Laser Cutter Cutting Wood: A Comprehensive Guide

Introduction

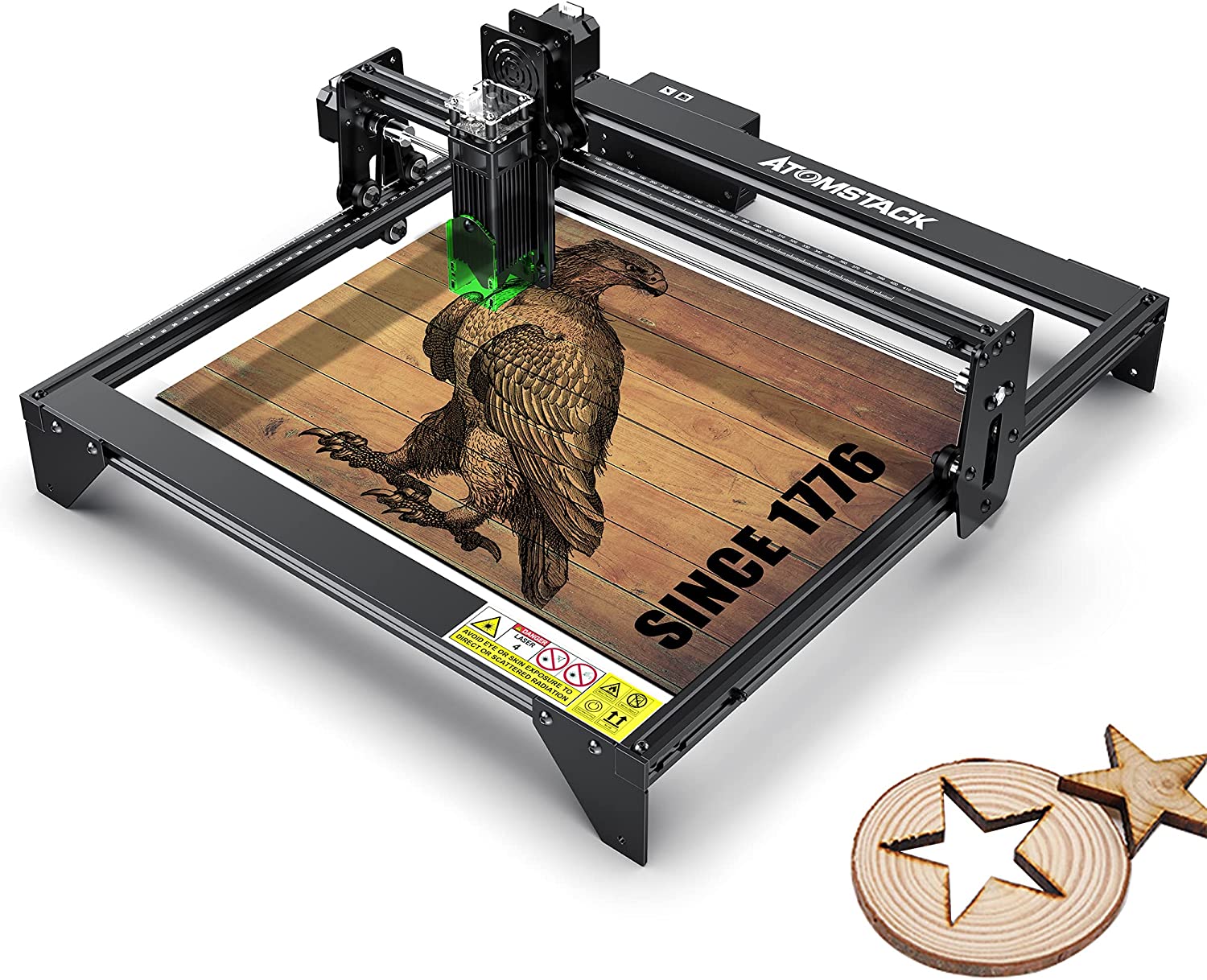

Laser cutting has revolutionized the woodworking industry, enabling precise and intricate cuts on various wood types. This article delves into the fundamentals of laser cutter cutting wood, exploring its advantages, limitations, and best practices.

Table of Content

- 1 Laser Cutter Cutting Wood: A Comprehensive Guide

- 1.1 Introduction

- 1.2 Advantages of Laser Cutter Cutting Wood

- 1.3 Limitations of Laser Cutter Cutting Wood

- 1.4 Advantages of Laser Cutter Cutting Wood

- 1.5 Best Practices for Laser Cutter Cutting Wood

- 1.6 Applications of Laser Cutter Cutting Wood

- 1.7 Conclusion

- 1.8 FAQs

Advantages of Laser Cutter Cutting Wood

DOWNLOAD SVG FILES FOR LASER CUTTING

Limitations of Laser Cutter Cutting Wood

- Cost: Laser cutters can be expensive to purchase and maintain.

- Material Thickness: The thickness of wood that can be cut is limited by the laser’s power and wavelength.

- Wooden Laser Cut Christmas Decorations Wooden Laser Cut Christmas Decorations: A Festive Touch For Your Home

- 3d Laser Wood Cutter 3D Laser Wood Cutter: A Comprehensive Guide To Laser Engraving And Cutting Technology

- Wood Laser Cutter Cost Wood Laser Cutter Cost: A Comprehensive Guide

- Laser Cut Wooden Lampshades Laser Cut Wooden Lampshades: Illuminating Your Space With Precision And Style

- Wooden Laser Cut Words H1: Wooden Laser Cut Words: A Versatile And Eye-Catching Embellishment

- Precision and Accuracy: Laser cutters offer unparalleled precision, ensuring accurate cuts even for complex designs.

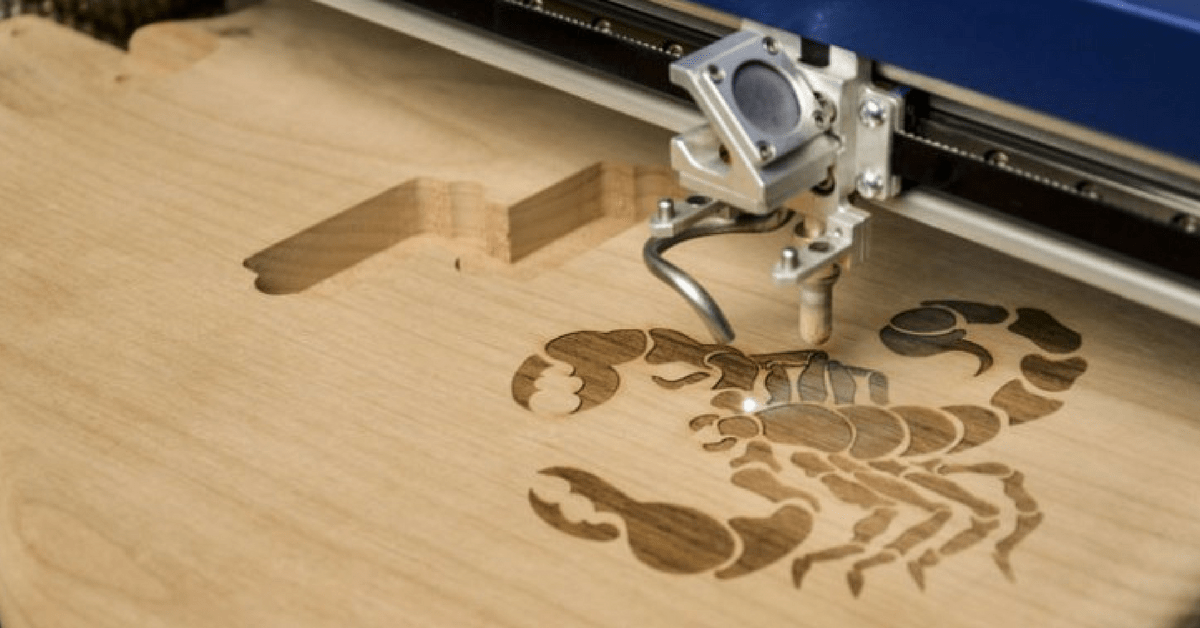

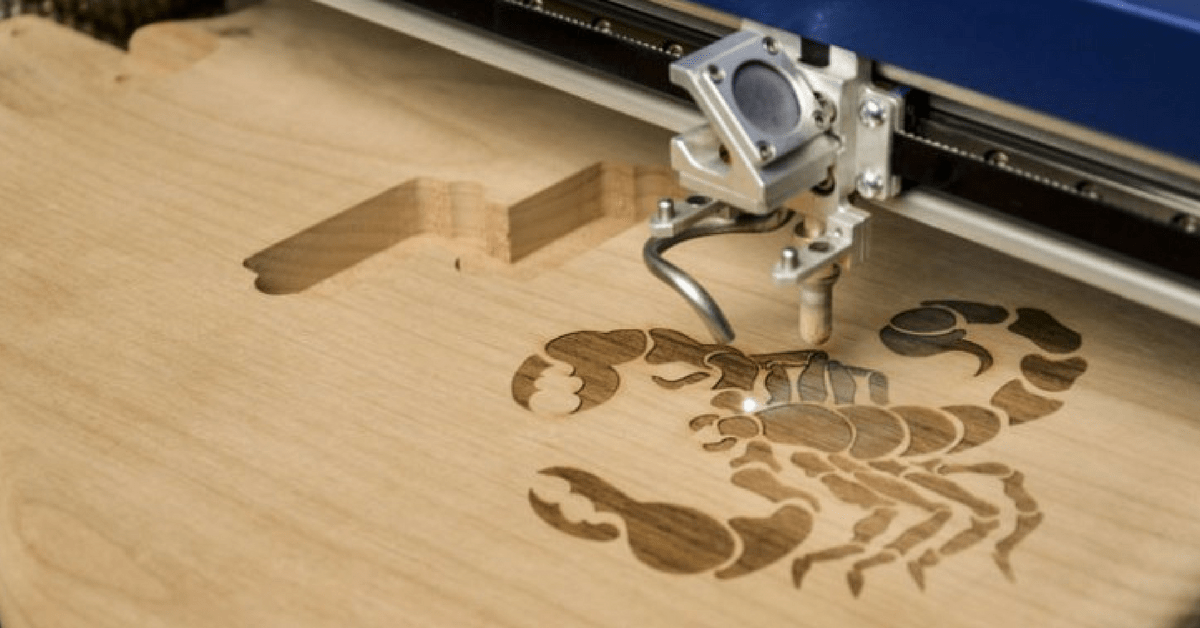

- Intricate Cuts: Lasers can create intricate cuts that would be impossible with traditional tools, expanding design possibilities.

- Speed and Efficiency: Laser cutters operate at high speeds, significantly reducing production time and increasing efficiency.

- Charring and Discoloration: Laser cutting can sometimes cause charring or discoloration around the cut edges, requiring additional finishing.

- Smoke and Fumes: Laser cutting wood releases smoke and fumes, necessitating proper ventilation and filtration systems.

- Consider the power, wavelength, and cutting area to match your specific needs.

- Ensure the laser is compatible with the type of wood you plan to cut.

- Select high-quality wood with minimal knots and defects.

- Clean the wood to remove dirt and debris.

- Apply masking tape to the cut areas to prevent charring and discoloration.

- Adjust the laser power, speed, and focus to achieve the desired cut quality.

- Experiment with different settings to determine the optimal combination for your material and design.

- Wear appropriate safety gear, including laser safety glasses and a respirator.

- Ensure the laser cutter is properly ventilated and filtered.

- Never leave the laser unattended while operating.

- Furniture and Cabinetry: Creating intricate designs, precision cuts, and custom-sized components.

- Musical Instruments: Crafting high-quality guitar bodies, drums, and other musical instruments.

- Toys and Games: Producing precision-cut wooden toys, puzzles, and game pieces.

- Signage and Decor: Creating unique and eye-catching signs, artwork, and home decor items.

- Industrial Applications: Manufacturing precision parts for machinery, prototypes, and other industrial components.

Laser cutting has revolutionized the woodworking industry, enabling precise and intricate cuts on various wood types. This article delves into the fundamentals of laser cutter cutting wood, exploring its advantages, limitations, and best practices.

Advantages of Laser Cutter Cutting Wood

DOWNLOAD SVG FILES FOR LASER CUTTING

Best Practices for Laser Cutter Cutting Wood

Choosing the Right Laser Cutter:

Preparing the Wood:

Optimizing Cut Parameters:

Safety Precautions:

Applications of Laser Cutter Cutting Wood

Laser cutter cutting wood finds wide application in various industries:

Conclusion

Laser cutter cutting wood offers numerous advantages for precision, efficiency, and design versatility. By understanding the principles, limitations, and best practices, woodworkers can harness the power of laser cutting to create stunning and intricate projects.

FAQs

Q: What is the best type of wood for laser cutting?

A: Hardwoods like maple, oak, and cherry yield clean cuts with minimal charring. Softwoods like pine and poplar are also suitable, but may require higher laser power.

Q: How do I prevent charring and discoloration?

A: Use masking tape, reduce laser power, and experiment with different cutting speeds.

Q: What are the safety concerns when laser cutting wood?

A: Wear laser safety glasses, use proper ventilation, and never leave the laser unattended.

Q: Can laser cutters cut all types of wood?

A: No, the thickness and density of the wood limit the cutting capabilities.

Q: What are the maintenance requirements for laser cutters?

A: Regular cleaning, lens alignment, and calibration are essential to ensure optimal performance and safety.