Laser Cutting Karton: A Comprehensive Guide for Precise and Efficient Fabrication

Introduction

Karton, a versatile material composed of paperboard, finds widespread use in packaging, displays, and various industrial applications. Laser cutting, a cutting-edge technology, offers exceptional precision and efficiency in shaping karton into complex and intricate designs. This article delves into the intricacies of laser cutting karton, providing a comprehensive guide for achieving optimal results.

Table of Content

- 1 Laser Cutting Karton: A Comprehensive Guide for Precise and Efficient Fabrication

- 1.1 Introduction

- 1.2 Understanding Laser Cutting

- 1.3 Laser Cutting Karton: Advantages

- 1.4 Laser Cutting Parameters

- 1.5 Understanding Laser Cutting

- 1.6 Laser Cutting Karton: Advantages

- 1.7 Material Considerations

- 1.8 Design Considerations

- 1.9 Applications of Laser Cutting Karton

- 1.10 Conclusion

- 1.11 Frequently Asked Questions (FAQs)

Understanding Laser Cutting

Laser Cutting Karton: Advantages

Laser cutting karton offers numerous advantages over traditional cutting methods:

- Precision: Laser cutting provides unparalleled precision, allowing for intricate and detailed designs with minimal distortion.

- Speed: Laser cutters operate at high speeds, significantly reducing production time compared to manual cutting or die cutting.

- Versatility: Laser cutting can handle a wide range of karton thicknesses and densities, making it suitable for various applications.

- Clean Cuts: The laser beam vaporizes or melts the karton, resulting in clean and burr-free cuts without the need for additional finishing.

- Automation: Laser cutters can be automated, reducing labor costs and increasing productivity.

DOWNLOAD SVG FILES FOR LASER CUTTING

Laser Cutting Parameters

Karton, a versatile material composed of paperboard, finds widespread use in packaging, displays, and various industrial applications. Laser cutting, a cutting-edge technology, offers exceptional precision and efficiency in shaping karton into complex and intricate designs. This article delves into the intricacies of laser cutting karton, providing a comprehensive guide for achieving optimal results.

- Laser Cut Birthday Gifts Laser Cut Birthday Gifts: The Perfect Way To Personalize Your Celebrations

- Laser Cut Cat Birthday Card Laser Cut Cat Birthday Card: A Purr-fect Way To Celebrate Your Feline Friend

- Laser Cut Birthday Cards Laser Cut Birthday Cards: A Unique And Elegant Way To Celebrate

- Laser Cut Birthday Laser Cut Birthday: A Guide To Crafting Personalized And Memorable Celebrations

- Laser Cut 30th Birthday Card Laser Cut 30th Birthday Card: A Timeless Keepsake For A Milestone Celebration

Understanding Laser Cutting

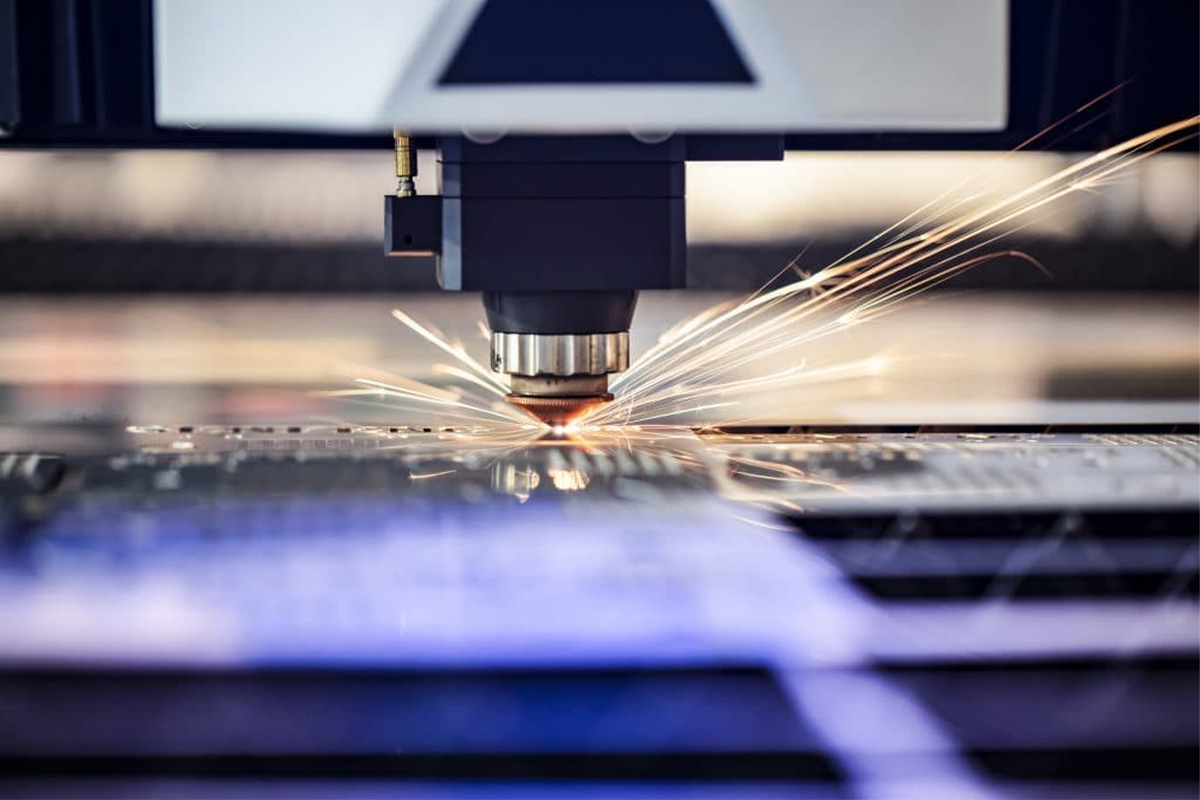

Laser cutting is a non-contact process that utilizes a highly focused laser beam to vaporize or melt material, resulting in clean and precise cuts. The laser beam is generated by a laser source and directed through a series of mirrors and lenses to the target material.

DOWNLOAD SVG FILES FOR LASER CUTTING

Laser Cutting Karton: Advantages

Laser cutting karton offers numerous advantages over traditional cutting methods:

- Laser Power: The power of the laser beam determines the cutting speed and edge quality.

- Laser Wavelength: The wavelength of the laser beam affects the absorption and interaction with the karton material.

- Cutting Speed: The speed at which the laser beam moves across the karton influences the cut quality and productivity.

- Gas Assist: Inert gases such as nitrogen or helium are used to assist the laser cutting process, reducing oxidation and improving cut quality.

- Thickness: Karton thickness affects the laser cutting speed and power requirements.

- Density: The density of karton influences the absorption of the laser beam and the resulting cut quality.

- Coating: Coatings on karton can affect the laser cutting process and require specific laser parameters.

- Kerf Width: The kerf width, which refers to the width of the laser-cut line, must be taken into account when designing parts.

- Material Strength: Laser cutting can weaken the material along the cut lines, so it is crucial to consider the structural integrity of the design.

- Tolerances: Laser cutting offers tight tolerances, but it is essential to specify the required tolerances for accurate part production.

- Packaging: Precision-cut karton boxes, displays, and inserts for packaging and presentation.

- Architecture: Intricate models, scale replicas, and architectural elements for design and visualization.

- Industrial: Gaskets, seals, and other components for industrial machinery and equipment.

- Art and Design: Unique and intricate artworks, sculptures, and decorative items.

To achieve optimal results in laser cutting karton, it is crucial to select the appropriate laser cutting parameters. These parameters include:

Material Considerations

The type and quality of karton play a significant role in laser cutting results. Factors to consider include:

Design Considerations

When designing for laser cutting karton, it is essential to consider the following:

Applications of Laser Cutting Karton

Laser cutting karton finds application in a wide range of industries, including:

Conclusion

Laser cutting karton is a versatile and efficient technology that offers exceptional precision, speed, and versatility. By understanding the principles of laser cutting, selecting the appropriate parameters, and considering the material and design factors, it is possible to achieve optimal results in laser cutting karton. This technology empowers designers, manufacturers, and artists to create complex and innovative products and designs.

Frequently Asked Questions (FAQs)

Q: What is the best laser type for cutting karton?

A: CO2 lasers are commonly used for cutting karton due to their high power and wavelength compatibility with the material.

Q: How can I reduce the risk of karton burning during laser cutting?

A: Using inert gases as assist gas and optimizing laser parameters can minimize burning.

Q: Can laser cutting karton create three-dimensional shapes?

A: While laser cutting typically produces two-dimensional cuts, combining it with other techniques such as scoring and folding can create three-dimensional shapes.

Q: What are the environmental implications of laser cutting karton?

A: Laser cutting karton is a relatively eco-friendly process, as it does not produce toxic fumes or waste materials.

Q: Is laser cutting karton suitable for high-volume production?

A: Yes, laser cutting is well-suited for high-volume production due to its speed and automation capabilities.