Laser Cut Wood Plaques: A Comprehensive Guide to Customization and Design

Introduction

Laser cut wood plaques are a versatile and elegant way to create personalized decor, commemorate special occasions, or display artwork. This guide will delve into the intricacies of laser cutting wood plaques, from materials and design considerations to customization options and practical applications.

Table of Content

- 1 Laser Cut Wood Plaques: A Comprehensive Guide to Customization and Design

- 1.1 Introduction

- 1.2 H1: Materials for Laser Cut Wood Plaques

- 1.3 H2: Design Considerations for Laser Cut Wood Plaques

- 1.4 H1: Materials for Laser Cut Wood Plaques

- 1.5 H3: Customization Options for Laser Cut Wood Plaques

- 1.6 H4: Practical Applications of Laser Cut Wood Plaques

- 1.7 H5: Conclusions from Discussion Topics

- 1.8 H6: Frequently Asked Questions (FAQs)

H1: Materials for Laser Cut Wood Plaques

- Hardwoods (e.g., Oak, Mahogany, Cherry): Known for their strength, durability, and intricate grain patterns.

- Softwoods (e.g., Pine, Cedar, Fir): More affordable and easier to cut, but less durable than hardwoods.

- Plywood: An engineered wood product made from thin layers of wood glued together, providing stability and reduced warping.

H2: Design Considerations for Laser Cut Wood Plaques

DOWNLOAD SVG FILES FOR LASER CUTTING

- Size and Shape: Determine the desired size and shape of the plaque based on its intended purpose and display location.

- Detail: Laser cutting allows for intricate and precise detailing, but excessive detail can compromise the plaque’s structural integrity.

- Font and Text: Choose fonts that complement the plaque’s design and ensure readability at the desired viewing distance.

- Large Wood Laser Cutter Large Wood Laser Cutter: The Ultimate Guide For Woodworking Professionals

- Laser Engraver For Wood Laser Engraver For Wood: A Comprehensive Guide

- Cnc Cut Wood Panels CNC Cut Wood Panels: Precision And Versatility For Diverse Applications

- Laser Cut Out Wood Laser Cut Out Wood: A Comprehensive Guide To Precision Cutting And Engraving

- Wood Laser Printing H1: Wood Laser Printing: A Comprehensive Guide To Engraving And Etching On Wood

- Hardwoods (e.g., Oak, Mahogany, Cherry): Known for their strength, durability, and intricate grain patterns.

- Softwoods (e.g., Pine, Cedar, Fir): More affordable and easier to cut, but less durable than hardwoods.

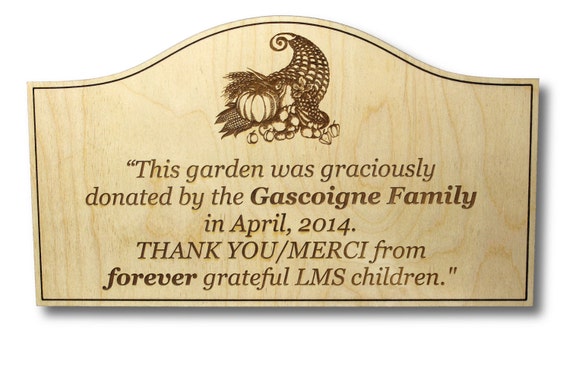

- Image and Graphics: Consider incorporating images or graphics to enhance the visual appeal of the plaque.

- Engraving: Laser engraving creates shallow indentations in the wood, producing a permanent and elegant design.

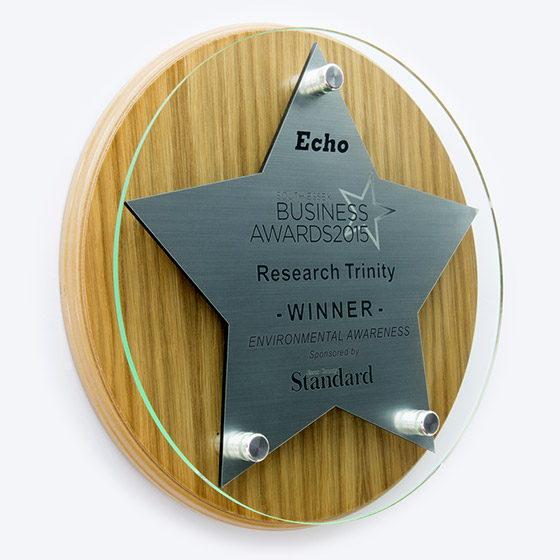

- Cutting: Laser cutting removes sections of wood, creating openwork designs or custom shapes.

- Inlays: Inlay different wood species or materials into the plaque to create contrasting effects or add depth.

- Finishing: Enhance the plaque’s appearance and protect it from wear with finishes such as stains, paints, or clear coats.

- Home Decor: Create personalized wall art, decorative signs, or table centerpieces.

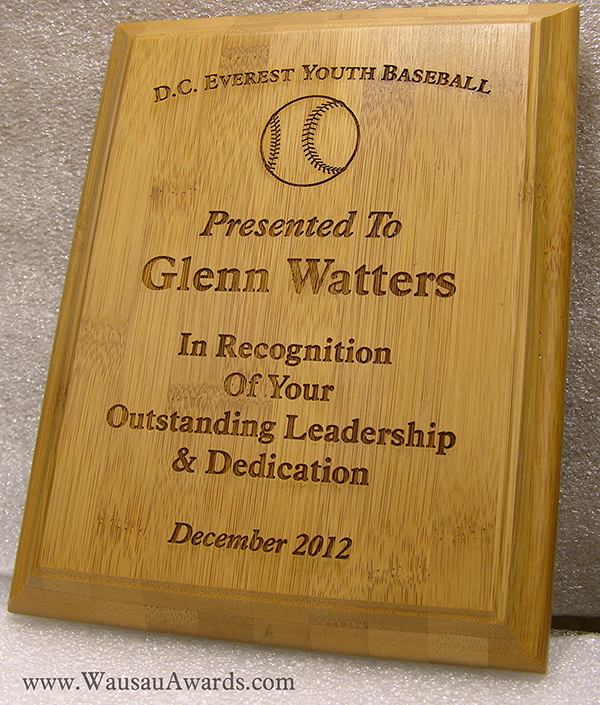

- Commemorative Gifts: Commemorate special occasions such as weddings, anniversaries, or graduations with custom plaques.

- Business Signage: Design professional-looking signs for offices, storefronts, or trade shows.

- Awards and Recognition: Honor achievements or recognize individuals with custom-engraved plaques.

- Material Selection: Hardwoods provide durability and intricate grain patterns, while softwoods are more affordable and easier to cut.

- Design Considerations: Balance detail with structural integrity, and carefully choose fonts and graphics to enhance readability and visual appeal.

- Customization Options: Explore engraving, cutting, inlays, and finishes to create unique and personalized designs.

- Practical Applications: Laser cut wood plaques serve a wide range of practical purposes, from home decor to business signage and commemorative gifts.

- What is the typical thickness of laser cut wood plaques? Usually between 1/8 inch and 1/2 inch, depending on the desired weight and durability.

- Can I use my own design for a laser cut wood plaque? Yes, most laser cutting services allow you to submit your own design files in vector formats.

- How long does it take to create a laser cut wood plaque? Production time varies based on the complexity of the design and the size of the order.

- Can I add color to a laser cut wood plaque? Yes, you can use stains, paints, or inlays to add color and enhance the plaque’s appearance.

Laser cut wood plaques are a versatile and elegant way to create personalized decor, commemorate special occasions, or display artwork. This guide will delve into the intricacies of laser cutting wood plaques, from materials and design considerations to customization options and practical applications.

H1: Materials for Laser Cut Wood Plaques

The choice of wood species significantly impacts the plaque’s appearance, durability, and ease of cutting. Popular options include:

DOWNLOAD SVG FILES FOR LASER CUTTING

H3: Customization Options for Laser Cut Wood Plaques

H4: Practical Applications of Laser Cut Wood Plaques

H5: Conclusions from Discussion Topics

H6: Frequently Asked Questions (FAQs)