Laser Cut Wood Design: Transforming Woodworking with Precision and Innovation

Introduction

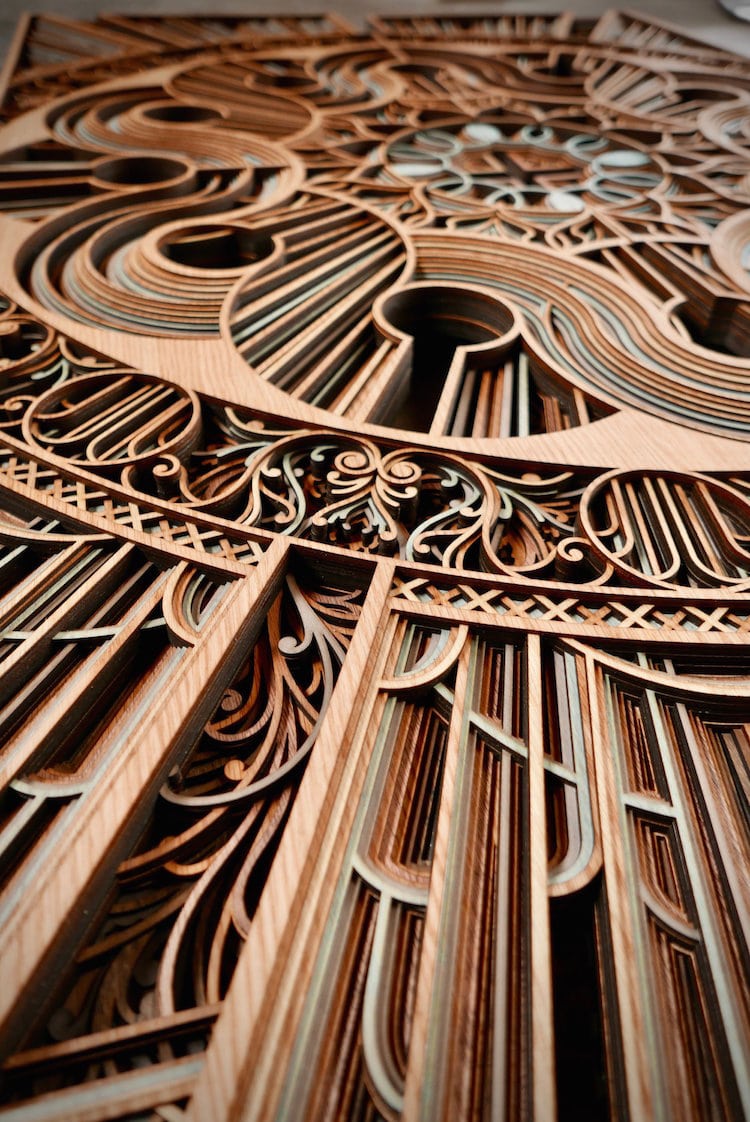

Laser cutting technology has revolutionized the woodworking industry, enabling the creation of intricate and precise designs with unprecedented efficiency. Laser cut wood design harnesses the power of lasers to cut, engrave, and etch wood, unlocking a world of possibilities for craftspeople, designers, and hobbyists alike.

Table of Content

- 1 Laser Cut Wood Design: Transforming Woodworking with Precision and Innovation

- 1.1 Introduction

- 1.2 Benefits of Laser Cut Wood Design

- 1.3 Applications of Laser Cut Wood Design

- 1.4 Benefits of Laser Cut Wood Design

- 1.5 Types of Laser Cutters

- 1.6 Design Considerations for Laser Cut Wood

- 1.7 Safety Precautions

- 1.8 Conclusion

- 1.9 Frequently Asked Questions (FAQs)

Benefits of Laser Cut Wood Design

- Precision: Lasers cut with extreme accuracy, ensuring consistent and clean cuts every time.

- Versatility: Lasers can cut a wide range of wood species and thicknesses, accommodating various project requirements.

- Speed: Laser cutting is significantly faster than manual cutting, reducing production time and increasing efficiency.

- Intricacy: Lasers can create intricate designs and patterns that would be impossible to achieve with hand tools.

- Customization: Laser cutting allows for personalized and unique designs, catering to specific tastes and needs.

Applications of Laser Cut Wood Design

Laser cut wood designs find application in a diverse array of industries and projects, including:

- Wood Panels For Laser Cutting Wood Panels For Laser Cutting: A Comprehensive Guide

- Laser Cut Out Wood Laser Cut Out Wood: A Comprehensive Guide To Precision Cutting And Engraving

- Custom Laser Cut Wood Custom Laser Cut Wood: A Comprehensive Guide To Precision And Creativity

- Cnc Laser For Wood CNC Laser For Wood: A Comprehensive Guide

- Custom Wood Laser Engraving Near Me Custom Wood Laser Engraving Near Me: Your Guide To Precision And Creativity

- Precision: Lasers cut with extreme accuracy, ensuring consistent and clean cuts every time.

- Versatility: Lasers can cut a wide range of wood species and thicknesses, accommodating various project requirements.

- Home Decor: Wall art, furniture accents, decorative panels, and custom lighting fixtures.

- Architecture: Architectural models, custom molding, and decorative elements.

- Industrial Design: Prototyping, product development, and precision manufacturing.

- Signage: Custom signs, logos, and branding materials.

- Toys and Games: Intricate puzzle pieces, game boards, and wooden toys.

- CO2 Laser Cutters: These lasers emit carbon dioxide gas, producing high-power beams that can cut through thick materials like plywood and hardwood.

- Fiber Laser Cutters: These lasers utilize a fiber optic cable to deliver a beam, resulting in faster cutting speeds and improved edge quality.

- Material: Choose wood species compatible with laser cutting and consider the thickness and grain direction.

- Design: Ensure that designs are clean and vector-based, with no overlapping lines or closed paths.

- Cutting Parameters: Adjust laser settings such as power, speed, and focus based on the material and design.

- Finishing: Consider post-processing techniques like sanding, staining, or painting to enhance the finished product.

- Wear appropriate safety gear, including eye protection, gloves, and a respirator.

- Ensure proper ventilation to remove fumes and dust.

- Never leave the laser unattended while in operation.

Laser cutting technology has revolutionized the woodworking industry, enabling the creation of intricate and precise designs with unprecedented efficiency. Laser cut wood design harnesses the power of lasers to cut, engrave, and etch wood, unlocking a world of possibilities for craftspeople, designers, and hobbyists alike.

Benefits of Laser Cut Wood Design

Laser cutting offers numerous advantages over traditional woodworking methods:

DOWNLOAD SVG FILES FOR LASER CUTTING

Types of Laser Cutters

Two main types of laser cutters are used for wood design:

Design Considerations for Laser Cut Wood

When designing for laser cutting, it’s essential to consider the following factors:

Safety Precautions

Laser cutting involves high-energy beams, so it’s crucial to adhere to safety precautions:

Conclusion

Laser cut wood design has become an indispensable tool for woodworkers and designers seeking precision, versatility, and creativity. By harnessing the power of lasers, this technology opens up endless possibilities for creating unique and intricate wooden creations. From home decor to architectural marvels, laser cutting transforms wood into a medium of unparalleled expression and innovation.

Frequently Asked Questions (FAQs)

Q: What are the advantages of laser cutting over traditional woodworking methods?

A: Laser cutting offers precision, versatility, speed, intricacy, and customization.

Q: What types of wood can be laser cut?

A: CO2 and fiber laser cutters can cut a wide range of wood species, including plywood, hardwood, and softwood.

Q: How thick can wood be laser cut?

A: The cutting thickness depends on the laser power and material. CO2 lasers typically cut up to 1 inch thick wood, while fiber lasers can handle thicker materials.

Q: What is the difference between CO2 and fiber laser cutters?

A: CO2 lasers emit carbon dioxide gas, providing high power for thicker materials. Fiber lasers use a fiber optic cable, delivering faster cutting speeds and better edge quality.

Q: What safety precautions should be taken when laser cutting wood?

A: Wear safety gear, ensure proper ventilation, and never leave the laser unattended while in operation.