Laser Cut Template: The Ultimate Guide to Precision Fabrication

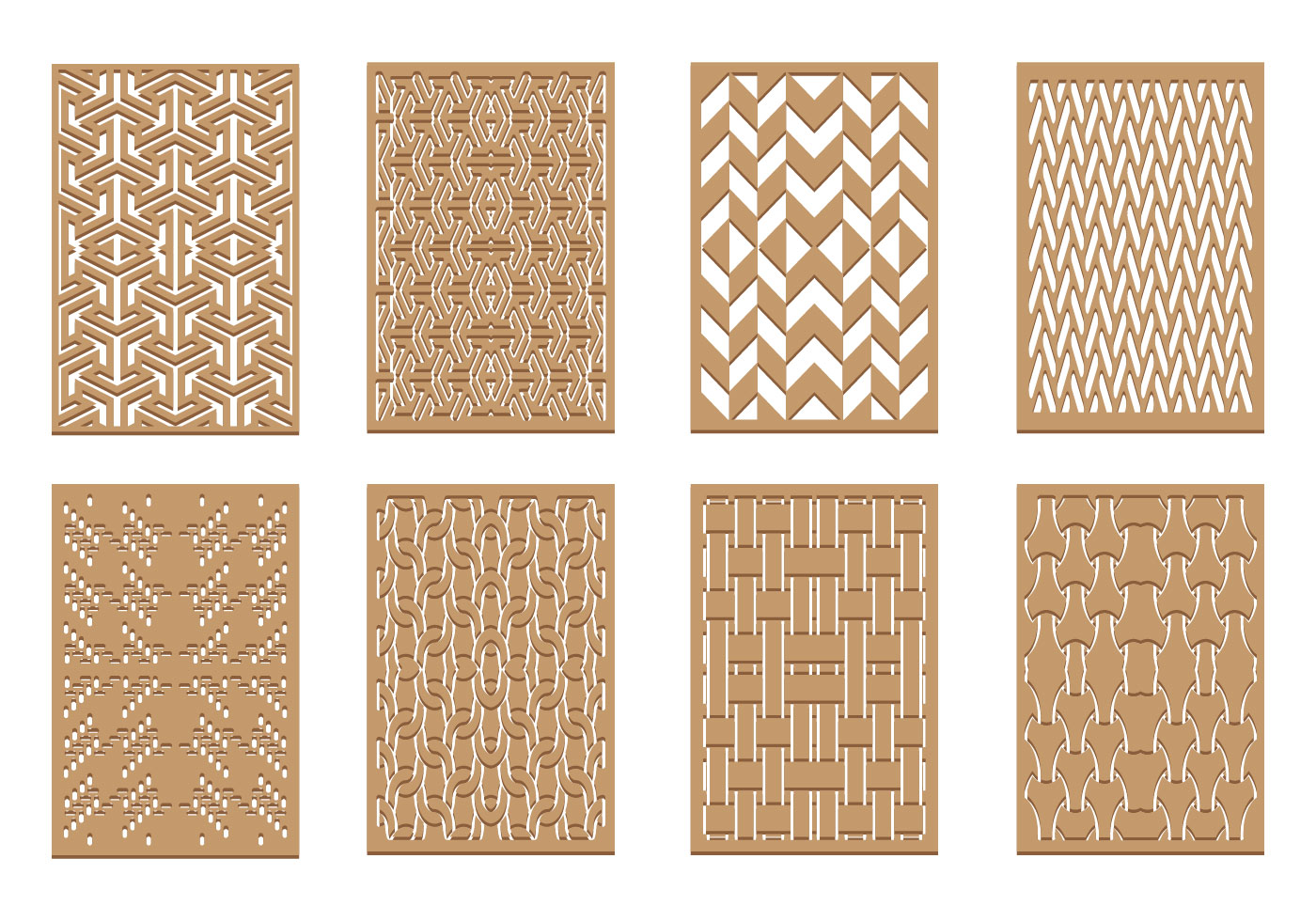

Laser cutting is a versatile and precise manufacturing technique that utilizes a focused laser beam to cut various materials, including wood, acrylic, metal, and paper. Laser cut templates are essential tools for a wide range of applications, from crafting to industrial production. This comprehensive guide will provide an in-depth understanding of laser cut templates, their benefits, and how to create them effectively.

H1: Understanding Laser Cut Templates

Table of Content

- 1 Laser Cut Template: The Ultimate Guide to Precision Fabrication

- 1.1 H1: Understanding Laser Cut Templates

- 1.2 H3: Creating Laser Cut Templates

- 1.3 H4: Applications of Laser Cut Templates

- 1.4 H1: Understanding Laser Cut Templates

- 1.5 H2: Benefits of Laser Cut Templates

- 1.6 H5: Conclusion

- 1.7 H6: FAQs

Laser cut templates are pre-designed patterns or shapes that guide a laser cutter to create precise cuts in the desired material. These templates can be created using CAD software and saved as digital files. When loaded into a laser cutter, the template controls the movement of the laser beam, ensuring accuracy and consistency in the final product.

1. Precision and Accuracy: Laser cut templates eliminate human error and ensure precise cuts, even for intricate designs. The laser beam follows the template precisely, resulting in clean and accurate edges.

2. Time-Saving: Laser cutting with templates significantly reduces production time compared to manual cutting methods. The laser cutter can cut multiple pieces simultaneously, making it an efficient solution for high-volume production.

3. Material Versatility: Laser cut templates can be used with a wide range of materials, including wood, acrylic, metal, paper, and fabric. This versatility allows for a variety of applications and material choices.

4. Customization: Laser cut templates can be easily customized to meet specific project requirements. Designers can create unique patterns, shapes, and logos to enhance the aesthetics and functionality of their products.

H3: Creating Laser Cut Templates

1. Design Software: Laser cut templates are typically created using computer-aided design (CAD) software. Popular CAD programs include AutoCAD, Inkscape, and Adobe Illustrator. These programs provide the necessary tools to design and manipulate shapes, lines, and curves.

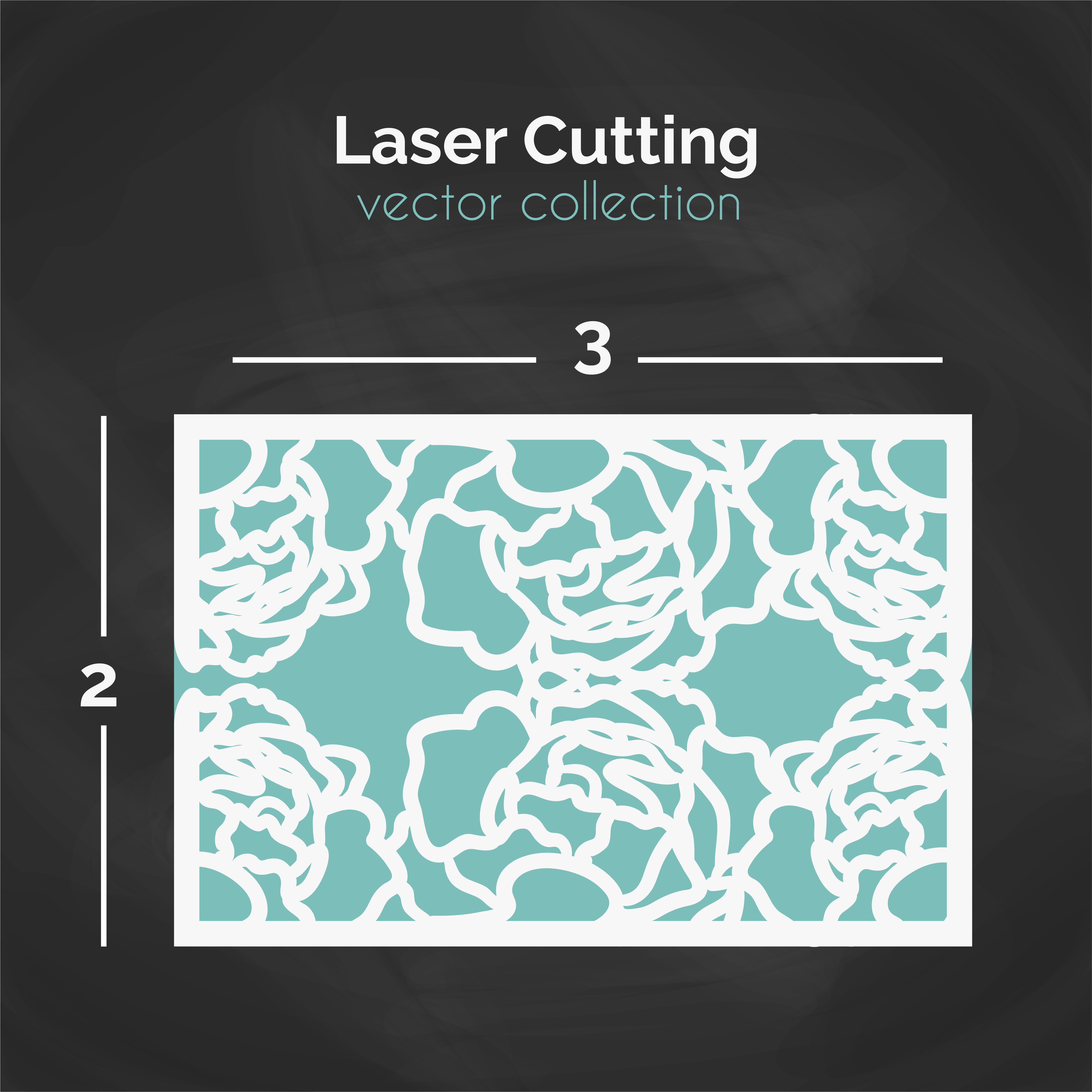

DOWNLOAD SVG FILES FOR LASER CUTTING

2. File Formats: Laser cutters require specific file formats to interpret the template design. Common file formats include DXF, SVG, and AI. The CAD software should be able to export the template in the appropriate file format.

3. Material Considerations: When designing laser cut templates, it is crucial to consider the material being cut. Different materials have varying cutting parameters, such as laser power and speed, which must be adjusted accordingly.

4. Test Cuts: Before cutting the actual material, it is advisable to perform test cuts on scrap material to ensure optimal settings and accuracy. This helps prevent costly mistakes and material wastage.

H4: Applications of Laser Cut Templates

H1: Understanding Laser Cut Templates

- Laser Cut Cat Birthday Card Laser Cut Cat Birthday Card: A Purr-fect Way To Celebrate Your Feline Friend

- Laser Cut Birthday Party Laser Cut Birthday Party: A Unique And Memorable Celebration

- Laser Cut Birthday Decor H1: Laser Cut Birthday Decor: Elevate Your Celebrations With Precision And Style

- Laser Cut Paper Box Laser Cut Paper Box: An Exquisite Craft For Unparalleled Presentations

- Laser Cut Birthday Laser Cut Birthday: A Guide To Crafting Personalized And Memorable Celebrations

Laser cut templates are pre-designed patterns or shapes that guide a laser cutter to create precise cuts in the desired material. These templates can be created using CAD software and saved as digital files. When loaded into a laser cutter, the template controls the movement of the laser beam, ensuring accuracy and consistency in the final product.

H2: Benefits of Laser Cut Templates

DOWNLOAD SVG FILES FOR LASER CUTTING

1. Precision and Accuracy: Laser cut templates eliminate human error and ensure precise cuts, even for intricate designs. The laser beam follows the template precisely, resulting in clean and accurate edges.

2. Time-Saving: Laser cutting with templates significantly reduces production time compared to manual cutting methods. The laser cutter can cut multiple pieces simultaneously, making it an efficient solution for high-volume production.

3. Material Versatility: Laser cut templates can be used with a wide range of materials, including wood, acrylic, metal, paper, and fabric. This versatility allows for a variety of applications and material choices.

1. Crafting: Laser cut templates are widely used in crafting, such as scrapbooking, card making, and jewelry making. They allow for precise cutting of intricate designs, enhancing the aesthetics and personalization of handmade items.

2. Industrial Production: In industrial manufacturing, laser cut templates are used for cutting metal parts, electronic components, and other precision components. The accuracy and repeatability of laser cutting make it ideal for high-volume production.

3. Architectural Modeling: Laser cut templates are also utilized in architectural modeling to create miniature models of buildings and structures. The precise cuts and detail reproduction capabilities make them valuable for architects and model makers.

4. Education and Research: Laser cut templates are used in educational institutions and research facilities to create prototypes, models, and teaching aids. The versatility and accuracy of laser cutting make it a valuable tool for hands-on learning and experimentation.

H5: Conclusion

Laser cut templates are essential tools for precision fabrication, offering numerous benefits such as accuracy, time-saving, and material versatility. By understanding the principles of laser cutting and utilizing appropriate design software, users can create custom templates to meet the specific requirements of their projects. Laser cut templates find applications in various fields, from crafting to industrial production, providing a cost-effective and efficient solution for cutting intricate designs and precision components.

H6: FAQs

1. What is the best software for creating laser cut templates?

Popular software options for creating laser cut templates include AutoCAD, Inkscape, and Adobe Illustrator.

2. What file formats are compatible with laser cutters?

Common file formats for laser cutters include DXF, SVG, and AI.

3. How do I adjust laser cutting parameters for different materials?

Laser cutting parameters, such as power and speed, vary depending on the material being cut. Refer to manufacturer specifications or perform test cuts to determine optimal settings.

4. How can I prevent warping or distortion during laser cutting?

To prevent warping or distortion, use appropriate laser cutting techniques, such as using a raster pattern for thicker materials or applying a protective layer to the material surface.

5. What are the safety precautions for laser cutting?

Laser cutting involves the use of high-powered lasers. Always follow safety precautions, such as wearing proper protective eyewear and operating the laser cutter in a well-ventilated area.