Laser Cutter for Wood: A Comprehensive Guide to Precision Cutting

Introduction

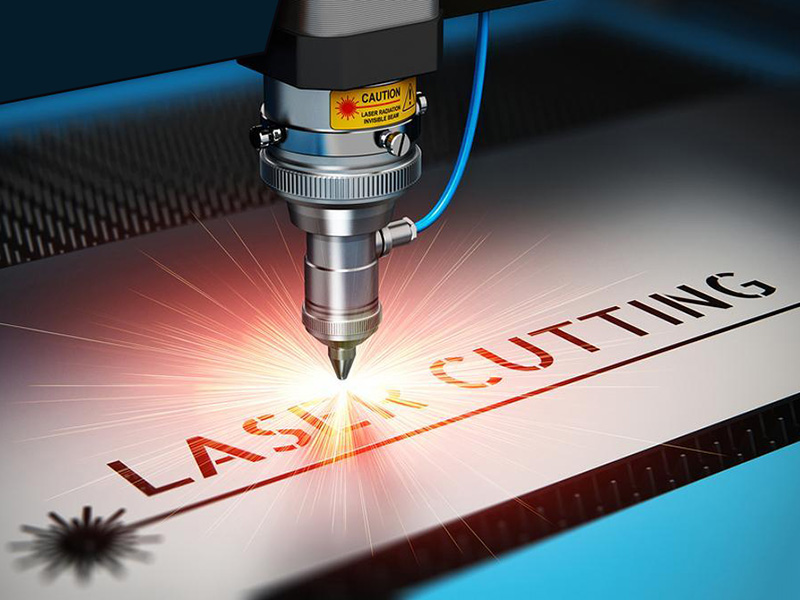

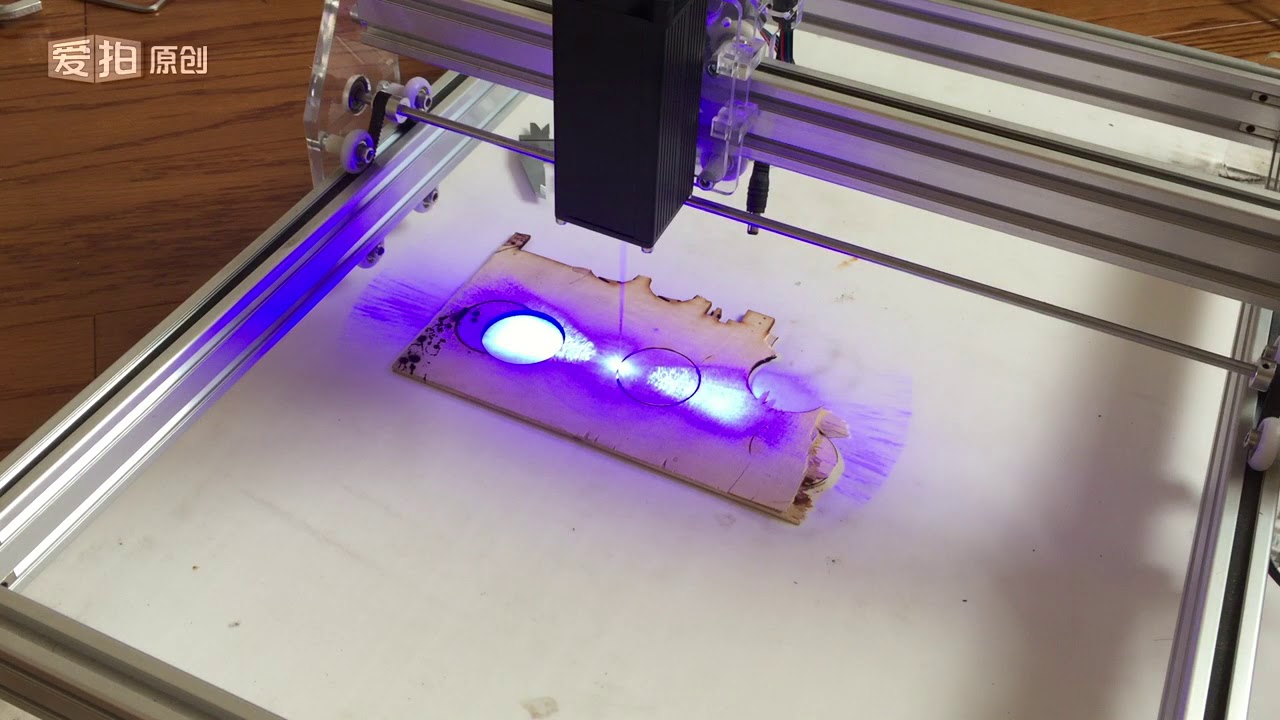

Laser cutting technology has revolutionized the wood industry, enabling intricate designs and precise cuts with unparalleled accuracy. Laser cutters employ a focused beam of light to vaporize or melt materials, resulting in clean, smooth edges and minimal waste. This guide will delve into the intricacies of laser cutters designed specifically for wood, providing a comprehensive understanding of their capabilities, applications, and factors to consider when choosing the right machine.

Table of Content

- 1 Laser Cutter for Wood: A Comprehensive Guide to Precision Cutting

- 1.1 Introduction

- 1.2 Types of Laser Cutters for Wood

- 1.3 Types of Laser Cutters for Wood

- 1.4 Key Features and Capabilities

- 1.5 Applications of Laser Cutters for Wood

- 1.6 Factors to Consider When Choosing a Laser Cutter for Wood

- 1.7 Conclusion

- 1.8 Frequently Asked Questions (FAQs)

Types of Laser Cutters for Wood

- Most commonly used for wood cutting

- Produces high-quality cuts with minimal charring

- Ideal for intricate designs and delicate materials

2. Fiber Laser Cutters:

DOWNLOAD SVG FILES FOR LASER CUTTING

- More recent technology, offering higher precision and faster cutting speeds

- Can cut through thicker materials and harder woods

- Less maintenance required compared to CO2 lasers

- Small Wooden Laser Cut Words Small Wooden Laser Cut Words: An Intricate Art Of Precision And Expression

- Laser Cut Wooden Keychain Laser Cut Wooden Keychain: A Unique And Customizable Accessory

- Best Wood Laser Cutter Ultimate Guide To The Best Wood Laser Cutter: Precision Cutting For Your Creative Projects

- Wood Laser Cutter Acrylic Wood Laser Cutter Acrylic: A Comprehensive Guide

- Laser Cut Wooden Lampshades Laser Cut Wooden Lampshades: Illuminating Your Space With Precision And Style

- Most commonly used for wood cutting

- Produces high-quality cuts with minimal charring

- Varies depending on the laser power and type of wood

- Common cutting thicknesses for CO2 lasers: 0.25-1 inch

- Fiber lasers can cut thicker woods, up to 2 inches or more

- Influenced by laser power, material thickness, and design complexity

- Typical cutting speeds for CO2 lasers: 10-50 inches per minute

- Fiber lasers offer significantly higher cutting speeds

- Laser cutters provide exceptional accuracy, with cutting tolerances of +/-0.005 inches

- Precision cuts enable intricate designs and complex shapes

- CO2 lasers produce clean, smooth edges with minimal charring

- Fiber lasers can achieve even finer edges with reduced heat-affected zones

- Cutting intricate designs on furniture pieces

- Creating custom furniture with precise joints and angles

- Producing wooden signs, plaques, and displays with sharp, detailed lettering

- Cutting intricate patterns and shapes for decorative purposes

- Engraving and cutting intricate designs on wood for artistic creations

- Creating unique and personalized wooden items

- Cutting wood for industrial products, such as packaging, toys, and musical instruments

- Producing precision parts with high accuracy and repeatability

- Higher laser power enables faster cutting speeds and thicker material cutting

- Consider the thickness of the wood you will be cutting

- CO2 lasers offer high-quality cuts and are suitable for most wood applications

- Fiber lasers provide higher precision and faster speeds but may be more expensive

- Determine the maximum size of the wood pieces you need to cut

- Choose a laser cutter with a cutting area that accommodates your needs

- Laser cutters require specialized software to design and control the cutting process

- Ensure compatibility with your design software and operating system

- Laser cutters vary in price depending on features and capabilities

- Set a budget and consider the long-term value and ROI

- Yes, laser cutters can cut most types of wood, including hardwoods, softwoods, and plywood. However, the cutting parameters may need to be adjusted based on the wood species.

- Laser cutters use a focused beam of light to vaporize or melt materials, while CNC routers use a rotating cutting tool to cut through the material. Laser cutters offer higher precision and can cut more intricate designs, while CNC routers are better suited for cutting thicker materials.

- Always wear appropriate safety gear, including laser safety glasses and gloves.

- Ensure proper ventilation to remove fumes and particles.

- Never leave the laser cutter unattended while operating.

Laser cutting technology has revolutionized the wood industry, enabling intricate designs and precise cuts with unparalleled accuracy. Laser cutters employ a focused beam of light to vaporize or melt materials, resulting in clean, smooth edges and minimal waste. This guide will delve into the intricacies of laser cutters designed specifically for wood, providing a comprehensive understanding of their capabilities, applications, and factors to consider when choosing the right machine.

Types of Laser Cutters for Wood

1. CO2 Laser Cutters:

DOWNLOAD SVG FILES FOR LASER CUTTING

Key Features and Capabilities

1. Cutting Thickness:

2. Cutting Speed:

3. Accuracy and Precision:

4. Edge Quality:

Applications of Laser Cutters for Wood

1. Furniture Making:

2. Signage and Display:

3. Art and Craft:

4. Industrial Applications:

Factors to Consider When Choosing a Laser Cutter for Wood

1. Laser Power:

2. Laser Type:

3. Cutting Area:

4. Software and Compatibility:

5. Price and Budget:

Conclusion

Laser cutters for wood offer unparalleled precision, efficiency, and versatility in the wood industry. By understanding the types, capabilities, and factors to consider, you can select the optimal laser cutter for your specific applications. With its ability to create intricate designs, achieve clean edges, and cut a wide range of wood thicknesses, a laser cutter empowers woodworkers to elevate their craft and unlock new possibilities.

Frequently Asked Questions (FAQs)

1. Can laser cutters cut all types of wood?

2. How does a laser cutter differ from a CNC router?

3. What are the safety precautions to consider when operating a laser cutter?