File Laser Cutting: Unlocking Limitless Possibilities for Precision Fabrication

Introduction

Laser cutting, a cutting-edge fabrication technique, has revolutionized the manufacturing industry by enabling precise and efficient cutting of various materials. From intricate designs to complex geometries, laser cutting offers unparalleled accuracy and versatility. This article delves into the world of file laser cutting, exploring its capabilities, advantages, and applications.

Table of Content

- 1 File Laser Cutting: Unlocking Limitless Possibilities for Precision Fabrication

- 1.1 Introduction

- 1.2 What is File Laser Cutting?

- 1.3 Advantages of File Laser Cutting

- 1.4 Applications of File Laser Cutting

- 1.5 What is File Laser Cutting?

- 1.6 Advantages of File Laser Cutting

- 1.7 How to Prepare Files for Laser Cutting

- 1.8 Safety Considerations

- 1.9 Conclusion

- 1.10 FAQs

What is File Laser Cutting?

Advantages of File Laser Cutting

Precision and Accuracy: Laser cutting offers exceptional precision and accuracy, enabling the creation of intricate designs with tight tolerances. This makes it ideal for applications requiring high precision and repeatability.

Material Versatility: File laser cutting can be used on a wide range of materials, including metals, plastics, wood, and ceramics. This versatility makes it a valuable tool for various industries.

Speed and Efficiency: Laser cutting is a fast and efficient process, reducing production time and increasing productivity. The automated nature of the process minimizes human error, further enhancing efficiency.

Low Maintenance: Laser cutting systems are relatively low maintenance, requiring minimal downtime for cleaning and calibration. This reduces operational costs and ensures consistent performance.

Applications of File Laser Cutting

DOWNLOAD SVG FILES FOR LASER CUTTING

File laser cutting finds applications in a wide range of industries, including:

Aerospace: Cutting precision components for aircraft and spacecraft.

Automotive: Fabricating parts for cars, trucks, and motorcycles.

Electronics: Creating intricate circuit boards and electronic components.

Laser cutting, a cutting-edge fabrication technique, has revolutionized the manufacturing industry by enabling precise and efficient cutting of various materials. From intricate designs to complex geometries, laser cutting offers unparalleled accuracy and versatility. This article delves into the world of file laser cutting, exploring its capabilities, advantages, and applications.

- Wooden Puzzle Animal Laser Cut Wooden Puzzle Animal Laser Cut: A Comprehensive Guide

- Laser Cut Animal Earrings H1: Laser Cut Animal Earrings: A Unique And Stylish Accessory

- Laser Cut Reindeer Head Laser Cut Reindeer Head: A Festive And Intricate DIY Project

- Laser Cut Animal Wall Art Laser Cut Animal Wall Art: A Unique And Modern Way To Decorate Your Home

- Giraffe Laser Cut Giraffe Laser Cut: Precision Cutting For Intricate Designs

What is File Laser Cutting?

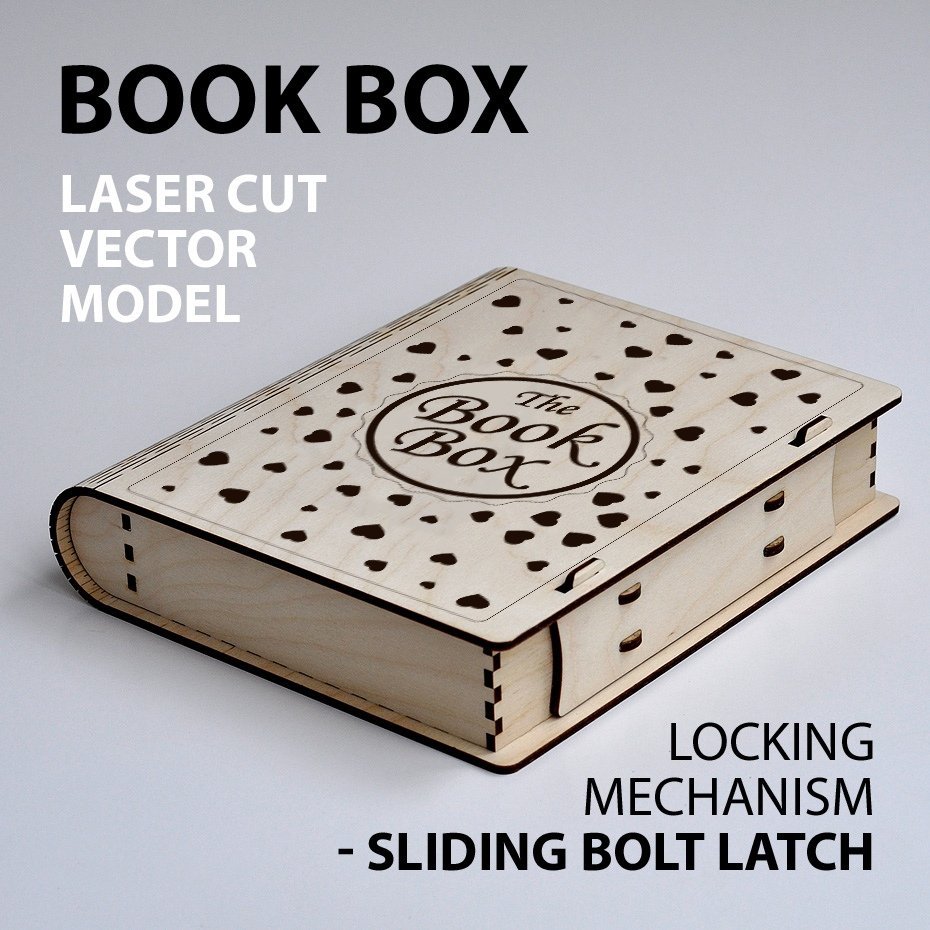

File laser cutting is a computer-controlled process that utilizes a focused laser beam to cut materials based on a digital file. The laser beam, generated by a laser source, is directed through a nozzle and onto the workpiece, where it melts, burns, or vaporizes the material along the programmed path. This allows for precise cutting of complex shapes, intricate details, and even fine holes.

DOWNLOAD SVG FILES FOR LASER CUTTING

Advantages of File Laser Cutting

Precision and Accuracy: Laser cutting offers exceptional precision and accuracy, enabling the creation of intricate designs with tight tolerances. This makes it ideal for applications requiring high precision and repeatability.

Material Versatility: File laser cutting can be used on a wide range of materials, including metals, plastics, wood, and ceramics. This versatility makes it a valuable tool for various industries.

Medical: Producing surgical instruments, medical devices, and implants.

Jewelry: Crafting intricate jewelry pieces with high precision and detail.

Art and Design: Creating unique and artistic pieces, from sculptures to custom signs.

How to Prepare Files for Laser Cutting

To ensure successful laser cutting, proper file preparation is crucial. Here are some guidelines:

File Format: Most laser cutting systems support industry-standard file formats such as DXF, DWG, and AI.

Geometry: Ensure that the geometry is closed and free of overlapping lines.

Line Thickness: Set line thickness to a value that is visible to the laser cutting software.

Scale and Units: Verify the scale and units of the file to match the laser cutting system’s requirements.

Material Properties: Consider the material properties and adjust cutting parameters accordingly.

Safety Considerations

Laser cutting involves the use of high-power lasers, which can pose potential hazards. It is essential to adhere to the following safety precautions:

Laser Safety Eyewear: Always wear appropriate laser safety eyewear to protect your eyes from harmful laser radiation.

Enclosure: Ensure that the laser cutting system is enclosed to prevent exposure to laser beams.

Ventilation: Provide adequate ventilation to remove fumes and particles generated during the cutting process.

Fire Safety: Have a fire extinguisher readily available and follow proper fire safety protocols.

Conclusion

File laser cutting has emerged as a transformative technology, enabling the creation of precision-cut components and intricate designs with unparalleled accuracy and efficiency. Its versatility and wide-ranging applications make it an indispensable tool for various industries. By adhering to proper file preparation and safety guidelines, you can harness the full potential of file laser cutting and unlock limitless possibilities for precision fabrication.

FAQs

Q: What is the difference between laser cutting and plasma cutting?

A: Laser cutting uses a focused laser beam to melt, burn, or vaporize the material, while plasma cutting uses a plasma arc to cut through the material. Laser cutting offers higher precision and can cut a wider range of materials.

Q: What materials can be cut using laser cutting?

A: File laser cutting can be used on metals, plastics, wood, ceramics, and other materials.

Q: How do I choose the right laser cutting machine for my needs?

A: Consider the materials you need to cut, the required precision, the cutting speed, and your budget when selecting a laser cutting machine.

Q: Is laser cutting a safe process?

A: Yes, laser cutting is a safe process when proper safety precautions are followed, including wearing laser safety eyewear, using an enclosed system, and providing adequate ventilation.