Laser Cutter 3D Printer: A Comprehensive Guide to Cutting-Edge Technology

Introduction

The advent of laser cutter 3D printers has revolutionized the manufacturing and prototyping industries. Combining the precision of laser cutting with the versatility of 3D printing, these machines offer unparalleled capabilities for creating intricate and highly detailed objects. This article provides a comprehensive guide to laser cutter 3D printers, exploring their features, applications, and the factors to consider when choosing one.

Table of Content

- 1 Laser Cutter 3D Printer: A Comprehensive Guide to Cutting-Edge Technology

- 1.1 Introduction

- 2 H1: Understanding Laser Cutter 3D Printers

- 2.2 H2: Key Features

- 3 H1: Applications of Laser Cutter 3D Printers

- 3.3 H2: Prototyping and Design

- 3.4 H2: Manufacturing

- 4 H1: Understanding Laser Cutter 3D Printers

- 4.5 H2: The Basics

- 4.6 H2: Key Features

- 4.7 H2: Customization and Personalization

- 5 H1: Choosing the Right Laser Cutter 3D Printer

- 5.8 H2: Considerations

- 6 H1: Conclusion

- 7 H1: FAQs

H1: Understanding Laser Cutter 3D Printers

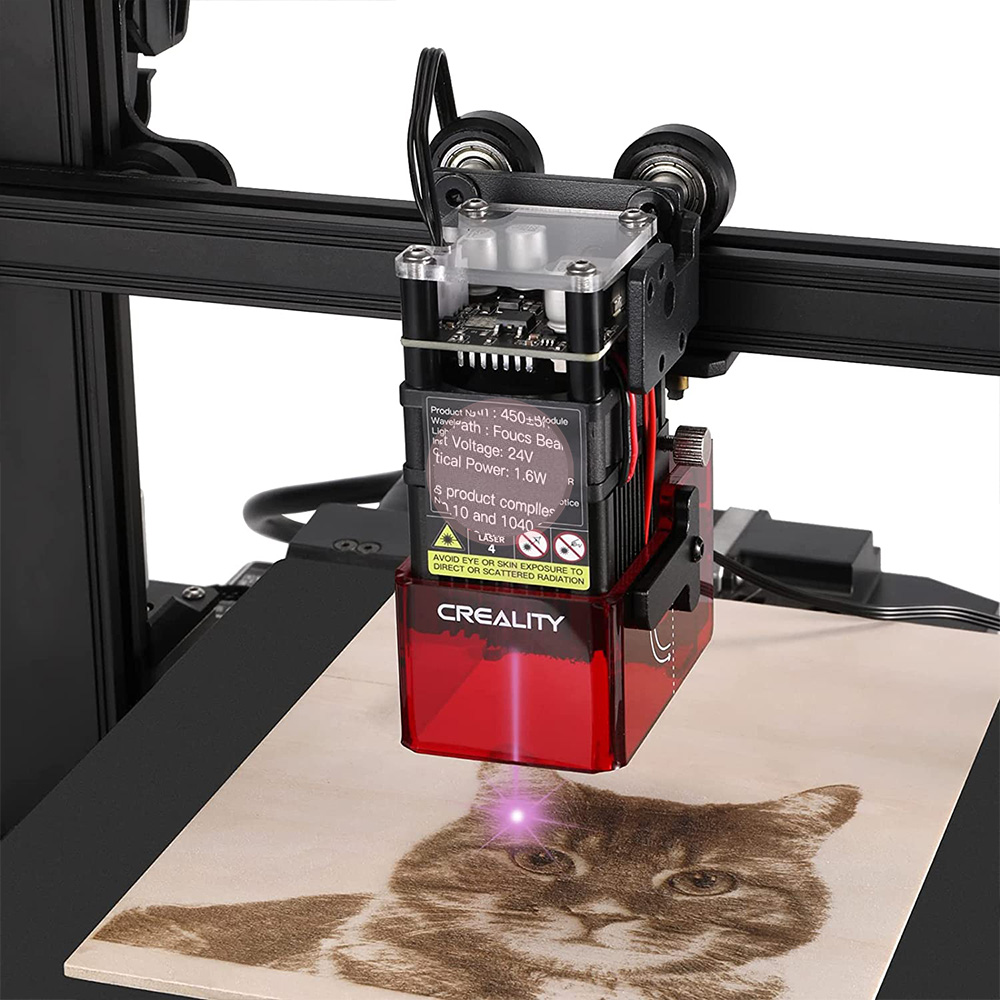

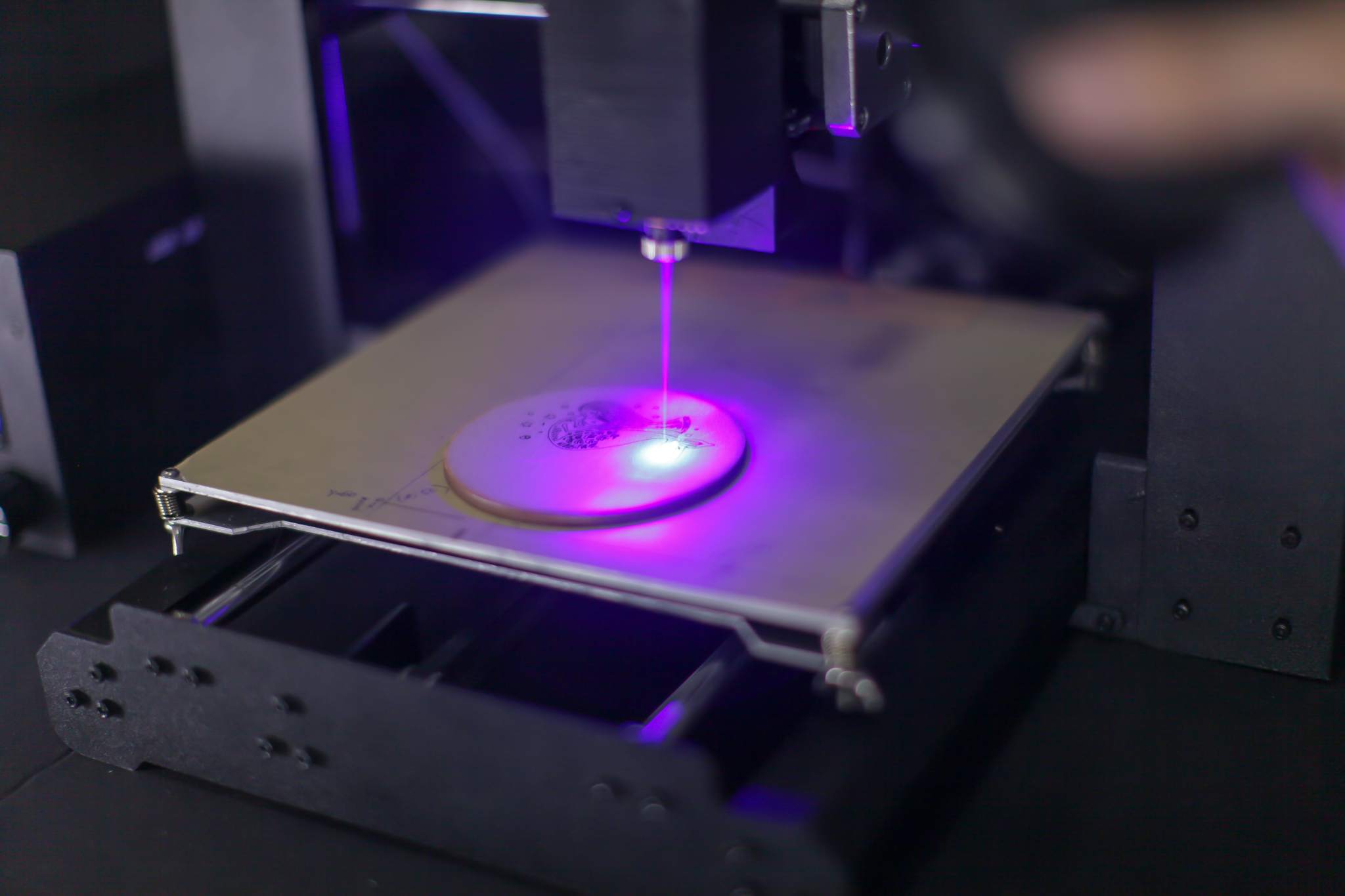

Laser cutter 3D printers utilize a high-powered laser beam to cut and engrave materials. The laser is guided by a computer-controlled system that follows a pre-determined design. Unlike traditional 3D printers that build objects layer by layer, laser cutters remove material to create the desired shape.

H2: Key Features

Laser Source: The type of laser used determines the cutting speed, precision, and material compatibility. Common options include CO2, fiber, and diode lasers.

Cutting Area: The cutting area refers to the maximum size of material that can be accommodated by the machine.

Precision: Laser cutter 3D printers offer high precision, enabling the creation of intricate designs with fine details.

Material Compatibility: Different laser cutter 3D printers support a range of materials, including wood, acrylic, metal, and leather.

H1: Applications of Laser Cutter 3D Printers

H2: Prototyping and Design

Laser cutter 3D printers excel in prototyping and design. They allow rapid and cost-effective creation of physical models from digital designs. This facilitates the testing and refinement of prototypes before mass production.

H2: Manufacturing

The advent of laser cutter 3D printers has revolutionized the manufacturing and prototyping industries. Combining the precision of laser cutting with the versatility of 3D printing, these machines offer unparalleled capabilities for creating intricate and highly detailed objects. This article provides a comprehensive guide to laser cutter 3D printers, exploring their features, applications, and the factors to consider when choosing one.

- 3d Laser Cut Maps 3D Laser Cut Maps: Unraveling The World’s Topography

- 3d Printer Laser Cutter Mod 3D Printer Laser Cutter Mod: Transform Your 3D Printer Into A Versatile Fabrication Tool

- Laser Cut 3d Flower Template Laser Cut 3D Flower Template: A Comprehensive Guide To Crafting Stunning Floral Masterpieces

- 3d Laser Cut Wooden Models For Sale 3D Laser Cut Wooden Models For Sale: A Comprehensive Guide

- Laser Cut Catan Thingiverse Laser Cut Catan Thingiverse: Elevate Your Board Game Experience

H1: Understanding Laser Cutter 3D Printers

H2: The Basics

Laser cutter 3D printers utilize a high-powered laser beam to cut and engrave materials. The laser is guided by a computer-controlled system that follows a pre-determined design. Unlike traditional 3D printers that build objects layer by layer, laser cutters remove material to create the desired shape.

H2: Key Features

Laser Source: The type of laser used determines the cutting speed, precision, and material compatibility. Common options include CO2, fiber, and diode lasers.

Laser cutter 3D printers are used in various manufacturing industries to produce high-quality components and products. They enable the efficient cutting and engraving of complex shapes, reducing production time and waste.

H2: Customization and Personalization

Laser cutter 3D printers empower makers, artists, and businesses to create personalized and unique items. They can engrave designs on a wide range of materials, from jewelry to home décor.

H1: Choosing the Right Laser Cutter 3D Printer

H2: Considerations

Material Compatibility: Determine the types of materials you need to cut or engrave.

Cutting Area: Choose a machine with a cutting area that meets your project requirements.

Precision: Consider the level of precision required for your applications.

Laser Source: Select the laser source that offers the optimal cutting speed, precision, and material compatibility.

Software: Ensure the machine is compatible with your preferred design software and supports popular file formats.

H1: Conclusion

Laser cutter 3D printers are a transformative technology that offer unparalleled capabilities for cutting and engraving materials. Their versatility and precision make them ideal for prototyping, manufacturing, customization, and a wide range of other applications. By carefully considering the key features and choosing the right machine, you can harness the power of laser cutter 3D printers to unlock new possibilities in design, manufacturing, and creativity.

H1: FAQs

Q: What is the difference between laser cutting and 3D printing?

A: Laser cutting removes material to create shapes, while 3D printing builds objects layer by layer.

Q: What types of materials can be cut with a laser cutter 3D printer?

A: Common materials include wood, acrylic, metal, and leather.

Q: How precise are laser cutter 3D printers?

A: Precision varies depending on the machine and laser source, but it can reach up to 0.001 inches.

Q: What software is used with laser cutter 3D printers?

A: Popular software options include LaserGRBL, LightBurn, and Inkscape.

/cdn.vox-cdn.com/uploads/chorus_asset/file/8132379/cover.jpg)

/cdn0.vox-cdn.com/uploads/chorus_image/image/53633569/Snapmaker_3_in_1.0.jpg)