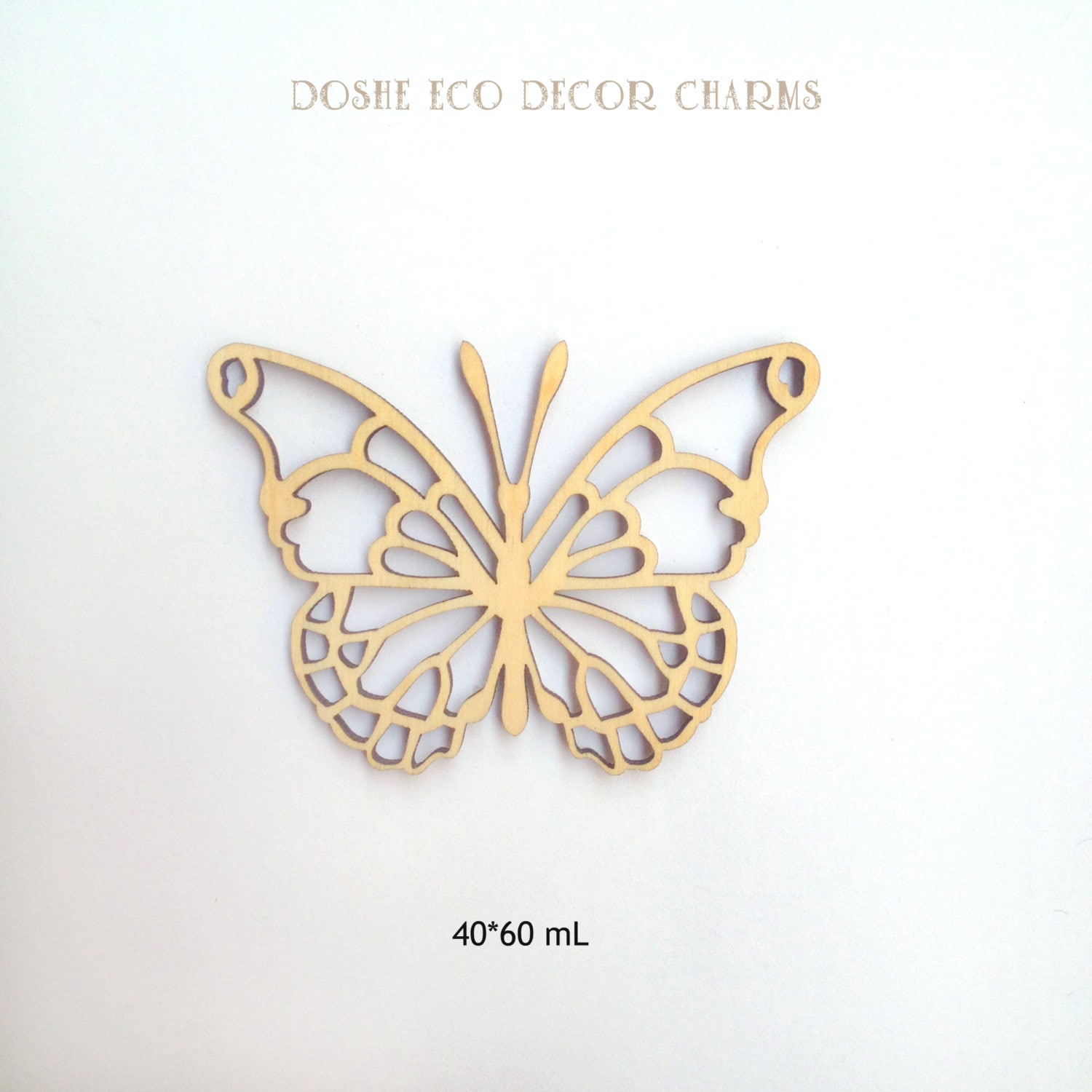

Butterfly Laser Cutting: Precision and Elegance in the Realm of Fabrication

Introduction

Butterfly laser cutting, an advanced manufacturing technique, harnesses the power of lasers to meticulously shape and cut materials with unparalleled precision and intricate detail. This cutting-edge process has revolutionized various industries, including aerospace, automotive, electronics, and medical devices. In this comprehensive guide, we delve into the intricacies of butterfly laser cutting, exploring its capabilities, applications, and transformative impact on the manufacturing landscape.

Table of Content

- 1 Butterfly Laser Cutting: Precision and Elegance in the Realm of Fabrication

- 1.1 Introduction

- 1.2 H1: Understanding Butterfly Laser Cutting

- 1.3 H1: Applications of Butterfly Laser Cutting

- 1.4 H1: Understanding Butterfly Laser Cutting

- 1.5 H1: Benefits and Impact of Butterfly Laser Cutting

- 1.6 H1: Conclusion

- 1.7 FAQs

H1: Understanding Butterfly Laser Cutting

Butterfly laser cutting employs a focused laser beam to vaporize and remove material from a workpiece, resulting in precise cuts with minimal heat-affected zones. The laser beam, guided by a computer-controlled system, follows a predetermined path, allowing for intricate and complex designs to be realized.

H2: Key Advantages

- Exceptional Precision: Butterfly laser cutting delivers unmatched precision, enabling the fabrication of parts with tight tolerances and complex geometries.

- Minimal Heat-Affected Zone: The laser’s focused beam minimizes heat exposure, preserving the integrity and properties of the material.

- Versatility: This cutting technique can handle a wide range of materials, including metals, plastics, and composites.

- Automation: Butterfly laser cutting is highly automated, reducing production time and ensuring consistent results.

DOWNLOAD SVG FILES FOR LASER CUTTING

H1: Applications of Butterfly Laser Cutting

H2: Aerospace and Automotive Industries

Butterfly laser cutting, an advanced manufacturing technique, harnesses the power of lasers to meticulously shape and cut materials with unparalleled precision and intricate detail. This cutting-edge process has revolutionized various industries, including aerospace, automotive, electronics, and medical devices. In this comprehensive guide, we delve into the intricacies of butterfly laser cutting, exploring its capabilities, applications, and transformative impact on the manufacturing landscape.

- Laser Cut Animal Shapes Laser Cut Animal Shapes: A Comprehensive Guide To Unleashing Creativity And Precision

- Cat Laser Cut H1: Cat Laser Cut: A Comprehensive Guide To Feline Fun

- Laser Cut 3d Animals Laser Cut 3D Animals: A Comprehensive Guide

- Animal Wood Laser Cut Animal Wood Laser Cut: A Comprehensive Guide To Crafting Unique And Intricate Designs

- Laser Cut Animal Head Laser Cut Animal Head: The Ultimate Guide To Crafting Intricate Animal Decor

H1: Understanding Butterfly Laser Cutting

H2: The Principle of Operation

DOWNLOAD SVG FILES FOR LASER CUTTING

Butterfly laser cutting employs a focused laser beam to vaporize and remove material from a workpiece, resulting in precise cuts with minimal heat-affected zones. The laser beam, guided by a computer-controlled system, follows a predetermined path, allowing for intricate and complex designs to be realized.

H2: Key Advantages

Butterfly laser cutting plays a crucial role in the production of lightweight and high-strength components for aircraft and automobiles. It enables the precise cutting of intricate shapes, reducing weight and improving fuel efficiency.

H2: Electronics and Medical Devices

In the electronics industry, butterfly laser cutting is used to create complex circuit boards and other electronic components. In the medical field, it facilitates the fabrication of surgical instruments, implants, and prosthetics with exceptional precision and detail.

H2: Other Applications

Butterfly laser cutting finds applications in diverse industries, including jewelry making, fashion design, and artistic creations. It empowers designers and manufacturers to realize their most imaginative ideas with unmatched precision.

H1: Benefits and Impact of Butterfly Laser Cutting

H2: Enhanced Production Efficiency

Butterfly laser cutting automates the cutting process, reducing production time and labor costs. It also minimizes material waste, leading to increased efficiency and sustainability.

H2: Improved Product Quality

The precision and minimal heat-affected zone of butterfly laser cutting result in high-quality parts with superior surface finishes and dimensional accuracy.

H2: Innovation and Customization

This cutting technique enables the creation of innovative designs and customized products that were previously impossible to manufacture. It fosters creativity and empowers businesses to differentiate their offerings.

H1: Conclusion

Butterfly laser cutting has emerged as a transformative technology in the manufacturing sector. Its unparalleled precision, versatility, and efficiency make it an indispensable tool for industries seeking to produce high-quality, complex parts. As the technology continues to evolve, we can expect even more groundbreaking applications and advancements in the years to come.

FAQs

Q: What materials can be cut with butterfly laser cutting?

A: Butterfly laser cutting can handle a wide range of materials, including metals (e.g., steel, aluminum, titanium), plastics, and composites.

Q: How does butterfly laser cutting differ from traditional laser cutting?

A: Butterfly laser cutting utilizes a unique focusing lens that produces a smaller and more precise laser beam, resulting in exceptional precision and minimal heat-affected zones.

Q: What are the advantages of butterfly laser cutting over other cutting methods?

A: Butterfly laser cutting offers advantages such as higher precision, reduced heat-affected zones, versatility, and automation, leading to improved product quality and production efficiency.

Q: Is butterfly laser cutting suitable for mass production?

A: Yes, butterfly laser cutting is highly automated and can be seamlessly integrated into production lines, enabling efficient mass production of high-quality parts.