3D Printer with Laser Cutter: The Ultimate Guide to Hybrid Manufacturing

Introduction

The convergence of 3D printing and laser cutting technologies has revolutionized manufacturing, enabling the creation of complex and intricate objects with unparalleled precision and efficiency. This comprehensive guide delves into the transformative capabilities of 3D printers with laser cutters, exploring their applications, benefits, and considerations for successful implementation.

Table of Content

- 1 3D Printer with Laser Cutter: The Ultimate Guide to Hybrid Manufacturing

- 1.1 Introduction

- 1.2 H1: Understanding 3D Printers with Laser Cutters

- 1.3 H2: Benefits of Using 3D Printers with Laser Cutters

- 1.4 H1: Understanding 3D Printers with Laser Cutters

- 1.5 H2: Benefits of Using 3D Printers with Laser Cutters

- 1.6 H2: Applications of 3D Printers with Laser Cutters

- 1.7 H3: Considerations for Implementing 3D Printers with Laser Cutters

- 1.8 H3: Conclusion

- 1.9 FAQs

H1: Understanding 3D Printers with Laser Cutters

H2: Benefits of Using 3D Printers with Laser Cutters

1. Enhanced Design Flexibility:

3D printers with laser cutters enable the production of complex geometries that would be challenging or impossible to achieve with traditional manufacturing methods. The combination of additive and subtractive processes allows for intricate designs with undercuts, internal cavities, and fine details.

2. Reduced Production Time:

By integrating both technologies, 3D printers with laser cutters streamline the manufacturing process, eliminating the need for separate production steps. This reduces overall lead times and enables faster product delivery.

3. Increased Precision and Accuracy:

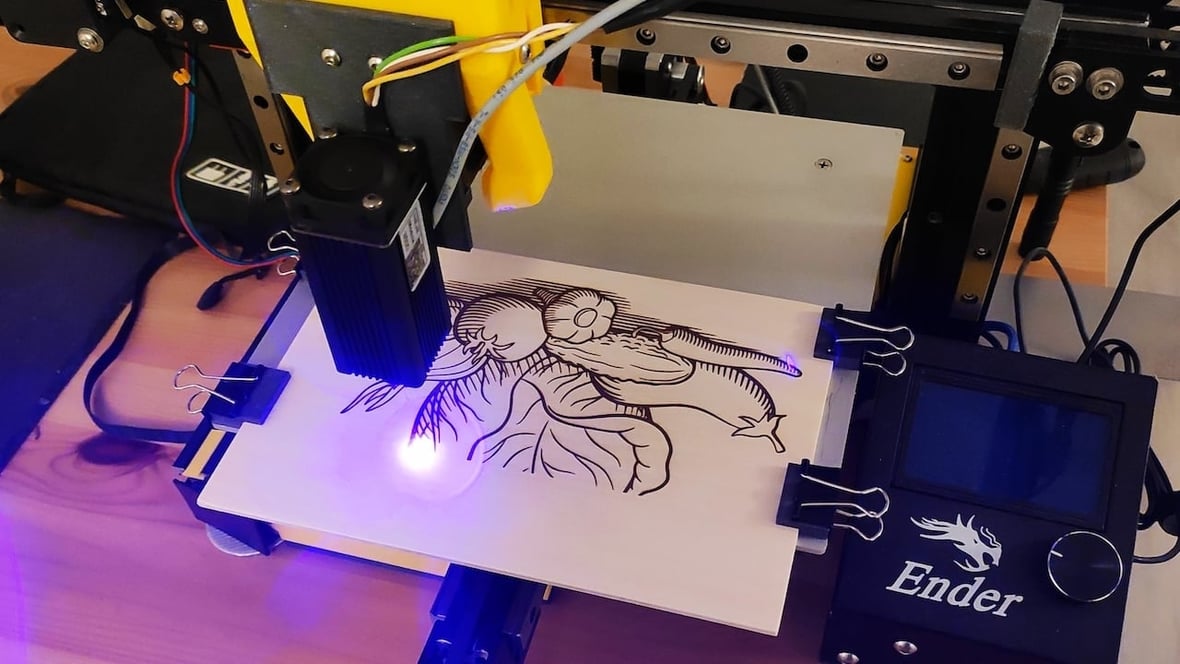

Laser cutters provide exceptional precision and accuracy in cutting, engraving, and marking operations. This precision translates to higher-quality products with sharp edges, clean lines, and consistent dimensions.

4. Material Versatility:

3D printers with laser cutters support a wide range of materials, including plastics, metals, wood, and fabrics. This versatility allows for the creation of objects with varying properties and applications.

5. Customization and Personalization:

The convergence of 3D printing and laser cutting technologies has revolutionized manufacturing, enabling the creation of complex and intricate objects with unparalleled precision and efficiency. This comprehensive guide delves into the transformative capabilities of 3D printers with laser cutters, exploring their applications, benefits, and considerations for successful implementation.

- 3d Tube Laser Cutting Machine 3D Tube Laser Cutting Machine: A Comprehensive Guide

- 3d Laser Marking Machine 3D Laser Marking Machine: A Comprehensive Guide

- Laser Cut 3d Pop Cards Laser Cut 3D Pop Cards: A Captivating Expression Of Creativity And Emotion

- Laser 3d Cutter Laser 3D Cutter: A Comprehensive Guide

- 3d Models For Laser Cutting 3D Models For Laser Cutting: Unleashing Precision And Creativity

H1: Understanding 3D Printers with Laser Cutters

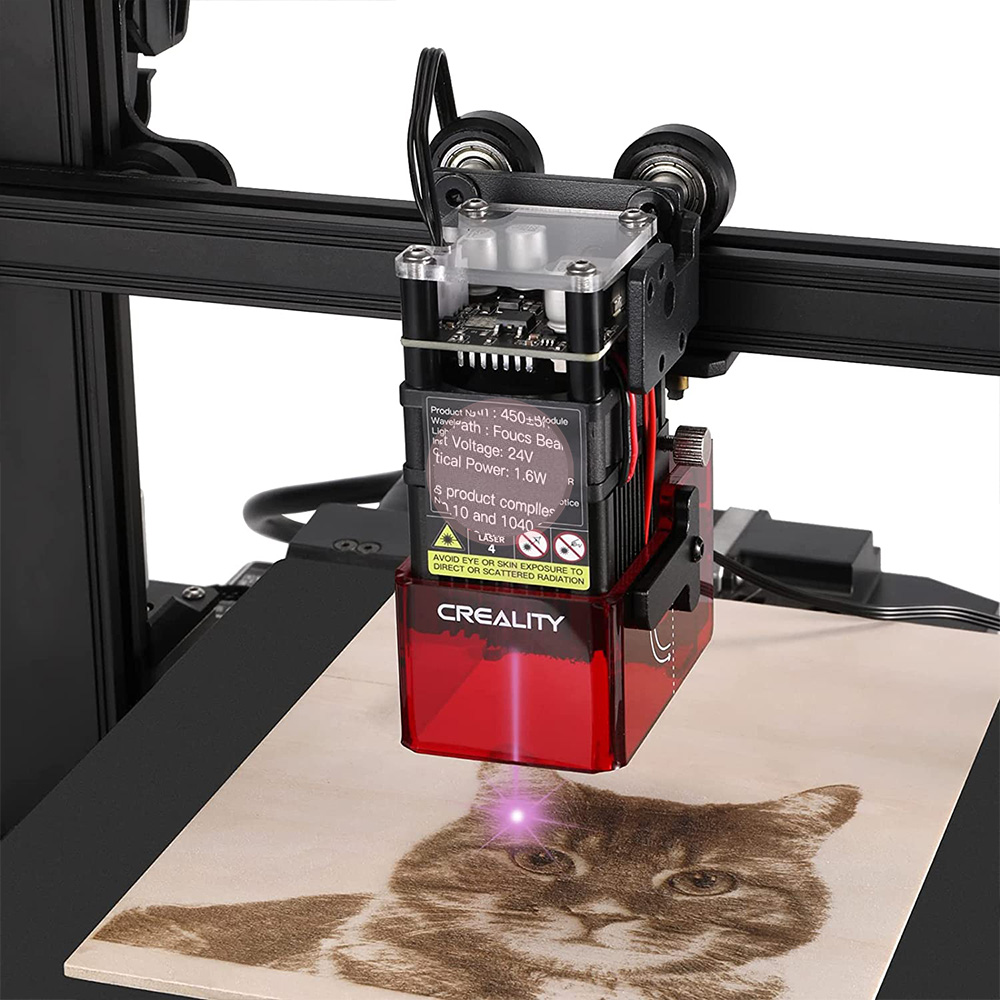

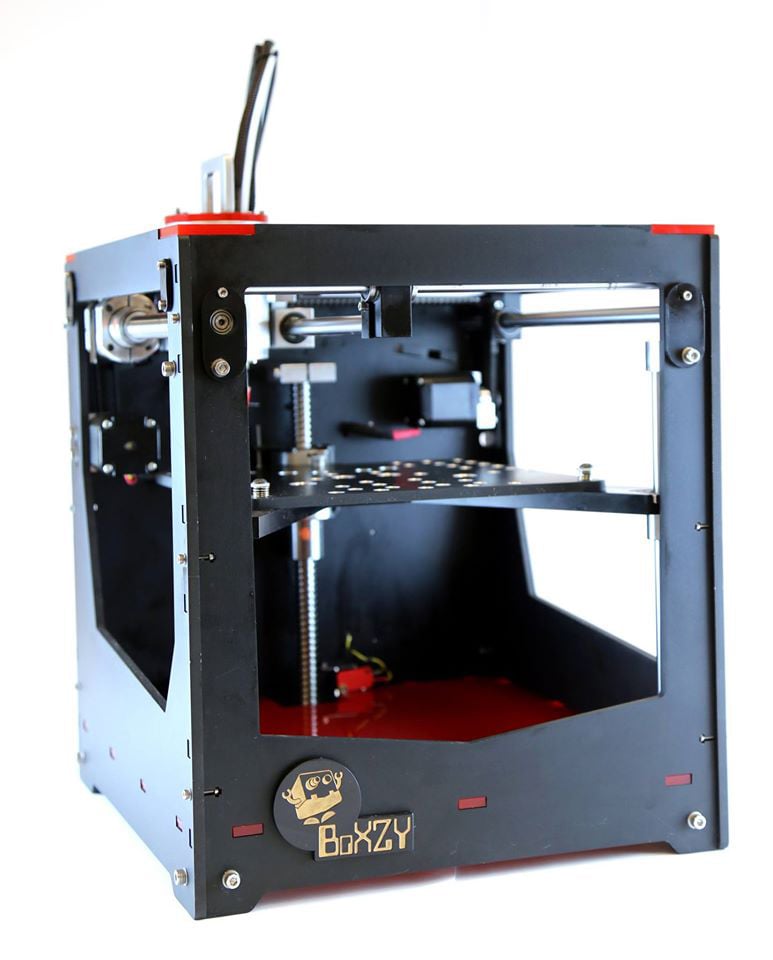

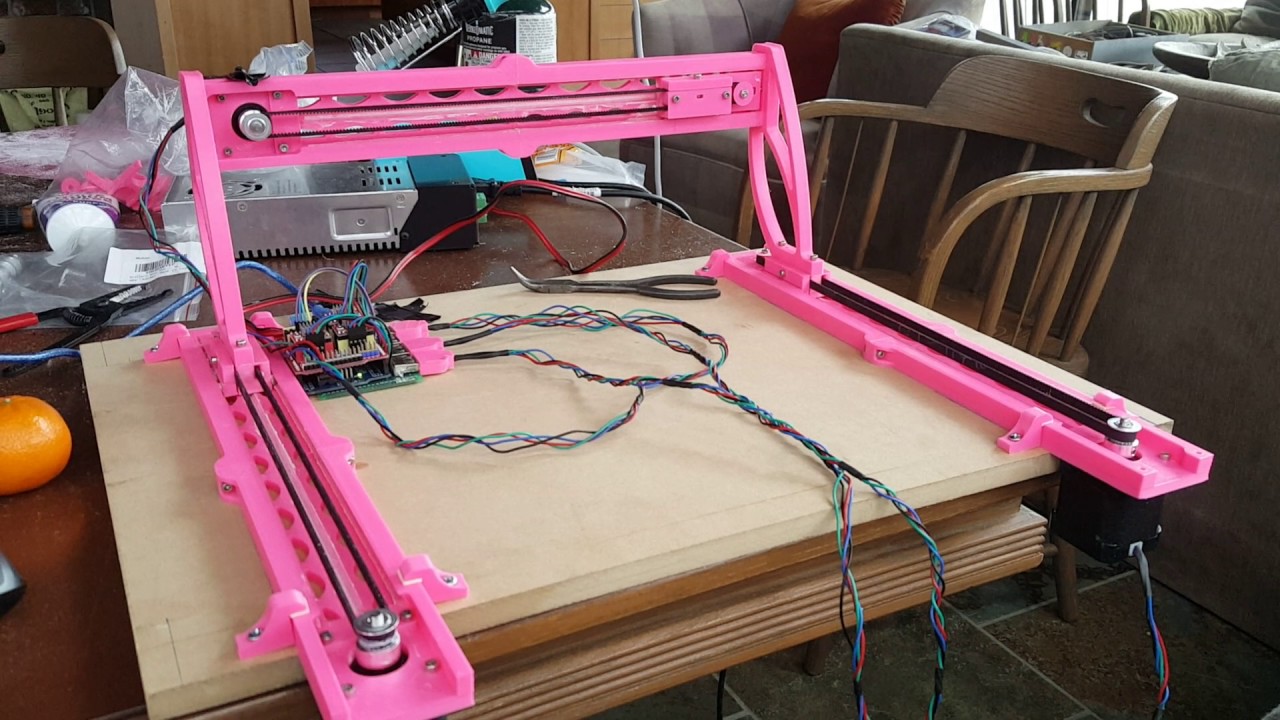

3D printers with laser cutters combine the additive manufacturing capabilities of 3D printing with the subtractive processes of laser cutting. They offer a versatile platform that allows users to create three-dimensional objects and simultaneously perform intricate cutting, engraving, and marking operations.

H2: Benefits of Using 3D Printers with Laser Cutters

1. Enhanced Design Flexibility:

3D printers with laser cutters enable the production of complex geometries that would be challenging or impossible to achieve with traditional manufacturing methods. The combination of additive and subtractive processes allows for intricate designs with undercuts, internal cavities, and fine details.

The combination of 3D printing and laser cutting enables the production of highly customized and personalized products. Users can easily modify designs, incorporate unique features, and create one-of-a-kind objects tailored to specific needs.

H2: Applications of 3D Printers with Laser Cutters

1. Prototyping and Rapid Manufacturing:

3D printers with laser cutters are ideal for rapid prototyping, allowing designers and engineers to quickly iterate and test designs before mass production. They also facilitate rapid manufacturing of small batches or customized products.

2. Jewelry Making:

Laser cutters are widely used in jewelry making for intricate cutting, engraving, and marking of precious metals. They enable the creation of unique and detailed jewelry designs with high precision and accuracy.

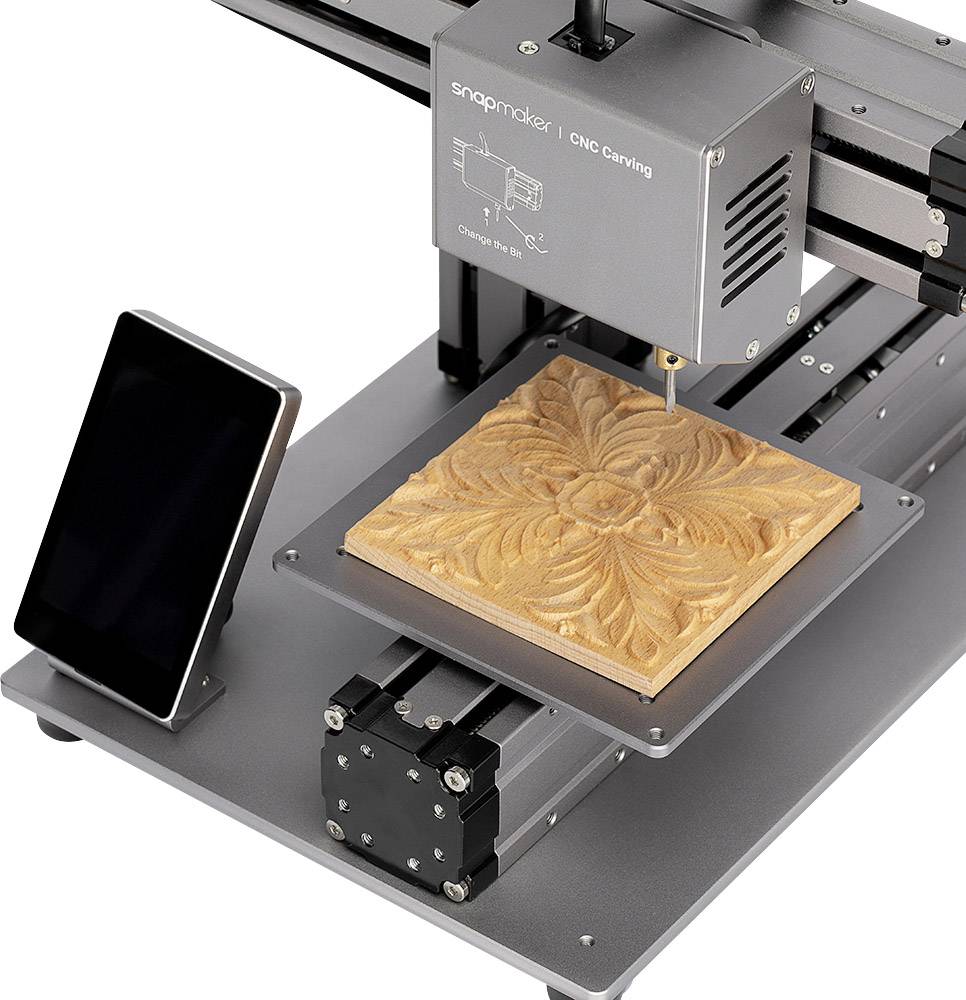

3. Woodworking and Furniture Making:

3D printers with laser cutters are transforming woodworking and furniture making. They can cut complex shapes, engrave designs, and assemble furniture components with precision, reducing labor costs and improving efficiency.

4. Electronics Manufacturing:

Laser cutters are essential in electronics manufacturing for precise cutting of circuit boards, engraving of component markings, and creating custom enclosures. They ensure high-quality production and improve component accuracy.

5. Medical and Dental Applications:

3D printers with laser cutters play a crucial role in medical and dental applications. They enable the creation of custom prosthetics, surgical guides, and dental implants with high precision and biocompatibility.

H3: Considerations for Implementing 3D Printers with Laser Cutters

1. Material Compatibility:

Ensure that the 3D printer and laser cutter are compatible with the materials you intend to use. Consider factors such as laser wavelength, material thickness, and melting point.

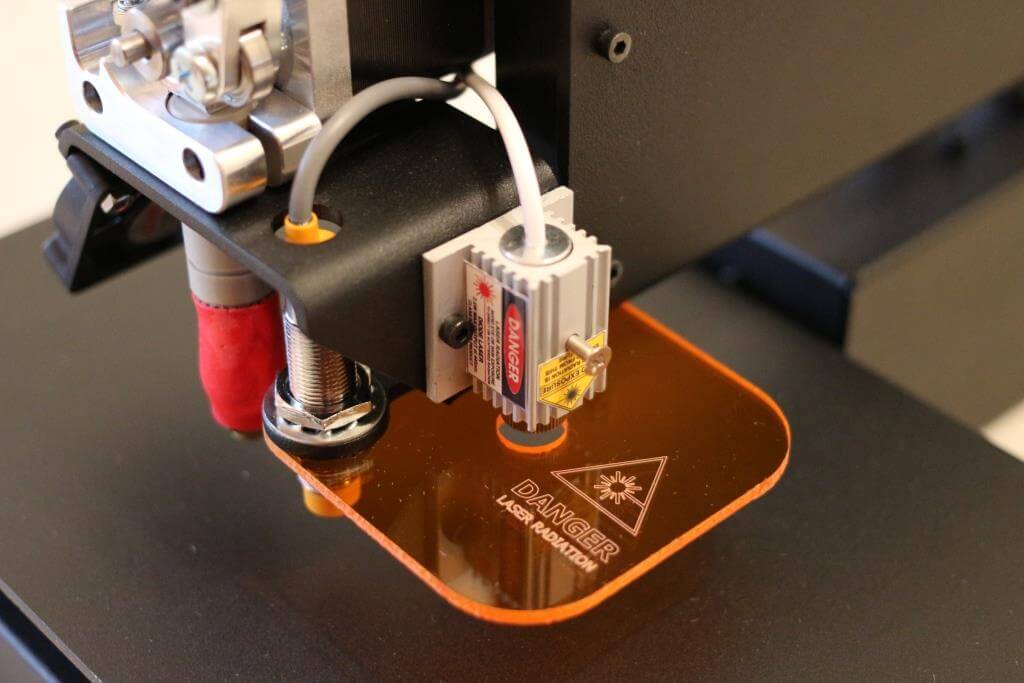

2. Safety Precautions:

Laser cutters emit high-energy beams, so it is essential to implement appropriate safety measures. Wear protective eyewear, ensure proper ventilation, and follow all safety protocols.

3. Software Integration:

Choose a software that seamlessly integrates with both the 3D printer and laser cutter, allowing for efficient design, slicing, and operation.

4. Training and Expertise:

Operators should receive comprehensive training on both the 3D printer and laser cutter to ensure safe and effective operation. Specialized knowledge in design software and laser cutting techniques is beneficial.

5. Maintenance and Calibration:

Regular maintenance and calibration are crucial to ensure optimal performance and longevity of the equipment. Follow manufacturer guidelines for cleaning, alignment, and calibration procedures.

H3: Conclusion

3D printers with laser cutters represent a transformative technology that empowers manufacturers, designers, and hobbyists to create complex objects with unprecedented precision, efficiency, and versatility. By combining the capabilities of additive and subtractive manufacturing, these hybrid machines unlock new possibilities in prototyping, rapid manufacturing, jewelry making, woodworking, electronics, and various other industries. With careful consideration of material compatibility, safety precautions, software integration, and operator training, businesses and individuals can harness the full potential of 3D printers with laser cutters to revolutionize their manufacturing processes and create innovative products.

FAQs

1. What materials can be used with 3D printers with laser cutters?

A: 3D printers with laser cutters support a wide range of materials, including plastics, metals, wood, fabrics, and ceramics.

2. How do I ensure safety when using a laser cutter?

A: Wear protective eyewear, ensure proper ventilation, and follow all safety protocols outlined by the manufacturer.

3. What software is best for 3D printing and laser cutting?

A: There are various software options available, such as Fusion 360, AutoCAD, and CorelDRAW, that offer integrated support for both 3D printing and laser cutting.

4. How do I maintain and calibrate a 3D printer with a laser cutter?

A: Follow manufacturer guidelines for cleaning, alignment, and calibration procedures to ensure optimal performance and longevity of the equipment.

5. What industries benefit from using 3D printers with laser cutters?

A: 3D printers with laser cutters find applications in various industries, including prototyping, jewelry making, woodworking, electronics manufacturing, and medical and dental applications.