Laser Cut Template: A Comprehensive Guide

Introduction

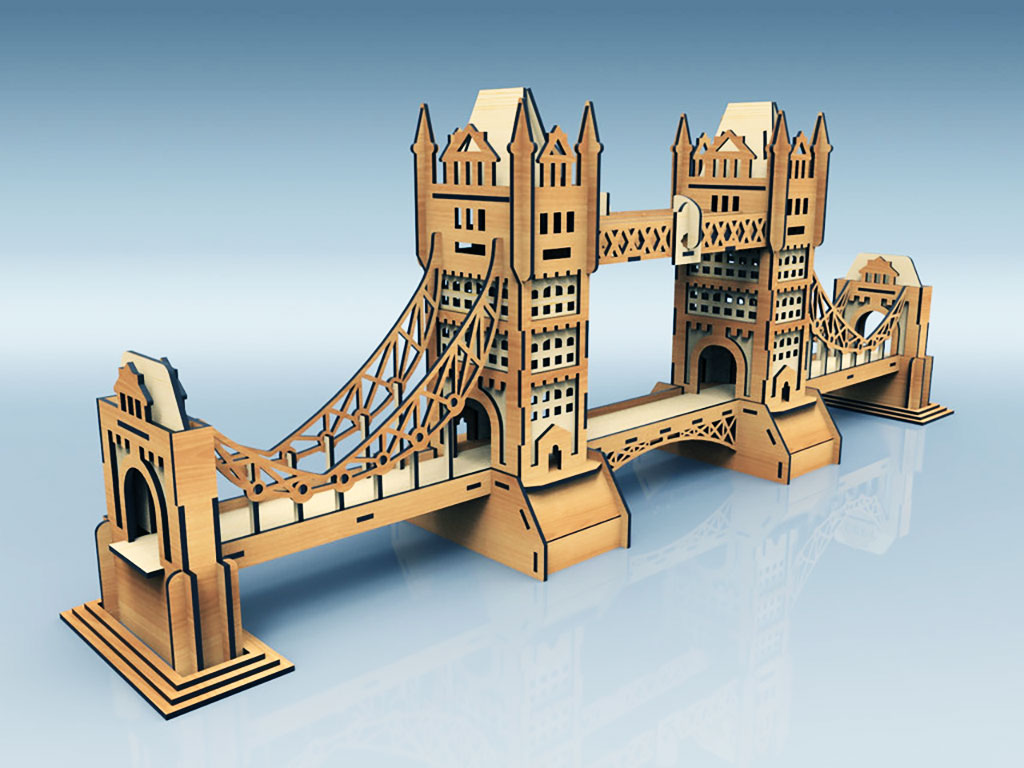

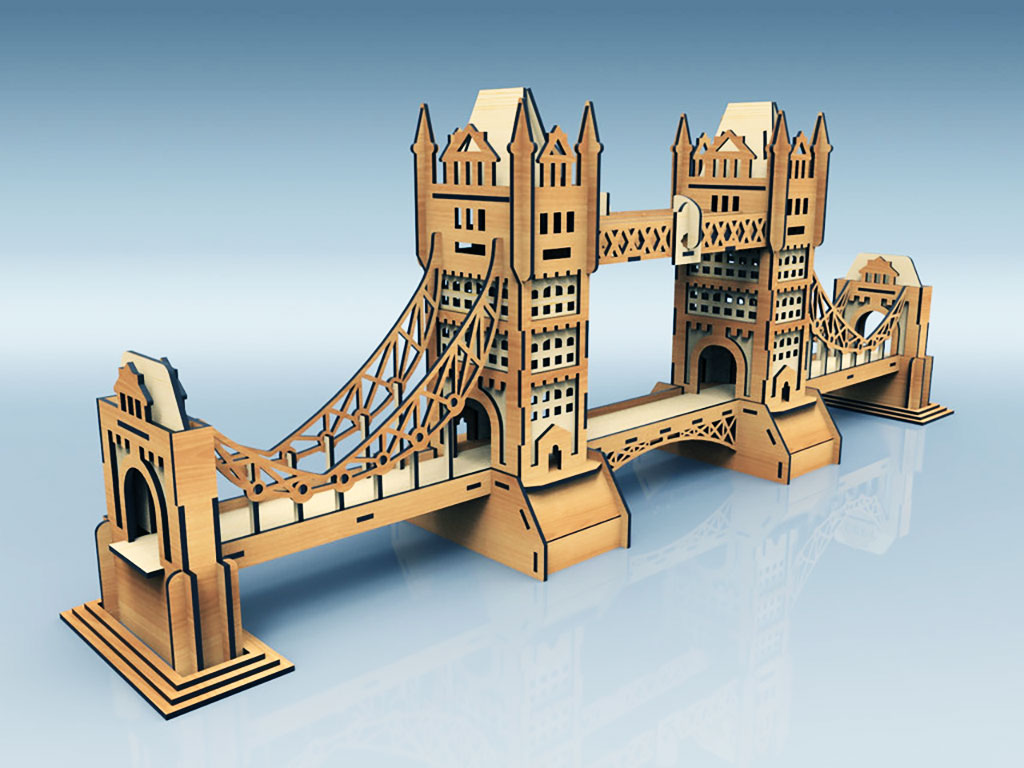

Laser cutting technology has revolutionized the fabrication industry, enabling precise and intricate designs to be created from various materials. Laser cut templates play a crucial role in this process, serving as blueprints that guide the laser cutting machine to produce accurate and consistent results. This article delves into the world of laser cut templates, exploring their types, applications, benefits, and considerations for creating and using them.

Table of Content

- 1 Laser Cut Template: A Comprehensive Guide

- 1.1 Introduction

- 1.2 H1: Types of Laser Cut Templates

- 1.2.1 H2: Acrylic Templates

- 1.2.2 H2: Metal Templates

- 1.3 H1: Applications of Laser Cut Templates

- 1.3.3 H2: Prototyping and Development

- 1.3.4 H2: Manufacturing and Fabrication

- 1.4 H1: Types of Laser Cut Templates

- 1.4.5 H2: Acrylic Templates

- 1.4.6 H2: Metal Templates

- 1.4.7 H3: Signage and Display

- 1.4.8 H3: Architectural and Interior Design

- 1.5 H1: Benefits of Using Laser Cut Templates

- 1.5.9 H2: Precision and Accuracy

- 1.5.10 H2: Speed and Efficiency

- 1.5.11 H3: Versatility and Customization

- 1.5.12 H3: Cost-Effectiveness

- 1.6 H1: Considerations for Creating and Using Laser Cut Templates

- 1.6.13 H2: Design and File Preparation

- 1.6.14 H2: Material Selection

- 1.6.15 H3: Laser Cutting Parameters

- 1.6.16 H3: Post-Processing

- 1.7 H1: Conclusion

- 1.8 FAQs

- 1.8.17 H2: What is the difference between laser cutting and CNC cutting?

- 1.8.18 H2: Can laser cut templates be used for multiple materials?

- 1.8.19 H3: How do I design a laser cut template?

- 1.8.20 H3: What are the safety precautions when using laser cut templates?

H1: Types of Laser Cut Templates

H2: Acrylic Templates

Acrylic templates are made from a durable and transparent plastic material. They are commonly used for creating prototypes, jigs, and fixtures due to their ability to withstand heat and chemicals. Acrylic templates are also easy to work with and can be cut into complex shapes.

H2: Metal Templates

Metal templates are fabricated from various metals such as steel, aluminum, and brass. They are highly durable and resistant to wear and tear, making them ideal for industrial applications. Metal templates are often used for cutting precise metal parts and components.

H1: Applications of Laser Cut Templates

Laser cut templates have a wide range of applications across various industries, including:

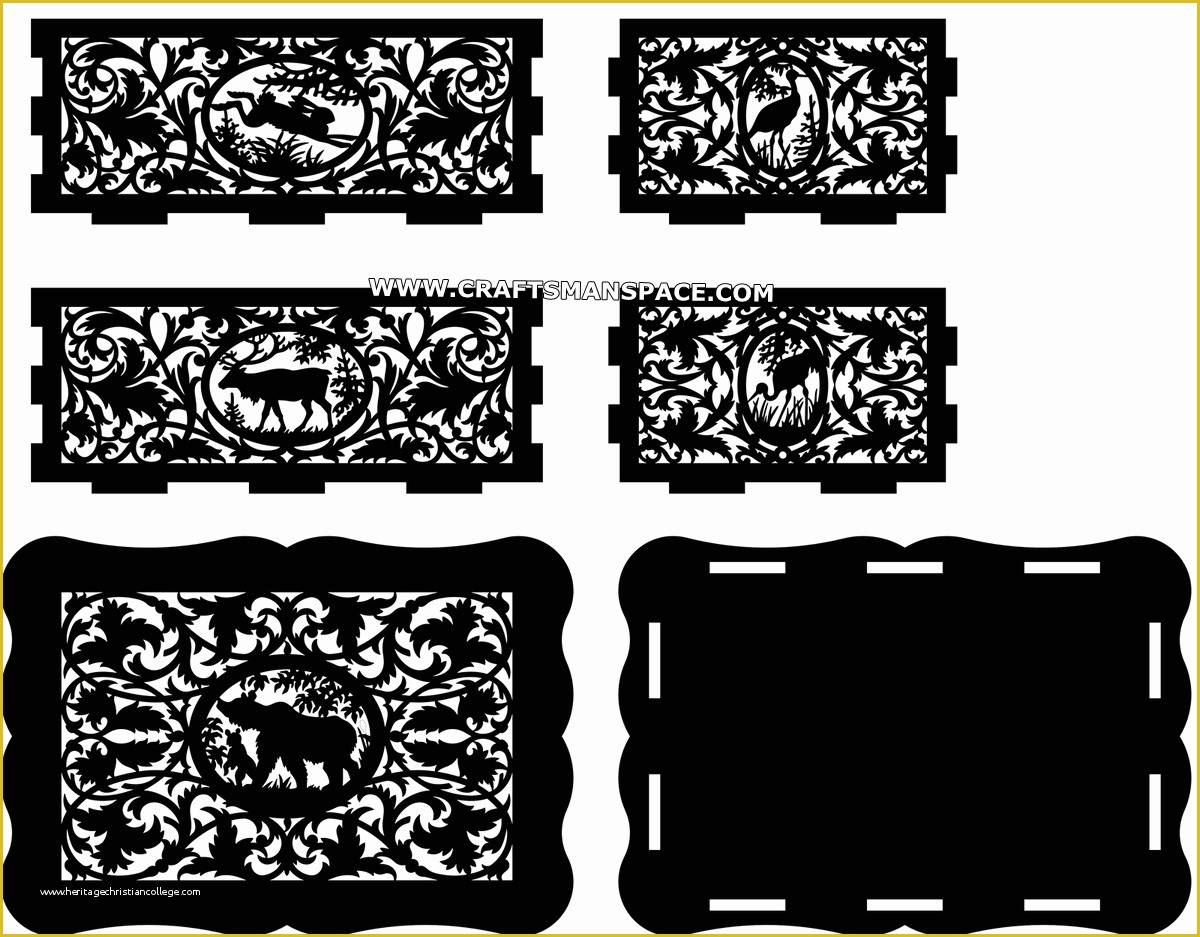

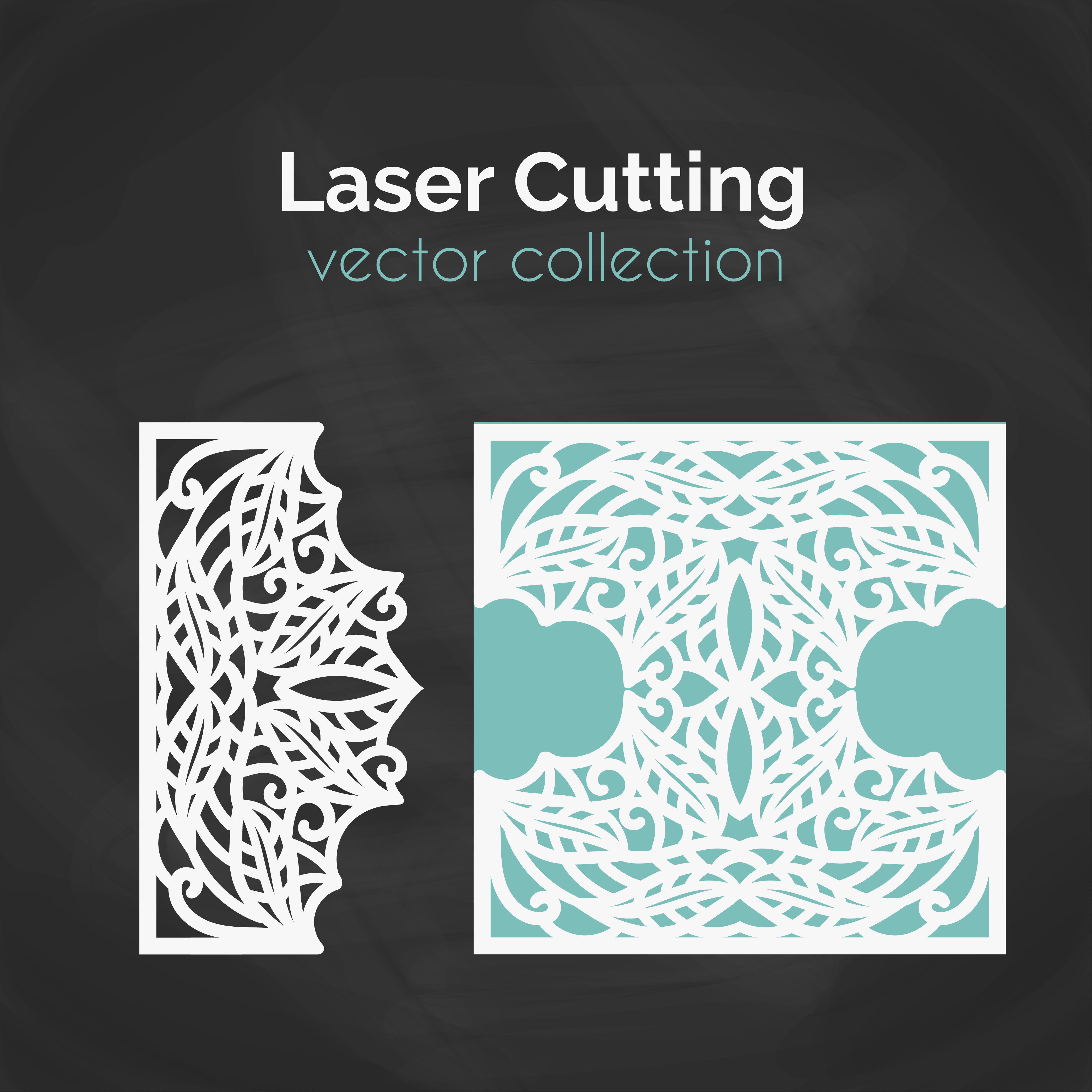

DOWNLOAD SVG FILES FOR LASER CUTTING

H2: Prototyping and Development

Laser cut templates are indispensable for creating prototypes and developing new products. They allow designers and engineers to quickly and accurately test different design iterations before committing to full-scale production.

H2: Manufacturing and Fabrication

Laser cut templates are used in manufacturing and fabrication to produce custom parts, components, and assemblies. They ensure precision and consistency in cutting, reducing errors and waste.

Laser cutting technology has revolutionized the fabrication industry, enabling precise and intricate designs to be created from various materials. Laser cut templates play a crucial role in this process, serving as blueprints that guide the laser cutting machine to produce accurate and consistent results. This article delves into the world of laser cut templates, exploring their types, applications, benefits, and considerations for creating and using them.

- Laser Cut Birthday Gifts For Her Laser Cut Birthday Gifts For Her: A Unique And Thoughtful Expression Of Love

- Laser Cut Birthday Gift Ideas Laser Cut Birthday Gift Ideas: A Creative And Personalized Touch

- Laser Cut Birthday Greeting Cards Laser Cut Birthday Greeting Cards: A Unique And Personalized Way To Celebrate

- Happy Birthday Laser Cut Free Happy Birthday Laser Cut Free: A Comprehensive Guide To Celebrate With Precision

- Laser Cut Birthday Laser Cut Birthday: A Guide To Crafting Personalized And Memorable Celebrations

H1: Types of Laser Cut Templates

Laser cut templates can be classified into two main types based on their material composition:

DOWNLOAD SVG FILES FOR LASER CUTTING

H2: Acrylic Templates

Acrylic templates are made from a durable and transparent plastic material. They are commonly used for creating prototypes, jigs, and fixtures due to their ability to withstand heat and chemicals. Acrylic templates are also easy to work with and can be cut into complex shapes.

H2: Metal Templates

H3: Signage and Display

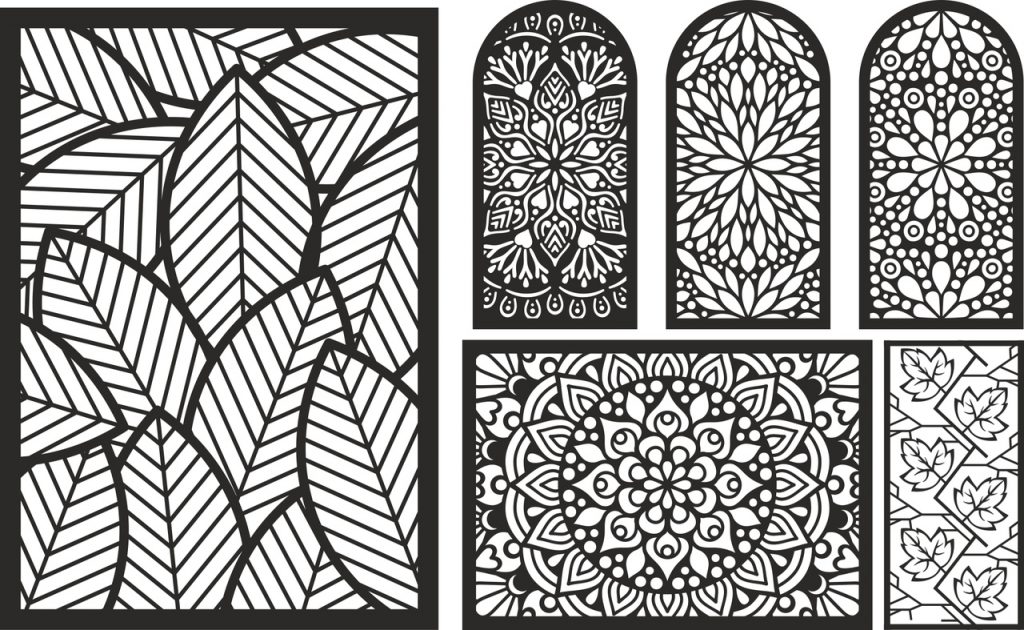

Laser cut templates are commonly employed in the production of signs, displays, and other visual communication materials. They enable the creation of intricate designs and lettering with sharp edges and smooth finishes.

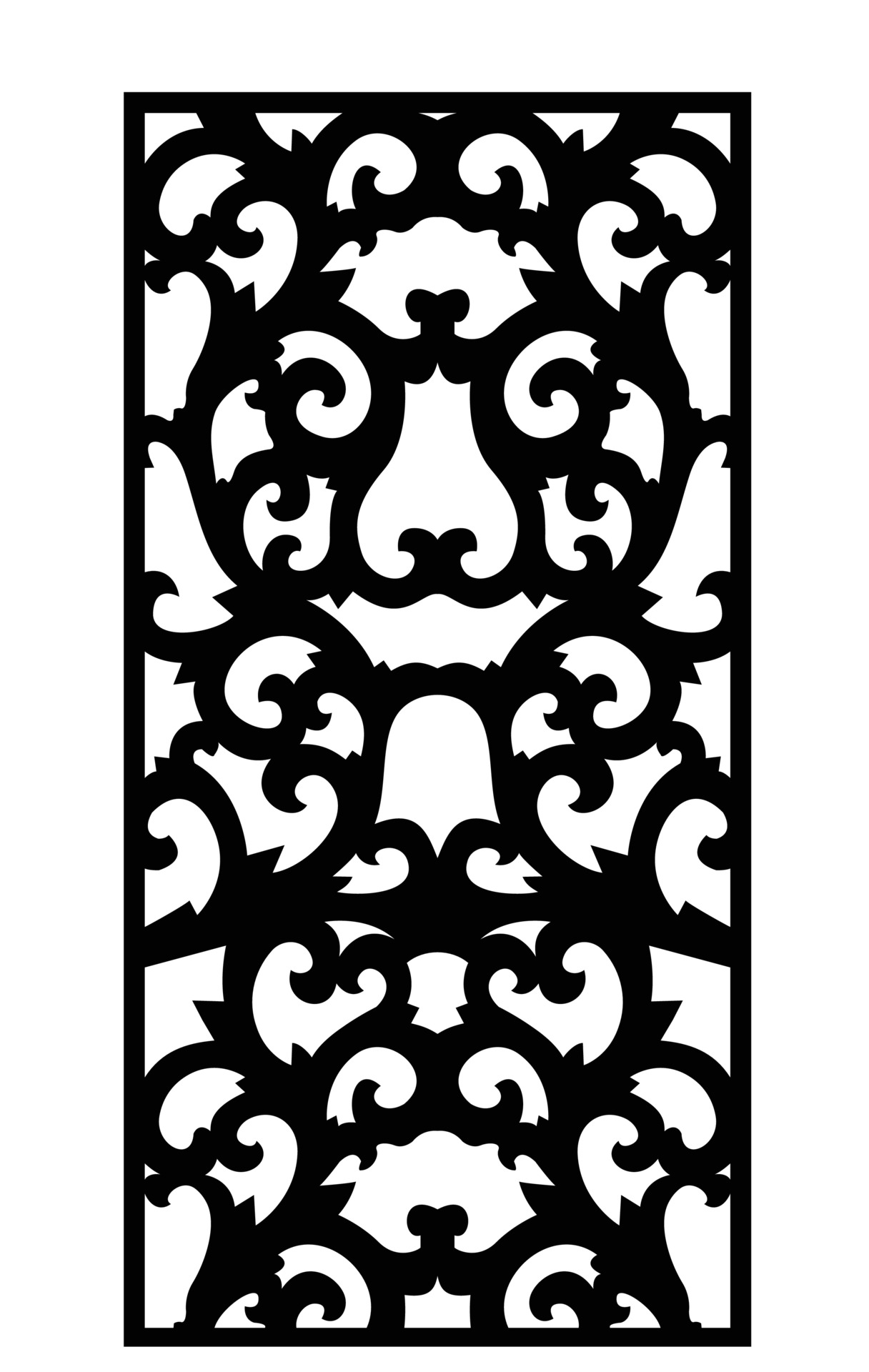

H3: Architectural and Interior Design

Laser cut templates are used in architectural and interior design to create decorative elements, such as wall panels, screens, and lighting fixtures. They add a touch of elegance and uniqueness to any space.

H1: Benefits of Using Laser Cut Templates

Laser cut templates offer several advantages over traditional methods of cutting and fabrication:

H2: Precision and Accuracy

Laser cutting technology ensures precise and accurate cuts, eliminating the need for manual adjustments or finishing. This precision is crucial for creating intricate designs and producing consistent results.

H2: Speed and Efficiency

Laser cutting is a fast and efficient process, reducing production time and increasing productivity. This speed advantage makes laser cut templates ideal for high-volume applications.

H3: Versatility and Customization

Laser cut templates can be created from a variety of materials and customized to meet specific design requirements. This versatility makes them suitable for a wide range of applications and industries.

H3: Cost-Effectiveness

While laser cutting machines require an initial investment, they can save money in the long run by reducing waste, increasing efficiency, and eliminating the need for expensive tooling.

H1: Considerations for Creating and Using Laser Cut Templates

H2: Design and File Preparation

The design of a laser cut template is critical for achieving desired results. CAD software is commonly used to create vector-based designs that accurately represent the desired shape and dimensions.

H2: Material Selection

The choice of material for a laser cut template depends on the specific application and requirements. Factors to consider include durability, heat resistance, and compatibility with the laser cutting process.

H3: Laser Cutting Parameters

Laser cutting parameters such as laser power, cutting speed, and focus must be optimized to ensure clean and precise cuts. These parameters vary depending on the material and thickness being cut.

H3: Post-Processing

Depending on the application, laser cut templates may require post-processing steps such as deburring, polishing, or painting to enhance their appearance or functionality.

H1: Conclusion

Laser cut templates are essential tools for precision cutting and fabrication across various industries. They offer numerous benefits, including accuracy, speed, versatility, and cost-effectiveness. By understanding the different types, applications, and considerations involved in creating and using laser cut templates, designers and manufacturers can leverage this technology to create innovative and high-quality products.

FAQs

H2: What is the difference between laser cutting and CNC cutting?

Laser cutting uses a laser beam to melt or vaporize material, while CNC cutting uses a rotating tool to cut material. Laser cutting offers higher precision and speed, while CNC cutting is more suitable for thicker materials.

H2: Can laser cut templates be used for multiple materials?

Yes, laser cut templates can be used for various materials, including acrylic, metal, wood, and fabric. However, the laser cutting parameters must be adjusted accordingly to suit the specific material.

H3: How do I design a laser cut template?

Laser cut templates can be designed using CAD software that supports vector graphics. The design should accurately represent the desired shape and dimensions, and the file should be saved in a compatible format for the laser cutting machine.

H3: What are the safety precautions when using laser cut templates?

When using laser cut templates, it is important to wear appropriate protective gear, including safety glasses, gloves, and a respirator. The laser cutting machine should be operated in a well-ventilated area to avoid exposure to harmful fumes.