Laser Cut Vector: A Comprehensive Guide

Introduction

Laser cut vector graphics are becoming increasingly popular in a wide range of industries, from manufacturing to design. They offer a number of advantages over traditional cutting methods, including precision, speed, and versatility. This guide will provide you with all the information you need to know about laser cut vector graphics, including how they are created, the benefits they offer, and the different types of materials that can be cut.

Table of Content

- 1 Laser Cut Vector: A Comprehensive Guide

- 1.1 Introduction

- 1.2 What is Laser Cut Vector?

- 1.3 How is Laser Cut Vector Created?

- 1.4 Benefits of Laser Cut Vector

- 1.5 What is Laser Cut Vector?

- 1.6 How is Laser Cut Vector Created?

- 1.7 Benefits of Laser Cut Vector

- 1.8 Types of Materials that Can Be Laser Cut

- 1.9 Applications of Laser Cut Vector

- 1.10 Conclusion

- 1.11 FAQs

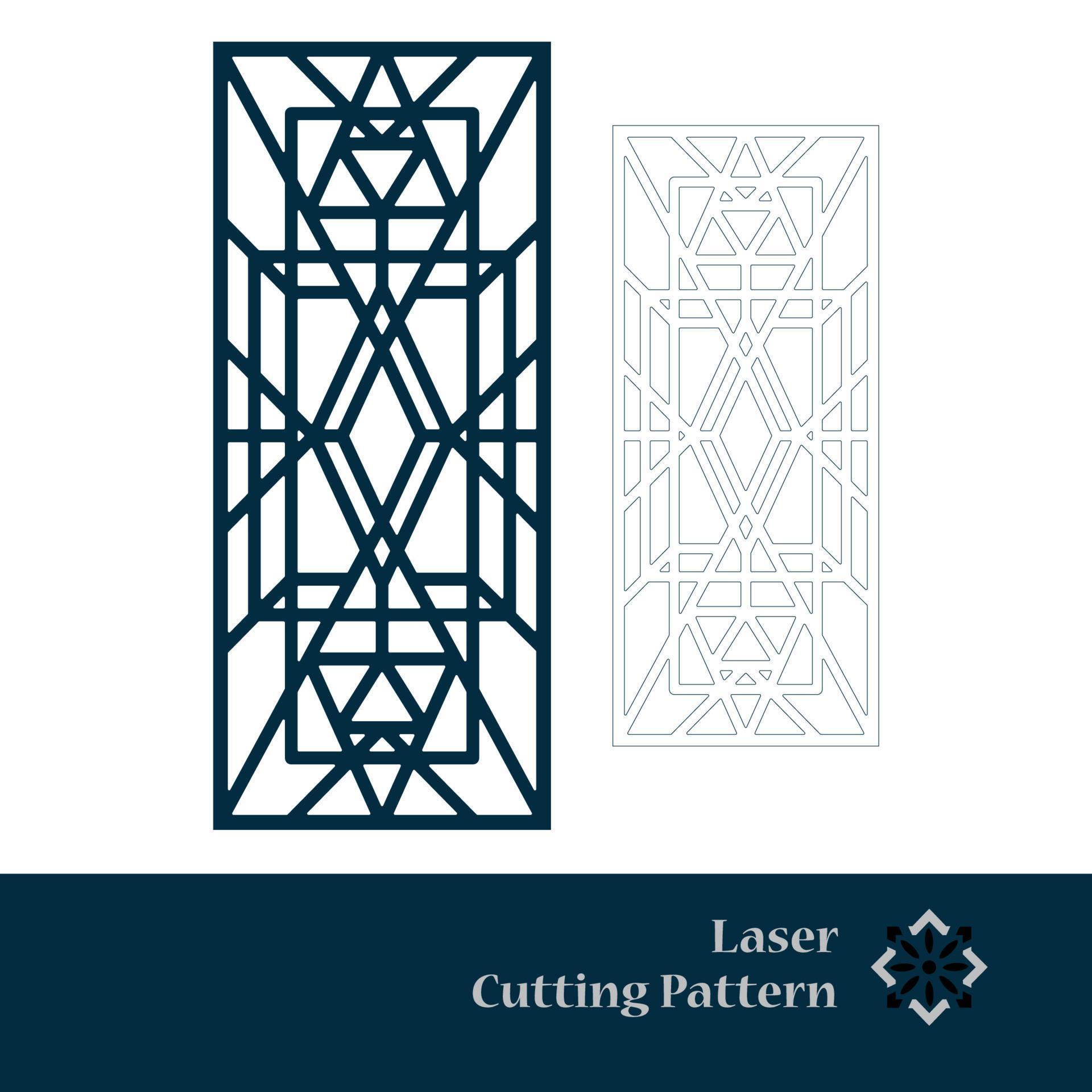

What is Laser Cut Vector?

How is Laser Cut Vector Created?

Laser cut vector graphics are created using a process called laser cutting. Laser cutting is a subtractive manufacturing process, which means that material is removed from the workpiece to create the desired shape. The laser beam is focused on the workpiece and moved along the desired path. The laser beam melts or vaporizes the material, creating a clean and precise cut.

Benefits of Laser Cut Vector

Laser cut vector graphics offer a number of benefits over traditional cutting methods, including:

- Precision: Laser cutting is a very precise process, which allows for intricate and detailed cuts.

- Speed: Laser cutting is a fast process, which can save you time and money.

- Versatility: Laser cutting can be used to cut a wide range of materials, including metal, plastic, wood, and fabric.

- No tooling required: Laser cutting does not require any tooling, which can save you money and time.

- No burrs or sharp edges: Laser cutting produces clean and precise cuts, with no burrs or sharp edges.

- Laser Cut Birthday Calendar Laser Cut Birthday Calendar: A Unique And Thoughtful Gift For Loved Ones

- Laser Cut Birthday Card Template Free H1: Laser Cut Birthday Card Template Free: Elevate Your Celebrations With Exquisite Designs

- Laser Cut Happy Birthday Sign Laser Cut Happy Birthday Sign: A Unique And Personalized Way To Celebrate

- Personalised Laser Cut Birthday Cards Personalised Laser Cut Birthday Cards: A Unique And Thoughtful Gift

- Laser Cut Template Laser Cut Template: The Ultimate Guide To Precision Fabrication

DOWNLOAD SVG FILES FOR LASER CUTTING

Laser cut vector graphics are becoming increasingly popular in a wide range of industries, from manufacturing to design. They offer a number of advantages over traditional cutting methods, including precision, speed, and versatility. This guide will provide you with all the information you need to know about laser cut vector graphics, including how they are created, the benefits they offer, and the different types of materials that can be cut.

What is Laser Cut Vector?

Laser cut vector graphics are created by using a laser to cut a design into a material. The laser is controlled by a computer, which allows for precise and intricate cuts. Vector graphics are made up of lines and curves, which can be scaled to any size without losing quality.

DOWNLOAD SVG FILES FOR LASER CUTTING

How is Laser Cut Vector Created?

Laser cut vector graphics are created using a process called laser cutting. Laser cutting is a subtractive manufacturing process, which means that material is removed from the workpiece to create the desired shape. The laser beam is focused on the workpiece and moved along the desired path. The laser beam melts or vaporizes the material, creating a clean and precise cut.

Benefits of Laser Cut Vector

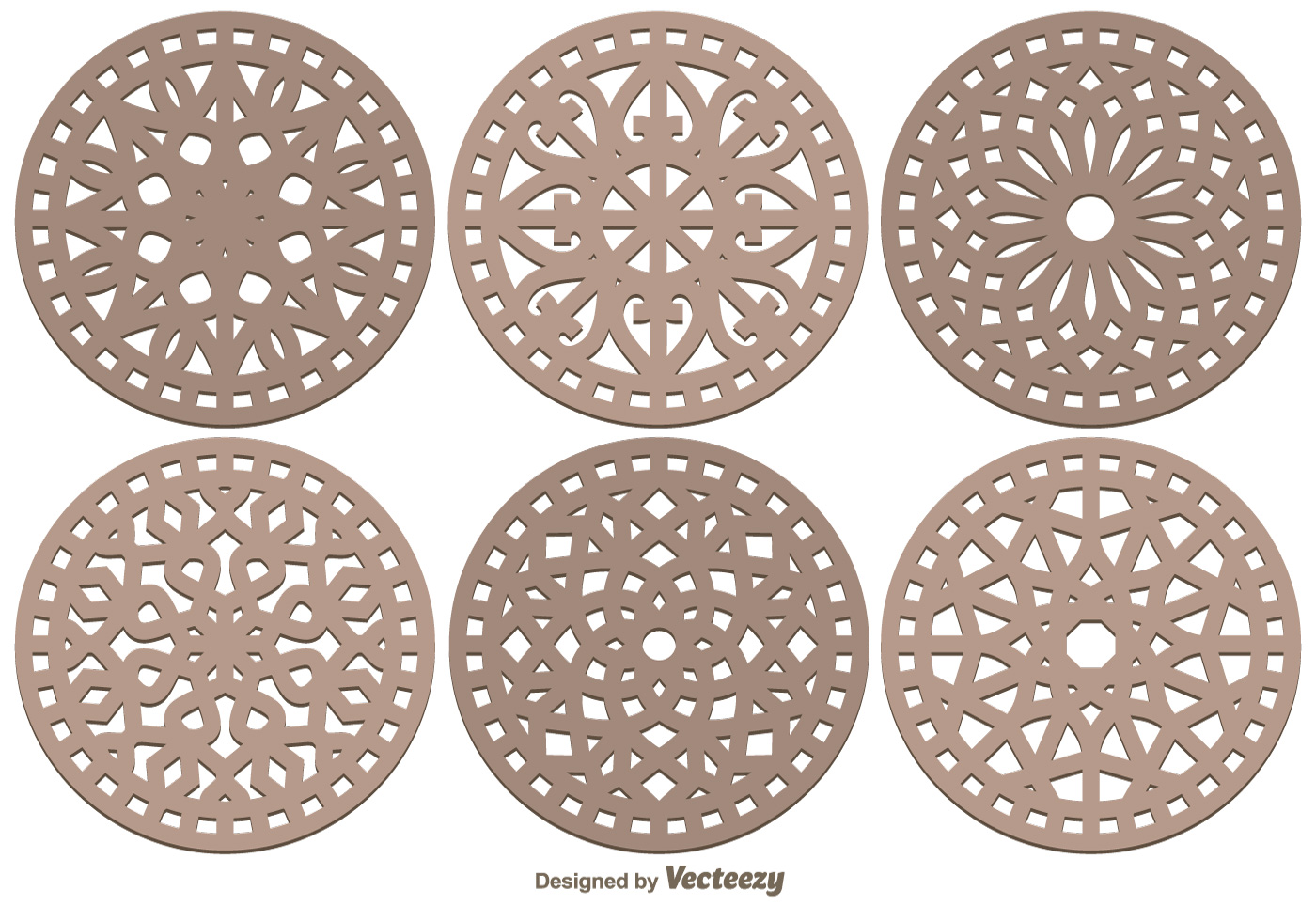

Types of Materials that Can Be Laser Cut

Laser cutting can be used to cut a wide range of materials, including:

- Metal: Laser cutting is commonly used to cut metal, such as steel, aluminum, and stainless steel.

- Plastic: Laser cutting can also be used to cut plastic, such as acrylic, polycarbonate, and polyethylene.

- Wood: Laser cutting can be used to cut wood, such as plywood, MDF, and hardwood.

- Fabric: Laser cutting can also be used to cut fabric, such as cotton, polyester, and nylon.

Applications of Laser Cut Vector

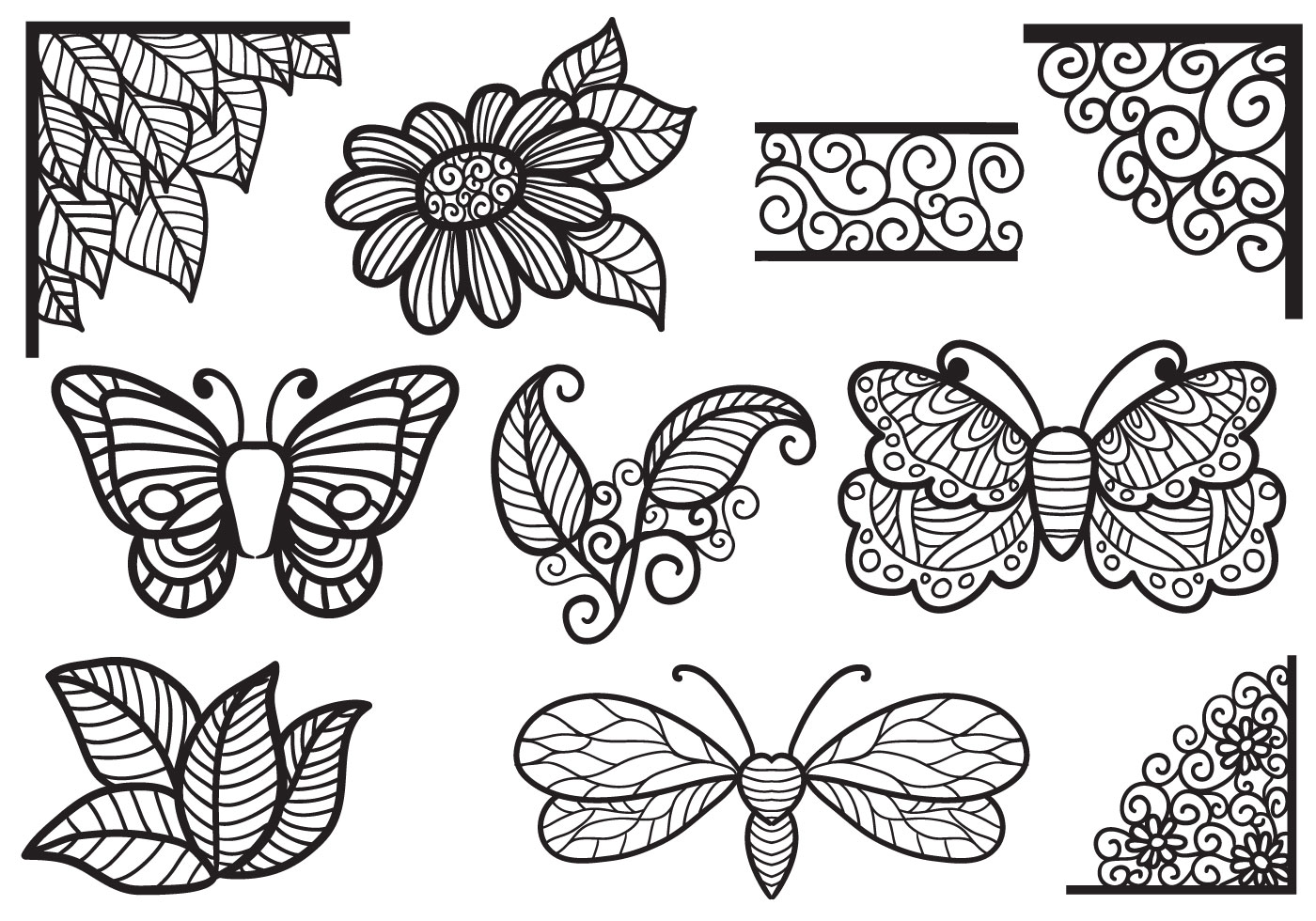

Laser cut vector graphics are used in a wide range of applications, including:

- Manufacturing: Laser cut vector graphics are used in manufacturing to create parts for a variety of products, such as cars, appliances, and electronics.

- Design: Laser cut vector graphics are used in design to create signage, logos, and other decorative items.

- Art: Laser cut vector graphics are used in art to create sculptures, paintings, and other works of art.

Conclusion

Laser cut vector graphics offer a number of advantages over traditional cutting methods, including precision, speed, and versatility. They can be used to cut a wide range of materials, and they are used in a variety of applications. If you are looking for a precise and efficient way to cut materials, laser cutting is a great option.

FAQs

Q: What is the difference between laser cutting and engraving?

A: Laser cutting is a subtractive process that removes material from the workpiece to create the desired shape. Laser engraving is an additive process that creates a design on the surface of the workpiece by melting or vaporizing the material.

Q: What is the maximum thickness of material that can be laser cut?

A: The maximum thickness of material that can be laser cut depends on the type of material and the power of the laser. Most lasers can cut through metal up to 1/2 inch thick, and plastic up to 1 inch thick.

Q: What is the cost of laser cutting?

A: The cost of laser cutting depends on the size and complexity of the design, the type of material, and the quantity of parts being cut.