Laser Cut Wooden Box Design: A Comprehensive Guide

Introduction

Laser cut wooden boxes offer a blend of elegance, precision, and versatility. They have become increasingly popular for a wide range of applications, from storage to decoration. This article provides an in-depth guide to laser cut wooden box design, exploring the various factors to consider, design techniques, and best practices.

Table of Content

H1: Design Considerations

The choice of wood for your laser cut box is crucial. Consider factors such as:

- Hardness: Softwoods like pine are easy to cut but may not provide sufficient durability. Hardwoods like oak offer greater strength and longevity.

- Grain Pattern: The grain pattern can affect the appearance and structural integrity of the box. Choose a wood with a grain that complements your design.

- Color and Finish: The natural color and finish of the wood can be preserved or enhanced with stains, paints, or clear coatings.

DOWNLOAD SVG FILES FOR LASER CUTTING

H2: Box Shape and Size

Determine the desired shape and size of your box based on its intended purpose. Consider:

- Length, Width, and Height: Ensure the box is large enough to accommodate its contents while maintaining a practical size.

- Wood Laser Engraver And Cutter Wood Laser Engraver And Cutter: A Comprehensive Guide

- Unfinished Laser Cut Wood Unfinished Laser Cut Wood: A Comprehensive Guide

- Wooden Laser Cut Ornaments Wooden Laser Cut Ornaments: A Timeless And Versatile Holiday Decoration

- Fiber Laser Wood Fiber Laser Wood: A Comprehensive Guide

- Laser Cut Wood Shapes Laser Cut Wood Shapes: Unleashing Creativity And Precision

- Hardness: Softwoods like pine are easy to cut but may not provide sufficient durability. Hardwoods like oak offer greater strength and longevity.

- Shape: Explore various shapes such as rectangular, square, round, or hexagonal to suit your aesthetic preferences.

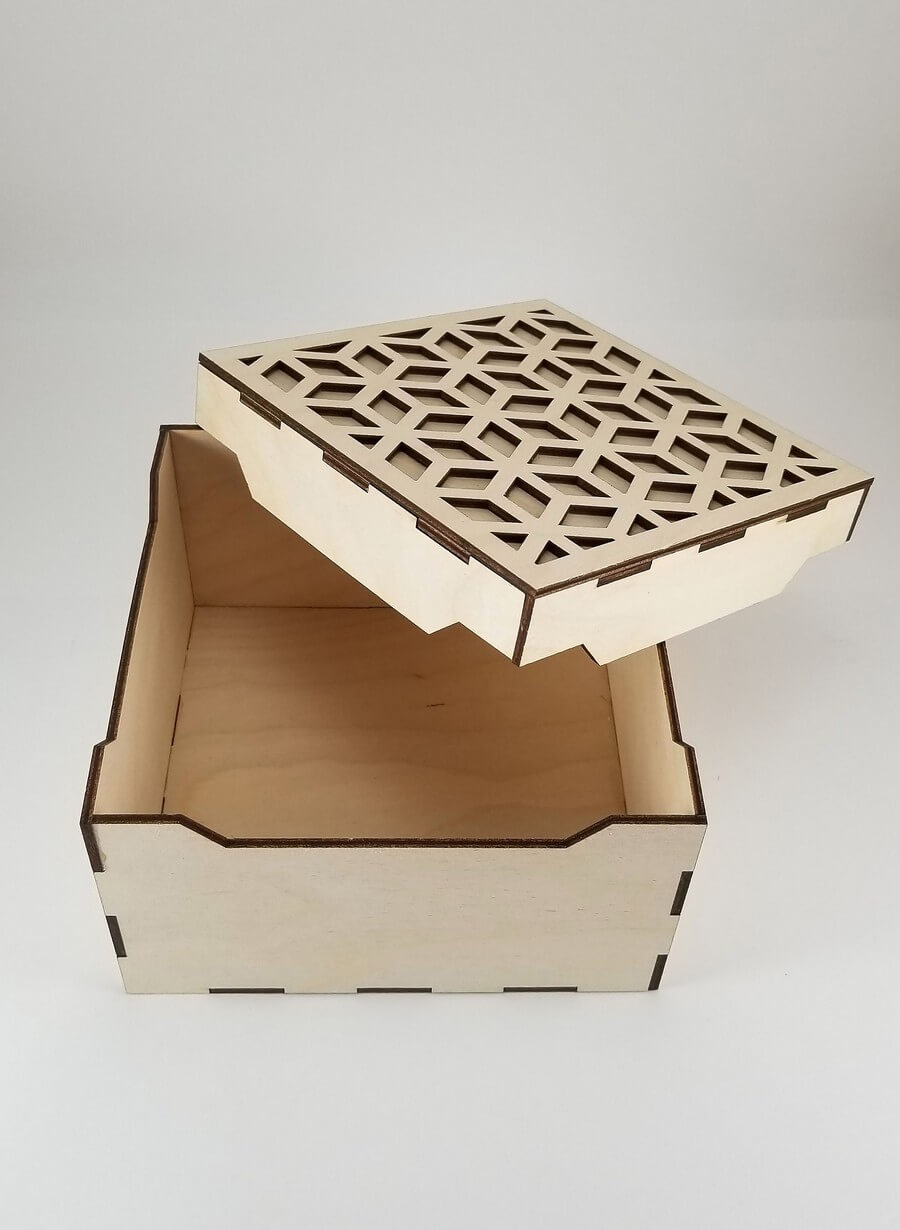

- Lid Design: Choose a lid style that provides secure closure and complements the overall design, such as hinged, sliding, or lift-off.

- Laser Power: Adjust the power to ensure clean and precise cuts without burning or charring the wood.

- Cutting Speed: A higher cutting speed can lead to faster production, but it may compromise cut quality. Find the optimal balance for your material.

- Focal Length: The focal length of the laser lens influences the depth and width of the cut. Adjust it to achieve the desired cut depth.

- Finger Joints: Interlocking finger-shaped joints create a sturdy and aesthetically pleasing connection.

- Box Joints: Box joints offer increased strength and stability, making them suitable for larger or heavy-duty boxes.

- Dovetail Joints: Dovetail joints provide a highly durable and decorative connection, commonly used in fine woodworking.

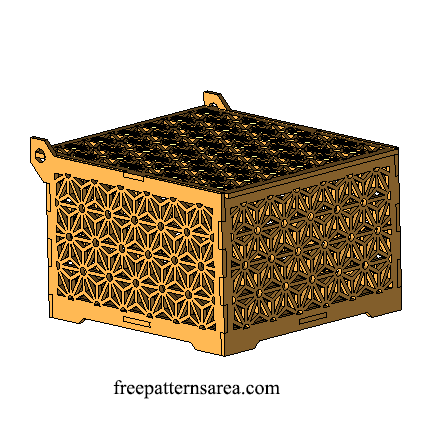

- Engraving: Engrave designs, logos, or text onto the wood surface for a personalized touch.

- Inlays: Cut out shapes from contrasting materials and inlay them into the wood surface to create intricate patterns.

- Perforations: Cut small holes or patterns into the wood to create a decorative and functional feature.

- Wear Protective Gear: Wear appropriate eye protection, gloves, and respiratory mask during laser operation.

- Ventilate the Area: Ensure proper ventilation to remove fumes and dust particles generated during cutting.

- Secure the Material: Clamp or hold the wood material securely to prevent movement during cutting.

Laser cut wooden boxes offer a blend of elegance, precision, and versatility. They have become increasingly popular for a wide range of applications, from storage to decoration. This article provides an in-depth guide to laser cut wooden box design, exploring the various factors to consider, design techniques, and best practices.

H1: Design Considerations

H2: Material Selection

DOWNLOAD SVG FILES FOR LASER CUTTING

The choice of wood for your laser cut box is crucial. Consider factors such as:

H3: Laser Cutting Parameters

The laser cutting parameters significantly impact the quality of the cut. Optimize these settings based on:

H1: Design Techniques

H2: Vector Graphics

Laser cutting requires vector graphics as input. Use a design software to create accurate vector files that define the shape and dimensions of the box.

H3: Joint Design

Choose joint designs that provide strong and secure connections between the box parts. Consider:

H2: Decorative Elements

Incorporate decorative elements into your design to enhance its visual appeal. Explore techniques such as:

H1: Best Practices

H2: Material Preparation

Prepare the wood material properly to ensure optimal laser cutting results. Sand and smooth the surface to remove any imperfections or splinters.

H3: Test Cuts

Before cutting the actual box parts, perform test cuts on scrap wood to fine-tune the laser cutting parameters and minimize waste.

H2: Safety Precautions

Laser cutting involves potential hazards. Adhere to safety precautions such as:

Conclusion

Laser cut wooden boxes offer a versatile and elegant solution for a wide range of applications. By carefully considering the design considerations, employing effective design techniques, and following best practices, you can create stunning and functional wooden boxes that meet your specific requirements.

FAQs

Q: What is the best wood for laser cutting boxes?

A: Hardwoods like oak, mahogany, or walnut provide excellent durability and cut quality.

Q: How do I create vector graphics for laser cutting?

A: Use design software such as Adobe Illustrator or CorelDRAW to create accurate vector files that define the shape and dimensions of the box.

Q: What is the difference between finger joints and box joints?

A: Finger joints are interlocking finger-shaped joints, while box joints offer increased strength and stability due to their interlocking box-shaped design.

Q: How do I prevent the wood from burning or charring during laser cutting?

A: Optimize the laser cutting parameters, such as power and speed, to minimize heat buildup and ensure clean cuts.