Acrylic Laser Cutter: A Comprehensive Guide

Acrylic laser cutters are revolutionizing the fabrication industry, offering unparalleled precision, versatility, and speed. This article will delve into the world of acrylic laser cutting, providing an in-depth analysis of its capabilities, applications, and best practices.

H1: Understanding Acrylic Laser Cutters

Table of Content

- 1 Acrylic Laser Cutter: A Comprehensive Guide

- 1.1 H1: Understanding Acrylic Laser Cutters

- 1.2 H3: Applications of Acrylic Laser Cutting

- 1.3 H1: Understanding Acrylic Laser Cutters

- 1.4 H2: Advantages of Acrylic Laser Cutting

- 1.5 H2: Choosing the Right Acrylic Laser Cutter

- 1.6 H3: Best Practices for Acrylic Laser Cutting

- 1.7 H2: Conclusion

- 1.8 FAQs

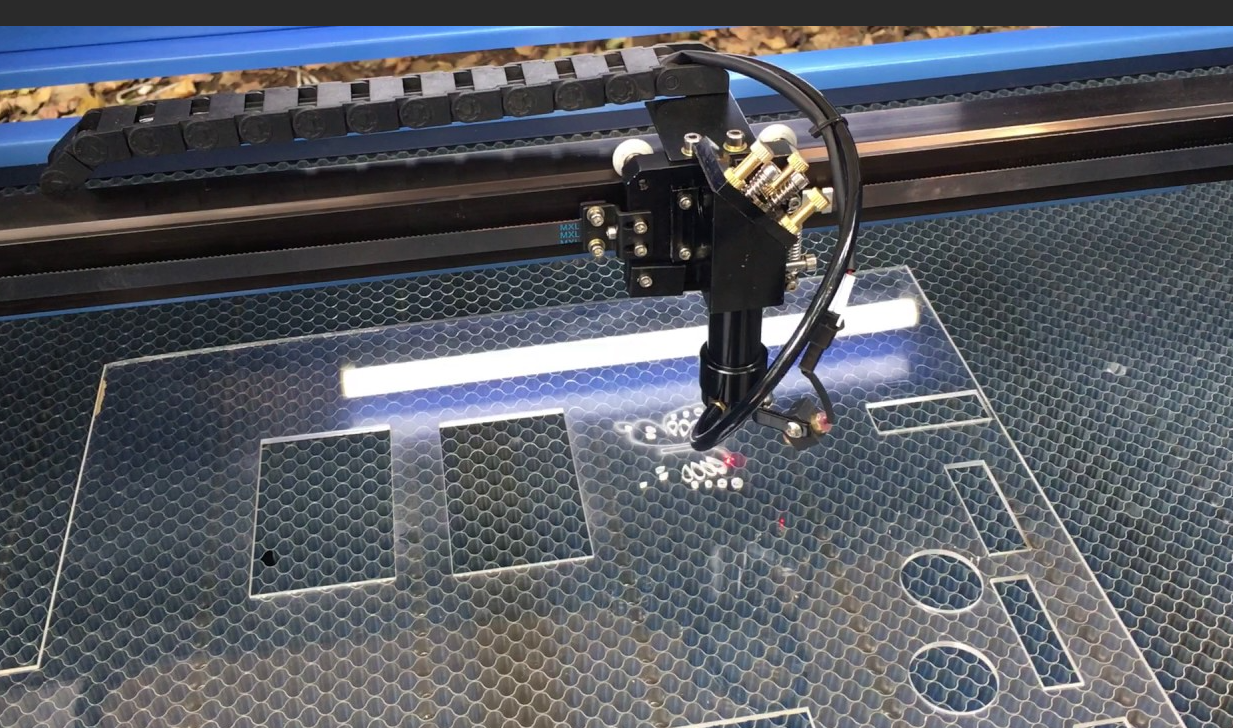

Acrylic laser cutters are specialized machines that utilize laser technology to precisely cut, engrave, and etch acrylic materials. These cutters emit a focused beam of light that vaporizes or melts the acrylic, creating clean and intricate designs.

- Precision: Laser cutters offer exceptional precision, enabling the production of highly detailed and accurate parts.

- Versatility: Acrylic laser cutters can handle a wide range of acrylic thicknesses and colors, making them suitable for various applications.

- Speed: Laser cutting is a fast process, significantly reducing production time compared to traditional methods.

- Non-Contact: The laser beam does not physically touch the acrylic, eliminating the risk of damage or deformation.

- Automation: Laser cutters can be programmed to operate autonomously, increasing efficiency and reducing labor costs.

H3: Applications of Acrylic Laser Cutting

- Signage and Display: Creating custom signs, displays, and promotional materials.

- 3d Laser Printer And Cutter 3D Laser Printer And Cutter: A Comprehensive Guide

- File Laser Cutting Free File Laser Cutting: Unleashing Precision And Versatility

- 3d Laser Cut Box 3D Laser Cut Box: A Comprehensive Guide

- Laser Cutting 3d Animal Puzzle Template Laser Cutting 3D Animal Puzzle Template: A Comprehensive Guide

- 3d Design For Laser Cutting 3D Design For Laser Cutting: A Comprehensive Guide

- Precision: Laser cutters offer exceptional precision, enabling the production of highly detailed and accurate parts.

- Versatility: Acrylic laser cutters can handle a wide range of acrylic thicknesses and colors, making them suitable for various applications.

- Industrial Fabrication: Producing components for automotive, aerospace, and medical industries.

- Product Prototyping: Rapidly creating prototypes for product development and testing.

- Art and Design: Engraving and cutting intricate designs for wall art, jewelry, and sculptures.

- Home Decor: Personalizing home décor items such as lampshades, picture frames, and coasters.

- Power: The power of the laser determines the thickness and speed at which it can cut acrylic.

- Bed Size: The bed size limits the maximum size of acrylic sheets that can be processed.

- Software: The software controls the laser cutter and should be user-friendly and feature-rich.

- Durability: The cutter’s durability ensures reliable operation over time.

- Price: The cost of the cutter should align with the intended usage and budget.

- Material Selection: Choose high-quality acrylic sheets with appropriate thickness and color.

- Design Optimization: Use design software to create optimized cutting paths and minimize material waste.

- Proper Setup: Ensure the laser cutter is calibrated and the bed is level.

- Laser Focus: Adjust the laser focus to achieve optimal cutting results.

- Ventilation: Provide adequate ventilation to remove fumes and debris generated during cutting.

- Safety Precautions: Wear appropriate safety gear and follow safety protocols.

H1: Understanding Acrylic Laser Cutters

Acrylic laser cutters are specialized machines that utilize laser technology to precisely cut, engrave, and etch acrylic materials. These cutters emit a focused beam of light that vaporizes or melts the acrylic, creating clean and intricate designs.

H2: Advantages of Acrylic Laser Cutting

H2: Choosing the Right Acrylic Laser Cutter

Selecting the appropriate acrylic laser cutter requires considering several factors:

H3: Best Practices for Acrylic Laser Cutting

H2: Conclusion

Acrylic laser cutters are versatile and powerful tools that enable the creation of high-quality acrylic products. By understanding their advantages, applications, and best practices, businesses and individuals can leverage this technology to streamline production, enhance creativity, and achieve superior results.

FAQs

Q: What is the difference between cutting and engraving with a laser cutter?

A: Cutting involves vaporizing or melting the acrylic to create a clean edge, while engraving etches the surface without cutting through the material.

Q: Can acrylic laser cutters cut other materials?

A: Yes, some acrylic laser cutters can also cut other materials such as wood, leather, and paper.

Q: How do I clean and maintain an acrylic laser cutter?

A: Regular cleaning and maintenance are crucial. Use a soft cloth and isopropyl alcohol to clean the lens, mirrors, and bed. Inspect the laser tube and replace it if necessary.

Q: Is it safe to operate an acrylic laser cutter at home?

A: Yes, it is safe if operated responsibly. Ensure proper ventilation, wear safety gear, and follow the manufacturer’s guidelines.