Fiber Laser Wood: A Comprehensive Guide

Introduction

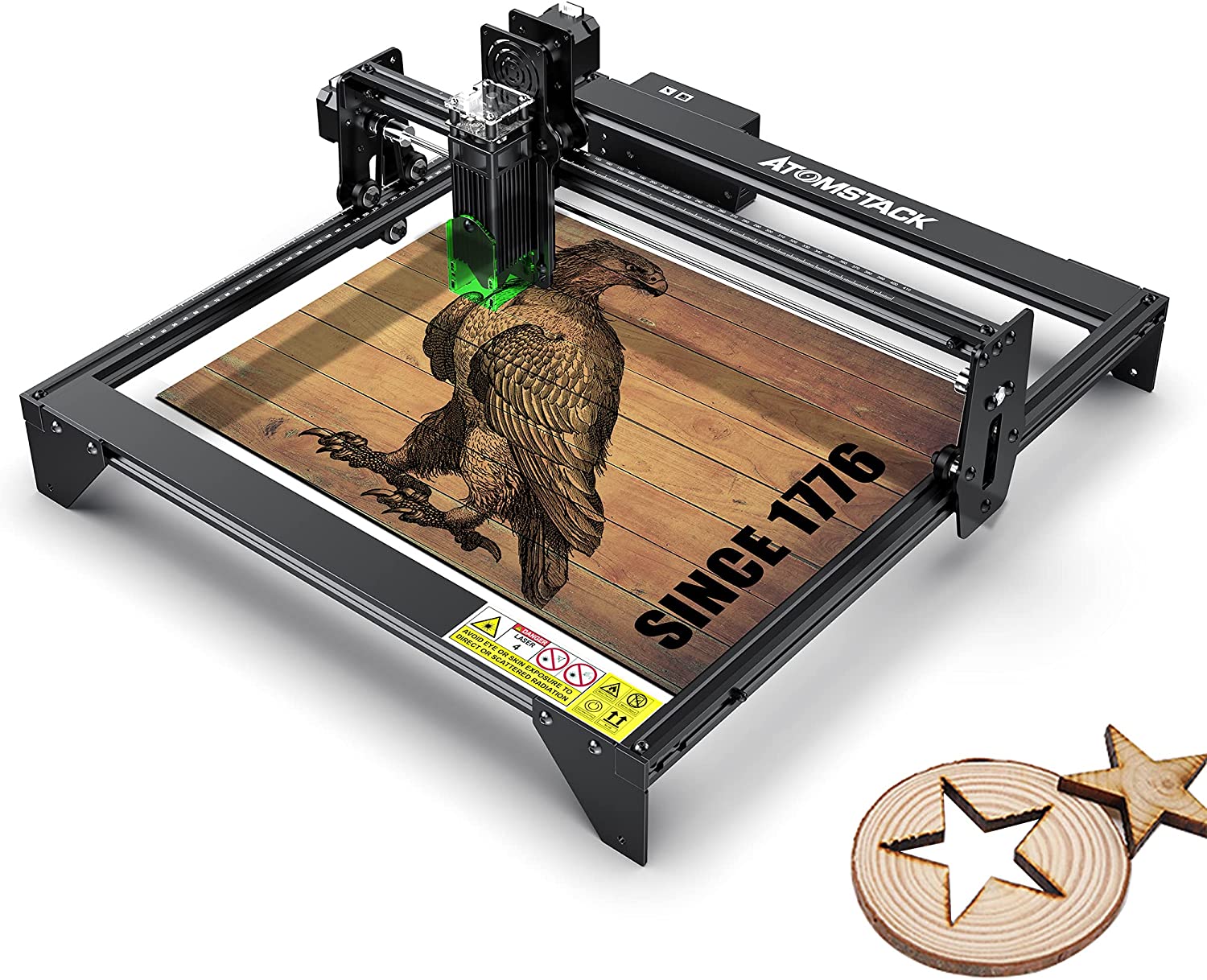

Fiber laser wood, a cutting-edge technology, revolutionizes the wood processing industry with its precision, speed, and versatility. This article delves into the intricacies of fiber laser wood, exploring its benefits, applications, and considerations for optimal use.

Table of Content

Benefits of Fiber Laser Wood

Fiber lasers emit a highly focused beam, enabling intricate and detailed cuts with exceptional precision.

2. High Speed:

Compared to traditional cutting methods, fiber lasers operate at blazing speeds, increasing productivity and efficiency.

3. Minimal Heat-Affected Zone:

The laser’s narrow beam minimizes heat-affected zones, preserving the integrity and quality of the wood.

4. Versatility: DOWNLOAD SVG FILES FOR LASER CUTTING

Fiber lasers can cut a wide variety of wood species and thicknesses, offering flexibility for various applications.

5. Low Maintenance:

Fiber lasers require minimal maintenance, reducing downtime and operational costs.

Applications of Fiber Laser Wood

Fiber laser wood, a cutting-edge technology, revolutionizes the wood processing industry with its precision, speed, and versatility. This article delves into the intricacies of fiber laser wood, exploring its benefits, applications, and considerations for optimal use.

- Wood Laser Engraver And Cutter Wood Laser Engraver And Cutter: A Comprehensive Guide

- Wood Laser Cutting Near Me Wood Laser Cutting Near Me: A Comprehensive Guide To Finding The Best Services

- Laser Wood Signs Laser Wood Signs: A Comprehensive Guide To Crafting Custom Masterpieces

- Die Cut Wooden Shapes Die Cut Wooden Shapes: A Versatile Material For Endless Creative Possibilities

- Laser Cutting On Wood Near Me Laser Cutting On Wood: A Comprehensive Guide For Precision And Intricacy

Benefits of Fiber Laser Wood

1. Precision Cutting: DOWNLOAD SVG FILES FOR LASER CUTTING

Fiber lasers emit a highly focused beam, enabling intricate and detailed cuts with exceptional precision.

2. High Speed:

Compared to traditional cutting methods, fiber lasers operate at blazing speeds, increasing productivity and efficiency.

1. Furniture Manufacturing:

Fiber lasers create intricate designs, fine details, and smooth edges on furniture components.

2. Signage and Engraving:

The precision of fiber lasers enables the production of highly detailed signage, plaques, and engravings.

3. Architectural Applications:

Fiber lasers cut complex shapes and intricate designs for architectural elements such as decorative panels and moldings.

4. Craft and Hobby:

Fiber lasers empower hobbyists and artisans to create custom wood projects with precision and creativity.

5. Prototyping and Model Making:

The speed and accuracy of fiber lasers make them ideal for rapid prototyping and model making.

Considerations for Optimal Use

1. Material Selection:

Choosing the appropriate wood species and thickness is crucial for optimal cutting results.

2. Laser Power:

The power of the fiber laser must be calibrated to the thickness and density of the wood.

3. Cutting Speed:

The cutting speed should be adjusted to ensure a clean and precise cut without compromising speed.

4. Focus:

Proper focus of the laser beam is essential for achieving the desired cut quality.

5. Ventilation:

Adequate ventilation is necessary to remove smoke and fumes generated during the cutting process.

Conclusion

Fiber laser wood technology offers a plethora of advantages for the wood processing industry. Its precision, speed, versatility, and low maintenance requirements make it an ideal choice for various applications. By understanding the benefits, applications, and considerations for optimal use, businesses and individuals can harness the full potential of fiber laser wood to create innovative and high-quality wood products.

FAQs

Q: What are the advantages of fiber laser wood over traditional cutting methods?

A: Fiber lasers provide higher precision, faster cutting speeds, reduced heat-affected zones, and greater versatility.

Q: What types of wood can fiber lasers cut?

A: Fiber lasers can cut a wide range of wood species, including hardwoods, softwoods, and engineered wood products.

Q: What are the environmental implications of fiber laser wood cutting?

A: Fiber laser cutting produces minimal fumes and waste, making it an environmentally friendly process compared to traditional cutting methods.

Q: Is fiber laser wood cutting suitable for small businesses?

A: Yes, fiber lasers are available in various sizes and power levels, making them accessible to small businesses and home workshops.

Q: How do I choose the right fiber laser for my needs?

A: Consider the required cutting speed, material thickness, and desired cut quality to determine the appropriate laser power and specifications.