Laser Cutting Thick Wood: A Comprehensive Guide

Introduction

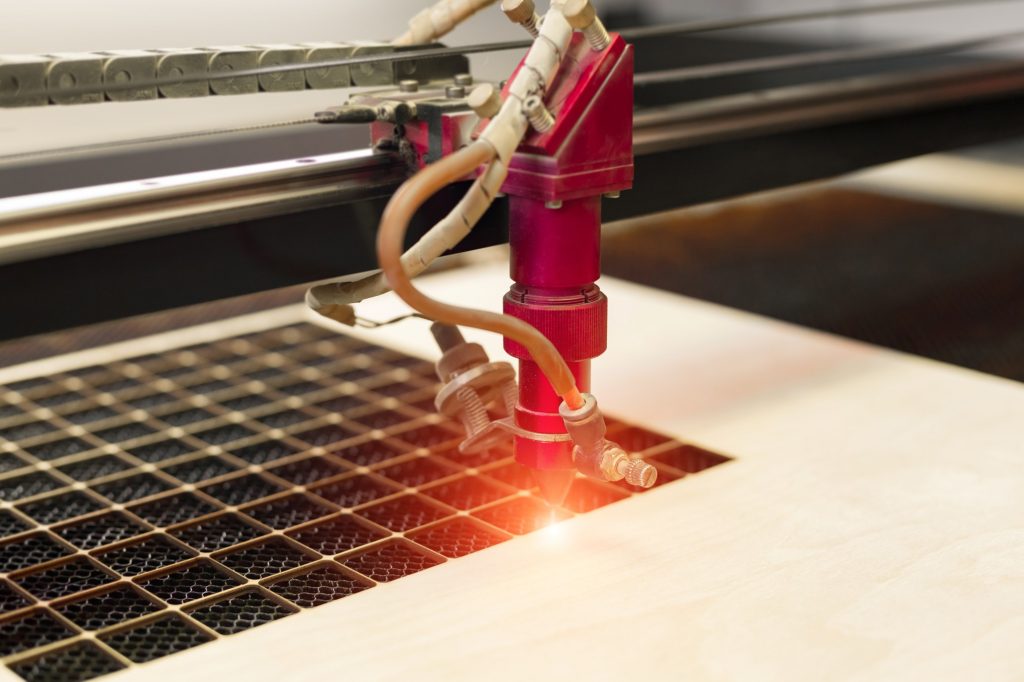

Laser cutting has revolutionized the woodworking industry, enabling the precise and efficient cutting of wood of varying thicknesses. This technology has opened up new possibilities for artisans, manufacturers, and hobbyists alike. This guide delves into the intricacies of laser cutting thick wood, providing insights into the process, considerations, and best practices to achieve optimal results.

Table of Content

Understanding Laser Cutting

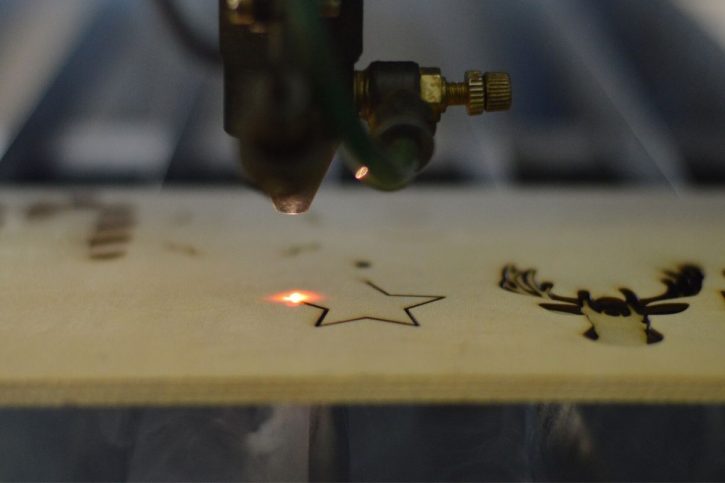

Laser cutting involves directing a concentrated beam of light onto a workpiece, causing the material to vaporize or melt at the point of contact. The laser beam is guided by a computer-controlled system, allowing for precise cutting patterns and intricate designs.

H2: Laser Types

Different types of lasers are used for wood cutting, each with its own characteristics:

- CO2 Lasers: Common for cutting thick wood, offering high power and precision.

- Fiber Lasers: Compact and efficient, providing high beam quality and fast cutting speeds.

- Diode Lasers: Suitable for thinner wood, offering lower power and slower cutting speeds.

DOWNLOAD SVG FILES FOR LASER CUTTING

Considerations for Laser Cutting Thick Wood

H2: Wood Species

Laser cutting has revolutionized the woodworking industry, enabling the precise and efficient cutting of wood of varying thicknesses. This technology has opened up new possibilities for artisans, manufacturers, and hobbyists alike. This guide delves into the intricacies of laser cutting thick wood, providing insights into the process, considerations, and best practices to achieve optimal results.

- Co2 Laser Wood Engraving CO2 Laser Wood Engraving: A Comprehensive Guide To Precision And Creativity

- Custom Laser Cut Wood Panels Custom Laser Cut Wood Panels: Elevate Your Designs With Precision And Versatility

- Good Wood For Laser Engraving Good Wood For Laser Engraving: A Comprehensive Guide To Choosing The Perfect Material

- Laser Cut Pumpkin Wood Laser Cut Pumpkin Wood: A Guide To Carving Intricate Designs For Halloween

- Cut Wood Shapes Cut Wood Shapes: A Comprehensive Guide To Precision Cutting Techniques

Understanding Laser Cutting

H2: Laser Cutting Technology

DOWNLOAD SVG FILES FOR LASER CUTTING

Laser cutting involves directing a concentrated beam of light onto a workpiece, causing the material to vaporize or melt at the point of contact. The laser beam is guided by a computer-controlled system, allowing for precise cutting patterns and intricate designs.

H2: Laser Types

Different types of lasers are used for wood cutting, each with its own characteristics:

The type of wood chosen for laser cutting affects the results. Hardwoods, such as oak and mahogany, require higher laser power and slower cutting speeds compared to softwoods, like pine and cedar.

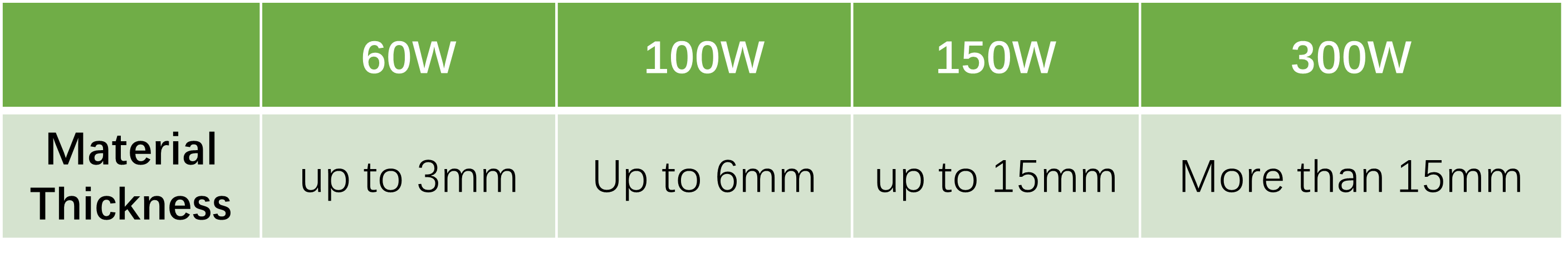

H2: Wood Thickness

The thickness of the wood determines the laser power and cutting parameters required. Thicker wood requires higher laser power and multiple passes to achieve a clean cut.

H2: Laser Power and Speed

Laser power and cutting speed are critical factors. Higher laser power allows for faster cutting, but it can also lead to charring or burning of the wood. Optimal settings vary depending on the wood species and thickness.

H2: Focus and Beam Diameter

The focus and beam diameter of the laser affect the cut quality. A smaller beam diameter and tighter focus result in finer and more precise cuts.

Best Practices for Laser Cutting Thick Wood

H2: Preparing the Wood

- Ensure the wood is clean, dry, and free of knots or defects.

- Sand the surface to remove any imperfections or coatings.

- Mark the cutting design accurately on the wood surface.

H2: Setting Laser Parameters

- Determine the appropriate laser power, cutting speed, and focus based on the wood species and thickness.

- Use test cuts to fine-tune the settings for optimal results.

- Allow for multiple passes for thicker wood to achieve a complete cut.

H2: Cutting Techniques

- Use a vacuum or compressed air to remove debris during cutting.

- Position the wood perpendicular to the laser beam for straight cuts.

- For intricate designs, use a raster engraving mode to ensure accuracy.

H2: Post-Processing

- Sand or polish the cut edges to smooth any rough surfaces.

- Apply a sealant or finish to protect the wood from moisture or wear.

Conclusion

Laser cutting thick wood is a versatile and precise process that requires careful consideration of various factors. By understanding the technology, selecting the appropriate wood species, and following best practices, artisans and manufacturers can achieve high-quality cuts and intricate designs. This advanced technique opens up endless possibilities for woodworking projects, from furniture and cabinetry to architectural elements and artistic creations.

Frequently Asked Questions (FAQs)

Q: What is the maximum thickness of wood that can be laser cut?

A: The maximum thickness depends on the laser power and type of wood. Generally, CO2 lasers can cut wood up to 25 mm thick, while fiber lasers can cut up to 12 mm thick.

Q: How do I prevent charring or burning during laser cutting?

A: Use lower laser power, slower cutting speeds, and a tight focus to minimize heat buildup.

Q: Can I cut different types of wood with the same laser settings?

A: No, different wood species require different laser settings due to variations in density and moisture content.

Q: How do I ensure the accuracy of intricate designs?

A: Use a raster engraving mode and ensure the laser beam is properly focused.

Q: What safety precautions should I take when laser cutting thick wood?

A: Wear appropriate safety gear, including eye protection, gloves, and a respirator. Ensure proper ventilation and fire safety measures.