Laser Cutter on Wood: A Comprehensive Guide to Precision Cutting and Engraving

Introduction

Laser cutters have revolutionized the woodworking industry, enabling precise cutting and intricate engraving with unparalleled accuracy. Whether you’re a hobbyist or a professional, a laser cutter can empower you to create stunning wooden masterpieces. This comprehensive guide will delve into the world of laser cutting on wood, providing insights into its capabilities, techniques, and best practices.

Table of Content

- 1 Laser Cutter on Wood: A Comprehensive Guide to Precision Cutting and Engraving

- 1.1 Introduction

- 2 H1: Understanding Laser Cutters

- 2.2 H2: Laser Cutter Components

- 3 H1: Understanding Laser Cutters

- 3.3 H2: Types of Laser Cutters

- 4 H2: Laser Cutting Techniques

- 4.4 H3: Vector Cutting

- 4.5 H3: Raster Engraving

- 4.6 H3: Laser Marking

- 5 H2: Choosing the Right Wood for Laser Cutting

- 5.7 H3: Hardwoods

- 5.8 H3: Softwoods

- 5.9 H3: Plywood

- 6 H2: Safety Precautions

- 7 H2: Laser Cutter Maintenance

- 7.10 H3: Cleaning the Laser Head:** Clean the laser head regularly to remove debris and ensure proper beam alignment.

- 7.11 H3: Aligning the Laser Beam:** Check and adjust the laser beam alignment periodically to maintain precise cutting and engraving.

- 7.12 H3: Calibrating the Laser Cutter:** Calibrate the laser cutter to ensure accurate cutting and engraving dimensions.

- 8 H2: Tips and Tricks for Laser Cutting on Wood

- 9 H2: Applications of Laser Cutting on Wood

- 10 Conclusion

- 11 FAQs

- 11.13 Q: What are the benefits of using a laser cutter on wood?

- 11.14 Q: How do I choose the right laser cutter for my needs?

- 11.15 Q: What safety precautions should I take when using a laser cutter on wood?

H1: Understanding Laser Cutters

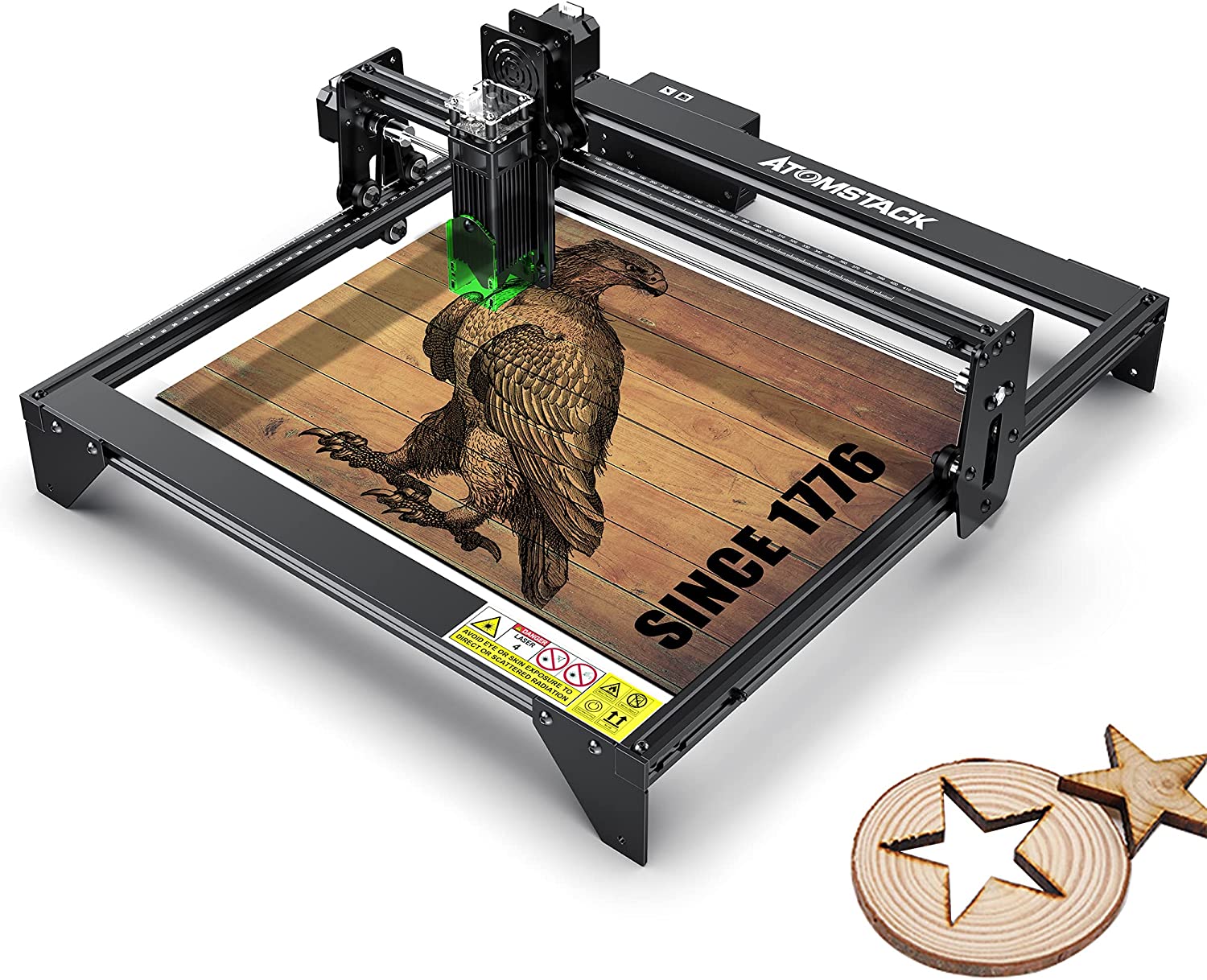

Laser cutters come in various types, each with its own advantages and applications:

- CO2 Laser Cutters: Best suited for cutting and engraving wood, acrylic, and other non-metallic materials.

- Fiber Laser Cutters: Ideal for cutting and engraving metals, but can also be used on wood.

- Diode Laser Cutters: Suitable for low-power applications such as engraving on wood and leather.

DOWNLOAD SVG FILES FOR LASER CUTTING

H2: Laser Cutter Components

A laser cutter comprises several key components:

- Laser Source: Generates the laser beam used for cutting and engraving.

- Fiber Laser Wood Cutting Fiber Laser Wood Cutting: A Comprehensive Guide

- Wood Laser Cut Wood Laser Cut: A Comprehensive Guide To Precision Crafting

- Laser Cutter Burning Wood Laser Cutter Burning Wood: A Comprehensive Guide

- 3d Wood Laser Cutter 3D Wood Laser Cutter: Revolutionizing Woodworking With Precision And Efficiency

- Laser Cut Wooden Shapes Uk Laser Cut Wooden Shapes UK: A Comprehensive Guide To Customization And Versatility

- CO2 Laser Cutters: Best suited for cutting and engraving wood, acrylic, and other non-metallic materials.

- Laser Head: Directs the laser beam onto the workpiece.

- Cutting Table: Supports the workpiece during the cutting process.

- Exhaust System: Removes fumes and debris created during cutting.

- Wear Protective Gear: Wear safety glasses, gloves, and a respirator to protect yourself from laser beams, fumes, and debris.

- Adequate Ventilation: Ensure proper ventilation in the workspace to remove fumes and prevent breathing problems.

- Avoid Flammable Materials: Keep flammable materials away from the laser cutter to prevent fires.

- Never Look Directly into the Laser: Direct eye contact with the laser beam can cause serious eye damage.

- Use High-Quality Wood: Choose high-quality wood with minimal knots and defects to ensure clean cuts and engravings.

- Set the Correct Laser Power: Adjust the laser power based on the thickness and type of wood you’re cutting or engraving.

- Use Compressed Air: Use compressed air to remove debris and fumes during cutting, resulting in cleaner cuts.

- Experiment with Different Cutting Speeds: Vary the cutting speed to achieve different effects, such as faster speeds for clean cuts and slower speeds for detailed engravings.

- Consider the Grain Direction: The grain direction of the wood can affect the quality of the cut. Cut parallel to the grain for smoother cuts.

- Furniture Making: Creating intricate designs and patterns on furniture pieces.

- Signage and Displays: Producing custom signs, display boards, and promotional materials.

- Toys and Games: Manufacturing toys, puzzles, and game components with precise cuts and engravings.

- Arts and Crafts: Creating decorative items, jewelry, and home décor with unique designs.

- Prototyping and Model Making: Fabricating prototypes and models with high accuracy and detail.

- Precision Cutting: Laser cutters provide extremely precise cuts, allowing for intricate designs and tight tolerances.

- Detailed Engraving: Laser engraving enables detailed and high-resolution engravings, creating stunning images and text on wood.

- Efficiency: Laser cutters can cut and engrave wood quickly and efficiently, saving time and effort.

- Versatility: Laser cutters can work on various types of wood, from hardwoods to softwoods, and can perform both cutting and engraving tasks.

- Type of Wood: Determine the types of wood you’ll be working with and choose a laser cutter that’s suitable for those materials.

- Cutting and Engraving Requirements: Identify the specific cutting and engraving tasks you need to perform and select a laser cutter with the appropriate power and capabilities.

- Budget: Set a budget and explore laser cutters that fit within your price range.

- Brand Reputation and Support: Research different laser cutter brands and read reviews to ensure reliable performance and customer support.

- Wear Protective Gear: Always wear safety glasses, gloves, and a respirator to protect yourself from laser beams, fumes, and debris.

- Adequate Ventilation: Ensure proper ventilation in the workspace to remove fumes and prevent breathing problems.

- Avoid Flammable Materials: Keep flammable materials away from the laser cutter to prevent fires.

- Never Look Directly into the Laser: Direct eye contact with the laser beam can cause serious eye damage.

Laser cutters have revolutionized the woodworking industry, enabling precise cutting and intricate engraving with unparalleled accuracy. Whether you’re a hobbyist or a professional, a laser cutter can empower you to create stunning wooden masterpieces. This comprehensive guide will delve into the world of laser cutting on wood, providing insights into its capabilities, techniques, and best practices.

H1: Understanding Laser Cutters

H2: Types of Laser Cutters

DOWNLOAD SVG FILES FOR LASER CUTTING

Laser cutters come in various types, each with its own advantages and applications:

H2: Laser Cutting Techniques

H3: Vector Cutting

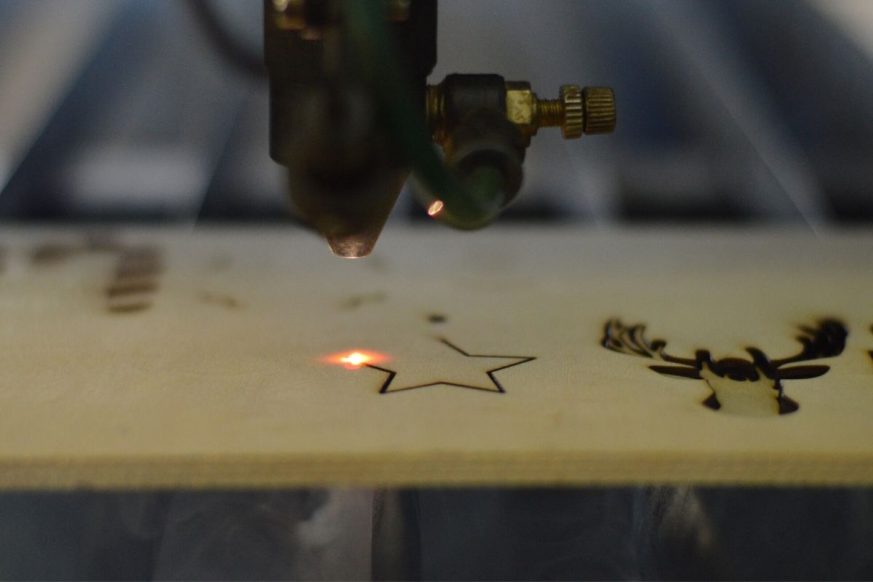

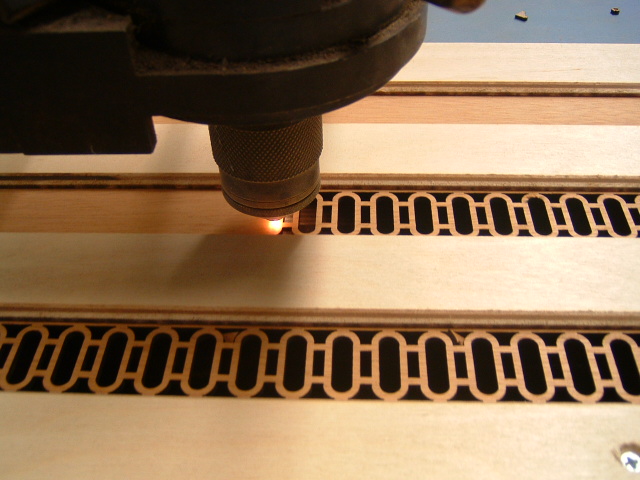

Vector cutting involves following a defined path with the laser beam to cut through the wood. It’s ideal for creating precise shapes and intricate designs.

H3: Raster Engraving

Raster engraving uses the laser beam to scan across the surface of the wood, creating images or text. It allows for detailed and complex engravings.

H3: Laser Marking

Laser marking uses a low-power laser to etch or mark the surface of the wood without cutting through it. It’s often used for branding or adding decorative elements.

H2: Choosing the Right Wood for Laser Cutting

The type of wood you choose for laser cutting impacts the quality of the cut and the final product. Some woods are more suitable for certain techniques than others.

H3: Hardwoods

Hardwoods, such as oak, maple, and mahogany, are dense and durable, making them ideal for vector cutting and engraving.

H3: Softwoods

Softwoods, such as pine, spruce, and fir, are less dense and easier to cut. They’re suitable for both vector cutting and raster engraving.

H3: Plywood

Plywood consists of multiple layers of wood glued together. It’s a versatile material for laser cutting, offering strength and stability.

H2: Safety Precautions

Laser cutting involves high-powered lasers, so safety is paramount. Follow these precautions:

H2: Laser Cutter Maintenance

Regular maintenance is crucial to ensure optimal performance and longevity of your laser cutter.

H3: Cleaning the Laser Head:** Clean the laser head regularly to remove debris and ensure proper beam alignment.

H3: Aligning the Laser Beam:** Check and adjust the laser beam alignment periodically to maintain precise cutting and engraving.

H3: Calibrating the Laser Cutter:** Calibrate the laser cutter to ensure accurate cutting and engraving dimensions.

H2: Tips and Tricks for Laser Cutting on Wood

H2: Applications of Laser Cutting on Wood

Laser cutters have a wide range of applications in the woodworking industry, including:

Conclusion

Laser cutters have revolutionized the woodworking industry, empowering makers, hobbyists, and professionals alike to create stunning wooden masterpieces. By understanding the different types of laser cutters, techniques, and safety precautions, you can harness the power of laser cutting to elevate your woodworking projects to new heights. Whether you’re looking to create intricate designs, detailed engravings, or functional objects, a laser cutter can help you achieve your creative goals with unparalleled precision and efficiency.

FAQs

Q: What are the benefits of using a laser cutter on wood?

A: Laser cutting on wood offers numerous benefits, including:

Q: How do I choose the right laser cutter for my needs?

A: Consider the following factors when choosing a laser cutter:

Q: What safety precautions should I take when using a laser cutter on wood?

A: Laser cutting on wood requires strict adherence to safety precautions: