Laser Cutter for Wood: A Comprehensive Guide

Introduction

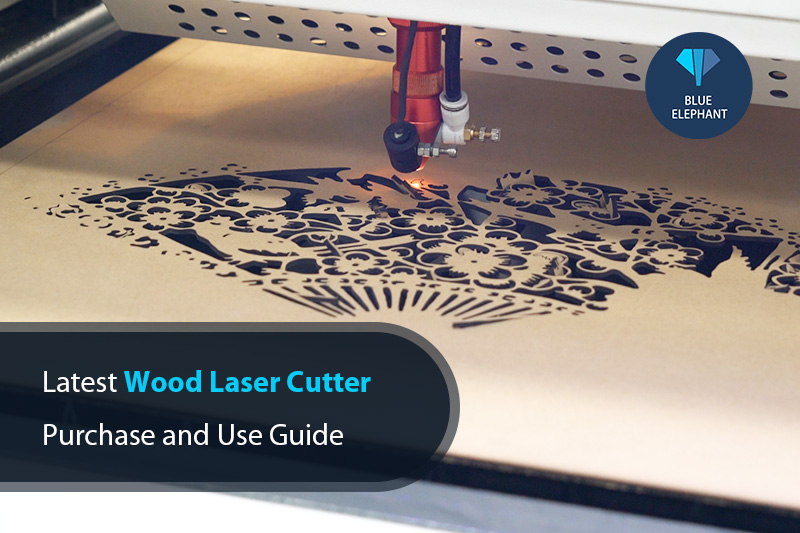

Laser cutting is a precise and versatile technology that has revolutionized the woodworking industry. Laser cutters use a focused beam of light to vaporize and cut through materials, enabling intricate designs and precise cuts. This guide will provide a comprehensive overview of laser cutters for wood, including their benefits, applications, types, and factors to consider when selecting one.

Table of Content

- 1 Laser Cutter for Wood: A Comprehensive Guide

- 1.1 Introduction

- 1.2 Benefits of Laser Cutters for Wood

- 1.3 Applications of Laser Cutters for Wood

- 1.4 Benefits of Laser Cutters for Wood

- 1.5 Types of Laser Cutters for Wood

- 1.6 Factors to Consider When Selecting a Laser Cutter for Wood

- 1.7 Conclusion

- 1.8 Frequently Asked Questions

Benefits of Laser Cutters for Wood

DOWNLOAD SVG FILES FOR LASER CUTTING

Applications of Laser Cutters for Wood

Laser cutters are used in a wide range of woodworking applications, including:

- Furniture making: Cutting intricate designs for furniture components, such as table legs, chair backs, and cabinet doors.

- Wooden Laser Cut Designs Wooden Laser Cut Designs: Elevate Your Home Décor And Unleash Your Creativity

- Laser Cut Wood Products Laser Cut Wood Products: A Comprehensive Guide

- Fiber Laser On Wood Fiber Laser On Wood: A Comprehensive Guide

- Wood Laser Cutter Frame Wood Laser Cutter Frame: A Comprehensive Guide

- Laser Cut Wooden Bowls Laser Cut Wooden Bowls: A Comprehensive Guide

- Precision: Laser cutters offer unmatched precision, allowing for intricate designs and precise cuts with minimal waste.

- Speed: Laser cutting is a fast process, significantly reducing production time compared to traditional methods.

- Versatility: Laser cutters can process various types of wood, including plywood, MDF, and hardwoods.

- Signage: Creating custom signs, logos, and lettering for businesses and organizations.

- Toys and games: Cutting out puzzle pieces, dollhouse parts, and other components for toys and games.

- Home décor: Producing decorative items such as wall art, picture frames, and candle holders.

- Architectural models: Creating scale models of buildings and other structures for architectural design and planning.

- Use carbon dioxide gas as the laser source.

- Ideal for cutting and engraving wood, acrylic, and other non-metallic materials.

- Offer high power and accuracy.

- Use a fiber optic cable to deliver the laser beam.

- Suitable for cutting thin metals, including stainless steel and aluminum.

- Can also cut wood, but may require higher power settings.

- Power: Measured in watts, power determines the thickness and speed at which the laser can cut.

- Bed size: The size of the cutting bed determines the maximum dimensions of the materials you can process.

- Accuracy: The accuracy of the laser cutter determines the precision of the cuts.

- Software: User-friendly software is essential for designing and controlling the laser cutter.

- Ventilation: Laser cutting generates fumes, so adequate ventilation is necessary to ensure a safe working environment.

Laser cutting is a precise and versatile technology that has revolutionized the woodworking industry. Laser cutters use a focused beam of light to vaporize and cut through materials, enabling intricate designs and precise cuts. This guide will provide a comprehensive overview of laser cutters for wood, including their benefits, applications, types, and factors to consider when selecting one.

Benefits of Laser Cutters for Wood

DOWNLOAD SVG FILES FOR LASER CUTTING

Types of Laser Cutters for Wood

There are two main types of laser cutters for wood:

CO2 Laser Cutters:

Fiber Laser Cutters:

Factors to Consider When Selecting a Laser Cutter for Wood

When choosing a laser cutter for wood, consider the following factors:

Conclusion

Laser cutters offer numerous benefits for woodworking, enabling precision, speed, versatility, and automation. By understanding the types of laser cutters, their applications, and the factors to consider when selecting one, you can choose the right machine to meet your specific needs. Laser cutting technology continues to advance, providing new possibilities for innovation and creativity in the woodworking industry.

Frequently Asked Questions

Q: What is the difference between laser cutting and engraving?

A: Laser cutting involves vaporizing and cutting through the material, while laser engraving only removes the surface layer.

Q: Can laser cutters cut all types of wood?

A: Yes, laser cutters can cut various types of wood, but the power and settings may need to be adjusted depending on the wood’s density and thickness.

Q: Is laser cutting safe?

A: Yes, laser cutting is safe when used properly. Adequate ventilation and proper safety precautions are essential to prevent fumes and laser beam exposure.