Acrylic Laser Cutting 3D Printer: Revolutionizing Fabrication with Precision and Efficiency

Introduction

Acrylic laser cutting 3D printers have emerged as a transformative technology in the realm of fabrication. These advanced machines harness the power of lasers to precisely cut and shape acrylic materials, enabling the creation of intricate and complex 3D objects. In this comprehensive guide, we will delve into the intricacies of acrylic laser cutting 3D printers, exploring their capabilities, benefits, and applications.

Table of Content

- 1 Acrylic Laser Cutting 3D Printer: Revolutionizing Fabrication with Precision and Efficiency

- 1.1 Introduction

- 1.2 H1: Understanding Acrylic Laser Cutting 3D Printers

- 1.3 H2: Advantages of Acrylic Laser Cutting 3D Printers

- 1.4 H1: Understanding Acrylic Laser Cutting 3D Printers

- 1.5 H3: Applications of Acrylic Laser Cutting 3D Printers

- 1.6 H2: Considerations for Choosing an Acrylic Laser Cutting 3D Printer

- 1.7 H3: Conclusion

- 1.8 Frequently Asked Questions (FAQs)

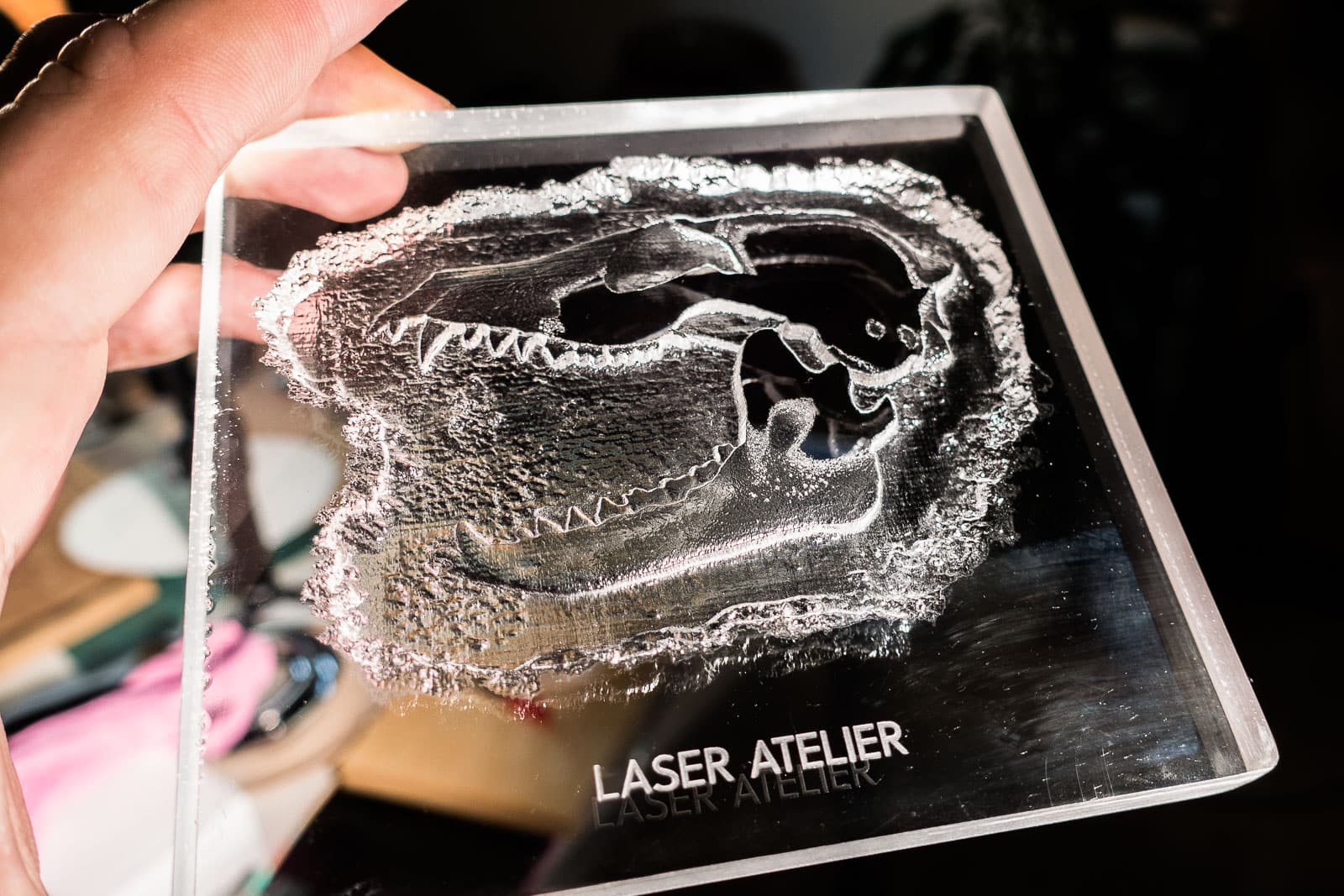

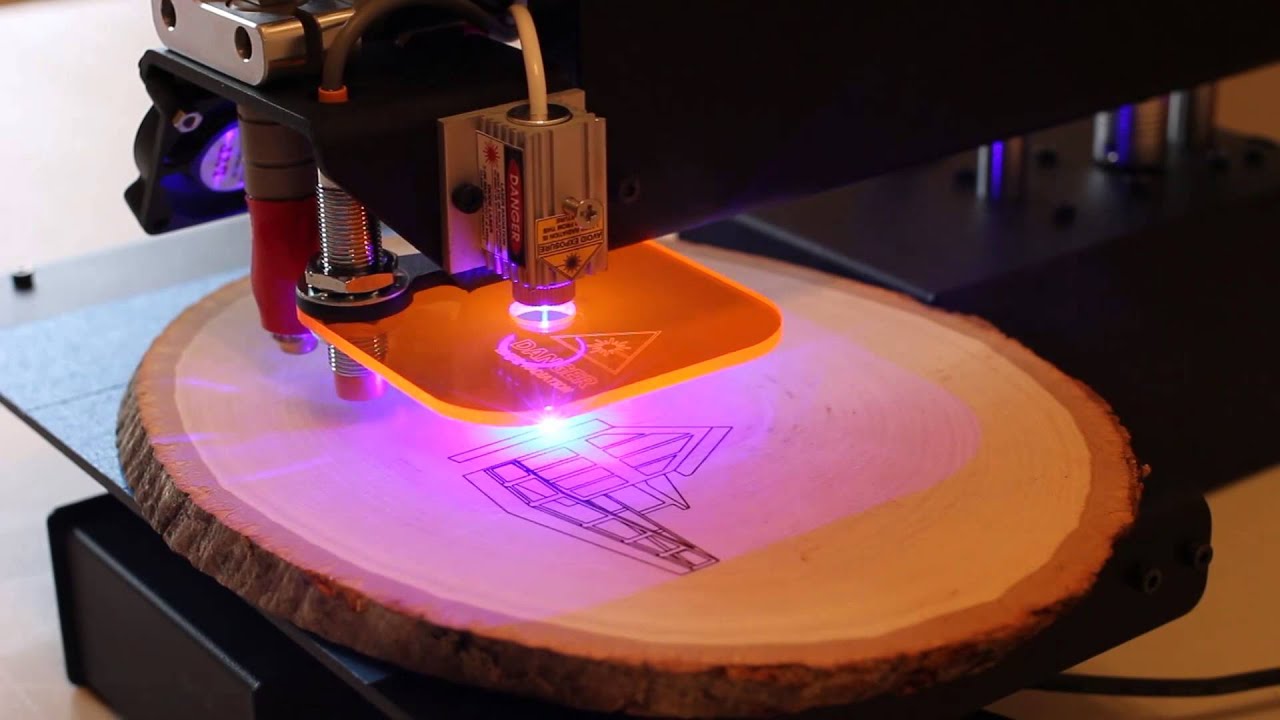

H1: Understanding Acrylic Laser Cutting 3D Printers

- Laser Beam Generation: The laser is generated within the printer’s laser source, typically a CO2 or fiber laser.

- Material Positioning: The acrylic sheet is placed on the printer’s bed and secured.

- Laser Cutting: The laser beam is directed onto the acrylic sheet, following the path defined by the CAD software. The laser vaporizes the material, creating a precise cut.

- 3D Object Creation: By stacking and bonding multiple cut acrylic layers, complex 3D objects can be fabricated.

H2: Advantages of Acrylic Laser Cutting 3D Printers

Acrylic laser cutting 3D printers offer numerous advantages over traditional fabrication methods:

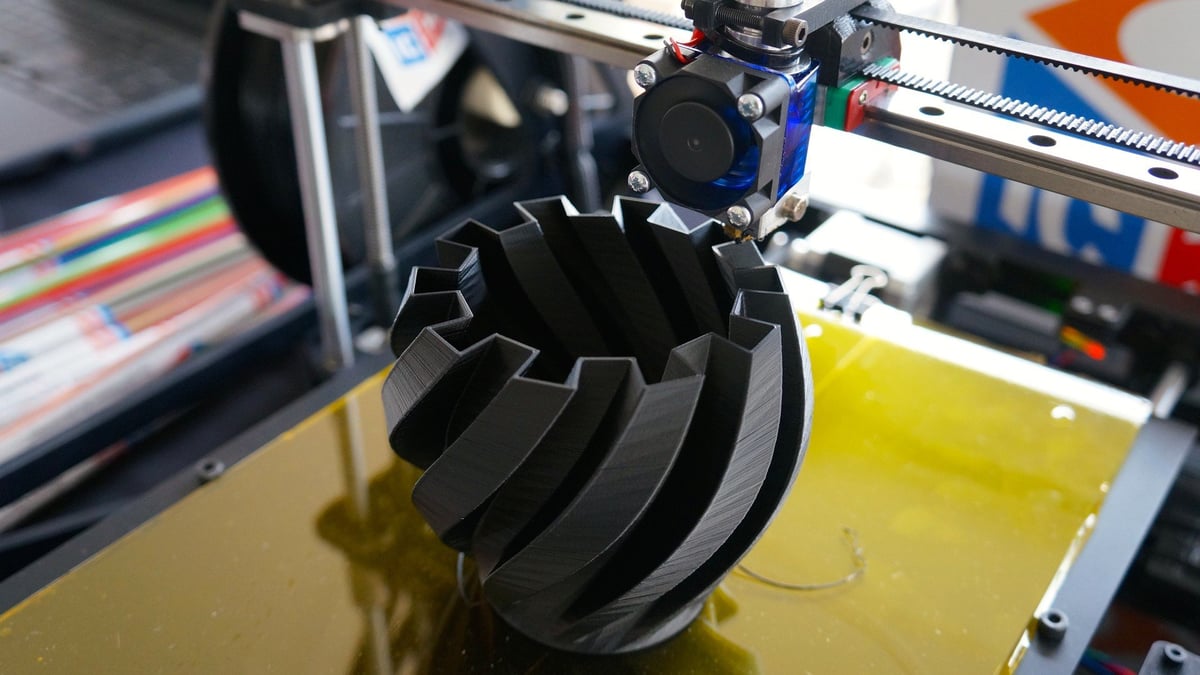

- Precision and Accuracy: The laser beam provides exceptional precision and accuracy, enabling the creation of intricate details and complex geometries.

- 3d 5 Axis Laser Cutting Machine 3D 5-Axis Laser Cutting Machine: A Comprehensive Guide

- How To Laser Cut A 3d Model How To Laser Cut A 3D Model: A Comprehensive Guide

- 3d Laser Cut Tree 3D Laser Cut Tree: A Revolutionary Home Décor Element

- Laser Cut 3d Numbers Laser Cut 3D Numbers: A Comprehensive Guide

- 3d Laser Cut Flower 3D Laser Cut Flowers: A Guide To Design, Creation, And Applications

- Laser Beam Generation: The laser is generated within the printer’s laser source, typically a CO2 or fiber laser.

- Material Positioning: The acrylic sheet is placed on the printer’s bed and secured.

- Speed and Efficiency: Laser cutting is a fast and efficient process, making it ideal for high-volume production.

- Material Versatility: Acrylic laser cutting printers can process a wide range of acrylic materials, including clear, colored, and textured acrylic.

- Smooth Edges: The laser’s focused beam creates smooth and polished edges on the cut pieces, minimizing the need for post-processing.

- Low Maintenance: Laser cutting systems require minimal maintenance, making them a cost-effective solution.

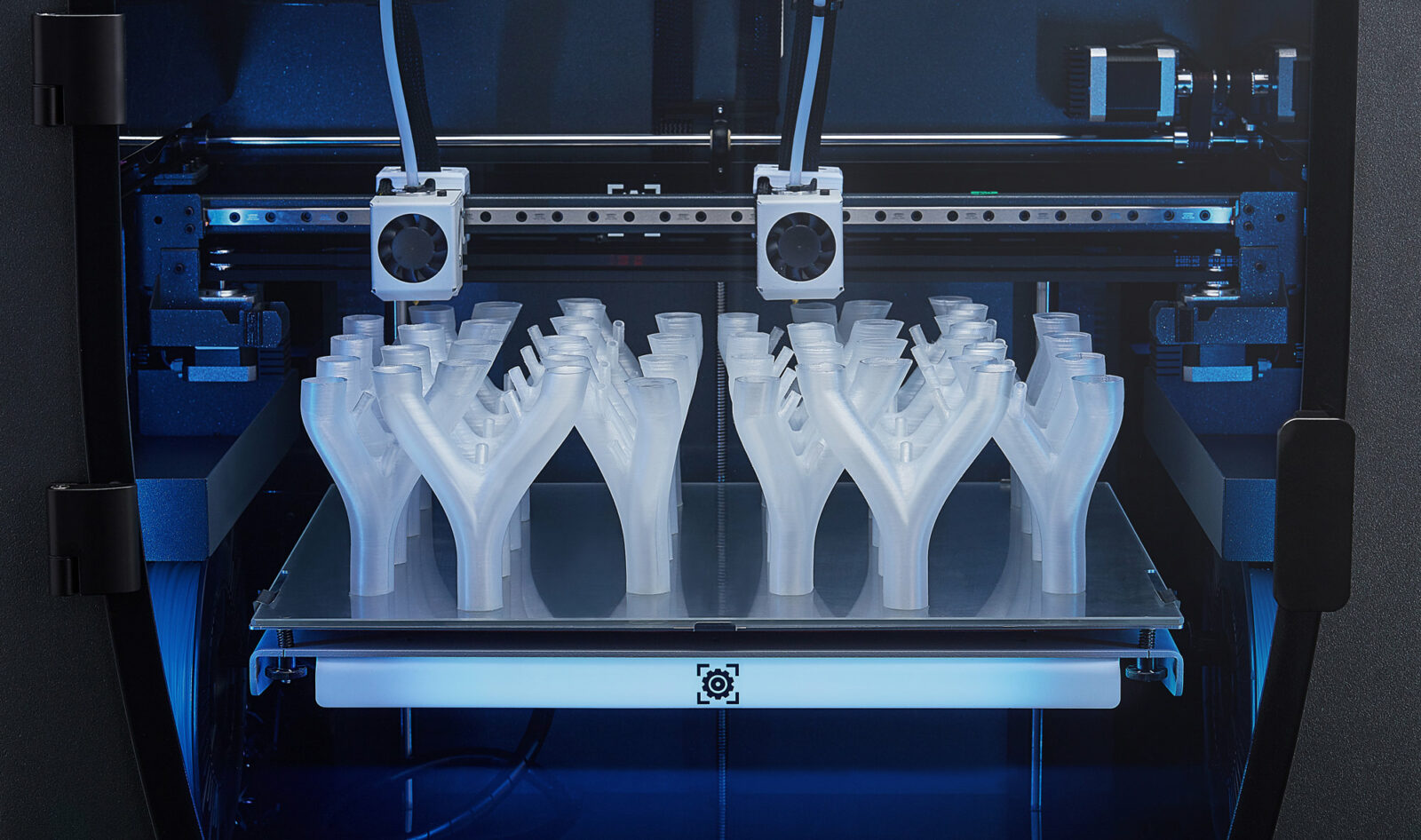

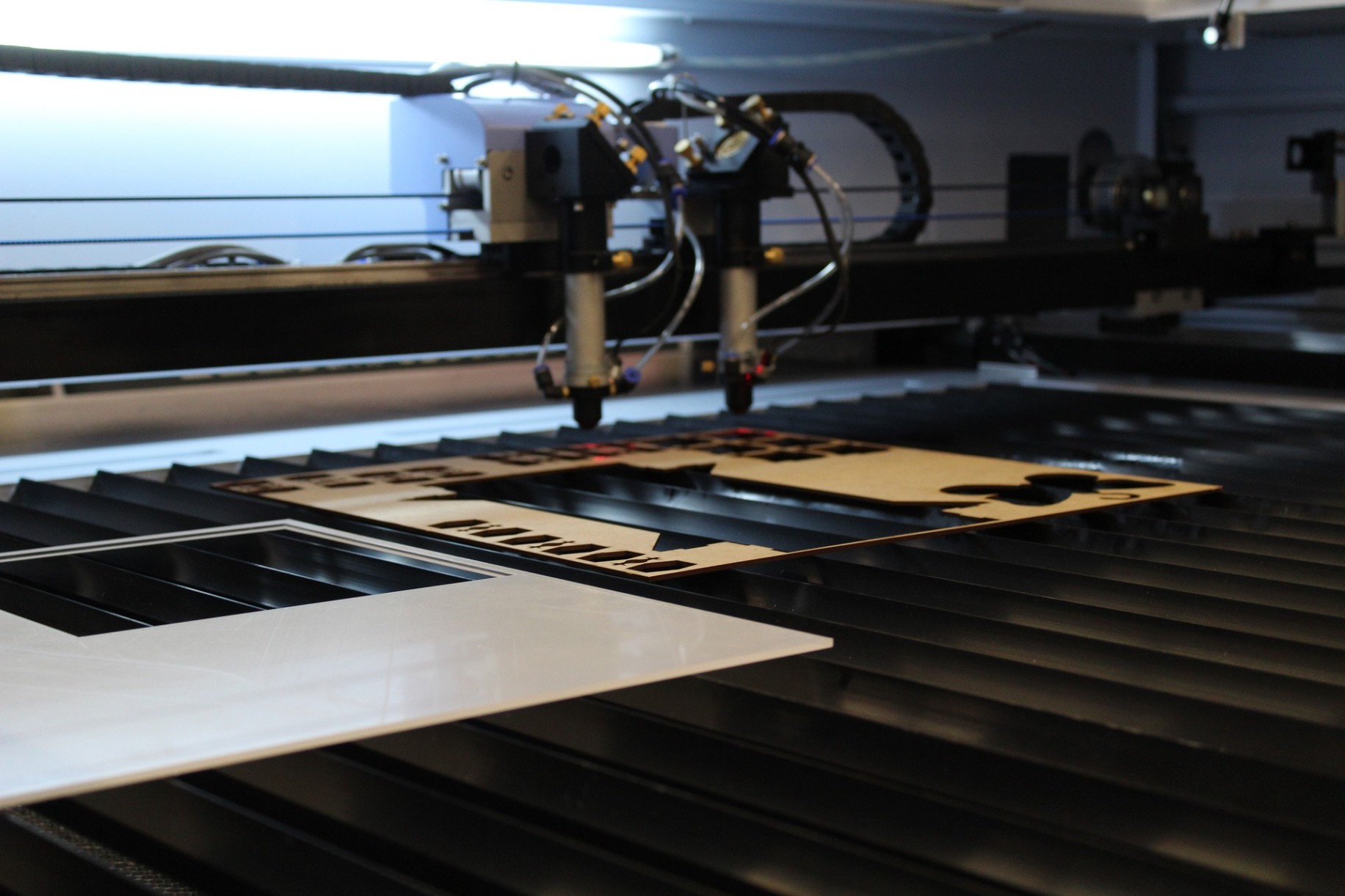

- Automotive: Prototyping, interior components, and custom trim

- Medical: Surgical instruments, prosthetics, and medical devices

- Consumer Products: Toys, home décor, and jewelry

- Architecture: Scale models, architectural elements, and interior design

- Education: Prototyping, project development, and hands-on learning

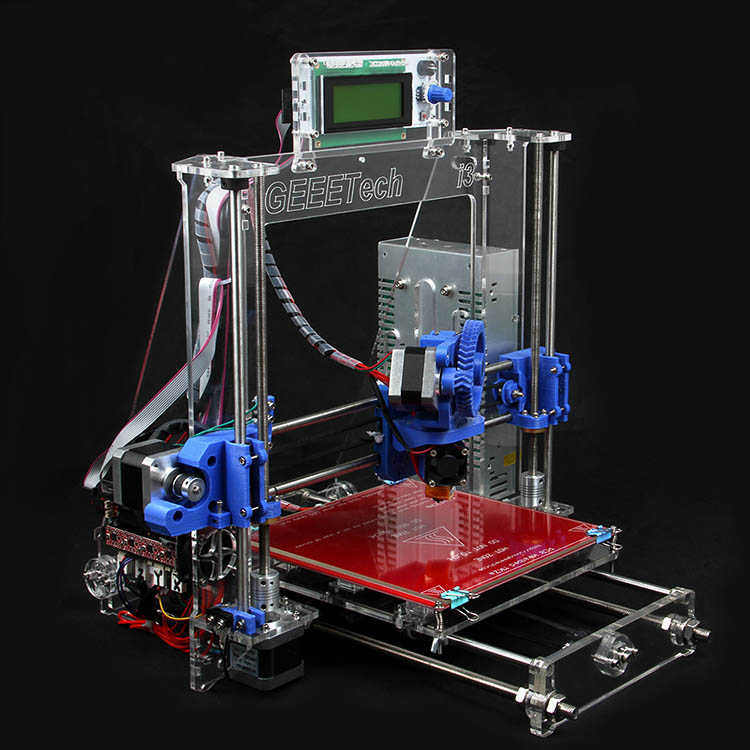

- Laser Power: The laser power determines the thickness and type of acrylic that can be cut.

- Bed Size: The bed size determines the maximum size of the objects that can be fabricated.

- Software Compatibility: The printer should be compatible with popular CAD software for seamless design integration.

- Ease of Use: The printer should have an intuitive interface and user-friendly controls.

- Safety Features: The printer should incorporate safety features such as laser shielding and ventilation systems.

Acrylic laser cutting 3D printers have emerged as a transformative technology in the realm of fabrication. These advanced machines harness the power of lasers to precisely cut and shape acrylic materials, enabling the creation of intricate and complex 3D objects. In this comprehensive guide, we will delve into the intricacies of acrylic laser cutting 3D printers, exploring their capabilities, benefits, and applications.

H1: Understanding Acrylic Laser Cutting 3D Printers

Acrylic laser cutting 3D printers employ a high-powered laser beam to selectively remove material from acrylic sheets. The laser is precisely controlled by a computer-aided design (CAD) software, allowing for the creation of intricate designs and shapes. The process involves the following steps:

H3: Applications of Acrylic Laser Cutting 3D Printers

Acrylic laser cutting 3D printers have found applications in various industries, including:

H2: Considerations for Choosing an Acrylic Laser Cutting 3D Printer

When selecting an acrylic laser cutting 3D printer, several factors should be considered:

H3: Conclusion

Acrylic laser cutting 3D printers are a revolutionary technology that empowers makers, engineers, and designers with unparalleled precision, efficiency, and material versatility. Their ability to create intricate 3D objects from acrylic materials has opened up new possibilities in various industries. As the technology continues to evolve, we can expect even more groundbreaking applications in the future.

Frequently Asked Questions (FAQs)

Q: What is the difference between acrylic laser cutting and 3D printing?

A: Acrylic laser cutting involves removing material from acrylic sheets, while 3D printing involves adding material to create an object.

Q: Can acrylic laser cutting 3D printers cut other materials besides acrylic?

A: While acrylic is the primary material used, some printers can also cut other materials such as wood, leather, and cardboard.

Q: What are the safety precautions to take when using an acrylic laser cutting 3D printer?

A: Wear protective eyewear, avoid exposure to laser beams, and ensure proper ventilation to remove fumes.

Q: How do I maintain an acrylic laser cutting 3D printer?

A: Regular cleaning, lens inspection, and laser calibration are essential for optimal performance and safety.

Q: What is the future of acrylic laser cutting 3D printing?

A: The technology is expected to advance with higher precision, faster speeds, and increased material compatibility.