Hard Wood Laser Cutter: A Comprehensive Guide

Laser cutting technology has revolutionized the woodworking industry, enabling precise and intricate cuts with unprecedented speed and efficiency. Hard wood laser cutters, in particular, have emerged as the preferred choice for artisans and professionals seeking to create exceptional wood products. This article delves into the world of hard wood laser cutters, exploring their capabilities, benefits, and considerations.

H1: Understanding Hard Wood Laser Cutters

Table of Content

- 1 Hard Wood Laser Cutter: A Comprehensive Guide

- 1.1 H1: Understanding Hard Wood Laser Cutters

- 1.2 H3: Considerations for Choosing a Hard Wood Laser Cutter

- 1.3 H1: Understanding Hard Wood Laser Cutters

- 1.4 H2: Benefits of Hard Wood Laser Cutters

- 1.5 H2: Applications of Hard Wood Laser Cutters

- 1.6 H3: Conclusion

- 1.7 FAQs

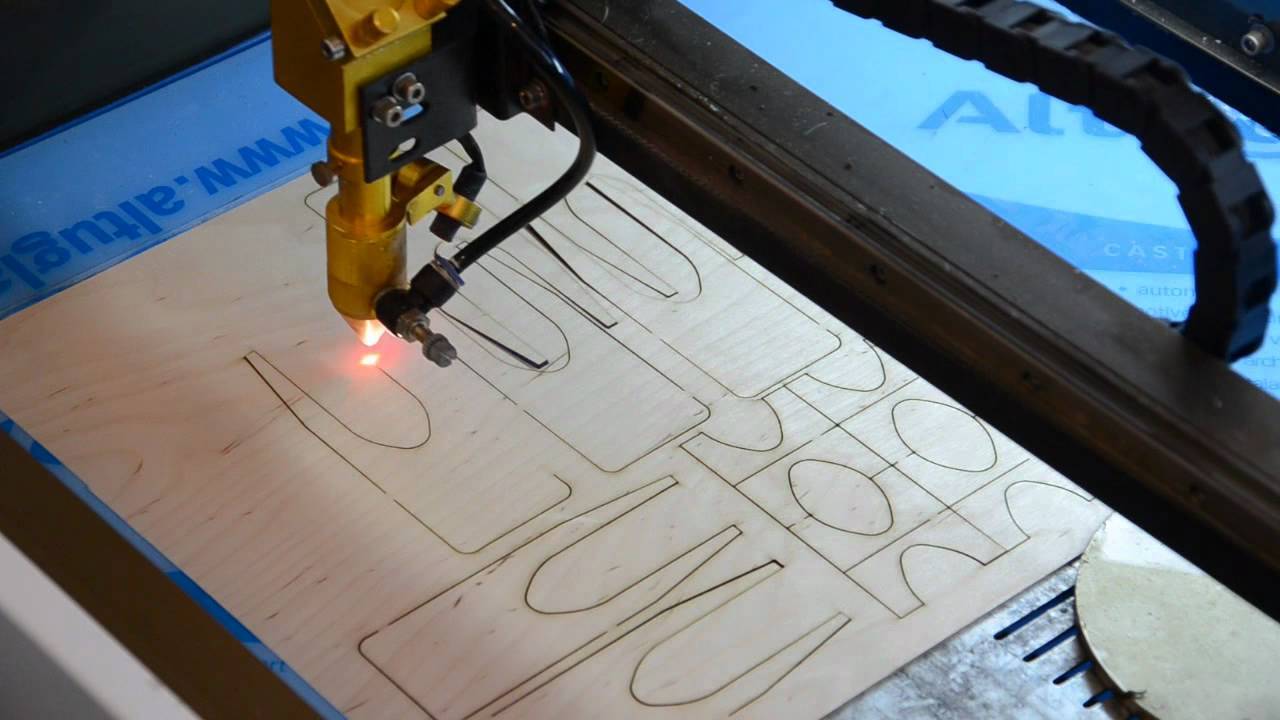

Hard wood laser cutters utilize a high-powered laser beam to cut and engrave hard wood materials with exceptional accuracy. The laser beam is focused through a lens, creating a narrow and intense beam that melts or vaporizes the wood, resulting in clean and precise cuts.

1. Precision and Accuracy:

Laser cutters provide unparalleled precision and accuracy, allowing for intricate designs and precise cuts. The laser beam can follow complex paths with ease, eliminating the need for manual cutting and reducing errors.

2. Speed and Efficiency:

Hard wood laser cutters operate at high speeds, significantly reducing production time compared to traditional cutting methods. This increased efficiency allows for larger production runs and faster turnaround times.

3. Versatility:

Laser cutters can handle a wide range of hard wood species, from softwoods like pine to hardwoods like oak and mahogany. This versatility enables artisans to create a diverse range of products.

DOWNLOAD SVG FILES FOR LASER CUTTING

4. No Tooling Required:

Unlike traditional cutting methods, laser cutters do not require specialized tools or blades. The laser beam itself acts as the cutting tool, eliminating the need for frequent tool changes and maintenance.

H3: Considerations for Choosing a Hard Wood Laser Cutter

1. Laser Power:

H1: Understanding Hard Wood Laser Cutters

- Wooden Laser Cutting Services Wooden Laser Cutting Services: Precision And Versatility For Your Woodworking Projects

- Wood Laser Cutting Machine Wood Laser Cutting Machine: Precision And Versatility For Woodworking

- Laser Cut Wooden Earring Blanks Laser Cut Wooden Earring Blanks: The Ultimate Guide For Earring Makers

- Laser Cutter Burning Wood Laser Cutter Burning Wood: A Comprehensive Guide

- Laser Cut Wooden Box Kit Laser Cut Wooden Box Kit: A Comprehensive Guide

Hard wood laser cutters utilize a high-powered laser beam to cut and engrave hard wood materials with exceptional accuracy. The laser beam is focused through a lens, creating a narrow and intense beam that melts or vaporizes the wood, resulting in clean and precise cuts.

H2: Benefits of Hard Wood Laser Cutters

DOWNLOAD SVG FILES FOR LASER CUTTING

1. Precision and Accuracy:

Laser cutters provide unparalleled precision and accuracy, allowing for intricate designs and precise cuts. The laser beam can follow complex paths with ease, eliminating the need for manual cutting and reducing errors.

2. Speed and Efficiency:

The laser power determines the thickness and type of wood that can be cut. Higher laser power enables cutting thicker and harder woods.

2. Cutting Area:

Consider the size of the cutting area to accommodate the dimensions of the projects you intend to create. Larger cutting areas provide greater flexibility.

3. Software Compatibility:

Ensure the laser cutter is compatible with your preferred design software to seamlessly transfer designs for cutting.

4. Safety Features:

Laser cutters should be equipped with safety features such as enclosed cutting areas, fume extraction systems, and interlocks to prevent accidents.

H2: Applications of Hard Wood Laser Cutters

Hard wood laser cutters find applications in various industries, including:

1. Furniture Making:

Laser cutters are used to create intricate furniture designs, such as decorative panels, tabletops, and chair backs.

2. Signage and Display:

Laser cutters produce precise and durable signage, display stands, and promotional items from hard wood.

3. Toys and Games:

Laser cutters enable the creation of wooden toys, puzzles, and board games with complex shapes and designs.

4. Architectural Elements:

Laser cutters are employed to create architectural elements such as decorative molding, wall panels, and stair railings.

5. Musical Instruments:

Hard wood laser cutters are used to produce musical instruments, such as guitar bodies, violin scrolls, and drum shells.

H3: Conclusion

Hard wood laser cutters have revolutionized the woodworking industry, providing artisans and professionals with a powerful tool to create exceptional wood products. Their precision, speed, versatility, and ease of use make them an indispensable asset for businesses and hobbyists alike. By carefully considering the factors discussed in this article, you can select the optimal hard wood laser cutter for your specific needs and embark on a journey of creativity and innovation.

FAQs

Q: What is the maximum thickness of wood that can be cut with a hard wood laser cutter?

A: The maximum thickness depends on the laser power. Typically, hard wood laser cutters can cut wood up to 1 inch thick.

Q: How do I maintain a hard wood laser cutter?

A: Regular cleaning of the laser lens and mirrors, as well as proper ventilation to remove fumes, are essential for maintaining optimal performance.

Q: What are the safety precautions to take when using a hard wood laser cutter?

A: Wear appropriate safety gear, such as safety glasses and a respirator. Ensure the cutting area is well-ventilated and avoid touching the laser beam or workpiece during operation.