Laser Cut Wood Suppliers: A Comprehensive Guide

Introduction

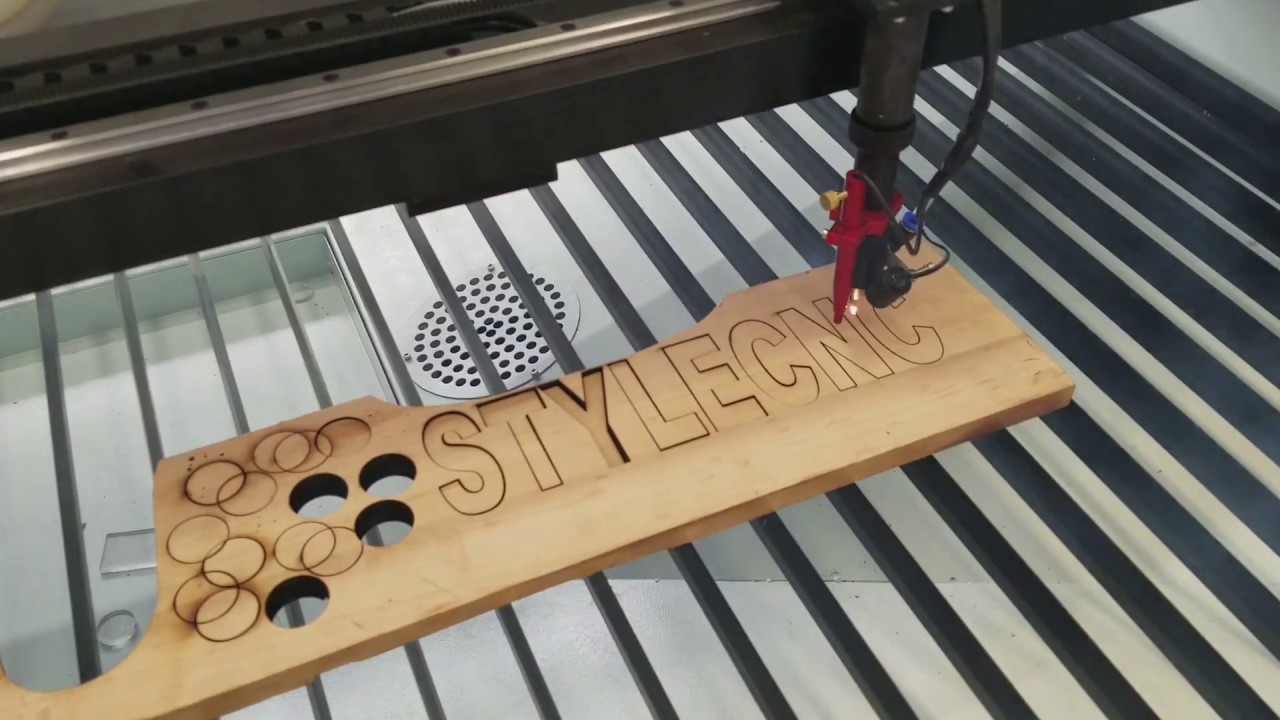

Laser cutting has revolutionized the woodworking industry, enabling precise and intricate designs that were once impossible to achieve with traditional tools. Laser cut wood suppliers cater to this growing demand, providing high-quality materials and services to businesses and individuals alike. This comprehensive guide will explore the key aspects of laser cut wood suppliers, from material selection to design considerations and market trends.

Table of Content

- 1 Laser Cut Wood Suppliers: A Comprehensive Guide

- 1.1 Introduction

- 1.2 H1: Choosing the Right Laser Cut Wood Supplier

- 1.3 H3: Thickness and Grain Orientation

- 1.4 H4: Quality and Consistency

- 1.5 H1: Choosing the Right Laser Cut Wood Supplier

- 1.6 H2: Material Selection

- 1.7 H5: Customer Service and Support

- 1.8 H1: Design Considerations for Laser Cut Wood

- 1.9 H2: File Format and Software

- 1.10 H3: Design Complexity and Detail

- 1.11 H4: Kerf Width and Burn Line

- 1.12 H5: Finishing and Post-Processing

- 1.13 H1: Market Trends and Innovations

- 1.14 H2: Sustainability and Environmental Impact

- 1.15 H3: Automation and Technology

- 1.16 H4: Custom and Bespoke Designs

- 1.17 Conclusion

- 1.18 FAQs

H1: Choosing the Right Laser Cut Wood Supplier

Laser cut wood suppliers offer a wide range of wood species, each with its own unique properties and characteristics.

- Hardwoods: Maple, oak, and cherry are popular hardwoods known for their strength, durability, and attractive grain patterns.

- Softwoods: Pine, cedar, and fir are softwoods that are less dense and more affordable, making them ideal for large-scale projects.

- Engineered Woods: Plywood, MDF, and particle board are engineered wood products that provide a smooth, consistent surface for laser cutting.

DOWNLOAD SVG FILES FOR LASER CUTTING

H3: Thickness and Grain Orientation

The thickness of the wood will determine the depth of the laser cut and the overall strength of the finished product. The grain orientation can also affect the appearance and durability of the laser cut.

H4: Quality and Consistency

Reputable laser cut wood suppliers prioritize quality and consistency in their products. They use high-quality wood and state-of-the-art laser cutting equipment to ensure precise cuts and a clean finish.

Laser cutting has revolutionized the woodworking industry, enabling precise and intricate designs that were once impossible to achieve with traditional tools. Laser cut wood suppliers cater to this growing demand, providing high-quality materials and services to businesses and individuals alike. This comprehensive guide will explore the key aspects of laser cut wood suppliers, from material selection to design considerations and market trends.

- Wooden Laser Cut Wooden Laser Cut: A Comprehensive Guide

- Laser Cutter For Wood Signs Laser Cutter For Wood Signs: The Ultimate Guide To Precision And Creativity

- 3d Laser Wood Cutter 3D Laser Wood Cutter: A Comprehensive Guide To Laser Engraving And Cutting Technology

- Laser Wood Cutter And Engraver Laser Wood Cutter And Engraver: The Ultimate Guide

- Laser Cut Timber Laser Cut Timber: Unlocking Intricate Designs And Precision Manufacturing

H1: Choosing the Right Laser Cut Wood Supplier

H2: Material Selection

DOWNLOAD SVG FILES FOR LASER CUTTING

Laser cut wood suppliers offer a wide range of wood species, each with its own unique properties and characteristics.

- Hardwoods: Maple, oak, and cherry are popular hardwoods known for their strength, durability, and attractive grain patterns.

H5: Customer Service and Support

Excellent customer service is essential for a seamless experience. Look for suppliers who are responsive, knowledgeable, and willing to provide guidance and support throughout the project.

H1: Design Considerations for Laser Cut Wood

H2: File Format and Software

Laser cutting machines require specific file formats, such as DXF or AI. Suppliers often provide design templates or software that can be used to create compatible files.

H3: Design Complexity and Detail

Laser cutting allows for intricate and complex designs. However, it’s important to consider the limitations of the laser machine and the material being used.

H4: Kerf Width and Burn Line

Kerf width refers to the narrow cut created by the laser beam. Burn line is the slight discoloration around the cut edge. Both factors can affect the appearance and precision of the finished product.

H5: Finishing and Post-Processing

Laser cut wood may require additional finishing, such as sanding, painting, or staining. Suppliers can provide recommendations or services for post-processing.

H1: Market Trends and Innovations

H2: Sustainability and Environmental Impact

Consumers are increasingly demanding sustainable and environmentally friendly products. Laser cut wood suppliers are responding by using FSC-certified wood and adopting eco-friendly practices.

H3: Automation and Technology

Laser cutting technology is constantly evolving, with new advancements in automation and efficiency. Suppliers are investing in state-of-the-art equipment to meet the growing demands of the industry.

H4: Custom and Bespoke Designs

Laser cut wood suppliers are increasingly offering custom and bespoke design services. This enables businesses and individuals to create unique and personalized products.

Conclusion

Laser cut wood suppliers play a crucial role in the woodworking industry, providing high-quality materials and services to businesses and individuals alike. By choosing the right supplier, considering design factors, and staying abreast of market trends, you can unlock the full potential of laser cutting for your projects.

FAQs

Q: What is the best wood for laser cutting?

A: The best wood for laser cutting depends on the desired application. Hardwoods offer strength and durability, while softwoods are more affordable and easier to cut.

Q: How thick can laser cut wood be?

A: The thickness of laser cut wood varies depending on the laser machine and material being used. Most suppliers can cut wood up to 1/2 inch thick.

Q: Can laser cut wood be painted or stained?

A: Yes, laser cut wood can be painted or stained to enhance its appearance and protect it from the elements.

Q: What is the kerf width of a laser cut?

A: The kerf width is typically 0.005 to 0.01 inches, depending on the laser machine and material being used.

Q: How do I choose a laser cut wood supplier?

A: Consider factors such as material selection, quality and consistency, customer service, and design support when choosing a laser cut wood supplier.