Laser Cutter on Balsa Wood: A Comprehensive Guide to Precision Cutting and Intricate Designs

Introduction

Laser cutters have revolutionized the world of crafting and prototyping by enabling intricate and precise cutting on a wide range of materials. Among these materials, balsa wood stands out due to its lightweight, versatility, and exceptional cutting properties. This article delves into the intricacies of laser cutting balsa wood, exploring the techniques, applications, and best practices for achieving optimal results.

Table of Content

- 1 Laser Cutter on Balsa Wood: A Comprehensive Guide to Precision Cutting and Intricate Designs

- 1.1 Introduction

- 1.2 Understanding Laser Cutting Technology

- 1.3 Laser Cutter Types for Balsa Wood

- 1.4 Understanding Laser Cutting Technology

- 1.5 Laser Cutter Types for Balsa Wood

- 1.6 Laser Cutting Parameters for Balsa Wood

- 1.7 Applications of Laser Cutting on Balsa Wood

- 1.8 Best Practices for Laser Cutting Balsa Wood

- 1.9 Troubleshooting Common Issues

- 1.10 Conclusion

- 1.11 FAQs

Understanding Laser Cutting Technology

Laser Cutter Types for Balsa Wood

The choice of laser cutter depends on the desired cutting quality, speed, and budget.

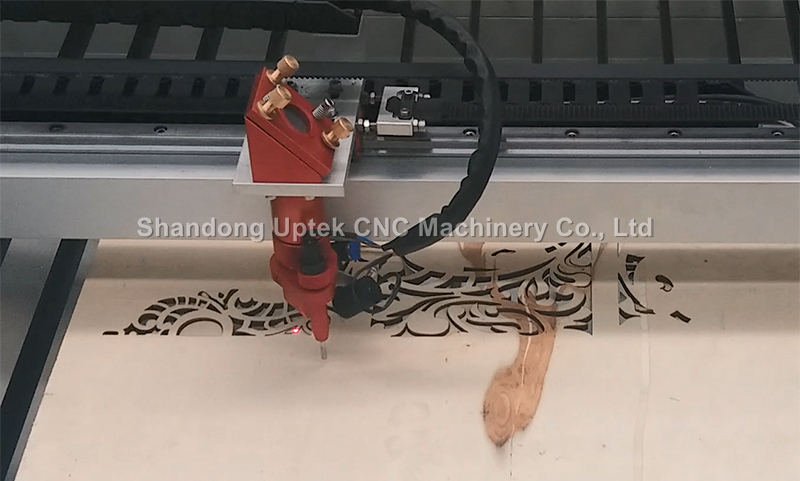

CO2 Laser Cutters:

- Most commonly used for balsa wood cutting

- Produce high-quality cuts with minimal charring

- Suitable for intricate designs and mass production

DOWNLOAD SVG FILES FOR LASER CUTTING

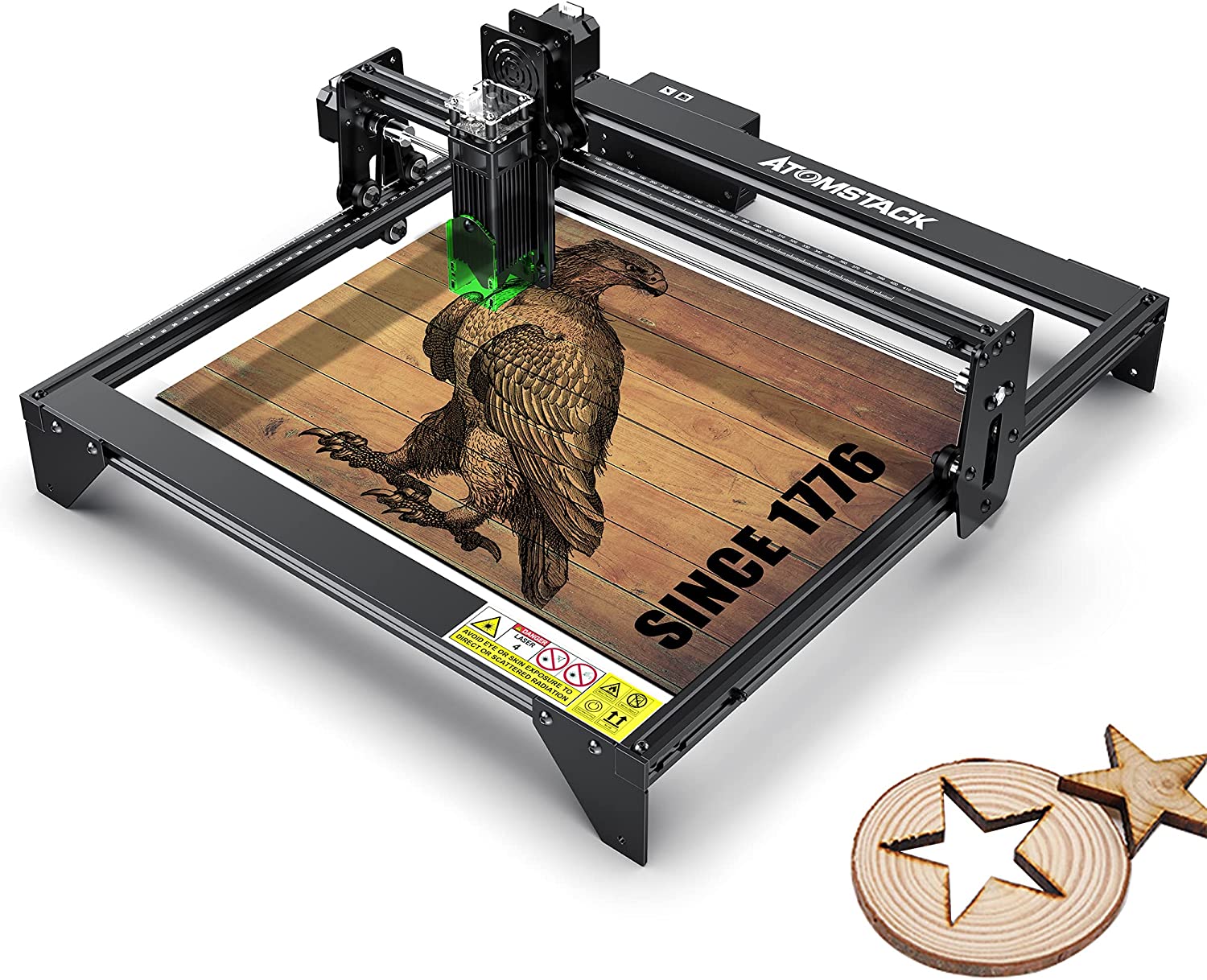

Fiber Laser Cutters:

- Laser Wood Cutter Machine Cost Laser Wood Cutter Machine Cost: A Comprehensive Guide For Smart Investments

- Laser Cut Wooden Box For Sale Laser Cut Wooden Box For Sale: A Comprehensive Guide

- Wood Panels For Laser Cutting Wood Panels For Laser Cutting: A Comprehensive Guide

- Laser Wood Engraver And Cutter Laser Wood Engraver And Cutter: A Comprehensive Guide

- Laser Cut Wooden Plaques Laser Cut Wooden Plaques: A Timeless Art Form For Recognition And Decor

- Capable of cutting thicker balsa wood

- Provide faster cutting speeds and higher precision

- Ideal for industrial applications and high-volume production

Laser cutters have revolutionized the world of crafting and prototyping by enabling intricate and precise cutting on a wide range of materials. Among these materials, balsa wood stands out due to its lightweight, versatility, and exceptional cutting properties. This article delves into the intricacies of laser cutting balsa wood, exploring the techniques, applications, and best practices for achieving optimal results.

Understanding Laser Cutting Technology

Laser cutting involves directing a concentrated beam of laser light onto the surface of a material, causing localized heating and vaporization. This process allows for precise cutting, etching, and engraving on various materials, including wood, acrylic, and metal.

DOWNLOAD SVG FILES FOR LASER CUTTING

Laser Cutter Types for Balsa Wood

The choice of laser cutter depends on the desired cutting quality, speed, and budget.

CO2 Laser Cutters:

Laser Cutting Parameters for Balsa Wood

Achieving optimal cutting results requires careful adjustment of laser parameters.

Power:

- Typically between 10-50 watts for balsa wood

- Higher power results in faster cutting but may increase charring

Speed:

Focal Length:

- Distance between the laser lens and the material

- Shorter focal lengths provide finer cuts but reduce cutting depth

Air Assist:

- Flow of compressed air directed onto the cutting zone

- Removes debris and reduces charring

Applications of Laser Cutting on Balsa Wood

Laser cutting on balsa wood finds applications in various industries and hobbies.

Model Making:

- Creating intricate model aircraft, boats, and architectural structures

Prototyping:

- Rapid prototyping of functional parts and assemblies

Decorative Items:

- Laser-cut balsa wood can be used to create decorative wall hangings, ornaments, and coasters

Packaging:

- Precise cutting of balsa wood for protective packaging and custom inserts

Best Practices for Laser Cutting Balsa Wood

Material Selection:

- Choose high-quality balsa wood with a fine grain and minimal knots

Design Optimization:

- Design parts with clean lines and avoid sharp corners to minimize charring

Ventilation:

- Ensure adequate ventilation during cutting to remove smoke and fumes

Safety Precautions:

- Wear appropriate safety gear, including laser safety glasses and a respirator

Troubleshooting Common Issues

Charring:

- Adjust laser power, speed, or focal length

- Use air assist to remove debris

Rough Cuts:

- Check laser alignment and focus

- Ensure the material is flat and securely clamped

Warping:

- Use a sacrificial layer beneath the balsa wood

- Apply a light coat of wood glue to the surface before cutting

Conclusion

Laser cutting on balsa wood opens up endless possibilities for precision cutting, intricate designs, and innovative applications. By understanding the technology, choosing the right laser cutter, and following best practices, users can achieve exceptional results and unlock the full potential of this versatile material.

FAQs

Q: Can I laser cut balsa wood at home?

A: Yes, small CO2 laser cutters are available for home use, but proper safety precautions must be followed.

Q: What is the maximum thickness of balsa wood that can be laser cut?

A: Fiber laser cutters can cut balsa wood up to 1/2 inch thick.

Q: How can I prevent smoke and fumes from laser cutting balsa wood?

A: Use air assist and ensure adequate ventilation during cutting.

Q: Is laser cutting balsa wood safe?

A: Yes, with proper safety precautions, including wearing laser safety glasses and a respirator.

Q: What are some creative uses for laser-cut balsa wood?

A: Model making, prototyping, decorative items, packaging, and custom inserts.