Laser Cutter 3D Printer: The Ultimate Guide for Precision Cutting and Creation

Introduction

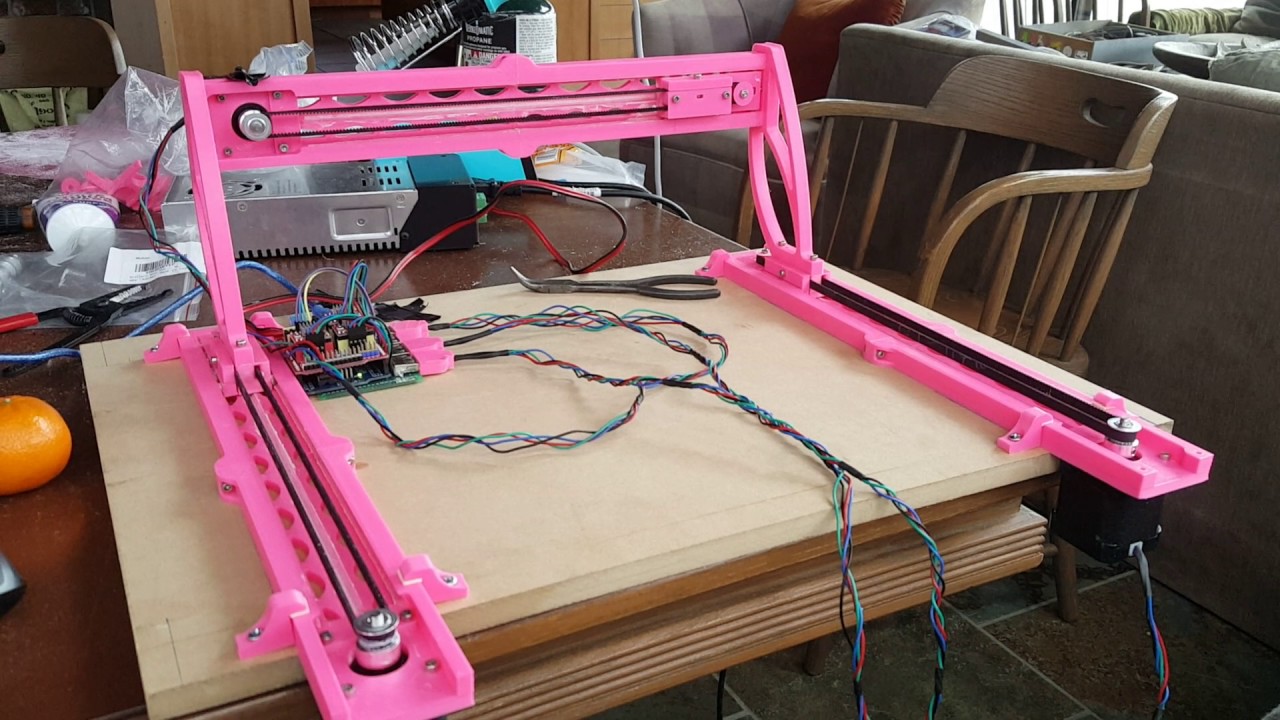

In the realm of fabrication and prototyping, the convergence of laser cutters and 3D printers has revolutionized the landscape. Laser cutter 3D printers combine the precision and speed of laser cutting with the versatility and layered deposition capabilities of 3D printing, empowering makers, engineers, and designers alike to create intricate and functional objects with unparalleled accuracy and efficiency.

Table of Content

- 1 Laser Cutter 3D Printer: The Ultimate Guide for Precision Cutting and Creation

- 1.1 Introduction

- 1.2 H1: Understanding the Technology Behind Laser Cutter 3D Printers

- 1.3 H2: Advantages of Laser Cutter 3D Printers

- 1.4 H3: Applications of Laser Cutter 3D Printers

- 1.5 H1: Understanding the Technology Behind Laser Cutter 3D Printers

- 1.6 H2: Advantages of Laser Cutter 3D Printers

- 1.7 H4: Factors to Consider When Choosing a Laser Cutter 3D Printer

- 1.8 H5: Safety Precautions for Laser Cutter 3D Printers

- 1.9 H6: Troubleshooting Common Issues

- 1.10 Conclusion

- 1.11 FAQs

H1: Understanding the Technology Behind Laser Cutter 3D Printers

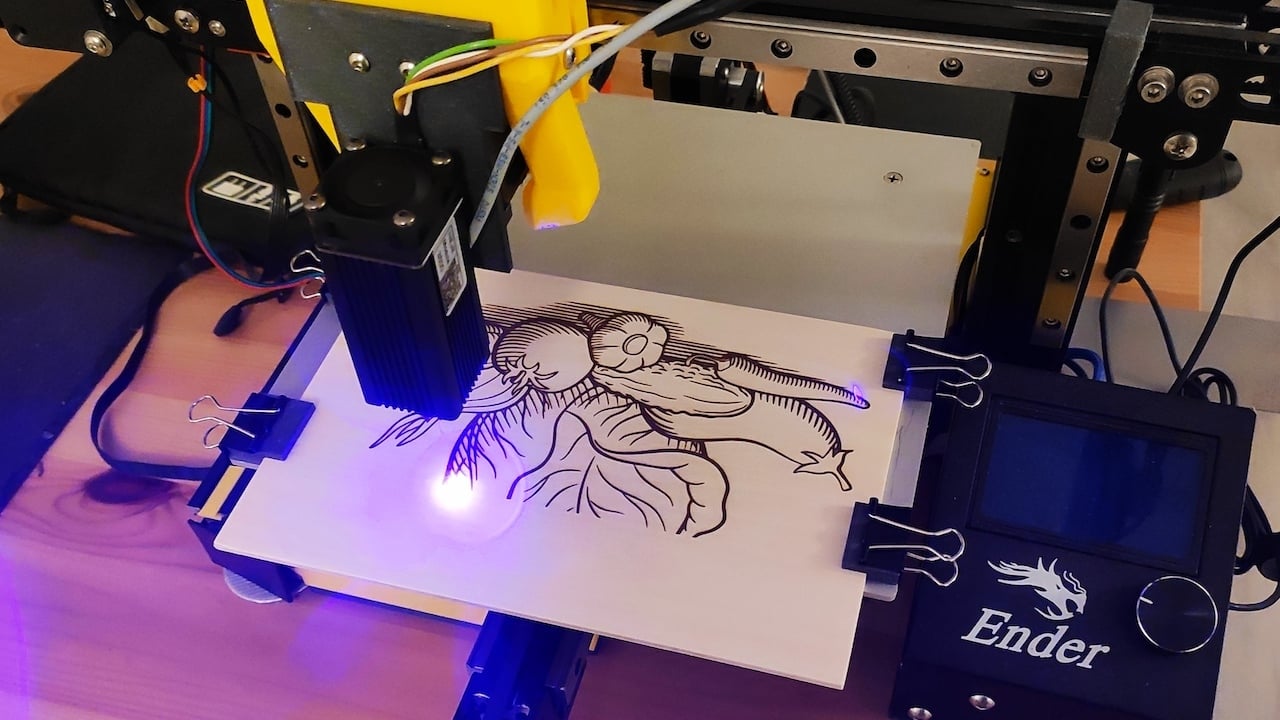

Laser Cutting: Laser cutters utilize a high-powered laser beam to precisely cut through various materials, including wood, acrylic, metal, and even fabrics. The laser beam is computer-controlled, enabling intricate designs and precise cuts with minimal waste.

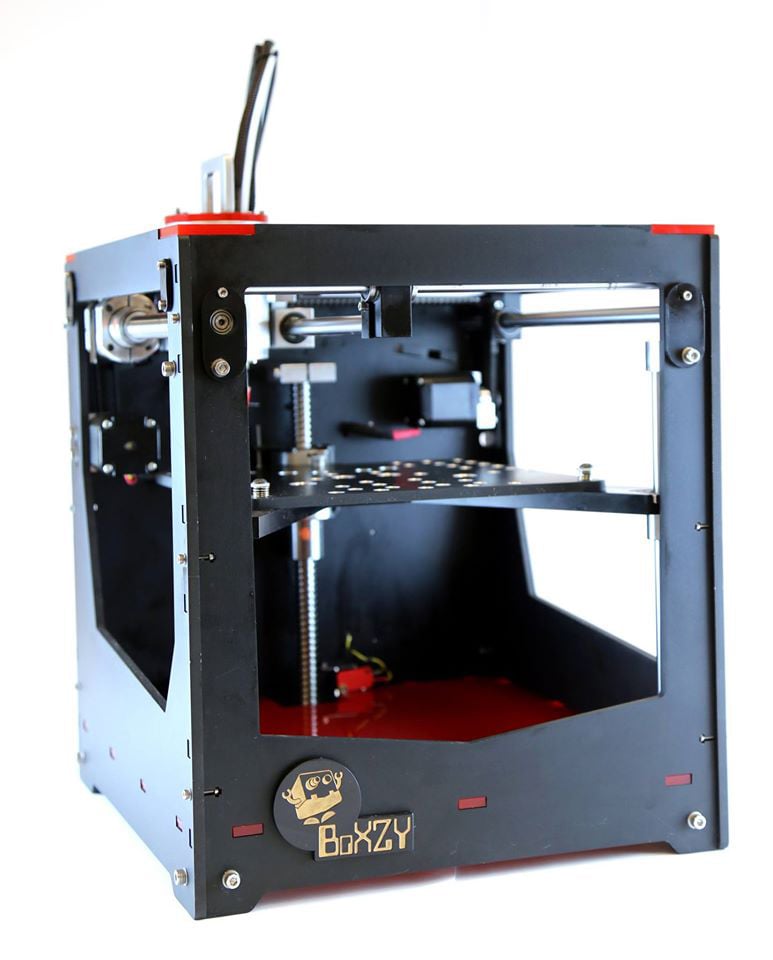

3D Printing: 3D printers build objects by depositing layers of material, typically plastic or metal, onto a build platform. The layers gradually accumulate to form the desired three-dimensional shape.

H2: Advantages of Laser Cutter 3D Printers

The combination of laser cutting and 3D printing offers numerous advantages:

Precision and Accuracy: Laser cutters provide exceptional precision, allowing for intricate cuts and fine details. This precision is crucial for applications such as prototyping, jewelry making, and model building.

Versatility: Laser cutter 3D printers can work with a wide range of materials, from wood and acrylic to metal and fabrics. This versatility enables the creation of a diverse range of objects, from functional prototypes to decorative pieces.

Speed and Efficiency: Laser cutters operate at high speeds, making them suitable for rapid prototyping and mass production. The automation of the cutting process also enhances efficiency.

Cost-effectiveness: Laser cutter 3D printers can reduce production costs by minimizing material waste and eliminating the need for expensive tooling.

H3: Applications of Laser Cutter 3D Printers

Laser cutter 3D printers have found applications in various industries, including:

In the realm of fabrication and prototyping, the convergence of laser cutters and 3D printers has revolutionized the landscape. Laser cutter 3D printers combine the precision and speed of laser cutting with the versatility and layered deposition capabilities of 3D printing, empowering makers, engineers, and designers alike to create intricate and functional objects with unparalleled accuracy and efficiency.

- 3d Laser Cut Free 3D Laser Cutting: A Comprehensive Guide To Free Tools And Techniques

- 3d Laser Cut Letters 3D Laser Cut Letters: Elevate Your Signage And Décor With Precision And Style

- 3d Robot Laser Cutting Machine 3D Robot Laser Cutting Machine: A Comprehensive Guide

- Anycubic Mega Pro Laser Cutting Anycubic Mega Pro: A Comprehensive Guide To Laser Cutting Precision

- 3d Laser Cutting Machine Suppliers 3D Laser Cutting Machine Suppliers: A Comprehensive Guide

H1: Understanding the Technology Behind Laser Cutter 3D Printers

Laser cutter 3D printers employ two distinct technologies: laser cutting and 3D printing.

Laser Cutting: Laser cutters utilize a high-powered laser beam to precisely cut through various materials, including wood, acrylic, metal, and even fabrics. The laser beam is computer-controlled, enabling intricate designs and precise cuts with minimal waste.

3D Printing: 3D printers build objects by depositing layers of material, typically plastic or metal, onto a build platform. The layers gradually accumulate to form the desired three-dimensional shape.

H2: Advantages of Laser Cutter 3D Printers

Prototyping: Creating functional prototypes for testing and design iteration.

Jewelry Making: Cutting and engraving intricate designs in metal and precious stones.

Model Building: Constructing detailed models for architecture, engineering, and hobbyists.

Art and Design: Creating unique sculptures, home décor, and other artistic objects.

Manufacturing: Producing small-batch and custom products with high precision and efficiency.

H4: Factors to Consider When Choosing a Laser Cutter 3D Printer

Selecting the right laser cutter 3D printer depends on several factors:

Materials: Consider the types of materials you plan to work with and ensure the printer supports them.

Cutting Area: Determine the maximum size of objects you need to cut.

Laser Power: Higher laser power allows for faster cutting speeds and thicker materials.

Software Compatibility: Choose a printer that is compatible with your preferred design software.

Ease of Use: Look for user-friendly software and intuitive controls to simplify the learning curve.

H5: Safety Precautions for Laser Cutter 3D Printers

Laser cutters generate high-power lasers, so safety is paramount. Follow these precautions:

Wear Protective Gear: Always wear safety glasses, gloves, and appropriate clothing to protect yourself from laser radiation and debris.

Ventilate Properly: Ensure adequate ventilation to remove fumes and particles generated during cutting.

Secure the Work Area: Keep the work area clear and secure the material being cut to prevent movement.

Never Look Directly into the Laser: Avoid exposing your eyes to the laser beam at all times.

H6: Troubleshooting Common Issues

Laser Not Cutting: Check the laser alignment, nozzle cleanliness, and laser power settings.

Material Scorching: Adjust laser speed, power, or focus to reduce scorching.

Uneven Cutting: Ensure the material is flat and securely held in place.

Conclusion

Laser cutter 3D printers represent a powerful tool for makers, engineers, and designers. By combining the precision of laser cutting with the versatility of 3D printing, these machines enable the creation of intricate and functional objects with unmatched accuracy and efficiency. When choosing a laser cutter 3D printer, consider the materials, cutting area, laser power, software compatibility, and ease of use. By adhering to safety precautions and troubleshooting common issues, you can harness the full potential of these remarkable devices to bring your creative visions to life.

FAQs

Q: What materials can laser cutter 3D printers cut?

A: Laser cutter 3D printers can cut a wide range of materials, including wood, acrylic, metal, fabrics, leather, and even some plastics.

Q: How thick can laser cutters cut?

A: The cutting thickness depends on the laser power and the material being cut. Most laser cutters can cut through materials up to several millimeters thick.

Q: Are laser cutter 3D printers safe?

A: Yes, laser cutter 3D printers are safe when used properly. Always wear protective gear, ventilate the work area, and never look directly into the laser beam.

Q: How much do laser cutter 3D printers cost?

A: The cost of laser cutter 3D printers varies depending on the size, features, and brand. Prices can range from a few hundred dollars to tens of thousands of dollars.