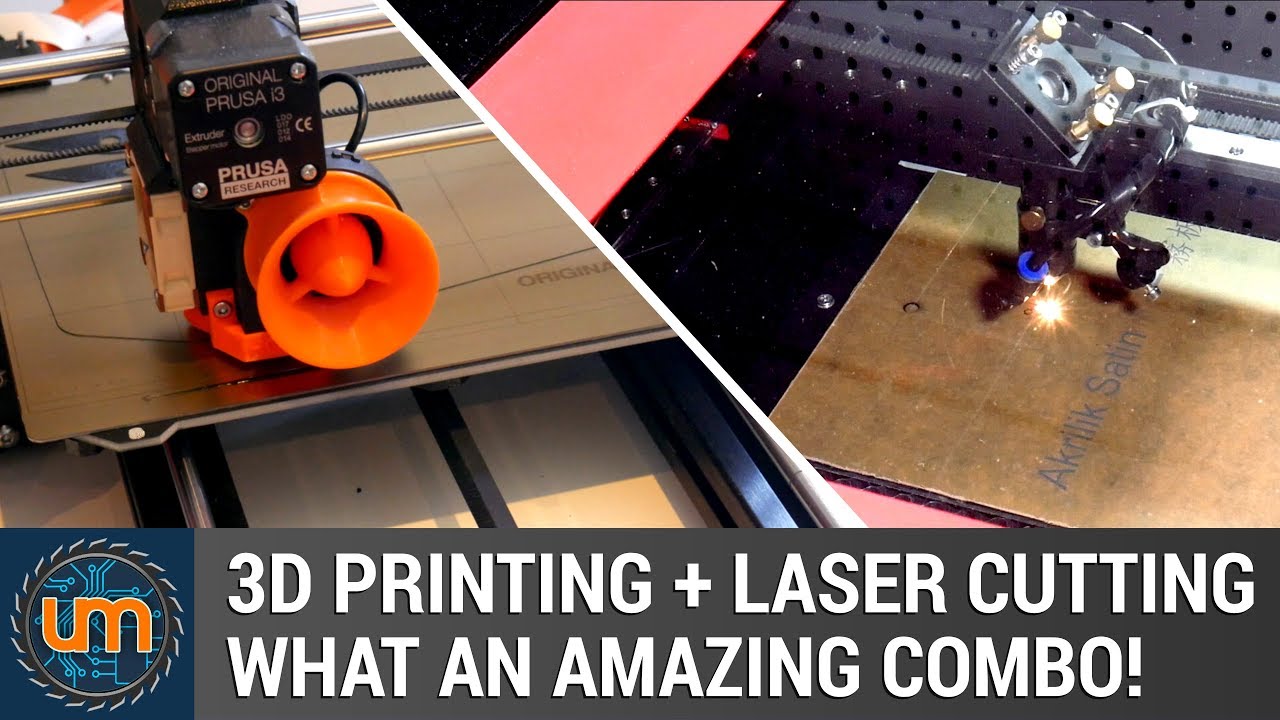

Convert 3D Printer to Laser Cutter: A Comprehensive Guide

Introduction

3D printers have revolutionized the way we create physical objects, but they can also be repurposed to perform other tasks, such as laser cutting. By converting a 3D printer to a laser cutter, you can unlock a new world of possibilities for your projects. This article will provide a comprehensive guide on how to convert a 3D printer to a laser cutter, including step-by-step instructions, safety precautions, and troubleshooting tips.

Table of Content

Step-by-Step Instructions

- 3D printer

- Laser diode (405nm or 445nm)

- Laser driver

- Heat sink

- Focusing lens

- Power supply

- Safety goggles

Instructions:

3D printers have revolutionized the way we create physical objects, but they can also be repurposed to perform other tasks, such as laser cutting. By converting a 3D printer to a laser cutter, you can unlock a new world of possibilities for your projects. This article will provide a comprehensive guide on how to convert a 3D printer to a laser cutter, including step-by-step instructions, safety precautions, and troubleshooting tips.

- 3d Laser Cutting Software 3D Laser Cutting Software: A Comprehensive Guide To Revolutionizing Your Fabrication

- 3d Ppt Templates Free Download 3D PPT Templates: Unleashing Visual Impact In Presentations

- Mazak 3d Laser Cutting Mazak 3D Laser Cutting: Revolutionizing Metal Fabrication

- Cnc Laser Cutting Dxf Files Free Download CNC Laser Cutting DXF Files: Free Download And Comprehensive Guide

- 3d Laser Wood Cutter 3D Laser Wood Cutter: A Comprehensive Guide

Step-by-Step Instructions

Materials:

- 3D printer

- Laser diode (405nm or 445nm)

- Remove the extruder: Unmount the extruder assembly from the printer’s hotend.

- Install the laser diode: Mount the laser diode to the hotend using a heat sink.

- Connect the laser driver: Connect the laser driver to the laser diode and the power supply.

- Install the focusing lens: Place the focusing lens in front of the laser diode to focus the beam.

- Adjust the laser: Adjust the laser’s power and focus using the laser driver’s controls.

- Install safety goggles: Wear safety goggles to protect your eyes from the laser beam.

- Always wear safety goggles when operating the laser cutter.

- Never point the laser beam at people or animals.

- Use a fume extractor to remove any hazardous fumes produced by the laser cutting process.

- Keep flammable materials away from the laser cutter.

- Do not leave the laser cutter unattended while operating.

- Laser is not cutting: Check the laser’s power, focus, and alignment.

- Laser is cutting too slowly: Increase the laser’s power or reduce the cutting speed.

- Laser is not cutting cleanly: Clean the focusing lens or adjust the laser’s alignment.

- Laser is overheating: Check the heat sink and ensure it is properly dissipating heat.

- Versatility: Can be used for both 3D printing and laser cutting.

- Cost-effective: Less expensive than purchasing separate 3D printer and laser cutter.

- Compact: Takes up less space than two separate machines.

- Limited cutting thickness: Laser cutters typically have a lower cutting thickness than dedicated laser cutters.

- Precision: Laser cutters may have lower precision than dedicated 3D printers.

- Setup: Requires some technical expertise to convert and calibrate the laser cutter.

- Engraving: Laser cutters can be used to engrave designs, logos, and text on a variety of materials, including wood, plastic, and metal.

- Cutting: Laser cutters can cut through thin materials, such as paper, cardboard, and thin wood.

- Prototyping: Laser cutters can be used to create prototypes of parts and components.

- Art and crafts: Laser cutters can be used to create custom artwork, jewelry, and home decor.

Safety Precautions

Troubleshooting Tips

Advantages and Disadvantages

Advantages:

Disadvantages:

Applications

Conclusion

Converting a 3D printer to a laser cutter is a great way to unlock new possibilities for your projects. By following the instructions outlined in this article, you can safely and effectively convert your 3D printer into a versatile laser cutting machine. Whether you’re looking to create custom engravings, cut out precise shapes, or prototype new designs, a converted laser cutter can be a valuable addition to your workshop.

FAQs

Q: What type of laser diode should I use?

A: For most applications, a 405nm or 445nm laser diode is suitable.

Q: How do I adjust the laser’s focus?

A: Use the focusing lens’s adjustment screw to move the lens closer or further from the laser diode.

Q: What materials can I cut with a laser cutter?

A: Laser cutters can cut through a variety of materials, including paper, cardboard, thin wood, plastic, and some metals.

Q: How thick can I cut with a laser cutter?

A: The cutting thickness depends on the laser’s power and the material being cut. Most converted laser cutters can cut through materials up to a few millimeters thick.

Q: Is it safe to operate a laser cutter?

A: Yes, as long as you follow the safety precautions outlined in this article.