Laser Cut Wood: A Comprehensive Guide to Precision, Creativity, and Versatility

Laser cutting, a cutting-edge technology, has revolutionized the world of woodworking, enabling intricate designs, precise cuts, and a wide range of applications. Laser cut wood, with its exceptional accuracy and versatility, has become an indispensable material for artists, hobbyists, and businesses alike.

Understanding Laser Cutting Technology

Table of Content

- 1 Laser Cut Wood: A Comprehensive Guide to Precision, Creativity, and Versatility

- 1.1 Understanding Laser Cutting Technology

- 1.2 Applications of Laser Cut Wood

- 1.3 Understanding Laser Cutting Technology

- 1.4 Benefits of Laser Cut Wood

- 1.5 Types of Laser Cutting Machines

- 1.6 Selecting the Right Laser Cutting Machine

- 1.7 Safety Considerations

- 1.8 Conclusion

- 1.9 Frequently Asked Questions

Laser cutting is a process that utilizes a highly focused laser beam to vaporize or melt material, creating clean and precise cuts. The laser beam, generated by a laser source, is directed through a series of mirrors and lenses to achieve the desired cutting pattern.

Laser cutting wood offers numerous advantages over traditional cutting methods, including:

- Precision: Laser beams can cut with extreme precision, allowing for intricate designs and fine details.

- Smooth Edges: The laser beam melts the edges of the wood, resulting in smooth and polished finishes.

- Speed: Laser cutting is a relatively fast process, making it efficient for large-scale production.

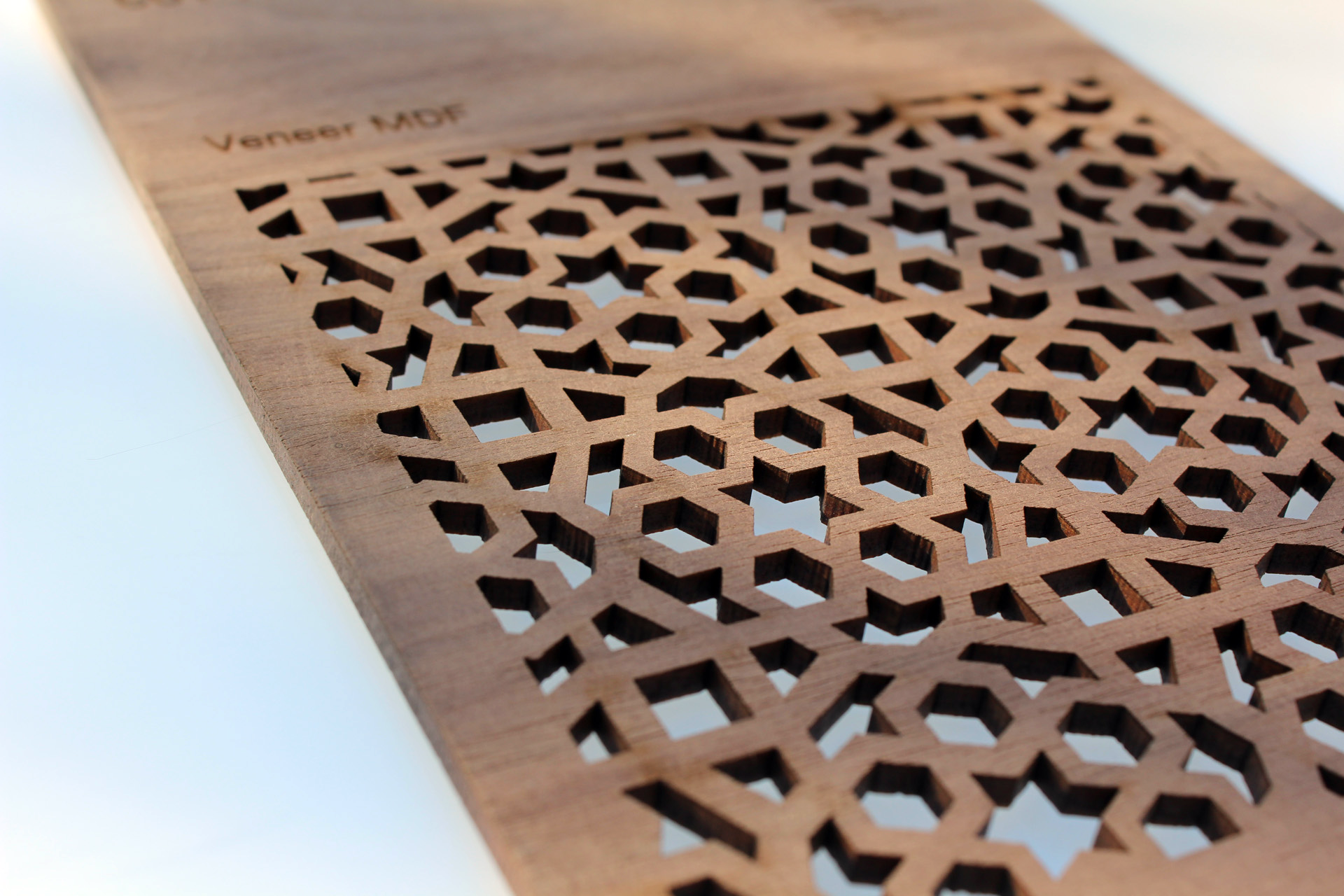

- Versatility: Laser cutting can be used on various wood types, including plywood, MDF, and hardwood.

- Environmental Friendliness: Laser cutting produces minimal waste and does not require the use of harmful chemicals.

DOWNLOAD SVG FILES FOR LASER CUTTING

Applications of Laser Cut Wood

Laser cut wood has found its way into a vast array of applications, including:

Understanding Laser Cutting Technology

- How To Use Wood Laser Cutter How To Use A Wood Laser Cutter: A Comprehensive Guide

- Laser Cut Wooden Arrow Laser Cut Wooden Arrow: A Comprehensive Guide

- Laser Cut Wooden Lampshades Laser Cut Wooden Lampshades: Illuminating Your Space With Precision And Style

- Wood Laser Cutter Canada Wood Laser Cutter Canada: A Comprehensive Guide To Precision Cutting Solutions

- Laser Cut Wooden Hinge Laser Cut Wooden Hinge: A Comprehensive Guide

Laser cutting is a process that utilizes a highly focused laser beam to vaporize or melt material, creating clean and precise cuts. The laser beam, generated by a laser source, is directed through a series of mirrors and lenses to achieve the desired cutting pattern.

Benefits of Laser Cut Wood

DOWNLOAD SVG FILES FOR LASER CUTTING

Laser cutting wood offers numerous advantages over traditional cutting methods, including:

- Precision: Laser beams can cut with extreme precision, allowing for intricate designs and fine details.

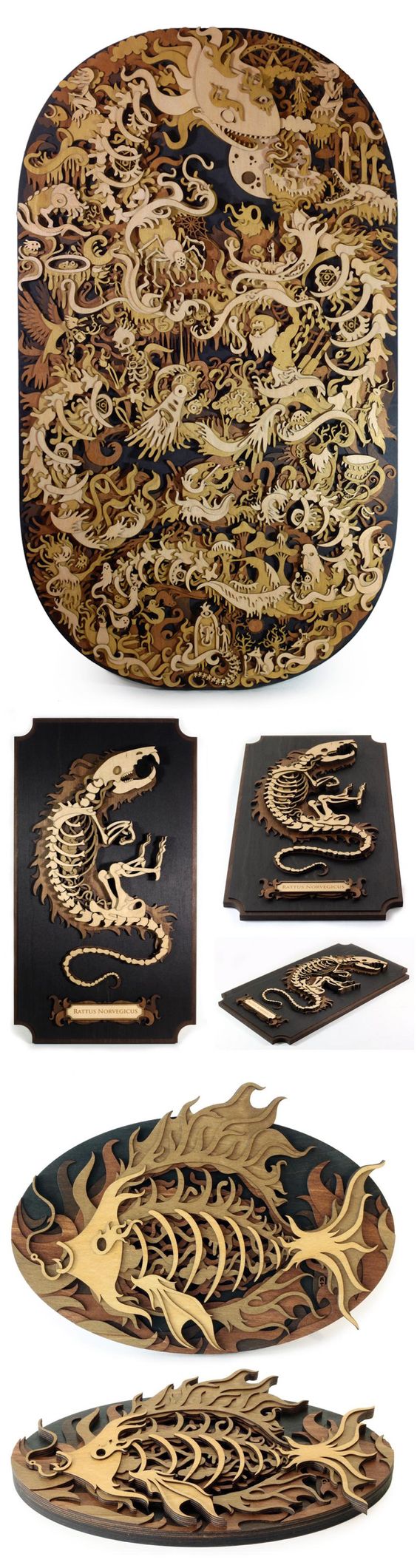

- Decorative Art: Laser cut wood is widely used for creating decorative wall art, sculptures, and home decor.

- Personalized Gifts: Laser cutting enables the creation of personalized gifts, such as engraved plaques, jewelry, and keepsakes.

- Toys and Games: Laser cut wood is ideal for crafting intricate toys, puzzles, and board games.

- Industrial Applications: Laser cut wood is used in industries such as packaging, furniture making, and automotive manufacturing.

- CO2 Laser Cutters: These machines use carbon dioxide gas to generate the laser beam and are suitable for cutting thicker wood materials.

- Fiber Laser Cutters: Fiber laser cutters use a fiber optic cable to deliver the laser beam, providing higher cutting speeds and precision.

- Diode Laser Cutters: Diode laser cutters are compact and affordable, but their cutting power is limited to thin wood materials.

- Cutting Thickness: Determine the maximum thickness of wood you need to cut.

- Cutting Speed: Consider the speed at which you need to cut the wood.

- Precision: Assess the level of precision required for your projects.

- Budget: Set a realistic budget for the machine and associated operating costs.

- Wear Proper Gear: Wear protective glasses, gloves, and a mask to protect yourself from laser radiation and fumes.

- Ventilate the Area: Ensure adequate ventilation to prevent the accumulation of harmful fumes.

- Keep Children and Pets Away: Laser cutting equipment should be operated in a secure area away from children and pets.

- Never Look Directly at the Laser: Direct exposure to the laser beam can cause severe eye damage.

Types of Laser Cutting Machines

Different types of laser cutting machines are available, each with its own capabilities and price range:

Selecting the Right Laser Cutting Machine

When choosing a laser cutting machine, consider the following factors:

Safety Considerations

Laser cutting involves the use of high-powered lasers, which can be dangerous if not handled properly. Always adhere to the following safety guidelines:

Conclusion

Laser cut wood has emerged as a versatile and powerful material that opens up a world of possibilities for creatives, hobbyists, and businesses. Its precision, speed, and environmental friendliness make it an ideal choice for a wide range of applications. By understanding laser cutting technology, choosing the right machine, and adhering to safety guidelines, you can harness the potential of laser cut wood to bring your projects to life.

Frequently Asked Questions

Q: What is the difference between laser cutting and CNC routing?

A: Laser cutting uses a laser beam to cut material, while CNC routing uses a rotating tool to cut material. Laser cutting provides higher precision and smoother edges, while CNC routing is more versatile and can cut a wider range of materials.

Q: Can laser cutting be used to cut metal?

A: Yes, laser cutting can be used to cut metal, but it requires a different type of laser machine and cutting parameters.

Q: What are the advantages of using laser cut wood for decorative art?

A: Laser cut wood offers intricate designs, precise cuts, and the ability to create complex patterns and textures that are difficult to achieve with traditional cutting methods.