Laser Cuttable Wood: A Comprehensive Guide for Precision Cutting and Crafting

Introduction

Laser cutting technology has revolutionized the woodworking industry, enabling intricate designs, precise cuts, and mass production. Laser cuttable wood has emerged as a versatile and cost-effective material for a wide range of applications. This article provides a comprehensive overview of laser cuttable wood, exploring its properties, advantages, applications, and techniques.

Table of Content

- 1 Laser Cuttable Wood: A Comprehensive Guide for Precision Cutting and Crafting

- 1.1 Introduction

- 1.2 Properties of Laser Cuttable Wood

- 1.3 Advantages of Using Laser Cuttable Wood

- 1.4 Properties of Laser Cuttable Wood

- 1.5 Applications of Laser Cuttable Wood

- 1.6 Techniques for Laser Cutting Wood

- 1.7 Choosing the Right Laser Cuttable Wood

- 1.8 Safety Considerations

- 1.9 Conclusion

- 1.10 FAQs

Properties of Laser Cuttable Wood

- Smooth and consistent surface: Ensures precise and clean cuts.

- Thinness: Allows for intricate and detailed designs.

- Stability: Resists warping and deformation during the cutting process.

- Laser-absorbent: Enables the laser to effectively engrave and cut the material.

DOWNLOAD SVG FILES FOR LASER CUTTING

Advantages of Using Laser Cuttable Wood

Laser cutting offers numerous advantages over traditional woodworking methods:

- Precision and accuracy: Lasers produce highly precise and repeatable cuts, minimizing waste and improving efficiency.

- Handheld Laser Wood Cutter Handheld Laser Wood Cutter: A Comprehensive Guide

- Laser Compatible Wood Laser Compatible Wood: A Comprehensive Guide To Engraving And Cutting

- Wood Laser Cutting Near Me Wood Laser Cutting Near Me: A Comprehensive Guide To Finding The Best Services

- Laser Engraving Wood Near Me Laser Engraving Wood Near Me: A Comprehensive Guide

- Laser Cutting On Wood Near Me Laser Cutting On Wood: A Comprehensive Guide For Precision And Intricacy

- Smooth and consistent surface: Ensures precise and clean cuts.

- Thinness: Allows for intricate and detailed designs.

- Intricate designs: Laser cutting enables the creation of complex and intricate designs that would be difficult or impossible to achieve manually.

- Speed and efficiency: Laser cutting is a fast and automated process, allowing for high-volume production.

- Versatility: Laser cuttable wood can be used for a variety of applications, from decorative pieces to functional components.

- Reduced labor costs: Automation reduces labor costs and improves productivity.

- Art and design: Intricate decorative pieces, custom artwork, and wall hangings.

- Home décor: Furniture components, wall panels, and lighting fixtures.

- Industrial: Prototyping, packaging, and signage.

- Educational: Models, puzzles, and teaching aids.

- Toys and games: Puzzle pieces, game boards, and wooden toys.

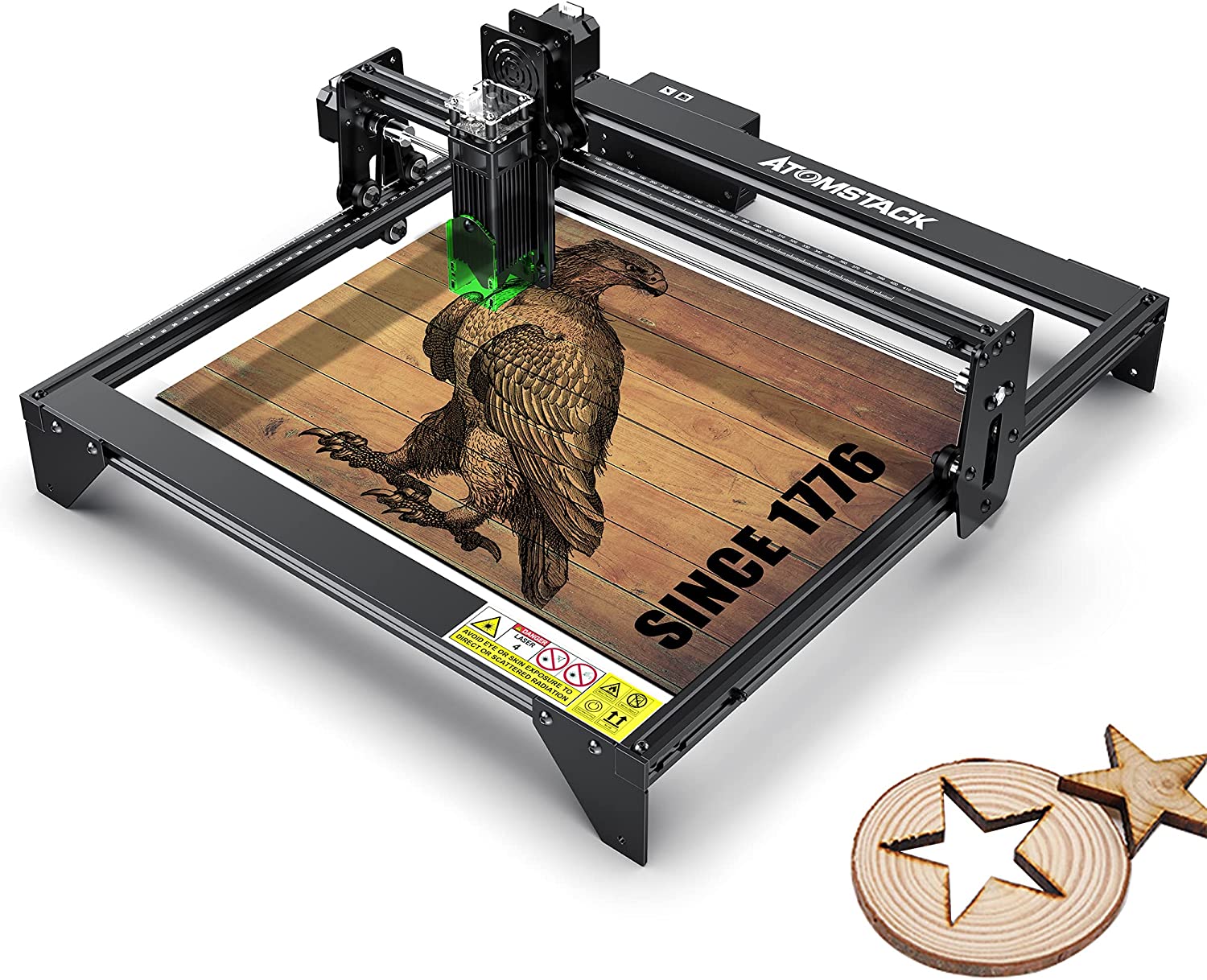

- Laser cutter: A machine that generates a focused laser beam to cut and engrave materials.

- CAD software: Design software used to create digital designs for the laser cutter.

- Laser settings: Adjusting laser power, speed, and focus to suit the material and desired cut quality.

- Material preparation: Ensuring the wood is clean and free of debris before cutting.

- Post-processing: Sanding, finishing, or painting to enhance the appearance and durability of the cut pieces.

- Plywood: Durable and versatile, suitable for structural components and decorative pieces.

- MDF: Smooth and dense, ideal for intricate designs and engraving.

- Acrylic: Translucent and lightweight, often used for decorative applications and signage.

- Eye protection: Wear laser-safe goggles to protect eyes from the laser beam.

- Ventilation: Adequate ventilation is necessary to remove harmful fumes and particles.

- Fire safety: Keep a fire extinguisher nearby and follow safety protocols in case of fire.

- Electrical safety: Ensure proper electrical connections and grounding.

Laser cutting technology has revolutionized the woodworking industry, enabling intricate designs, precise cuts, and mass production. Laser cuttable wood has emerged as a versatile and cost-effective material for a wide range of applications. This article provides a comprehensive overview of laser cuttable wood, exploring its properties, advantages, applications, and techniques.

Properties of Laser Cuttable Wood

Laser cuttable wood is typically made from thin sheets of plywood, MDF (medium-density fiberboard), or acrylic. These materials are chosen for their:

DOWNLOAD SVG FILES FOR LASER CUTTING

Applications of Laser Cuttable Wood

Laser cuttable wood finds applications in numerous industries, including:

Techniques for Laser Cutting Wood

Laser cutting wood requires specialized equipment and techniques to achieve optimal results:

Choosing the Right Laser Cuttable Wood

Selecting the appropriate laser cuttable wood depends on the specific application and desired results:

Safety Considerations

Laser cutting involves potential hazards that require safety precautions:

Conclusion

Laser cuttable wood has revolutionized woodworking by enabling precision cutting, intricate designs, and high-volume production. Its versatility and cost-effectiveness make it an ideal material for a wide range of applications. By understanding the properties, advantages, and techniques involved in laser cutting wood, users can harness its capabilities to create innovative and high-quality products.

FAQs

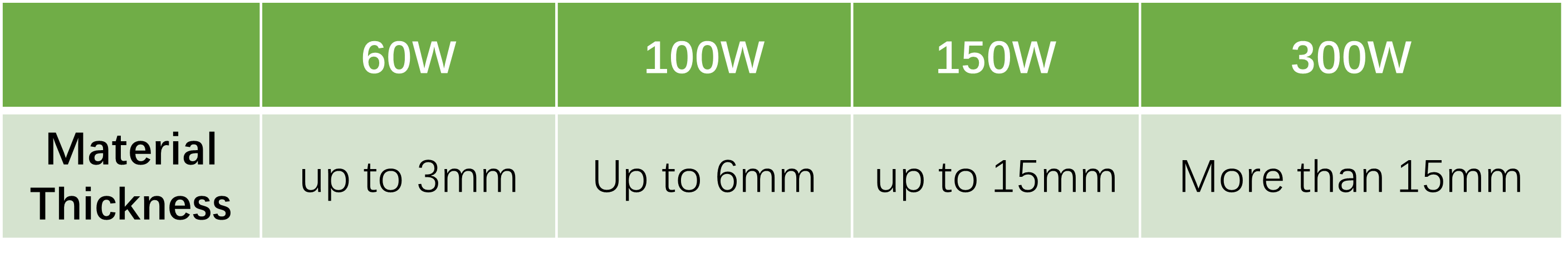

Q: What is the maximum thickness of wood that can be laser cut?

A: The maximum thickness depends on the laser cutter and material used. Typically, laser cutters can cut wood up to 1/4 inch thick.

Q: Can laser cut wood be painted or stained?

A: Yes, laser cut wood can be painted or stained to enhance its appearance and durability.

Q: How do I minimize burning and smoke during laser cutting?

A: Use appropriate laser settings, ensure good ventilation, and consider using masking tape to protect the wood surface.

Q: What are the common file formats used for laser cutting wood?

A: Common file formats include SVG, DXF, and AI.

Q: Can laser cutting create 3D objects from wood?

A: While laser cutting is primarily used for 2D cutting, it is possible to create 3D objects by stacking and assembling laser-cut pieces.