CNC Machine Laser Cutting: A Comprehensive Guide

Introduction

CNC machine laser cutting is a cutting-edge technology that utilizes a computer-controlled laser beam to precisely cut various materials. It offers unparalleled precision, speed, and versatility, making it an indispensable tool in numerous industries. This article provides a comprehensive guide to CNC machine laser cutting, covering its principles, applications, benefits, and considerations.

Table of Content

- 1 CNC Machine Laser Cutting: A Comprehensive Guide

- 1.1 Introduction

- 2 How Does CNC Machine Laser Cutting Work?

- 2.2 Types of Laser Sources

- 2.3 Cutting Process

- 3 How Does CNC Machine Laser Cutting Work?

- 3.4 Principle

- 3.5 Types of Laser Sources

- 4 Applications of CNC Machine Laser Cutting

- 4.6 Aerospace

- 4.7 Automotive

- 4.8 Electronics

- 4.9 Medical

- 4.10 Fabrication

- 4.11 Benefits of CNC Machine Laser Cutting

- 5 Considerations for CNC Machine Laser Cutting

- 5.12 Material Selection

- 5.13 Laser Power and Optics

- 5.14 CNC Programming

- 5.15 Safety Precautions

- 6 Conclusion

- 7 FAQs

- 7.16 What materials can CNC machine laser cutters cut?

- 7.17 What is the difference between CO2, fiber, and Nd:YAG lasers?

- 7.18 How thick can CNC machine laser cutters cut?

- 7.19 What are the advantages of CNC machine laser cutting over traditional cutting methods?

- 7.20 What safety precautions should be taken when using CNC machine laser cutters?

How Does CNC Machine Laser Cutting Work?

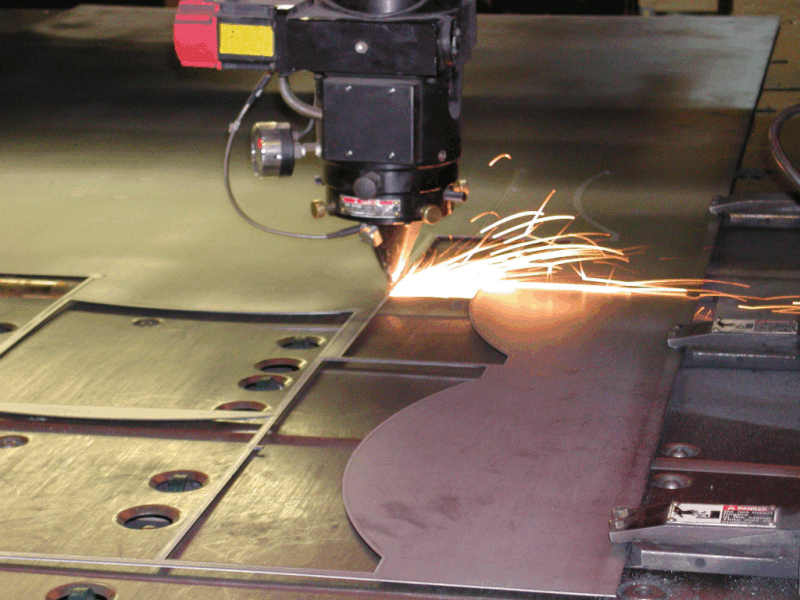

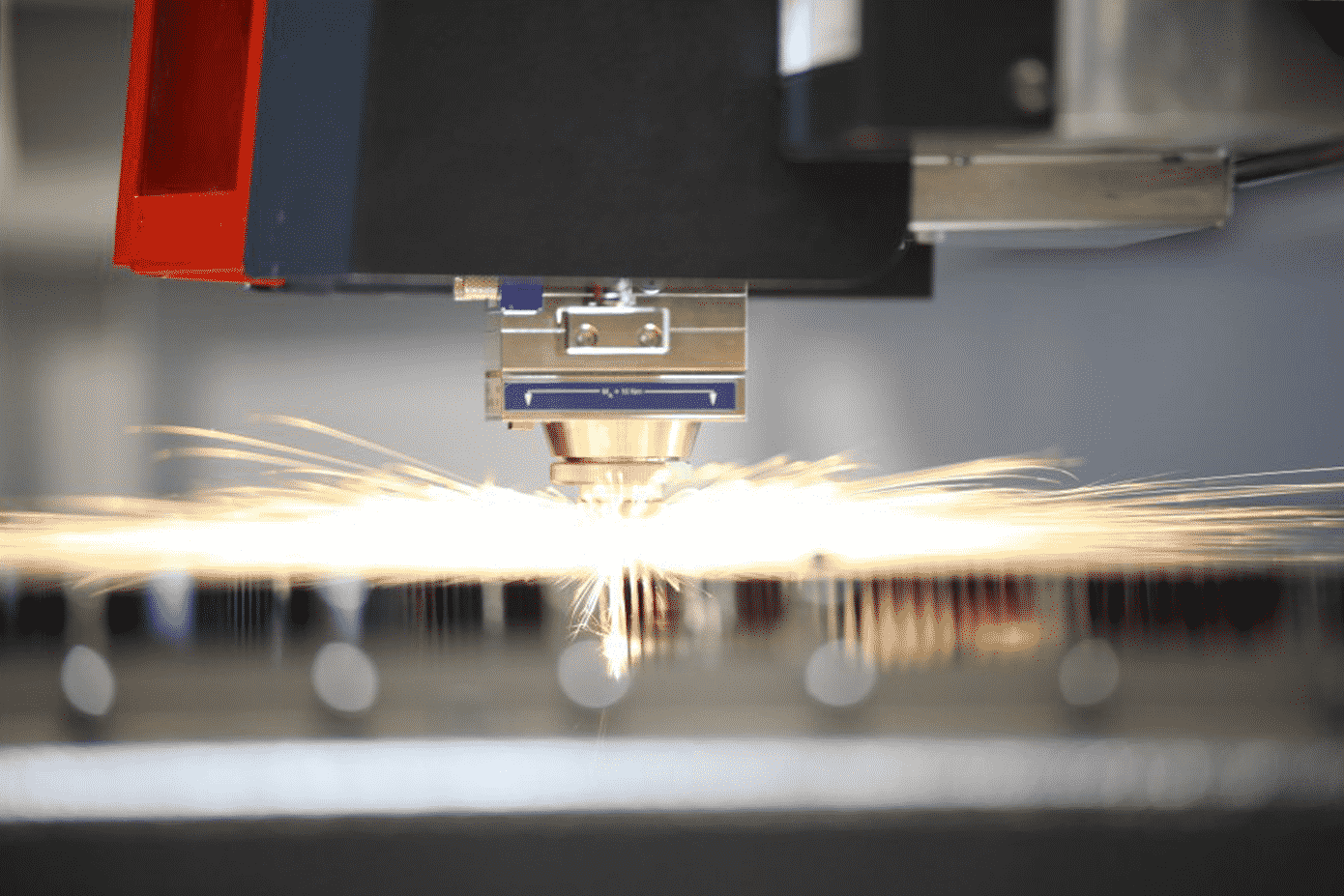

CNC machine laser cutting operates on the principle of laser ablation, where a high-powered laser beam is focused onto the workpiece material. The intense heat of the laser beam vaporizes the material, resulting in a precise cut. The laser beam is guided by a computer-controlled CNC (Computer Numerical Control) system, which ensures accurate and repeatable cutting operations.

Types of Laser Sources

Different types of laser sources are used in CNC machine laser cutting, each with its unique characteristics:

- CO2 lasers: Emit infrared light and are commonly used for cutting non-metals like wood, plastic, and textiles.

- Fiber lasers: Produce high-power beams in the visible spectrum and excel at cutting metals, including stainless steel, aluminum, and titanium.

- Nd:YAG lasers: Utilize a solid-state medium and are suitable for cutting a wide range of materials, including reflective surfaces.

Cutting Process

The laser cutting process involves the following steps:

CNC machine laser cutting is a cutting-edge technology that utilizes a computer-controlled laser beam to precisely cut various materials. It offers unparalleled precision, speed, and versatility, making it an indispensable tool in numerous industries. This article provides a comprehensive guide to CNC machine laser cutting, covering its principles, applications, benefits, and considerations.

- Laser Cutting 3d Vector Files Free Download Laser Cutting 3D Vector Files: Unleashing Creativity And Precision

- 3d Dinosaur Laser Cut 3D Dinosaur Laser Cut: Unleashing The Prehistoric Era With Precision

- 3d Laser Cut Objects 3D Laser Cut Objects: Revolutionizing Design And Manufacturing

- 3d Laser Cut Cat 3D Laser Cut Cat: A Unique And Personalized Home Decor

- Laser Cut 3d Skull Laser Cut 3D Skull: A Comprehensive Guide

How Does CNC Machine Laser Cutting Work?

Principle

CNC machine laser cutting operates on the principle of laser ablation, where a high-powered laser beam is focused onto the workpiece material. The intense heat of the laser beam vaporizes the material, resulting in a precise cut. The laser beam is guided by a computer-controlled CNC (Computer Numerical Control) system, which ensures accurate and repeatable cutting operations.

Types of Laser Sources

Different types of laser sources are used in CNC machine laser cutting, each with its unique characteristics:

- CAD/CAM Design: The desired cutting pattern is designed using CAD (Computer-Aided Design) software and converted into a CNC program.

- Material Loading: The workpiece material is securely mounted on the CNC machine table.

- Laser Alignment: The laser beam is calibrated to ensure optimal cutting performance.

- Cutting: The CNC system guides the laser beam along the programmed path, vaporizing the material and creating the desired cut.

- Part Removal: Once the cutting is complete, the finished part is removed from the machine.

Applications of CNC Machine Laser Cutting

CNC machine laser cutting finds applications in a vast array of industries:

Aerospace

- Precision cutting of aircraft components, such as turbine blades and fuselage panels.

Automotive

- Fabrication of complex parts for engines, transmissions, and body panels.

Electronics

- Cutting of printed circuit boards (PCBs), resistors, and capacitors.

Medical

- Production of surgical instruments, implants, and prosthetics.

Fabrication

- Cutting of sheet metal, pipes, and other materials used in construction and manufacturing.

Benefits of CNC Machine Laser Cutting

- Precision: Laser cutting offers unparalleled accuracy, producing cuts with tolerances within thousandths of an inch.

- Speed: CNC machines can cut materials at high speeds, increasing productivity and reducing lead times.

- Versatility: Laser cutters can handle a wide range of materials, from thin sheets to thick plates.

- Non-Contact Process: Laser cutting does not require physical contact with the material, minimizing tool wear and damage.

- Minimal Heat Affected Zone: The focused laser beam creates a narrow heat affected zone, preserving the material’s properties.

Considerations for CNC Machine Laser Cutting

Material Selection

The choice of material for laser cutting depends on factors such as thickness, melting point, and reflectivity.

Laser Power and Optics

The laser power and optics used determine the cutting speed, precision, and material thickness capabilities.

CNC Programming

Creating accurate and efficient CNC programs requires expertise in CAD/CAM software and laser cutting parameters.

Safety Precautions

Laser cutting involves high-powered beams, so proper safety precautions must be followed, including protective eyewear, ventilation, and fire suppression systems.

Conclusion

CNC machine laser cutting is a powerful technology that enables precise, fast, and versatile cutting of various materials. Its applications span multiple industries, from aerospace to medical, offering numerous benefits. By understanding the principles, applications, and considerations of CNC machine laser cutting, manufacturers can harness its capabilities to enhance their production processes and create innovative products.

FAQs

What materials can CNC machine laser cutters cut?

CNC machine laser cutters can cut a wide range of materials, including metals, plastics, wood, textiles, and composites.

What is the difference between CO2, fiber, and Nd:YAG lasers?

CO2 lasers emit infrared light and are suitable for non-metals. Fiber lasers produce high-power visible beams and excel at cutting metals. Nd:YAG lasers are versatile and can cut a variety of materials, including reflective surfaces.

How thick can CNC machine laser cutters cut?

The cutting thickness depends on the laser power, material properties, and cutting parameters. Generally, CNC machine laser cutters can cut materials up to several inches thick.

What are the advantages of CNC machine laser cutting over traditional cutting methods?

CNC machine laser cutting offers higher precision, speed, versatility, and non-contact operation compared to traditional cutting methods like milling, sawing, and waterjet cutting.

What safety precautions should be taken when using CNC machine laser cutters?

Proper safety precautions include wearing protective eyewear, using ventilation systems, and installing fire suppression systems. Operators should also receive adequate training and follow safety protocols.