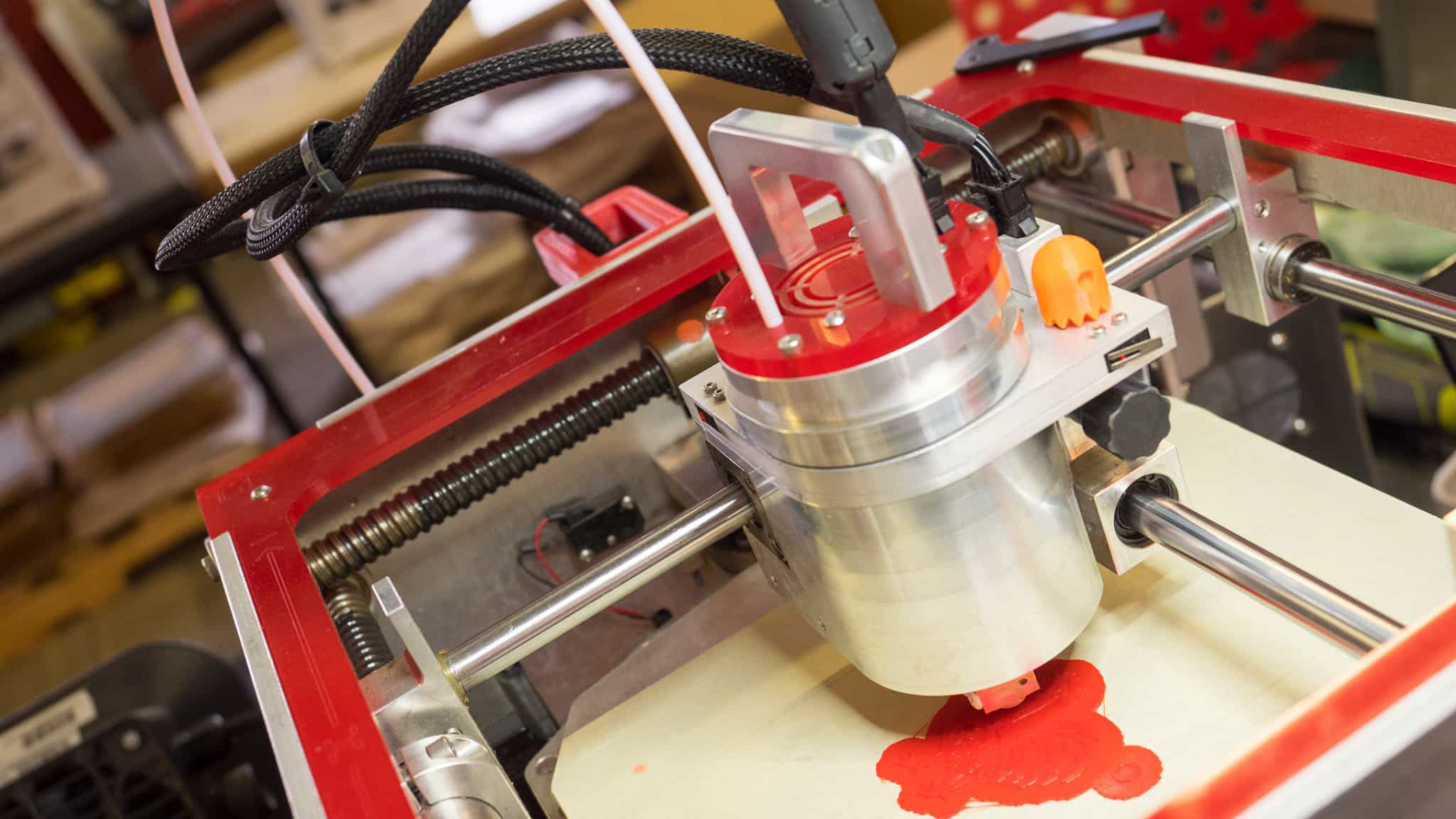

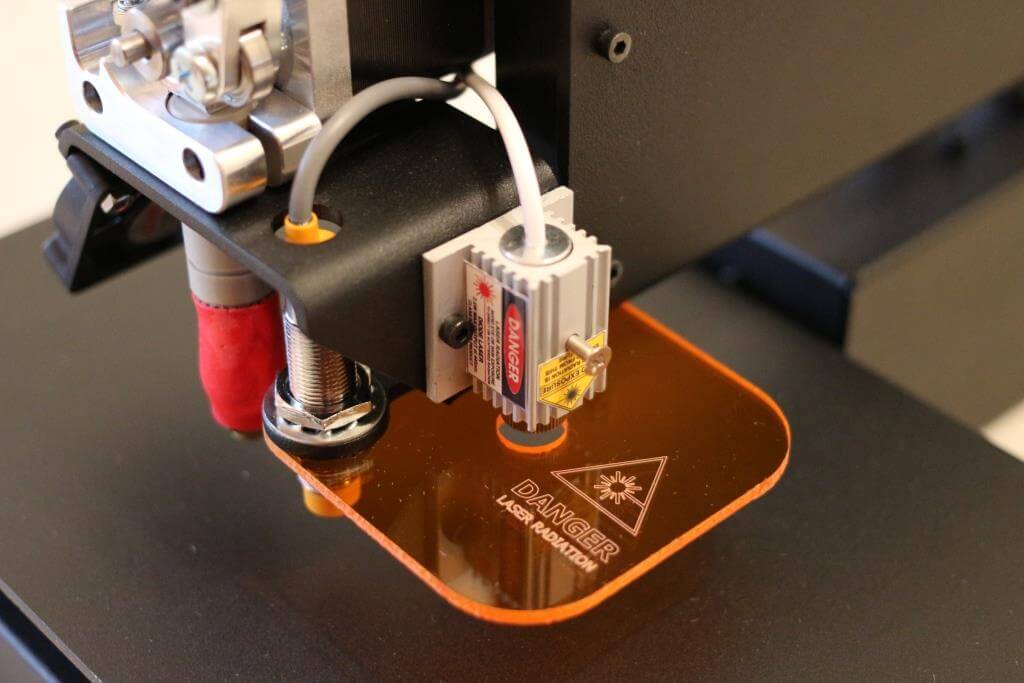

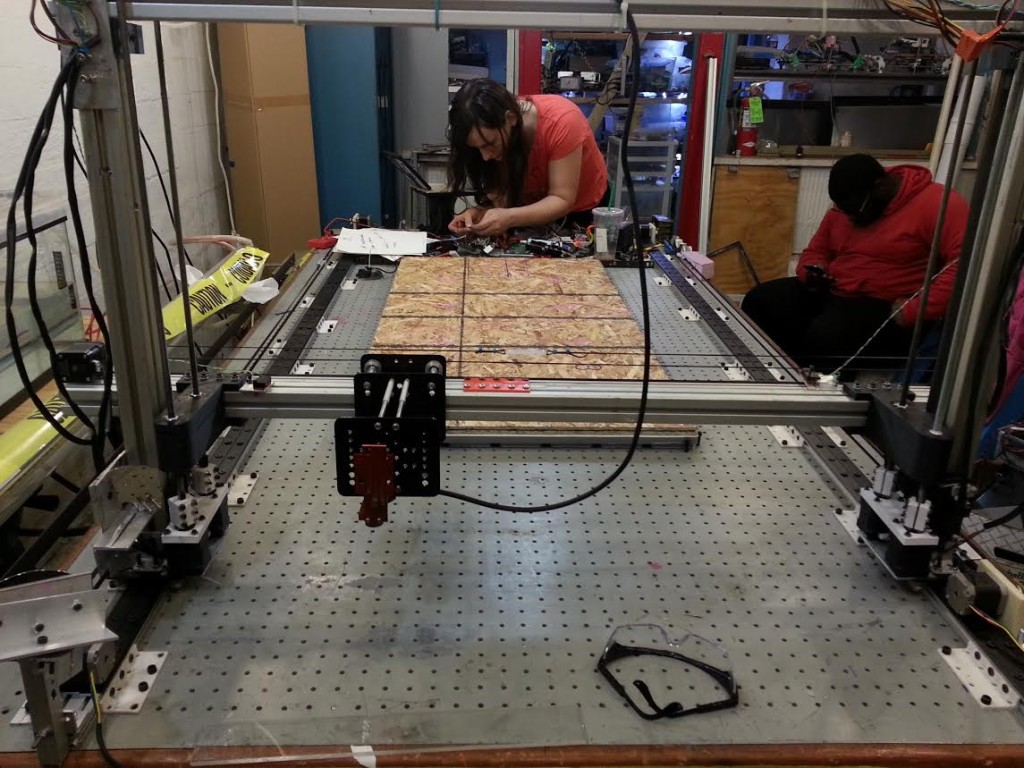

A laser cutter is a computer-controlled machine that utilizes a high-powered laser to precisely cut materials into complex shapes and designs. The laser beam focuses an intense beam of light onto the material, causing it to vaporize or melt, resulting in clean and accurate cuts.

Benefits of Laser Cutters

- Precision Cutting: Laser cutters offer exceptional precision, enabling intricate designs and fine details.

- Speed and Efficiency: Laser cutting is a fast and efficient process, allowing for high-volume production.

- Material Versatility: Laser cutters can cut a wide range of materials, including metals, plastics, wood, and fabrics.

- Reduced Waste: Laser cutting minimizes material waste by accurately cutting along designated paths.

- Automation: Laser cutters can be automated, reducing manual labor and increasing productivity.

Types of Laser Cutters

In today’s competitive manufacturing landscape, businesses are constantly seeking innovative technologies to enhance their efficiency, precision, and product quality. Laser cutters and 3D printers have emerged as game-changers, offering unparalleled capabilities that can transform manufacturing processes. This comprehensive guide will delve into the world of laser cutters and 3D printers, exploring their applications, benefits, types, and key considerations when making a purchase.

- 3d Laser Cut Wood Projects 3D Laser Cut Wood Projects: A Comprehensive Guide To Crafting Unique And Intricate Designs

- 3d Laser Cut 3D Laser Cutting: Revolutionizing Manufacturing And Design

- Laser 3d Cutter Laser 3D Cutter: A Comprehensive Guide

- 3d Laser Cut Maps 3D Laser Cut Maps: Unraveling The World’s Topography

- 3d Laser Cutting Machine Company 3D Laser Cutting Machine: Revolutionizing Fabrication

Laser Cutter: The Precision Cutting Solution

What is a Laser Cutter?

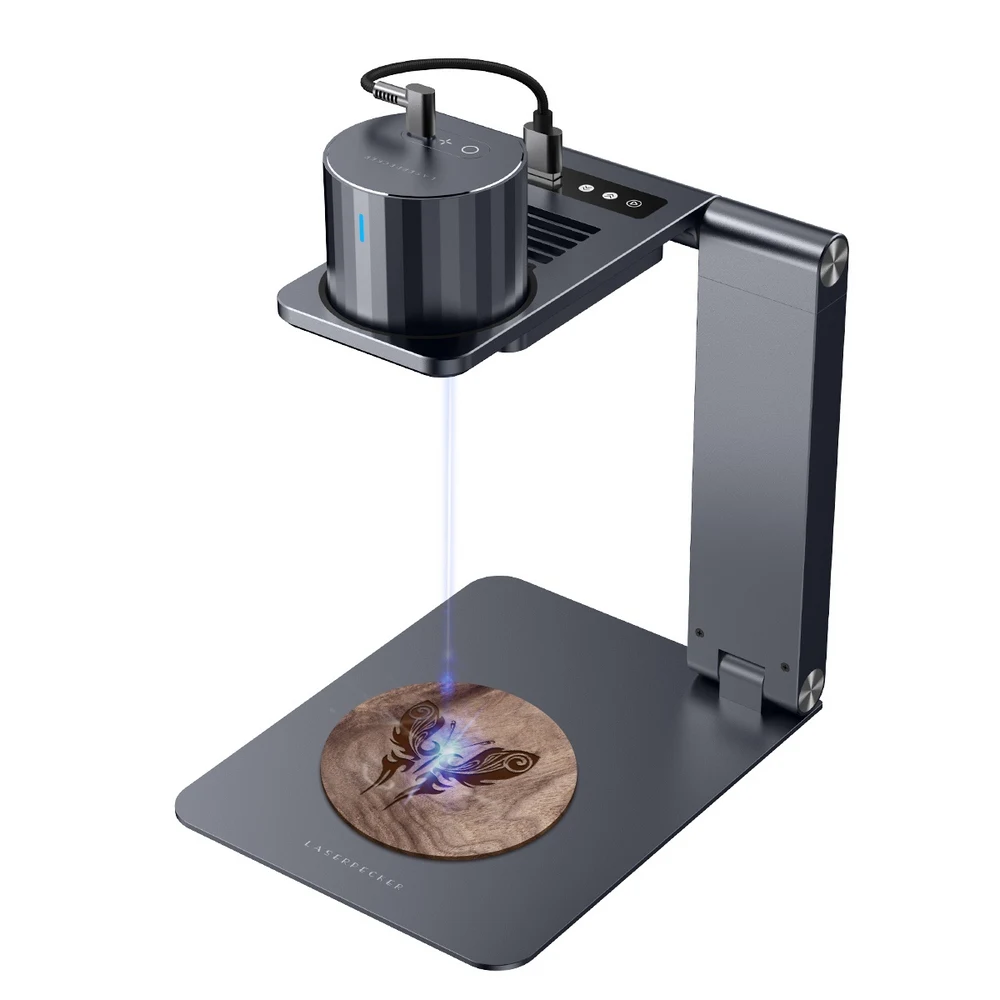

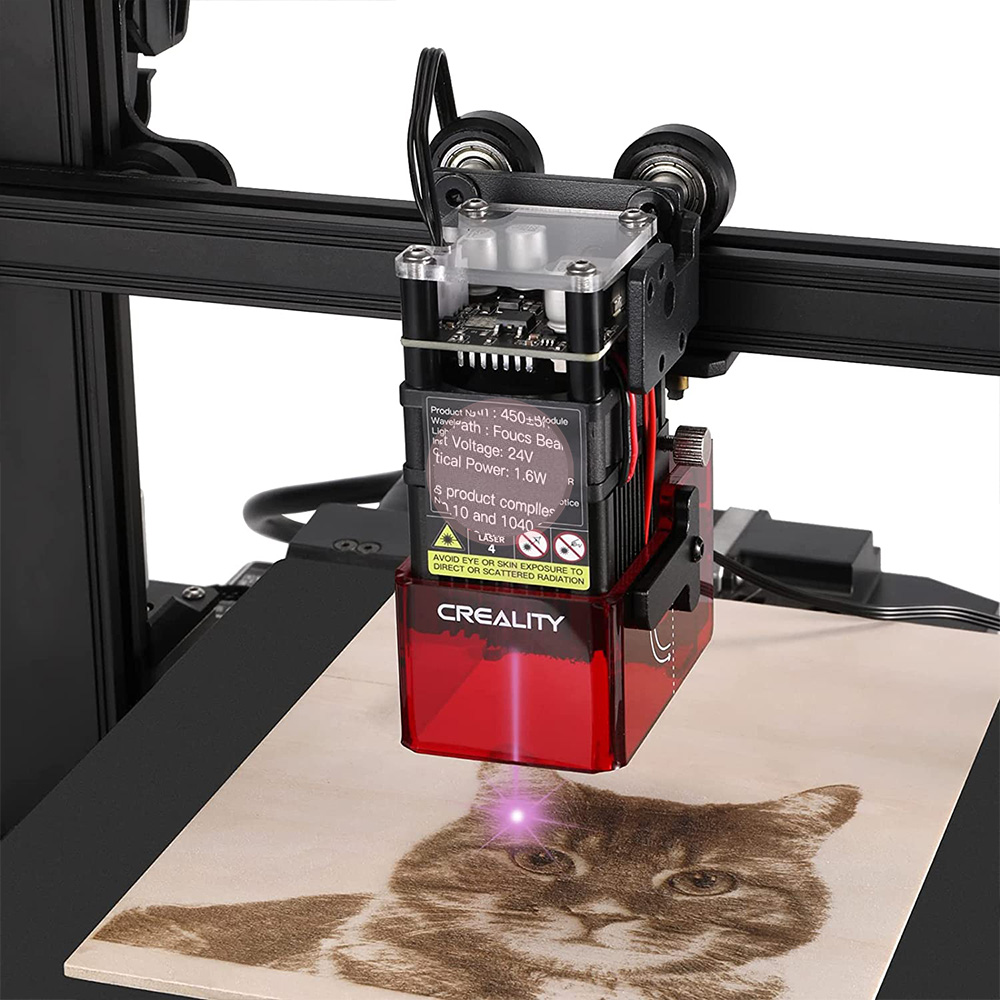

A laser cutter is a computer-controlled machine that utilizes a high-powered laser to precisely cut materials into complex shapes and designs. The laser beam focuses an intense beam of light onto the material, causing it to vaporize or melt, resulting in clean and accurate cuts.

Benefits of Laser Cutters

- CO2 Laser Cutters: Use carbon dioxide gas to generate the laser beam, ideal for cutting non-metallic materials.

- Fiber Laser Cutters: Utilize fiber optics to transmit the laser beam, suitable for cutting metals and reflective materials.

- Diode Laser Cutters: Employ laser diodes to generate the beam, commonly used for engraving and marking.

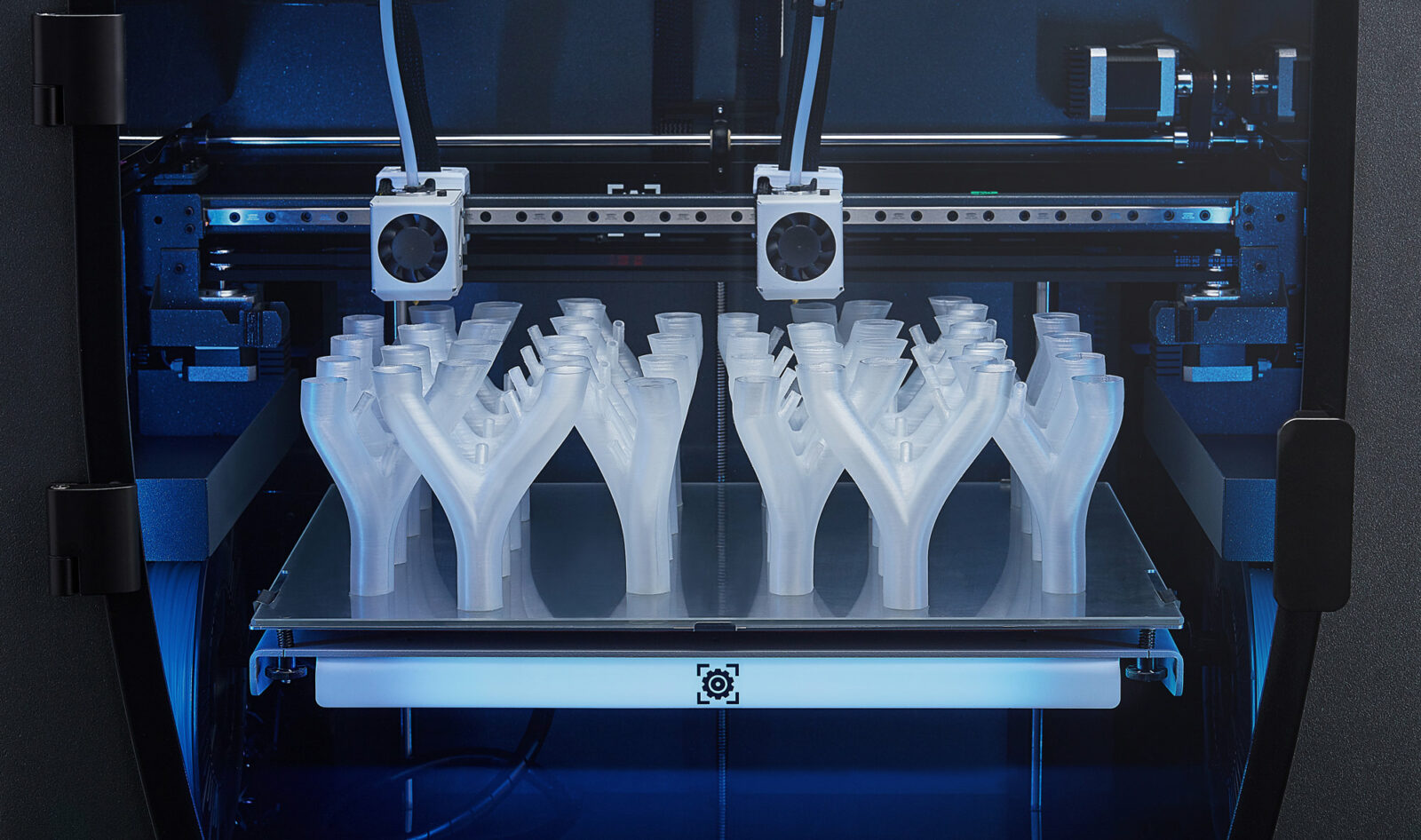

- Rapid Prototyping: 3D printers enable quick and affordable production of prototypes, accelerating product development.

- Customization: 3D printing allows for personalized products and on-demand manufacturing, meeting specific customer requirements.

- Complex Geometries: 3D printers can create intricate shapes and structures that are difficult or impossible to manufacture using traditional methods.

- Material Variety: 3D printers can work with various materials, including plastics, metals, ceramics, and composites.

- Reduced Lead Times: 3D printing eliminates the need for tooling and molds, reducing production lead times.

- Fused Deposition Modeling (FDM): Deposits molten plastic filament layer by layer to create objects.

- Stereolithography (SLA): Uses a UV laser to cure liquid resin, resulting in high-resolution prints.

- Selective Laser Sintering (SLS): Fuses powdered material using a laser, creating durable and complex parts.

- Multi-Jet Modeling (MJP): Deposits droplets of photopolymer resin to form objects with smooth surfaces.

- Cutting Area: Determine the maximum size of materials you need to cut.

- Laser Power: Higher power lasers cut thicker materials faster.

- Material Compatibility: Ensure the laser cutter is compatible with the materials you intend to cut.

- Software Compatibility: Verify that the laser cutter software integrates seamlessly with your design software.

- Safety Features: Prioritize safety features such as enclosed work areas and fume extraction systems.

- Build Volume: Select a printer with a build volume that accommodates your desired object sizes.

- Resolution: Higher resolution printers produce smoother surfaces and finer details.

- Material Compatibility: Consider the range of materials the printer can handle.

- Print Speed: Determine the desired printing speed and choose a printer that meets your productivity needs.

- Software Compatibility: Ensure the printer’s software is user-friendly and compatible with your design software.

- Metal Fabrication

- Plastic Fabrication

- Woodworking

- Textile Cutting

- Signage and Engraving

- Prototyping

- Product Development

- Medical Devices

- Custom Parts

- Architectural Models

3D Printer: The Additive Manufacturing Revolution

What is a 3D Printer?

A 3D printer is a computer-controlled machine that builds three-dimensional objects by depositing material layer by layer. It transforms digital designs into physical prototypes, products, and functional parts.

Benefits of 3D Printers

Types of 3D Printers

Considerations When Purchasing Laser Cutters and 3D Printers

Laser Cutter Considerations

3D Printer Considerations

Applications of Laser Cutters and 3D Printers

Laser Cutter Applications

3D Printer Applications

Conclusion

Laser cutters and 3D printers are transformative technologies that have revolutionized manufacturing processes across industries. Their precision, efficiency, and material versatility make them essential tools for businesses seeking to enhance their productivity, innovation, and product quality. By carefully considering the factors outlined in this guide, you can make an informed purchase decision and unlock the potential of these cutting-edge technologies to drive your business forward.

Frequently Asked Questions (FAQs)

Q: What are the key differences between CO2, fiber, and diode laser cutters?

A: CO2 lasers excel in cutting non-metals, fiber lasers are ideal for metals, and diode lasers are commonly used for engraving and marking.

Q: What is the difference between FDM, SLA, SLS, and MJP 3D printing technologies?

A: FDM uses plastic filaments, SLA uses liquid resin, SLS uses powdered material, and MJP deposits droplets of photopolymer resin.

Q: How do I choose the right laser cutter or 3D printer for my business?

A: Consider factors such as cutting area, laser power, material compatibility, software integration, and safety features for laser cutters, and build volume, resolution, material compatibility, print speed, and software compatibility for 3D printers.

Q: What are the advantages of using a laser cutter over traditional cutting methods?

A: Laser cutters offer superior precision, speed, material versatility, reduced waste, and automation capabilities.

Q: How can 3D printing benefit my product development process?

A: 3D printing enables rapid prototyping, customization, complex geometries, material variety, and reduced lead times.