Laser Cutter for Cutting Wood: A Comprehensive Guide

Laser cutters have revolutionized the woodworking industry, enabling precise and efficient cutting of intricate designs. This article provides a comprehensive guide to laser cutters specifically designed for cutting wood, covering their capabilities, benefits, and considerations.

H1: Laser Cutters for Woodworking

Table of Content

- 1 Laser Cutter for Cutting Wood: A Comprehensive Guide

- 1.1 H1: Laser Cutters for Woodworking

- 1.2 H2: Types of Laser Cutters for Wood

- 1.3 H1: Laser Cutters for Woodworking

- 1.4 H3: Considerations for Choosing a Laser Cutter

- 1.5 H2: Benefits of Using a Laser Cutter for Woodworking

- 1.6 H2: How to Use a Laser Cutter for Wood

- 1.7 H2: Safety Considerations

- 1.8 H3: Conclusion

- 1.9 FAQs

Laser cutters utilize a highly focused laser beam to vaporize or melt material, creating clean and precise cuts. For woodworking applications, laser cutters offer several advantages over traditional cutting methods:

H2: Types of Laser Cutters for Wood

DOWNLOAD SVG FILES FOR LASER CUTTING

There are two primary types of laser cutters used for woodworking:

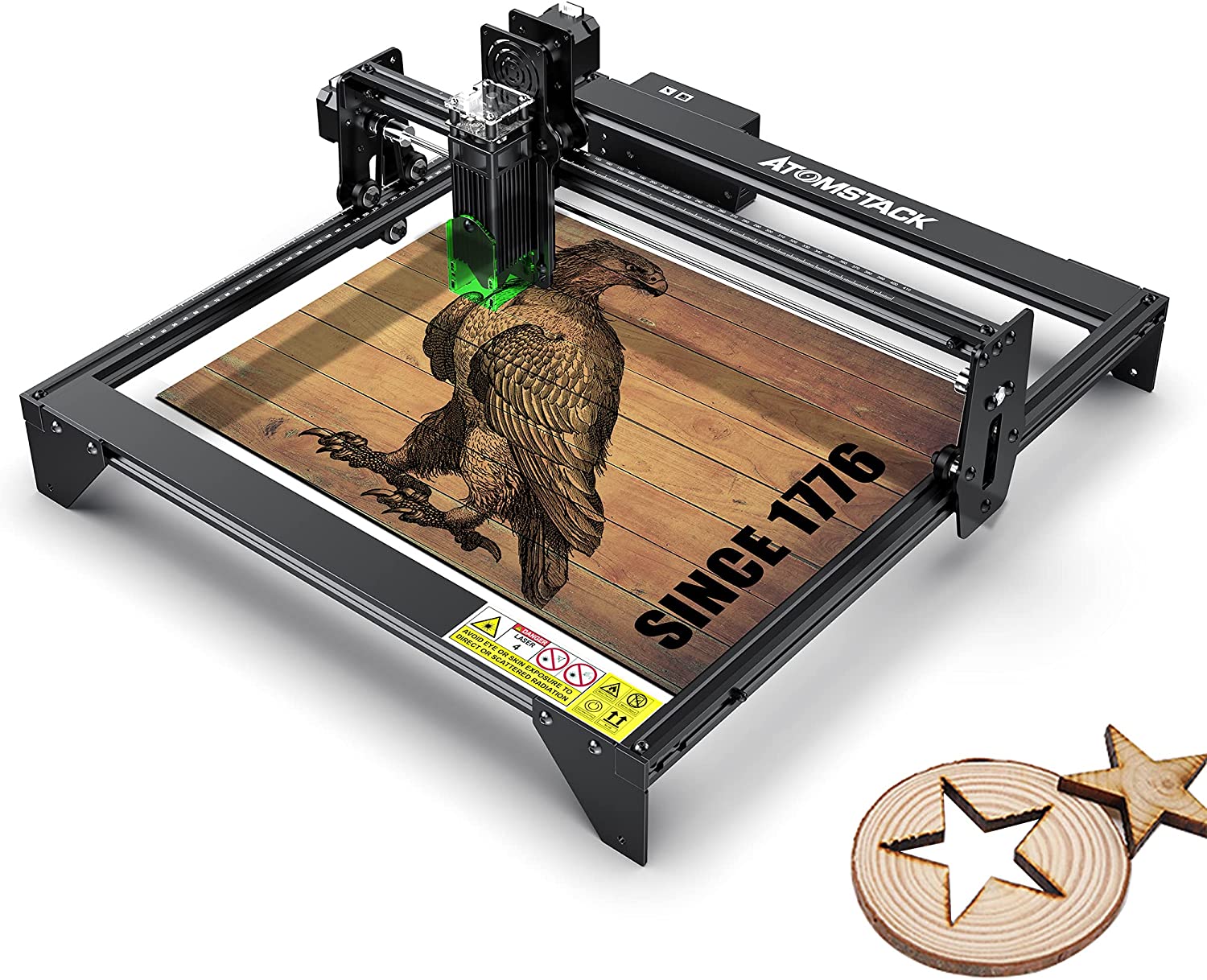

- CO2 Laser Cutters: CO2 laser cutters use a mixture of carbon dioxide and helium or nitrogen gases to generate the laser beam. They are suitable for cutting a wide range of woods, including hardwoods, softwoods, and plywood.

- Fiber Laser Cutters: Fiber laser cutters use a doped fiber optic cable as the laser medium. They offer higher cutting speeds and can handle thicker materials compared to CO2 laser cutters. However, they are typically more expensive.

- Wood Laser Engraver And Cutter Wood Laser Engraver And Cutter: A Comprehensive Guide

- Custom Cut Wood Pieces Custom Cut Wood Pieces: A Comprehensive Guide To Precision And Versatility

- Laser Wood Carving Near Me Laser Wood Carving Near Me: An In-Depth Guide

- Cnc Laser Wood Cutter CNC Laser Wood Cutter: A Comprehensive Guide

- Laser Wood Engraver And Cutter Laser Wood Engraver And Cutter: A Comprehensive Guide

- Precision: Laser cutters can cut with extreme accuracy, down to fractions of a millimeter, ensuring precise and repeatable results.

- Intricate Designs: Laser cutters can cut complex designs and shapes that are difficult or impossible to achieve with manual methods.

- Speed: Laser cutters operate at high speeds, increasing productivity and reducing production times.

- Cutting Area: Determine the maximum size of the materials you need to cut.

- Cutting Thickness: Consider the thickness of the wood you will be cutting.

- Laser Power: The laser power determines the cutting speed and accuracy.

- Software Compatibility: Ensure the laser cutter is compatible with your design software.

- Budget: Laser cutters range in price from a few thousand to hundreds of thousands of dollars.

- Versatile: Laser cutters can cut a wide variety of wood species, including both hardwoods and softwoods.

- Accuracy and Precision: Laser cutters provide highly accurate and precise cuts, minimizing waste and ensuring consistent results.

- Efficient: Laser cutters operate at high speeds, increasing productivity and reducing production times.

- Intricate Designs: Laser cutters can cut intricate designs and shapes with ease, expanding creative possibilities.

- Non-Contact Cutting: Laser cutting does not require physical contact with the material, reducing wear and tear on tools and minimizing material damage.

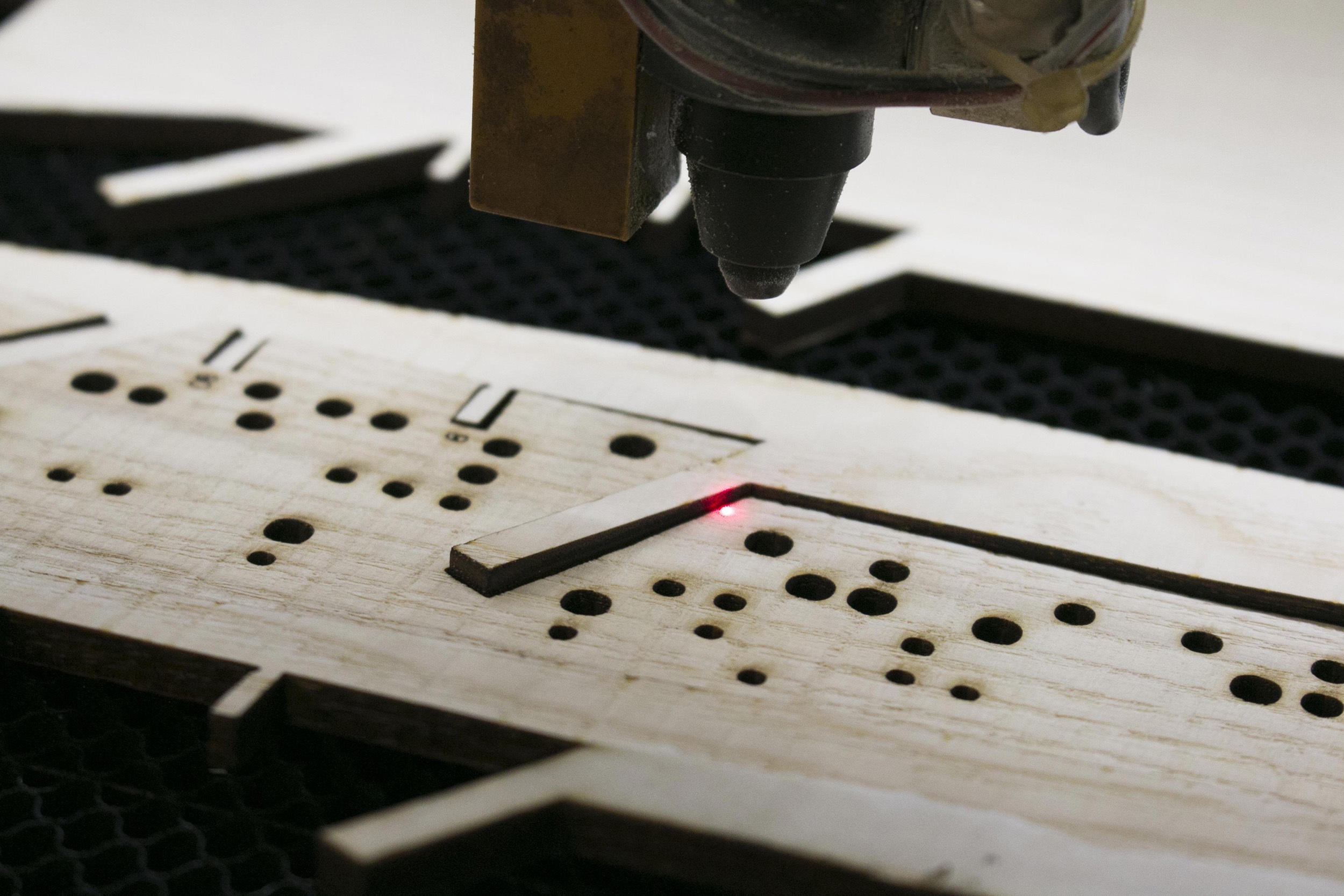

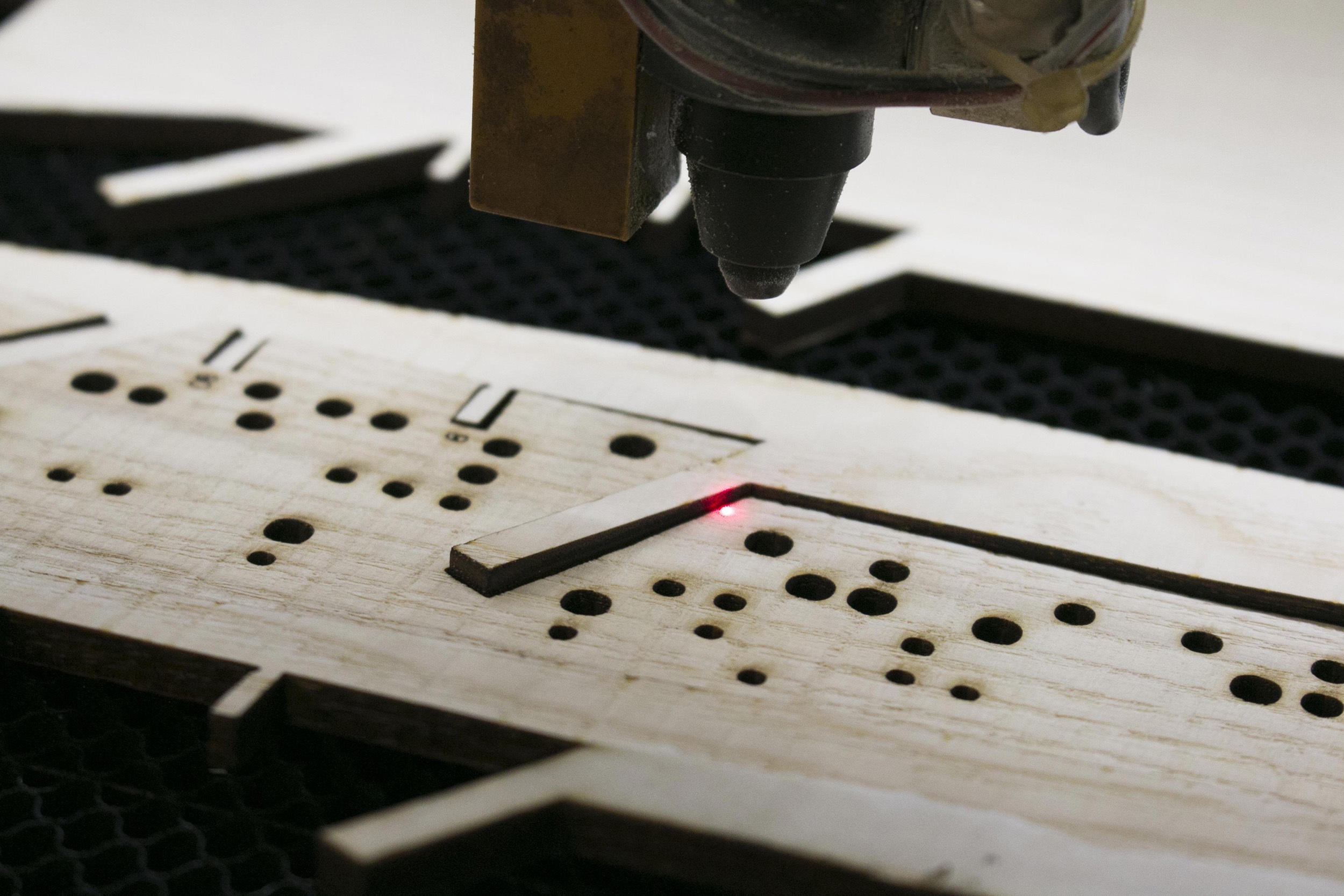

- Design: Create or import a design using a compatible design software.

- Prepare the Wood: Secure the wood on the cutting bed and ensure it is level.

- Set Parameters: Determine the appropriate laser power, cutting speed, and other parameters based on the material and design.

- Cut: Start the cutting process and monitor it closely.

- Post-Processing: Remove the cut pieces and perform any necessary post-processing, such as sanding or finishing.

- Wear Protective Gear: Always wear safety glasses, gloves, and appropriate clothing.

- Proper Ventilation: Ensure adequate ventilation to remove fumes and smoke produced during cutting.

- Avoid Direct Eye Contact: Never look directly into the laser beam or its reflection.

- Fire Safety: Have a fire extinguisher nearby and keep the work area clean of flammable materials.

- Electrical Safety: Follow all electrical safety guidelines and ensure the laser cutter is properly grounded.

H1: Laser Cutters for Woodworking

Laser cutters utilize a highly focused laser beam to vaporize or melt material, creating clean and precise cuts. For woodworking applications, laser cutters offer several advantages over traditional cutting methods:

DOWNLOAD SVG FILES FOR LASER CUTTING

H3: Considerations for Choosing a Laser Cutter

When choosing a laser cutter for woodworking, several factors should be considered:

H2: Benefits of Using a Laser Cutter for Woodworking

Laser cutters offer numerous benefits for woodworking applications:

H2: How to Use a Laser Cutter for Wood

Using a laser cutter for woodworking involves several steps:

H2: Safety Considerations

Laser cutters emit high-energy laser beams, so safety is paramount:

H3: Conclusion

Laser cutters for woodworking provide a powerful tool for creating precise, intricate, and efficient cuts. By understanding the capabilities, benefits, and considerations involved in choosing and using a laser cutter, woodworkers can harness this technology to enhance their projects and expand their creative possibilities.

FAQs

Q: What is the best laser cutter for woodworking?

A: The best laser cutter for woodworking depends on individual needs and budget. CO2 laser cutters are suitable for most applications, while fiber laser cutters offer higher speeds and can handle thicker materials.

Q: How thick of wood can a laser cutter cut?

A: The cutting thickness varies depending on the laser power and the type of wood. Typically, CO2 laser cutters can cut wood up to 1 inch thick, while fiber laser cutters can handle thicker materials.

Q: Is laser cutting wood safe?

A: Laser cutting wood is safe when proper safety precautions are followed. Wear protective gear, ensure adequate ventilation, and follow all electrical safety guidelines.