Ultimate Guide to the Best Wood Laser Cutter: Precision Cutting for Your Creative Projects

Introduction

Wood laser cutters have revolutionized the woodworking industry, enabling precise and intricate cuts with unmatched accuracy. Whether you’re a professional craftsman, hobbyist, or small business owner, choosing the right wood laser cutter is crucial for achieving optimal results. This comprehensive guide will explore the key factors to consider, provide detailed reviews of top-rated models, and guide you towards finding the perfect laser cutter for your specific needs.

Table of Content

- 1 Ultimate Guide to the Best Wood Laser Cutter: Precision Cutting for Your Creative Projects

- 1.1 Introduction

- 1.2 H1: Key Factors to Consider When Choosing a Wood Laser Cutter

- 1.3 H1: Key Factors to Consider When Choosing a Wood Laser Cutter

- 1.4 H2: Top-Rated Wood Laser Cutters

- 1.5 H3: Conclusion

- 1.6 FAQs

H1: Key Factors to Consider When Choosing a Wood Laser Cutter

- Laser power determines the cutting depth and speed. Higher power lasers can cut thicker materials and achieve faster production rates.

- Wavelength affects the type of wood that can be cut. CO2 lasers (10.6 μm) are ideal for hardwoods, while diode lasers (808-980 nm) are suitable for softwoods.

2. Cutting Area:

- The cutting area determines the maximum size of materials that can be cut. Consider the size of your projects and allow for some additional space for setup and handling.

DOWNLOAD SVG FILES FOR LASER CUTTING

3. Precision and Accuracy:

- Wood Laser Engraving Wood Laser Engraving: A Comprehensive Guide To Precision And Creativity

- Laser Wood Carving Near Me Laser Wood Carving Near Me: An In-Depth Guide

- Laser Cut Wooden Signs Near Me Laser Cut Wooden Signs Near Me: Elevate Your Décor With Precision And Style

- Wooden Laser Cut Clouds Wooden Laser Cut Clouds: An Ethereal Touch To Your Decor

- Wooden Toys Laser Cutting Wooden Toys Laser Cutting: A Comprehensive Guide

- Laser power determines the cutting depth and speed. Higher power lasers can cut thicker materials and achieve faster production rates.

- Wavelength affects the type of wood that can be cut. CO2 lasers (10.6 μm) are ideal for hardwoods, while diode lasers (808-980 nm) are suitable for softwoods.

- Laser cutters use stepper motors or servo motors for movement. Servo motors provide higher precision and accuracy, resulting in cleaner cuts and smoother edges.

- Choose a laser cutter compatible with your preferred design software. This ensures seamless integration and easy file transfer.

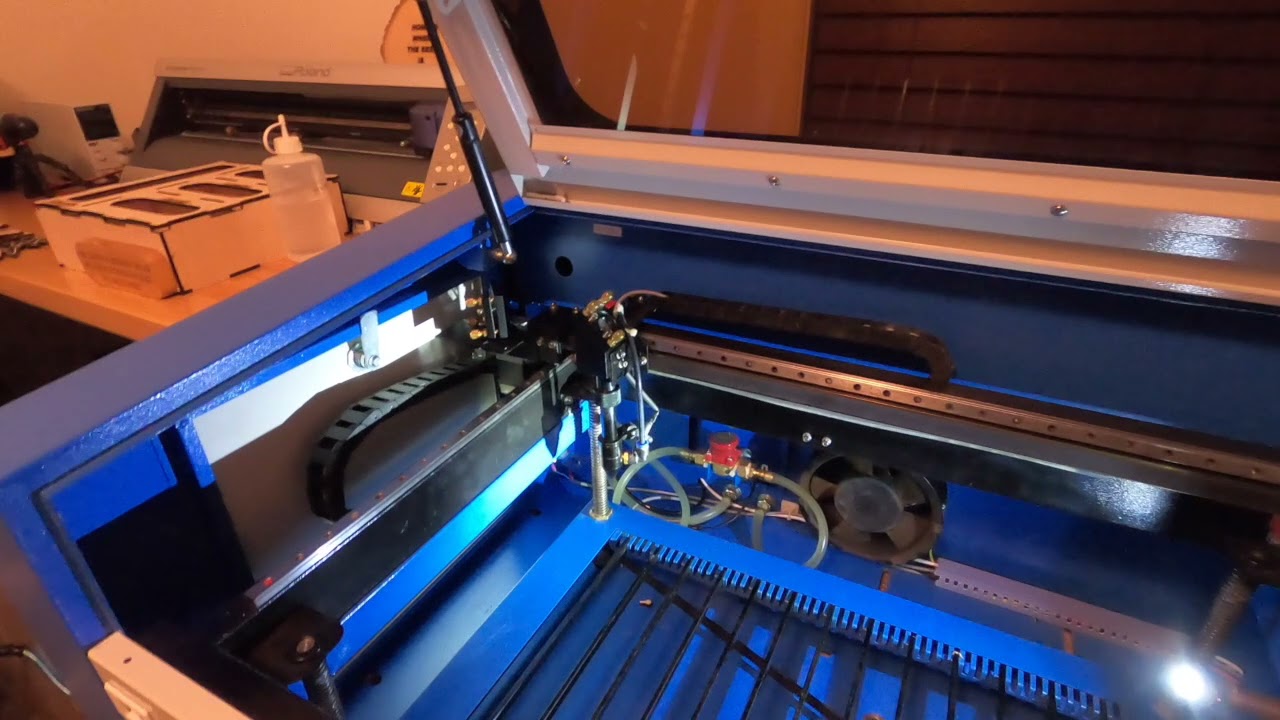

- Laser cutters generate intense beams of light, so safety features are essential. Look for models with enclosed workspaces, fume extraction systems, and interlock switches.

- Laser power: 30-60 watts

- Cutting area: 16" x 12"

- Features: Drag-and-drop interface, built-in camera, air assist

- Pros: User-friendly, precise cuts, excellent customer support

- Laser power: 25-120 watts

- Cutting area: 30" x 18"

- Features: Rotary attachment, touch screen control, dual-pass cutting

- Pros: Versatile, high-quality cuts, advanced features

- Laser power: 40 watts

- Cutting area: 12" x 20"

- Features: Cloud-based software, air filter, smartphone app

- Pros: Compact, easy to use, affordable for hobbyists

- Laser power: 40-100 watts

- Cutting area: 24" x 18"

- Features: Rotary attachment, autofocus system, honeycomb bed

- Pros: High power, fast cutting speeds, industrial-grade construction

- Laser power: 40-80 watts

- Cutting area: 20" x 12"

- Features: Air assist, touch screen control, remote monitoring

- Pros: Portable, affordable, suitable for small businesses

Wood laser cutters have revolutionized the woodworking industry, enabling precise and intricate cuts with unmatched accuracy. Whether you’re a professional craftsman, hobbyist, or small business owner, choosing the right wood laser cutter is crucial for achieving optimal results. This comprehensive guide will explore the key factors to consider, provide detailed reviews of top-rated models, and guide you towards finding the perfect laser cutter for your specific needs.

H1: Key Factors to Consider When Choosing a Wood Laser Cutter

1. Laser Power and Wavelength:

DOWNLOAD SVG FILES FOR LASER CUTTING

4. Software Compatibility:

5. Safety Features:

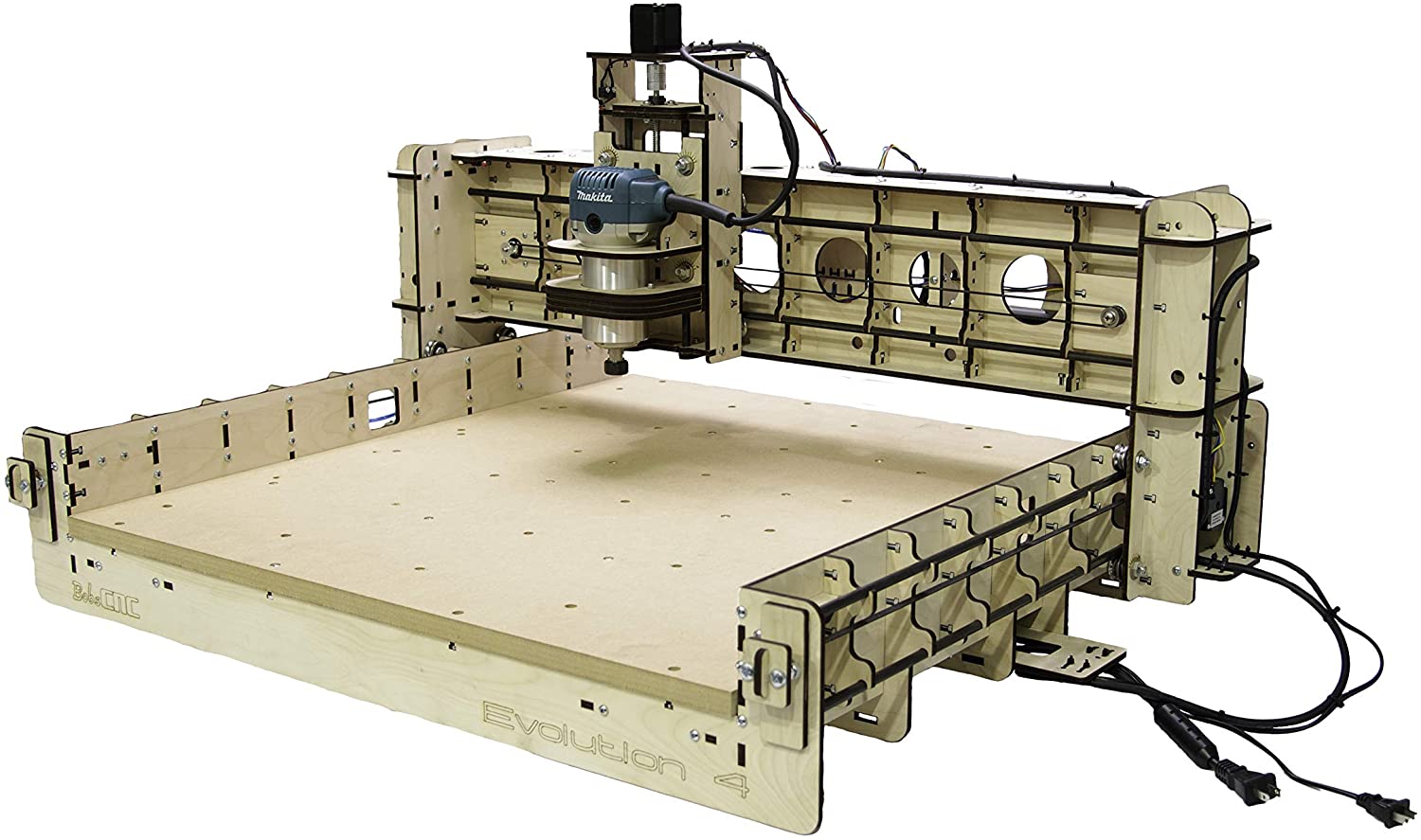

H2: Top-Rated Wood Laser Cutters

1. Epilog Zing Laser 16:

2. Trotec Speedy 300:

3. Glowforge Plus:

4. Thunder Laser Nova 24:

5. Aeon Mira 9:

H3: Conclusion

Choosing the right wood laser cutter is essential for unlocking your creative potential and achieving professional-grade results. By considering the key factors outlined above and reviewing the top-rated models, you can make an informed decision that aligns with your specific requirements. Whether you’re looking for precision, versatility, or affordability, there’s a wood laser cutter out there to empower your woodworking projects.

FAQs

1. What materials can a wood laser cutter cut?

Wood laser cutters can cut a wide range of wood materials, including hardwoods, softwoods, plywood, MDF, and acrylic.

2. How thick can a wood laser cutter cut?

The cutting depth depends on the laser power and material thickness. Most laser cutters can cut wood up to 1/4 inch thick, while some industrial models can cut thicker materials.

3. Is it safe to use a wood laser cutter?

Laser cutters generate intense beams of light, so safety precautions are crucial. Ensure the laser cutter has enclosed workspaces, fume extraction systems, and interlock switches.

4. How do I maintain a wood laser cutter?

Regular maintenance is essential to ensure optimal performance and longevity. Clean the optics, check the alignment, and replace consumables as needed.