H1: Unleashing Precision: Converting Your 3D Printer into a Laser Cutter

H2: Embracing the Versatility of Laser Cutting

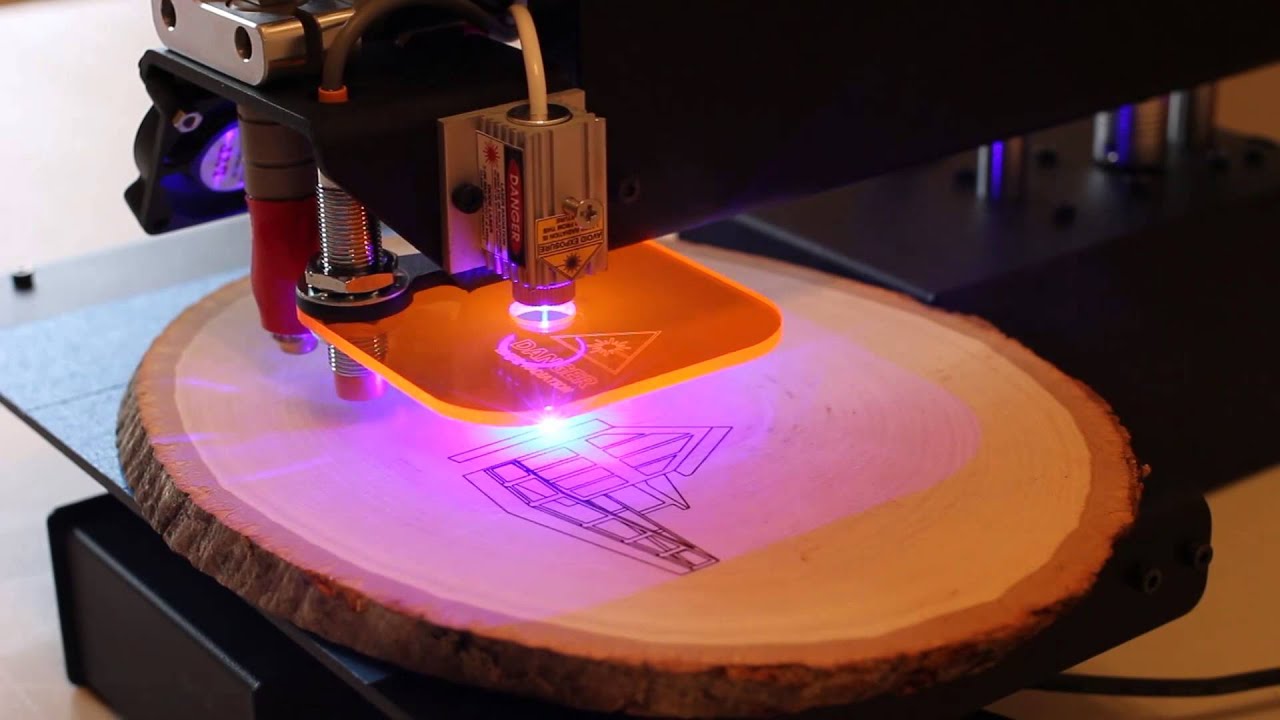

Laser cutting, a transformative technology, has revolutionized manufacturing and prototyping. With its ability to precisely cut and engrave various materials, laser cutters offer unparalleled versatility. They excel in creating intricate designs, detailed patterns, and precise components with exceptional accuracy.

Table of Content

- 1 H1: Unleashing Precision: Converting Your 3D Printer into a Laser Cutter

- 1.1 H2: Embracing the Versatility of Laser Cutting

- 1.2 H3: Advantages of Converting a 3D Printer to a Laser Cutter

- 1.3 H2: Step-by-Step Guide to Conversion

- 1.3.1 H3: Required Materials

- 1.4 H3: Advantages of Converting a 3D Printer to a Laser Cutter

- 1.4.2 H3: Installation and Setup

- 1.5 H2: Considerations for Laser Cutting

- 1.5.3 H3: Material Selection and Safety Precautions

- 1.5.4 H3: Design and Software

- 1.6 H2: Applications of Laser Cutting

- 1.7 H3: Conclusion

- 1.8 FAQs

H3: Advantages of Converting a 3D Printer to a Laser Cutter

- Enhanced Precision: Laser cutters boast superior accuracy and precision, enabling the creation of fine details and intricate designs.

- Versatile Material Compatibility: Laser cutters can handle a wide range of materials, including wood, acrylic, leather, and paper, expanding your creative possibilities.

- Increased Efficiency: Laser cutting is a rapid process, significantly reducing production time compared to traditional methods.

- Cost-Effectiveness: Converting a 3D printer to a laser cutter is a cost-efficient solution, avoiding the need to purchase a separate laser cutter.

H2: Step-by-Step Guide to Conversion

H3: Required Materials

- 3D printer with a sturdy frame and stable platform

- 3d Laser Cut Sticker 3D Laser Cut Stickers: Elevate Your Brand With Dimension And Impact

- 3d Laser Cut Kit 3D Laser Cut Kit: Unleashing Precision And Creativity In Model Making

- 3d And Laser Cut 3D And Laser Cutting: A Comprehensive Guide To Advanced Manufacturing Techniques

- 3d Printer Laser Cutter Engraver 3D Printer Laser Cutter Engraver: A Comprehensive Guide

- 3d Printer Laser Cutter Cnc Kickstarter 3D Printer, Laser Cutter, And CNC: The Ultimate Kickstarter Guide For Makers And Innovators

- Enhanced Precision: Laser cutters boast superior accuracy and precision, enabling the creation of fine details and intricate designs.

- Versatile Material Compatibility: Laser cutters can handle a wide range of materials, including wood, acrylic, leather, and paper, expanding your creative possibilities.

- Laser module compatible with your printer

- Safety goggles

- Ventilation system

- Remove the Extruder: Detach the extruder assembly from the 3D printer.

- Mount the Laser Module: Securely mount the laser module in place of the extruder, ensuring proper alignment.

- Connect the Electronics: Wire the laser module to the 3D printer’s controller board, following the manufacturer’s instructions.

- Configure Software: Update the 3D printer’s software to support laser cutting functionality.

- Choose materials compatible with laser cutting, considering their thickness and flammability.

- Wear safety goggles to protect your eyes from laser emissions.

- Ensure proper ventilation to remove fumes and debris generated during laser cutting.

- Use CAD software to design your laser cutting projects.

- Choose appropriate laser cutting parameters based on the material and design.

- Preview the laser path before cutting to avoid any potential errors.

- Prototyping: Create accurate and detailed prototypes for product development.

- Art and Design: Engrave intricate patterns, logos, and artwork on various materials.

- Jewelry Making: Cut and shape precise jewelry components with exceptional accuracy.

- Model Making: Build detailed models and miniatures with high levels of precision.

Laser cutting, a transformative technology, has revolutionized manufacturing and prototyping. With its ability to precisely cut and engrave various materials, laser cutters offer unparalleled versatility. They excel in creating intricate designs, detailed patterns, and precise components with exceptional accuracy.

H3: Advantages of Converting a 3D Printer to a Laser Cutter

Transforming your 3D printer into a laser cutter unlocks a myriad of benefits:

H3: Installation and Setup

H2: Considerations for Laser Cutting

H3: Material Selection and Safety Precautions

H3: Design and Software

H2: Applications of Laser Cutting

The versatility of laser cutters extends to numerous applications:

H3: Conclusion

Converting a 3D printer to a laser cutter is a transformative upgrade that unlocks a world of possibilities. By embracing the precision and versatility of laser cutting, you can elevate your creative projects, enhance your prototyping capabilities, and explore new avenues for innovation.

FAQs

Q: Is it difficult to convert a 3D printer to a laser cutter?

A: The conversion process is relatively straightforward, but it requires technical knowledge and attention to detail.

Q: What materials can a converted laser cutter handle?

A: The materials suitable for laser cutting include wood, acrylic, leather, paper, and some plastics.

Q: Are there safety concerns with laser cutting?

A: Yes, it is essential to wear safety goggles and ensure proper ventilation to protect yourself from laser emissions and fumes.