Large Wood Laser Cutter: The Ultimate Guide for Woodworking Professionals

Introduction

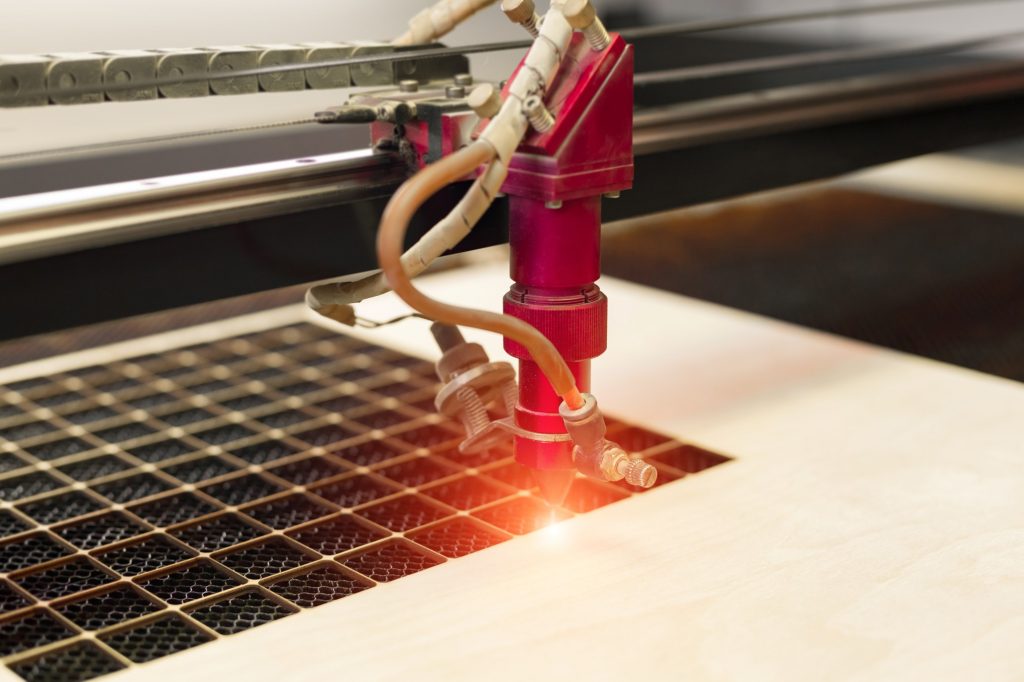

Large wood laser cutters have revolutionized the woodworking industry, enabling businesses and hobbyists alike to create intricate and precise designs with unprecedented speed and efficiency. These machines offer a wide range of capabilities, from cutting and engraving to marking and etching, making them an indispensable tool for a variety of applications.

Table of Content

- 1 Large Wood Laser Cutter: The Ultimate Guide for Woodworking Professionals

- 1.1 Introduction

- 1.2 Benefits of Large Wood Laser Cutters

- 1.3 Types of Large Wood Laser Cutters

- 1.4 Benefits of Large Wood Laser Cutters

- 1.5 Features to Consider When Choosing a Large Wood Laser Cutter

- 1.6 Applications of Large Wood Laser Cutters

- 1.7 Conclusion

- 1.8 FAQs

Benefits of Large Wood Laser Cutters

DOWNLOAD SVG FILES FOR LASER CUTTING

Types of Large Wood Laser Cutters

There are two main types of large wood laser cutters:

- CO2 Laser Cutters: These cutters utilize carbon dioxide gas to generate a laser beam. They are known for their high power and speed, making them ideal for cutting and engraving thick wood materials.

- Cnc Laser For Wood CNC Laser For Wood: A Comprehensive Guide

- Custom Cut Wood Pieces Custom Cut Wood Pieces: A Comprehensive Guide To Precision And Versatility

- Laser Wood Carving Laser Wood Carving: A Comprehensive Guide To Intricate Designs And Precision Cuts

- Laser Cutter For Wood Signs Laser Cutter For Wood Signs: The Ultimate Guide To Precision And Creativity

- Custom Laser Cut Wood Custom Laser Cut Wood: A Comprehensive Guide To Precision And Creativity

- Precision and Accuracy: Laser cutters utilize a highly focused laser beam to cut and engrave wood with extreme precision, resulting in clean, sharp edges and intricate details.

- Speed and Efficiency: Compared to traditional woodworking methods, laser cutters operate at lightning-fast speeds, significantly reducing production time and increasing productivity.

- Versatility: Large wood laser cutters can handle a wide range of wood species, including hardwoods, softwoods, and even plywood, making them suitable for a variety of projects.

- Fiber Laser Cutters: These cutters use a fiber optic cable to generate a laser beam. They offer superior precision and are particularly suitable for intricate engraving and fine details.

- Cutting Area: The cutting area determines the maximum size of wood that can be processed. Choose a machine with a cutting area that meets your project requirements.

- Laser Power: Laser power is measured in watts (W) and determines the thickness of wood that can be cut. Higher power lasers can cut thicker materials faster.

- Accuracy and Precision: The accuracy and precision of the laser cutter impact the quality of the cut or engraved design. Look for machines with high resolution and advanced motion control systems.

- Software Compatibility: The software compatibility of the laser cutter is important to ensure seamless integration with your design workflow.

- Safety Features: Laser cutters should be equipped with safety features such as enclosed cutting areas, fume extraction systems, and interlocks to prevent accidents.

- Furniture Manufacturing: Cutting and engraving intricate designs on furniture components, such as tabletops, chairs, and cabinets.

- Sign Making: Creating custom signs, logos, and lettering from wood materials.

- Musical Instrument Production: Cutting and shaping wood components for guitars, violins, and other instruments.

- Architectural Applications: Creating decorative elements, such as moldings, trims, and veneers, for architectural projects.

- Craft and Hobby: Personalizing and embellishing wood items, such as jewelry, toys, and home decor.

Large wood laser cutters have revolutionized the woodworking industry, enabling businesses and hobbyists alike to create intricate and precise designs with unprecedented speed and efficiency. These machines offer a wide range of capabilities, from cutting and engraving to marking and etching, making them an indispensable tool for a variety of applications.

Benefits of Large Wood Laser Cutters

DOWNLOAD SVG FILES FOR LASER CUTTING

Features to Consider When Choosing a Large Wood Laser Cutter

When selecting a large wood laser cutter, several key features should be considered:

Applications of Large Wood Laser Cutters

Large wood laser cutters are widely used in a variety of industries, including:

Conclusion

Large wood laser cutters are powerful tools that offer numerous benefits for woodworking professionals and hobbyists alike. By carefully considering the features and capabilities of different machines, you can select the optimal laser cutter to meet your specific needs and unlock the full potential of laser cutting technology.

FAQs

Q: What is the maximum thickness of wood that a large wood laser cutter can cut?

A: The maximum cutting thickness depends on the laser power and the type of wood being cut. Typically, CO2 laser cutters can cut wood up to 25mm thick, while fiber laser cutters can cut up to 12mm thick.

Q: Can large wood laser cutters cut other materials besides wood?

A: Yes, many large wood laser cutters can also cut and engrave other materials, such as acrylic, leather, fabric, and certain types of metal.

Q: Are large wood laser cutters easy to operate?

A: The ease of operation depends on the specific machine and its software. However, most modern laser cutters come with user-friendly interfaces and training programs to ensure smooth operation.

Q: How do I maintain a large wood laser cutter?

A: Regular maintenance is essential to ensure the longevity and performance of the laser cutter. This includes cleaning the optics, lubricating moving parts, and checking the alignment of the laser beam.