Laser Cutting Board: A Comprehensive Guide to Advanced Manufacturing

Introduction

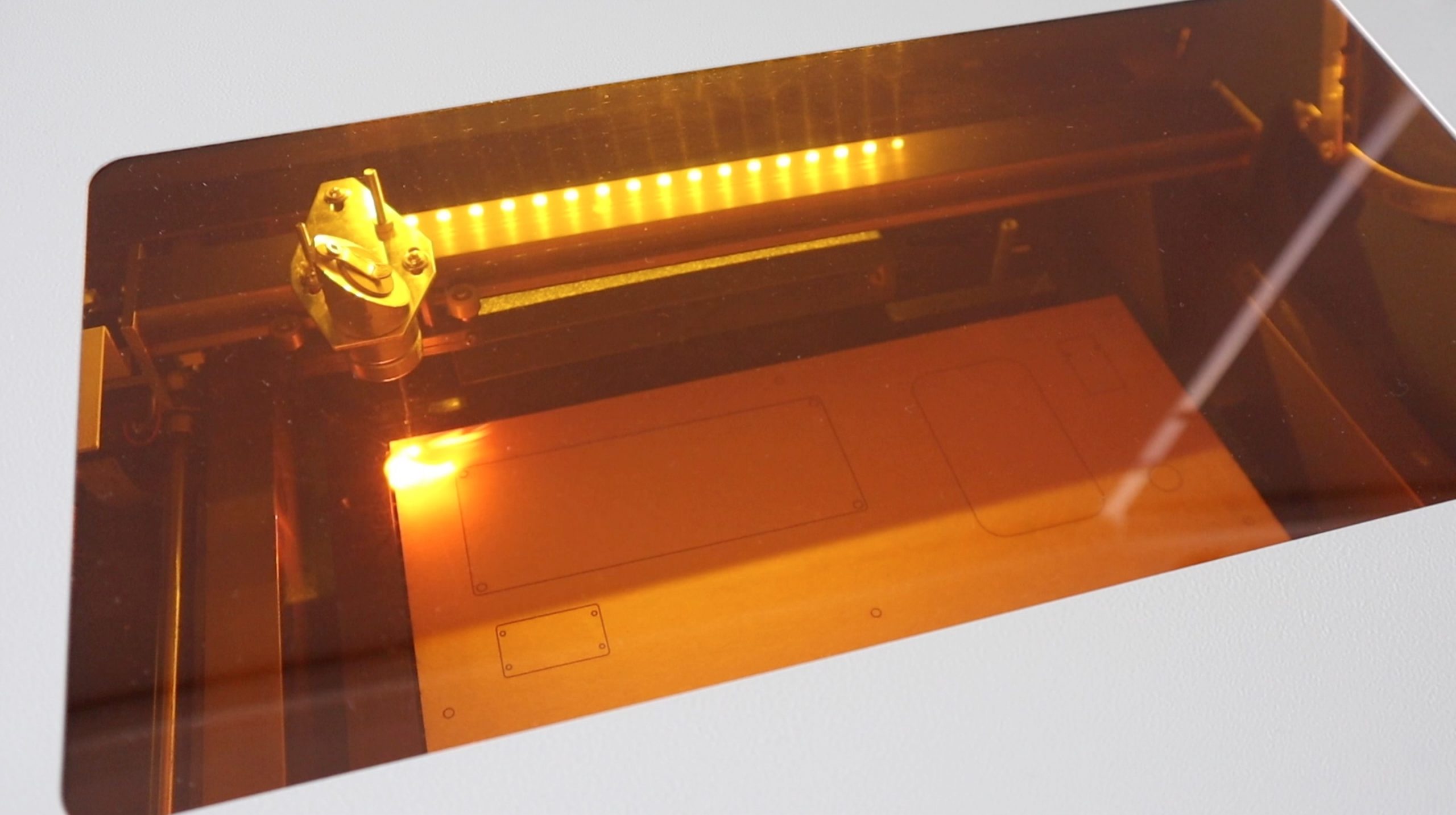

Laser cutting, a revolutionary technology, has transformed the manufacturing industry, offering unparalleled precision and efficiency. Laser cutting boards, equipped with advanced laser technology, enable the precise cutting of various materials, including wood, metal, acrylic, and plastics. This article delves into the intricacies of laser cutting boards, exploring their advantages, applications, and the factors to consider when selecting the ideal board for your specific needs.

Table of Content

Advantages of Laser Cutting Boards

2. Versatility: Laser cutting boards can cut a wide range of materials, from delicate fabrics to thick metals. This versatility makes them suitable for various industries, including manufacturing, prototyping, and art and design.

3. Non-Contact Process: Unlike traditional cutting methods that involve physical contact, laser cutting is a non-contact process. This eliminates the risk of tool wear and tear, resulting in longer tool life and reduced maintenance costs.

4. High Speed and Efficiency: Laser cutting boards operate at high speeds, significantly reducing production time. The automated process allows for continuous cutting, further enhancing efficiency.

Applications of Laser Cutting Boards

Laser cutting boards find applications in numerous industries, including:

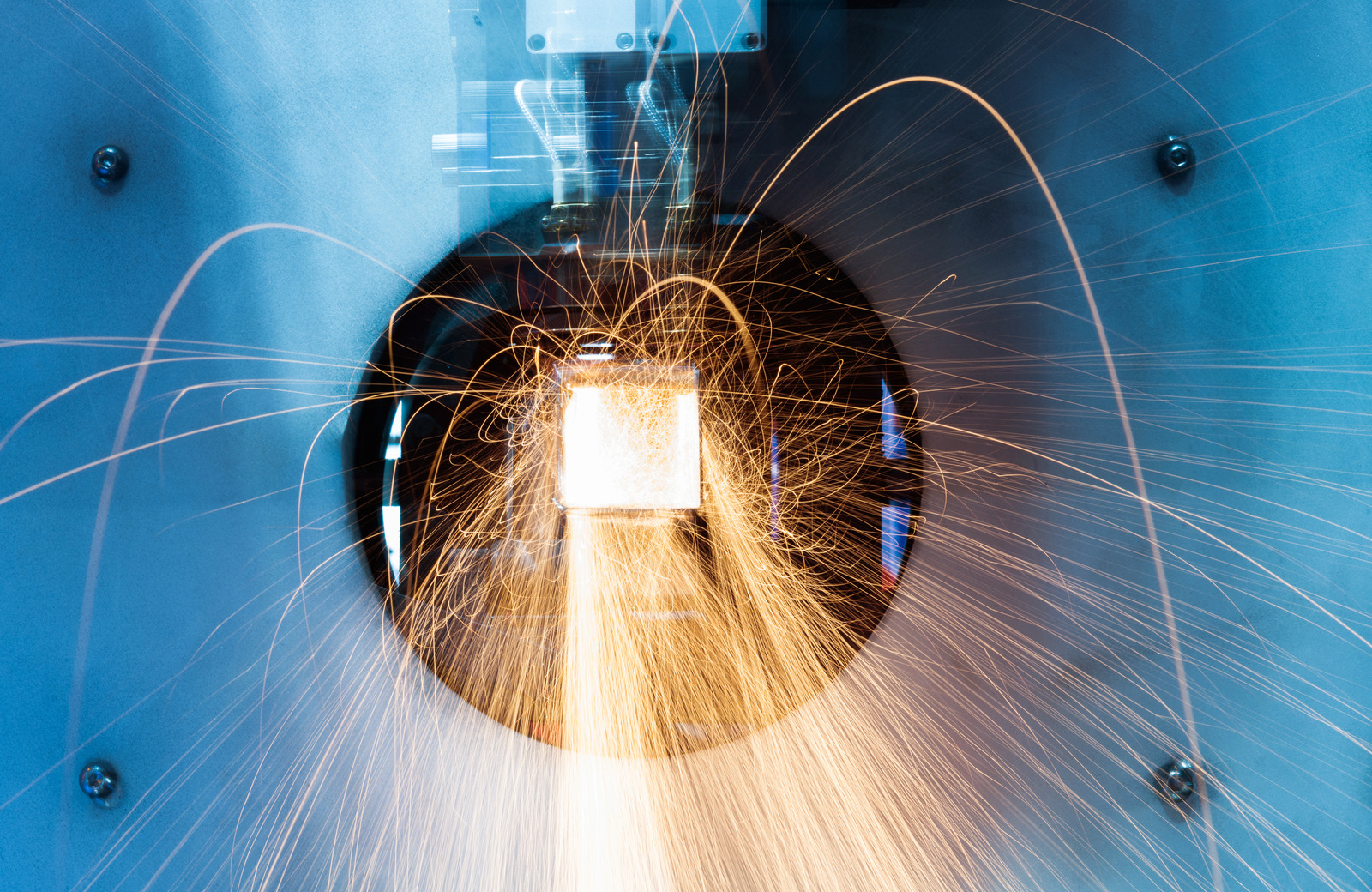

1. Manufacturing: Precision cutting of metal components, plastic parts, and electronic devices.

DOWNLOAD SVG FILES FOR LASER CUTTING

2. Prototyping: Rapid prototyping of new designs and products, enabling quick testing and iteration.

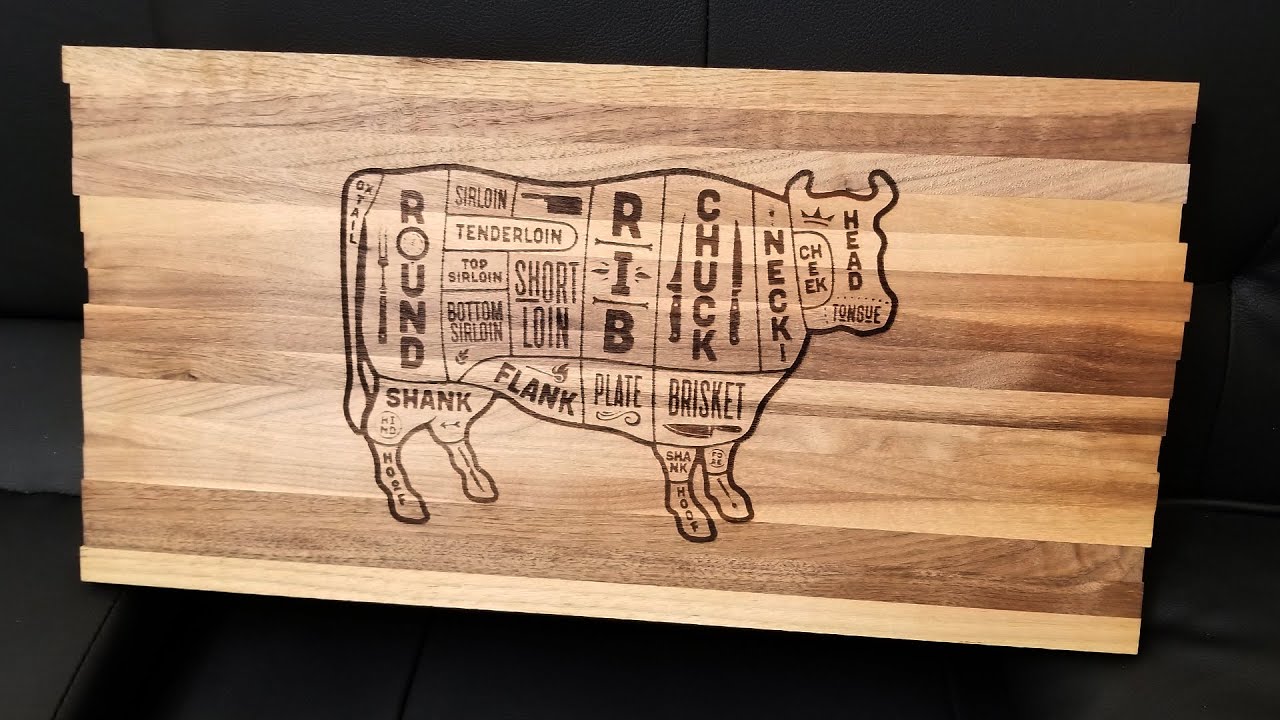

3. Art and Design: Creating intricate artwork, sculptures, and decorative pieces from wood, acrylic, and other materials.

4. Medical Device Manufacturing: High-precision cutting of medical devices and surgical instruments, ensuring accuracy and reliability.

Factors to Consider When Selecting a Laser Cutting Board

Laser cutting, a revolutionary technology, has transformed the manufacturing industry, offering unparalleled precision and efficiency. Laser cutting boards, equipped with advanced laser technology, enable the precise cutting of various materials, including wood, metal, acrylic, and plastics. This article delves into the intricacies of laser cutting boards, exploring their advantages, applications, and the factors to consider when selecting the ideal board for your specific needs.

- Laser Cutting Board Laser Cutting Board: A Comprehensive Guide

- Laser Cut Happy Birthday Card Laser Cut Happy Birthday Card: A Guide To Creating Unique And Personalized Celebrations

- Laser Cut Box Laser Cut Box: A Comprehensive Guide To Customization And Precision

- Laser Cut Wood Birthday Invitations Laser Cut Wood Birthday Invitations: Elevate Your Celebrations With Unforgettable Invites

- Happy Birthday Laser Cut File Happy Birthday Laser Cut File: A Comprehensive Guide For Crafting Personalized Celebrations

Advantages of Laser Cutting Boards

1. Precision and Accuracy: Laser cutting boards employ highly focused laser beams, resulting in extremely precise and accurate cuts. The laser’s ability to follow complex contours and create intricate designs sets it apart from traditional cutting methods.

DOWNLOAD SVG FILES FOR LASER CUTTING

2. Versatility: Laser cutting boards can cut a wide range of materials, from delicate fabrics to thick metals. This versatility makes them suitable for various industries, including manufacturing, prototyping, and art and design.

3. Non-Contact Process: Unlike traditional cutting methods that involve physical contact, laser cutting is a non-contact process. This eliminates the risk of tool wear and tear, resulting in longer tool life and reduced maintenance costs.

4. High Speed and Efficiency: Laser cutting boards operate at high speeds, significantly reducing production time. The automated process allows for continuous cutting, further enhancing efficiency.

1. Laser Power: The power of the laser determines the thickness and type of materials that can be cut. Higher power lasers can cut thicker materials more efficiently.

2. Bed Size: The bed size determines the maximum size of the materials that can be cut. Consider the size of the materials you need to cut when selecting a laser cutting board.

3. Material Compatibility: Ensure that the laser cutting board is compatible with the materials you intend to cut. Different materials may require different laser wavelengths and cutting parameters.

4. Software Compatibility: The software used to control the laser cutting board should be compatible with your design software. This ensures seamless integration and efficient workflow.

Conclusion

Laser cutting boards have revolutionized manufacturing and prototyping processes, offering unparalleled precision, versatility, and efficiency. By understanding the advantages, applications, and factors to consider when selecting a laser cutting board, you can harness this technology to enhance your productivity and achieve exceptional results.

FAQs

1. What is the difference between laser engraving and laser cutting?

Laser engraving involves marking or etching the surface of a material, while laser cutting completely cuts through the material.

2. Can laser cutting boards cut glass?

Yes, laser cutting boards can cut glass, but specialized glass-cutting lasers are required for optimal results.

3. What safety precautions should be taken when using laser cutting boards?

Wear appropriate safety gear, such as laser safety glasses and protective clothing, and ensure proper ventilation to avoid exposure to harmful fumes.