Acrylic Laser Cut: A Comprehensive Guide

Introduction

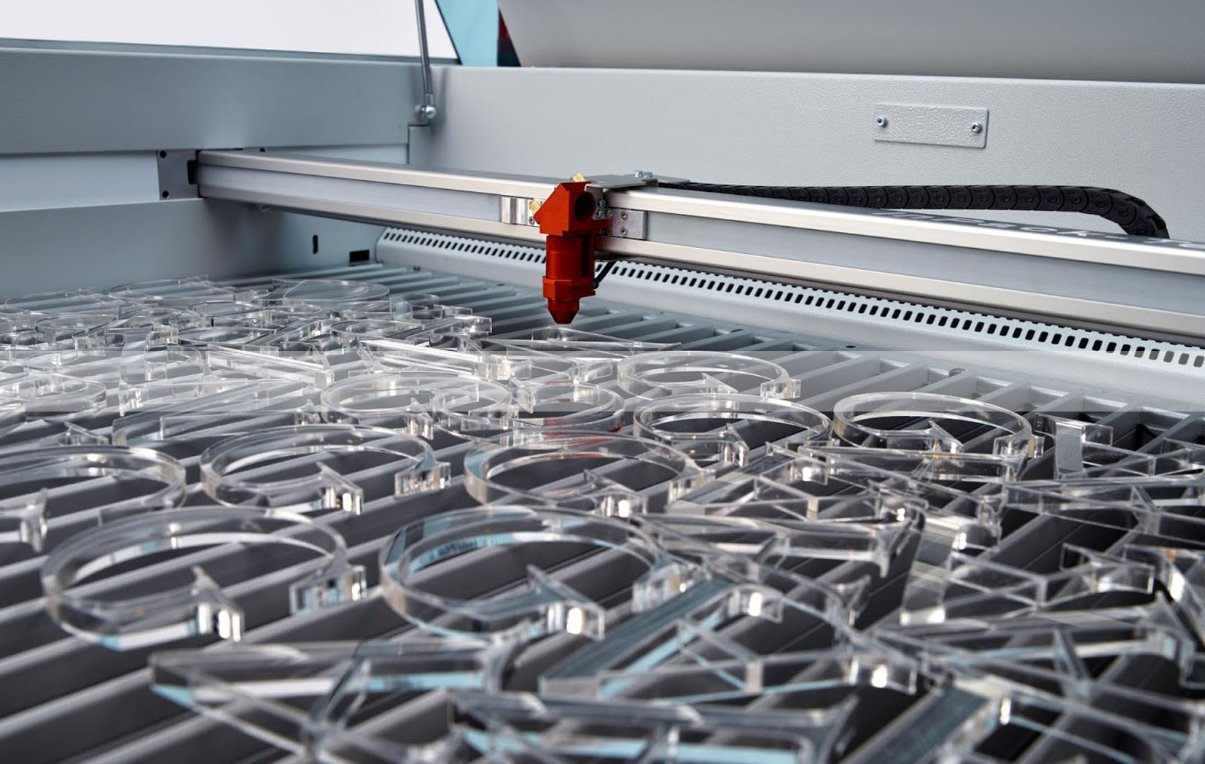

Acrylic laser cutting is a precise and versatile manufacturing process that utilizes a laser to cut intricate designs and shapes from acrylic sheets. This technique offers numerous advantages, including precision, speed, and design flexibility. This article explores the various aspects of acrylic laser cutting, from its benefits to applications and technical considerations.

Table of Content

H1: Benefits of Acrylic Laser Cutting

1. Precision and Accuracy:

Laser cutting ensures exceptional precision, resulting in clean and precise cuts with minimal distortion or burrs.

2. Speed and Efficiency:

The laser’s high-power density allows for fast and efficient cutting, reducing production time and increasing productivity.

3. Design Flexibility:

Laser cutting can create complex and intricate designs with ease, enabling the production of unique and customized products.

4. Non-Contact Process:

Unlike mechanical cutting methods, laser cutting does not involve physical contact with the material, eliminating the risk of surface damage.

5. Minimal Material Waste:

Laser cutting optimizes material usage, minimizing waste and reducing production costs.

Acrylic laser cutting is a precise and versatile manufacturing process that utilizes a laser to cut intricate designs and shapes from acrylic sheets. This technique offers numerous advantages, including precision, speed, and design flexibility. This article explores the various aspects of acrylic laser cutting, from its benefits to applications and technical considerations.

- 3d Laser Cutting Metal 3D Laser Cutting Metal: A Comprehensive Guide

- 3d Laser Engraving 3D Laser Engraving: A Comprehensive Guide

- Laser Cutting 3d Printer Laser Cutting 3D Printer: A Comprehensive Guide

- 3d Model Laser Cutting File 3D Model Laser Cutting File: A Comprehensive Guide

- 3d Laser Cutting Ideas 3D Laser Cutting Ideas: Unleashing Creativity And Innovation

H1: Benefits of Acrylic Laser Cutting

Acrylic laser cutting provides several key benefits that make it an attractive choice for various industries:

1. Precision and Accuracy:

Laser cutting ensures exceptional precision, resulting in clean and precise cuts with minimal distortion or burrs.

2. Speed and Efficiency:

H2: Applications of Acrylic Laser Cut

Acrylic laser cutting finds applications in a wide range of industries, including:

1. Signage and Displays:

Laser-cut acrylic is widely used for creating custom signs, displays, and promotional materials.

2. Home Decor:

Acrylic laser cutting is employed in the production of decorative items, such as wall art, furniture, and lighting fixtures.

3. Industrial Products:

Laser-cut acrylic is used in the manufacturing of components for various industrial applications, including electronics and medical devices.

4. Jewelry and Accessories:

Laser cutting is utilized in the creation of intricate jewelry pieces, watches, and other accessories.

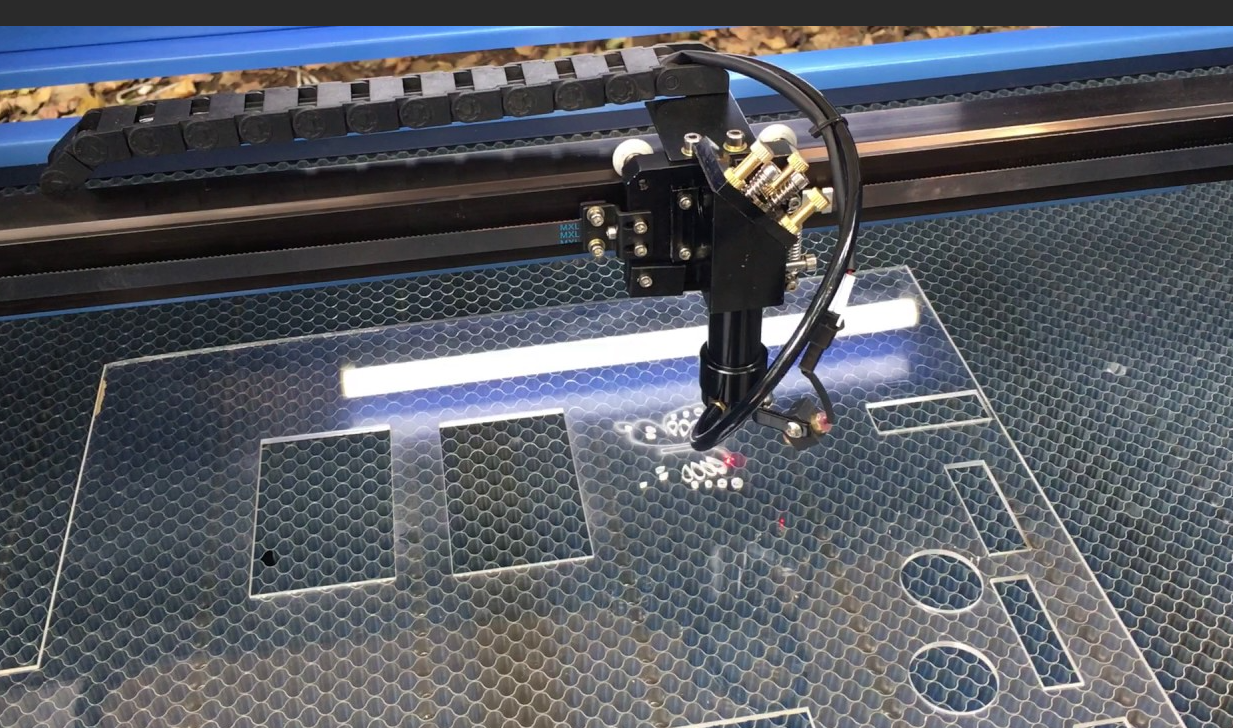

5. Prototyping and Model Making:

Laser-cut acrylic is ideal for rapid prototyping and model making, enabling quick and cost-effective design verification.

H3: Technical Considerations for Acrylic Laser Cutting

1. Material Selection:

The choice of acrylic sheet is crucial, as different types vary in thickness, color, and clarity.

2. Laser Power and Wavelength:

The laser’s power and wavelength determine the cutting speed and edge quality.

3. Cutting Parameters:

Optimizing cutting parameters, such as speed, power, and focus, is essential for achieving desired results.

4. Ventilation and Fume Extraction:

Laser cutting acrylic generates fumes, so proper ventilation and fume extraction systems are necessary for operator safety.

5. Post-Processing:

Depending on the application, post-processing steps like polishing or engraving may be required to enhance the aesthetic or functional properties of the laser-cut acrylic.

H3: Conclusion

Acrylic laser cutting offers a combination of precision, speed, and design flexibility, making it an invaluable tool in various industries. Its applications range from signage to industrial products, home decor to jewelry, and prototyping to model making. By understanding the benefits and technical considerations of acrylic laser cutting, businesses can leverage this technology to create innovative and high-quality products.

FAQs

1. What is the maximum thickness of acrylic that can be laser cut?

The maximum thickness depends on the laser’s power and wavelength, but typically ranges from 1/16 inch to 1 inch.

2. What is the difference between laser engraving and laser cutting?

Laser engraving removes a thin layer of material from the surface, while laser cutting cuts through the entire thickness of the material.

3. What is the best way to clean laser-cut acrylic?

Use a soft cloth with a mild detergent solution or rubbing alcohol. Avoid using abrasive cleaners or solvents.

4. Is laser-cut acrylic durable?

Laser-cut acrylic is durable and resistant to fading, scratching, and weathering.

5. How can I get a quote for acrylic laser cutting?

Contact a reputable acrylic laser cutting service provider and provide details about your design and material requirements.