Laser Cutter Attachment for 3D Printer: A Comprehensive Guide

Introduction

3D printing has revolutionized manufacturing, enabling users to create intricate and complex objects with precision. However, traditional 3D printing techniques are limited in their ability to cut or engrave materials. Laser cutter attachments for 3D printers offer a solution to this challenge, expanding the capabilities of these machines and unlocking new possibilities in fabrication.

Table of Content

- 1 Laser Cutter Attachment for 3D Printer: A Comprehensive Guide

- 1.1 Introduction

- 1.2 What is a Laser Cutter Attachment for 3D Printer?

- 1.3 Benefits of Laser Cutter Attachments

- 1.4 Considerations for Choosing a Laser Cutter Attachment

- 1.5 What is a Laser Cutter Attachment for 3D Printer?

- 1.6 Benefits of Laser Cutter Attachments

- 1.7 How to Use a Laser Cutter Attachment

- 1.8 Safety Considerations

- 1.9 Applications of Laser Cutter Attachments

- 1.10 Conclusion

- 1.11 FAQs

What is a Laser Cutter Attachment for 3D Printer?

Benefits of Laser Cutter Attachments

1. Enhanced Fabrication Capabilities:

Laser cutter attachments allow 3D printers to cut and engrave a wide range of materials, including wood, plastic, leather, paper, and even thin metals. This versatility enables users to create custom designs, prototypes, and functional parts with precise details.

2. Increased Precision:

Laser cutting and engraving offer exceptional precision, allowing for intricate designs and sharp edges. This level of accuracy is not achievable with traditional 3D printing techniques.

3. Time Savings:

Laser cutter attachments can significantly reduce production time compared to manual cutting or engraving methods. The automated process eliminates the need for manual labor, freeing up time for other tasks.

4. Cost-Effectiveness:

Laser cutter attachments can be a cost-effective solution for small-scale production and prototyping. Compared to dedicated laser cutters, they offer a lower investment cost while still providing similar capabilities.

Considerations for Choosing a Laser Cutter Attachment

3D printing has revolutionized manufacturing, enabling users to create intricate and complex objects with precision. However, traditional 3D printing techniques are limited in their ability to cut or engrave materials. Laser cutter attachments for 3D printers offer a solution to this challenge, expanding the capabilities of these machines and unlocking new possibilities in fabrication.

- 3d Design Software For Laser Cutting H1: Unlocking Precision And Creativity: 3D Design Software For Laser Cutting

- Laser Cut 3d Puzzle File Laser Cut 3D Puzzle File: A Comprehensive Guide

- 3d Ppt Templates Free Download 3D PPT Templates: Unleashing Visual Impact In Presentations

- 3d Laser Cutting Machines 3D Laser Cutting Machines: Revolutionizing Manufacturing With Precision And Efficiency

- Laser Cut 3d Snowflake H1: Laser Cut 3D Snowflake: A Festive And Intricate Holiday Decoration

What is a Laser Cutter Attachment for 3D Printer?

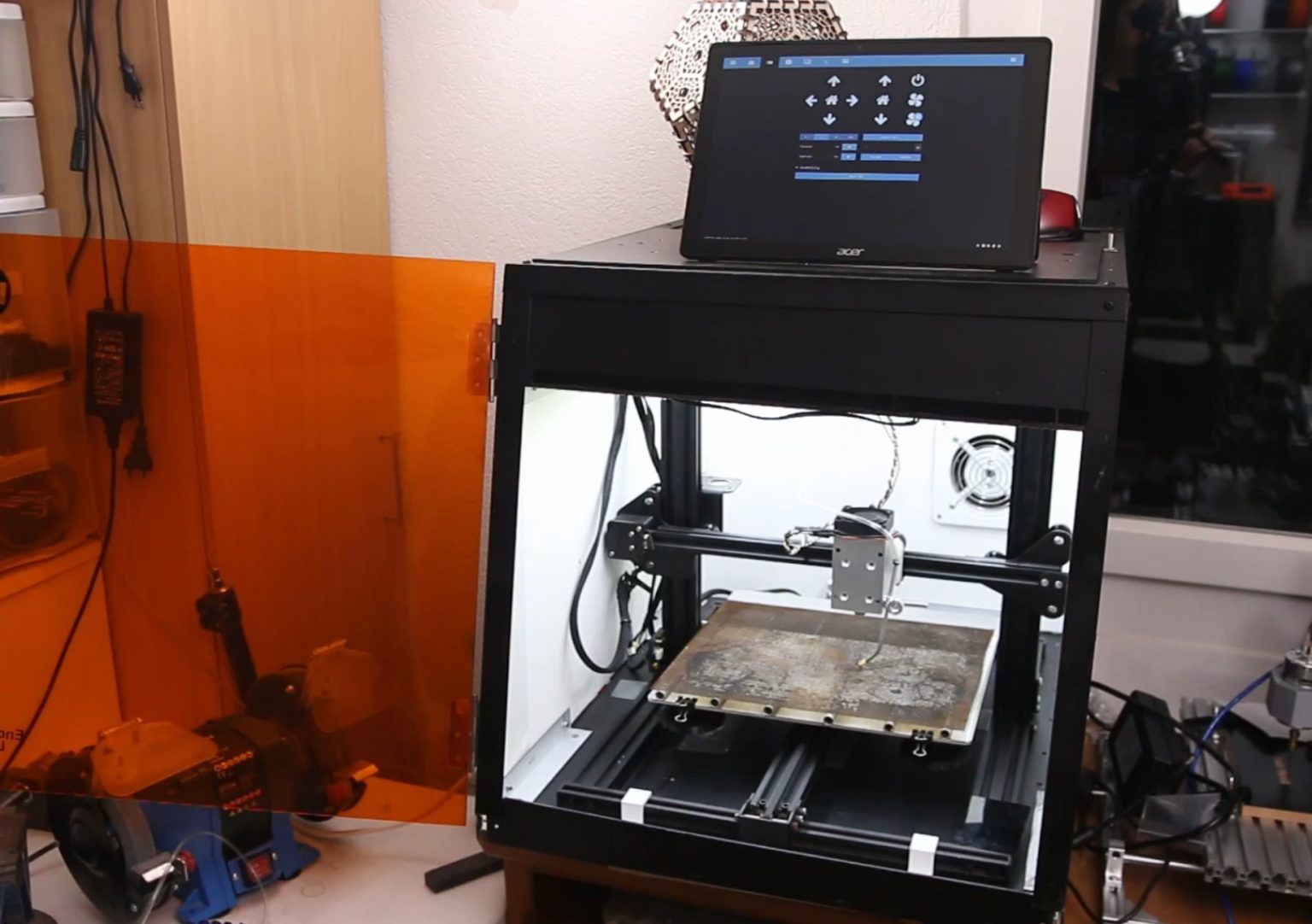

A laser cutter attachment is a device that can be integrated into a 3D printer, enabling it to cut or engrave materials using a focused laser beam. These attachments typically consist of a laser module, a focusing lens, and a control system that directs the laser’s movement.

Benefits of Laser Cutter Attachments

1. Enhanced Fabrication Capabilities:

Laser cutter attachments allow 3D printers to cut and engrave a wide range of materials, including wood, plastic, leather, paper, and even thin metals. This versatility enables users to create custom designs, prototypes, and functional parts with precise details.

1. Laser Power:

The laser power determines the cutting and engraving capabilities of the attachment. Higher power lasers can cut thicker materials and engrave deeper markings.

2. Laser Wavelength:

The laser wavelength determines the materials that the attachment can process. Common wavelengths include 445nm (blue), 450nm (blue), 808nm (infrared), and 1064nm (infrared).

3. Cutting Area:

The cutting area refers to the maximum size of material that the attachment can process. Consider the size of your intended projects when selecting an attachment.

4. Compatibility:

Ensure that the laser cutter attachment is compatible with your 3D printer model. Different attachments may have specific requirements for mounting and integration.

How to Use a Laser Cutter Attachment

1. Installation:

Follow the manufacturer’s instructions to install the laser cutter attachment properly. This may involve mounting the attachment to the printer’s frame and connecting it to the control system.

2. Software Setup:

Configure the laser cutter attachment software to define the laser parameters, cutting speed, and engraving depth. Most attachments come with dedicated software that integrates with popular 3D modeling programs.

3. Material Preparation:

Prepare the material to be cut or engraved by ensuring it is clean and free of debris. The material thickness should be within the specified range for the attachment’s laser power.

4. Design and Preparation:

Design your cutting or engraving project in a 3D modeling program and generate a compatible file format for the laser cutter attachment.

5. Operation:

Position the material on the cutting bed and initiate the cutting or engraving process. Monitor the progress and make adjustments as necessary.

Safety Considerations

1. Eye Protection:

Wear appropriate eye protection, such as laser safety glasses, to prevent eye damage from the laser beam.

2. Ventilation:

Ensure adequate ventilation in the work area to remove fumes and particles generated during the cutting or engraving process.

3. Material Compatibility:

Check the material compatibility of the laser cutter attachment and the material you intend to process. Some materials may release hazardous fumes or cause fire hazards.

Applications of Laser Cutter Attachments

Laser cutter attachments for 3D printers have a wide range of applications, including:

1. Prototyping:

Create custom prototypes with precise details and sharp edges for testing and evaluation.

2. Custom Designs:

Design and create unique and personalized items, such as jewelry, home décor, and giftware.

3. Signage:

Engrave or cut logos, text, and designs on various materials for signage and branding purposes.

4. Model Making:

Enhance model-making projects by adding intricate details and precise cuts to create realistic and detailed models.

5. Circuit Board Fabrication:

Cut and etch circuit boards with precision, enabling the production of custom electronics.

Conclusion

Laser cutter attachments for 3D printers offer a powerful tool for expanding the capabilities of these machines. By integrating laser cutting and engraving capabilities, users can create intricate designs, precise cuts, and functional parts with increased efficiency and cost-effectiveness. Whether for prototyping, custom fabrication, or model making, laser cutter attachments empower makers and hobbyists to unlock new possibilities in the world of 3D printing.

FAQs

1. Can I use a laser cutter attachment to cut metal?

Yes, some laser cutter attachments can cut thin metals, depending on the laser power and wavelength. However, the thickness and type of metal that can be cut will vary based on the attachment’s capabilities.

2. Is it difficult to learn how to use a laser cutter attachment?

The learning curve for using a laser cutter attachment depends on the user’s prior experience with 3D printing and laser cutting. With proper training and practice, most users can become proficient in operating the attachment.

3. How do I maintain a laser cutter attachment?

Regular maintenance of a laser cutter attachment is crucial to ensure its longevity and performance. This includes cleaning the laser lens, checking the alignment, and replacing worn components as needed.

4. Can I use a laser cutter attachment to engrave glass?

Yes, it is possible to engrave glass using a laser cutter attachment. However, the results may vary depending on the type of glass and the laser power and wavelength.